Sit 630 Eurosit User manual

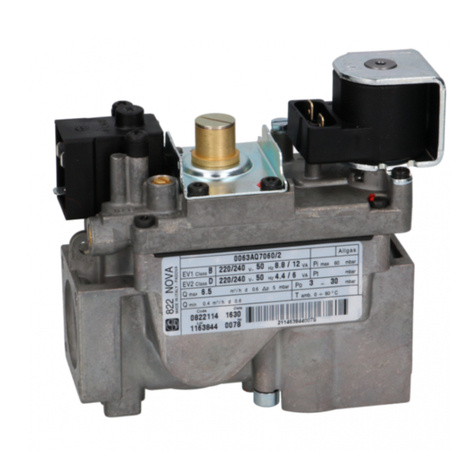

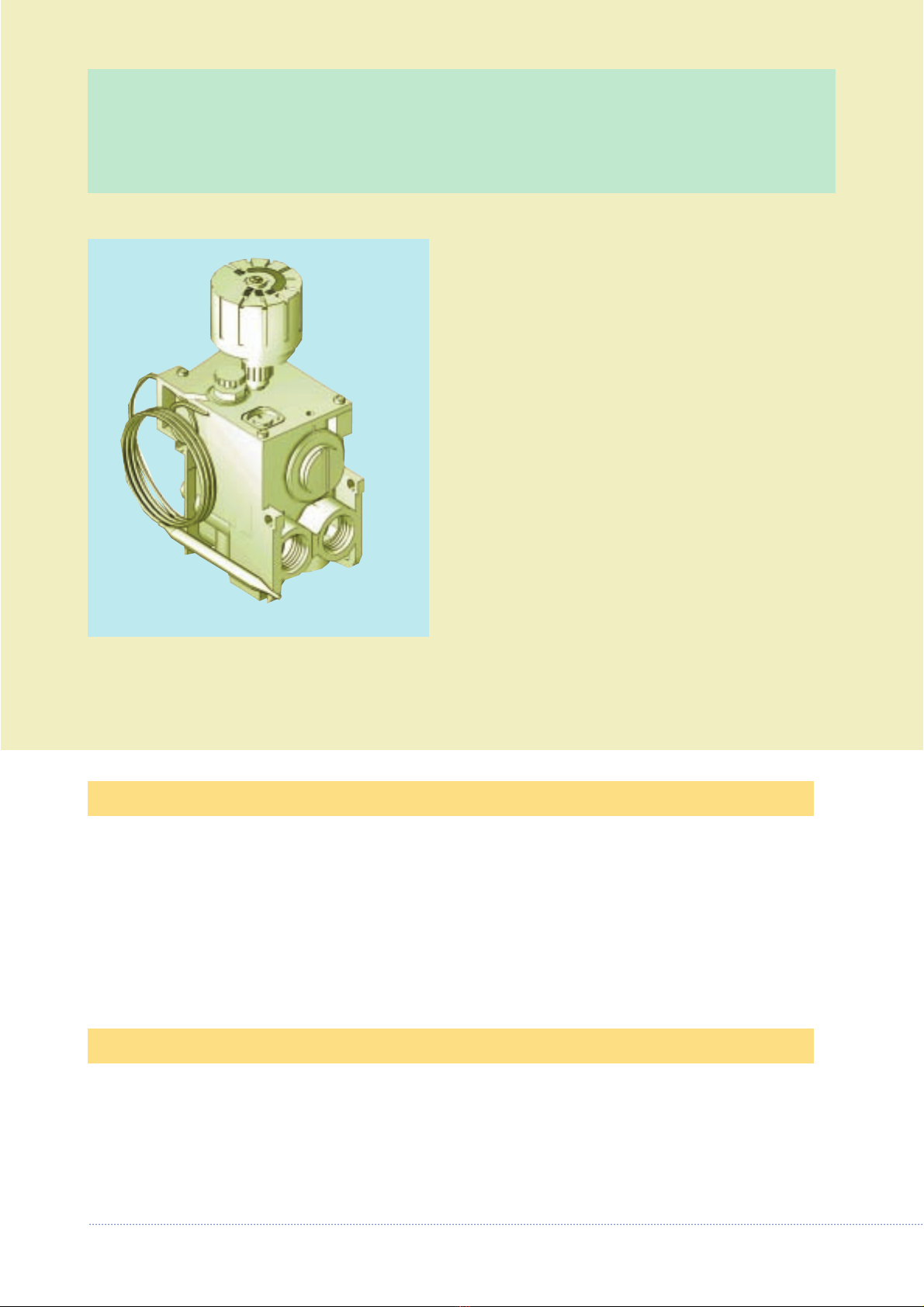

630 EUROSIT

SINGLE-KNOB CONTROL

(TEMPERATURE ADJUSTMENT, PILOT, OFF)

COMBINED MODULATING-SNAP ACTION

ON/OFF THERMOSTAT AT LOW SETTING

SIT Group

MULTIFUNCTIONAL GAS CONTROL

MAIN FEATURES

Single-knob multifunctional

control with thermoelectric

safety device and: interlock

device to prevent improper

operation, pressure regulator

and combined modulating-

ON/OFF thermostat. No exter-

nal power supply required.

MULTIFUNCTIONAL THERMOSTATIC

CONTROL

Manually operated gas valve. (Single knob operation)

Thermoelectric flame failure device.

Snap acting ON/OFF and modulating thermostat. (Optional)

Latching device (Interlok) which prevents incorrect ignition operation.

Pilot outlet suitable for 3/16” or 1/4” tubing.

Pilot flame adjustment.

Inlet and pilot filter.

3/8” NPT threaded gas inlets and outlets.

Inlet/Outlet pressure test ports.

Remote adaptor. (Optional)

Pressure regulator. (Optional)

630 EUROSIT is suitable for use with space heaters,

convectors, storage water heaters, boilers, catering

equipment and all gas appliances requiring

temperature control.

ACCESSORIES

Main accessories available upon request:

• cover

• cover with piezoelectric ignitor

• pilot shear off nut and olive

• remote adaptor

• cables for piezoelectric ignitor

• threaded plugs to close inlets and outlets which are not used

TECHNICAL DATA

DESCRIPTION

• Gas connections:

3/8” NPT X 3/8” NPT

• Mounting position: Multipoise

• Gas types: NG and LPG

• Maximum inlet pressure:

1/2 PSIG

• Outlet pressure setting range:

3.5” to 8.0” W.C. NG (8.0”-12.0” LPG)

• Working temperature range:

32 °F - 175 °F.

6 Inlet pressure test point

7 Outlet pressure test point

8 Pilot outlet

9 Thermocouple connection

10-11 Gas inlet

12-13 Gas Outlet

14 Mounting holes

1 Temperature sensing bulb

2 Outlet pressure adjustment screw

(Version with pressure regulator)

3 Minimum rate screw

4 Temperature setting knob

5 Pilot adjustment screw

▲▼

▲

▲

THERMOSTAT FEATURES

Thermostat range

a b c

55-100 °F 2.7 2.7 1.8

55-118 °F 4.5 4.5 2.7

Other ranges are available on request

Temperature

b

ca

Gas flow rate

5

3

1

8

7

9

10 11

12 13

14

2

6

4

DIMENSIONS

Capacity [BTU/hr]

NG NG

No Pressure Pressure

Regulator Regulator

55.000 40.000

The above capacities are based on Natural gas having a

heating value of 1.000 BTU per cu. ft., and a specific gravity

of 0.64 at a pressure drop of 1” W.C.

For Propane, (Liquefied Petroleum Gas), multiply by 1.62.

Pilot flow rate 2.5 °Ft3/hr at 0.5” Pressure Drop

CAPACITY

Ø 0.2 3 HOLES

0.91

1.97

1.48

0.98 2.09

2.76

0.49

0.59 0.26

3/8-18 NPT

3/8-18 NPT

11/32 ASA

7/16-24 UNS

Ø 1.57

0.2

2.224

0.118

1.3

0.28 0.39

0.35 5.32

1.52

0.5 0.98 0.5

0.98

3/8-18 NPT

3/8-18 NPT

Start up procedure

Turn knob to the OFF position; wait 5 minutes, turn knob until it

stops in the pilot position (PILOT) (fig. 1).

Depress knob and ligtht the pilot, keeping the knob depressed for

about 60 seconds.

Release the knob and check that the pilot flame stays on. If it goes

out, repeat the ignition operations.

Temperature setting

Turn the knob to the desired temperature setting. The maximum

temperature is obtained with the knob turned fully counter-

clockwise (HI position) (fig. 2).

Temporary shut-down procedure

To turn off the main burner only, turn the knob clockwise to the

pilot position (PILOT).

Complete shut-down procedure

Turn control knob to the OFF position (fig. 3).

WARNING:

This control has an interlock device; after shutting off all gas flow,

relighting of the pilot burner can not occur until the thermocouple

has cooled; allowing the electromagnet to be released (approx. 60

seconds).

The gas control knob is designed to be used by hand. DO NOT use

any tools during this operation. Damaged knobs may result in

serious injury.

OPERATION

REGULATOR CHARACTERISTICS

Range Minimum Maximum

Regulated Regulated

Capacity Capacity

(BTU/hr.) (BTU/hr.)

NG 3.5”-8.0” W.C. 10.000 40.000

fig. 2

fig. 3

fig. 1

630 EUROSIT valves conform to all current safety standards. All operations of installation,

calibration, or regulation must be undertaken exclusively by qualified personnel following

the instructions specified in this catalog and those in the instruction manual of the

appliance in which this valve is installed. Any other operation should be avoided.

WARNING

This control is not field serviceable, all adjustments must be done in the O.E.M. factory.

Mechanical connections

General reccomendations: do not tamper with sealed parts. Do not loosen assembly screws. Do

not remove labels. Avoid shocks to the valve (impact, falls, etc.) Remove inlet/outlet dust caps

only at the time of installation. Do not exceed reccomended torque values. Ensure that gas

flow follows arrows on the valve body. Prevent foreign matter from entering the valve during

mounting. In particular, check that the inlet/outlet pipes are clean. Mounting of Eurosit is to be

done using the three mounting holes.

Main gas connection

The connection must be made using properly reamed pipes with 3/8” NPT thread. Apply a

moderate amount of a good quality pipe dope and apply 23 Lb./Ft. of torque. The multi-

functional control is provided with two main inlets and outlets. It is therefore necessary to

close the inlet and outlet which are not used, by screwing the provided plug fully in.

Torque 5.2 Lb./Ft.. Do not overtorque as this could cause distortion of pipe, leakage, and

or malfunction of control.

Pilot gas connection

Connect pilot gas tubing using proper 1/4” or 3/16” shear off nut and olive. Tighten finger

tight, plus one turn with a wrench to assure a good seal.

Thermocouple connection

Insert threaded end of thermocouple into control. Tighten the fixing nut finger tight, plus

1/4 turn with a wrench to assure a good electrical connection.

Testing

After all connections have been made, check all seals and gas connections for leaks, then

set the appliance into operation to assure it is functioning correctly.

INSTALLATION

SETTINGS AND ADJUSTMENTS

Pressure readings

Inlet pressure can be checked by turning cap-

tured screw (6) counterclockwise 2 or 3 turns

then placing tube from gauge over test point.

Outlet can be checked in the same manner as

above, except by using captured screw (7).

Warning: After taking pressure readings, be

sure to turn captured screws clockwise firmly

to reseal. Do not overtorque.

Setting the thermostat

The thermostat (1) is set and sealed at the fac-

tory.

Gas flow

(Vented Units Only)

Maximum flow rate can be checked by cooling

the thermostatic bulb below room temperatu-

re and turning the knob (4) counterclockwise

to the HI position. Minimum flow rate can be

checked by cooling the thermostatic bulb

below room temperature and slowly turning

the knob counterclockwise and stopping when

you hear the snap. This flow rate is preset by

the O.E.M. at the design stage, and is set with

a pre-drilled minimum rate screw.

Pilot adjustment

(Vented Units Only)

Use a screwdriver to adjust the screw (5) to

achieve the desired pilot flame. Clockwise

decreases the amount of gas to the pilot.

Adjusting the pilot gas flow

7

6

Pressure readings

4

5

630 EUROSIT

Single-knob multifunctio-

nal control with combi-

ned modulating-ON/OFF

thermostat, for gas

appliances without

external electric power

supply.

S.I.T. Controls USA, Inc.

Subsidiary of SIT La Precisa Srl

8100 - G Arrowridge Blvd., Charlotte, N.C. 28273 USA

Telephone: (704) 522.6325 - Telefax (704) 522.7945

Cod. 9.955.729 - R00

Other manuals for 630 Eurosit

2

Other Sit Controllers manuals