Bedford B800 Series User manual

B800 Series

Frequency Inverter

BEDFORD (QUANZHOU) ELECTRONIC CO., LTD

Category

1. Preface ............................................................................................................ 3

2. Notes for safe operation.................................................................................. 3

3. Inspection checkpoints

3.1 Check procedure..................................................................... ……4

3.2 Model explanation.......................................................................... 4

4. Installation

4.1 Exterior size.................................................................................... 5

4.2 Operating environment................................................................... 3

4.3 Notice ............................................................................................. 4

5. Wiring

5.1 Connection diagram ......................................................................... 8

5.2 Notes for operation........................................................................... 9

6. Keyboard Operation

6.1 LCD and operation key .................................................................... 9

6.2 Utility of operation key .................................................................... 10

7. Test run operation........................................................................................... 10

7.1 Master some relevant functions which may let you acquire

more ideal use effects....................................................................... 10

7.2 Keyboard operation mode................................................................ 11

7.3 Keyboard operation for FOR/REV .................................................. 11

7.4 Terminal control mode ..................................................................... 13

7.5 Parameter resume ex-work value..................................................... 13

7.6 Saving condition after parameter modification................................ 14

8. The symbol explanation on LCD ................................................................... 15

9. Parameter and data sheet

9.1 Parameter list.................................................................................... 15

9.2 Parameter explanation...................................................................... 21

10. Fault diagnosis and corrective actions

10.1 Notes for remedy once fault detects................................................. 28

10.2 Troubleshooting................................................................................ 29

10.3 Notes during operation..................................................................... 30

11. BEDFORD- B800-1-200V series standard specification............................. 31

12. BEDFORD- B800-1-400V series standard specification ............................ 32

1. Preface

Thanks for you choose BEDFORD B800 series high functional

frequency inverter, please read this manual carefully before use.

2. Notes for safe operation

Frequency inverter is a latest product for electric and electronic; To

guard your safety, there are signals both “danger” and “notice” in this

manual to remind you safety precaution notices during movement,

installation, operation and check.

!DANGER Misuse may cause casualty.

! NOTICE Misuse may cause damage to inverter or system.

! DANGER

•Please don’t take down, alter! Otherwise, it may cause electric

shock, fire and injure.

•Don’t open the cover during electrify

•Don’t put or insert wire, stick and filament etc. into inverter to

avoid short circuit or electric shock.

•Please don’t splash water or other liquid onto inverter.

! NOTICE

•Please don’t perform a withstand voltage testing to the components

of inverter.

•Absolutely don’t connect output terminal (U, V, W) with AC main

circuit power supply.

•Components CMOS IC on circuit board are easily affected and

damaged by static electricity, please don’t touch it casually.

•Electromotor and inverter should fit to the matched AC power;

Otherwise, it may cause operate abnormality, even burn.

3. Inspection checkpoints

3.1 Check procedure

a) Make sure inverter is same as you purchase.

b) Make sure inverter is in good condition which don’t get

damaged during transportation; if damaged, please don’t

connect with AC main power.

c) Make sure the S/N on warranty is same as inverter.

Please inform our salesperson ASAP if you find the above problems.

3.2 Model explanation

BEDFORD - B800 – 2 001

Motor power: 001-1HP-0.75KW

Voltage: 2 -200V

4-400V

Series No.

Brand

4. Installation

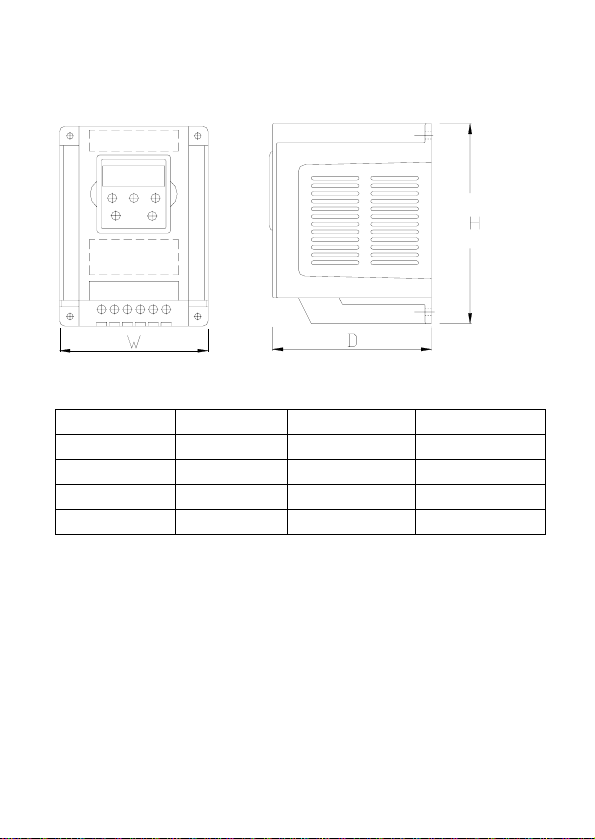

4.1 Exterior Size

400V 1~2HP 3-5HP 7~10HP

200V 1~2HP 3-5HP 7~10HP

H 165mm 214 255

W 120mm 151 180

D 123mm 160 180

4.2 Operating environment

To ensure proper performance and long operation life, Follow the

recommendations below when choosing a location for installing B800

series frequency inverter, Make sure the B800 series frequency inverter

is protected from the following conditions

. Ambient temperature: hanging type, -10~45℃

Tank closed type, -10~40℃.

. Rain, Moisture (For enclosed wall-mounted type)

. Oil fog, salt spray

. Direct sunlight.(Avoid use outdoors)

.Corrosive gases or liquid

. Dust or metallic particles in the air.

. Physical shock, Vibration

. Magnetic noise (Example: welding machine,power devices etc)

.High humidity

. Radioactive materials

. Combustibles: thinners, solvents, etc.

.If few inverters are mounted into cabinet, Please kindly put them on

ventilated position where the good ventilation is available. Further to

mount the cooling fan inside the cabinet to make the ambient

environment under 45℃

. Sufficient mounting space within below stipulation

4.3 Notice

! Notice

•Please don’t hold the front cover when move, the right way is to

hold the heatsink of inverter so as to avoid falling down which

could injury person or damage inverter itself.

•Please mount inverter onto nonflammable materials like metal and

other else; please don’t mount it nearby nonflammable materials

to avoid fire.

•If few inverters are mounted into a controlling cabinet, cooling fan

must be mounted inside cabinet to ensure temperature of cabinet

inside is lower than 45℃to avoid overheat.

• Please cut offAC main power prior to remove keyboard.

5. Wire

5.1 Connection diagram

Note: 1. three phases 380V use R/L, S/N, T as AC main power input terminal, Single

phase 220V only uses R/L and S/N.

2. Braking resistors of single phase 220V/1hp-2hp & three phase 400V/1hp –

2hp are all inbuilt.

3. B800 Series inverter default as keyboard control (F-12=1), it will work after

AC main power input

5.2 Notes for operation

• Parameter F-01 can be set as Max.30000 rpm/Min. of motor rotary,

please use this parameter with care.

• If user wants to operate the RPM of motor higher (F-09/F-10

parameter) than the rated speed of motor, please confirm the

allowable range both motor and machinery.

• The cooling fan of inverter would automatically start to work once

the temperature reach 40℃, Also, it would stop working when its

temperature is under indoor.

• Please attention other relevant parameter settings once braking

resistor used.

• Please don’t check the signal on PCB when inverter is running.

• Parameters have already been set when ex-work, please don’t adjust

it casually.

6.Keyboard Operation

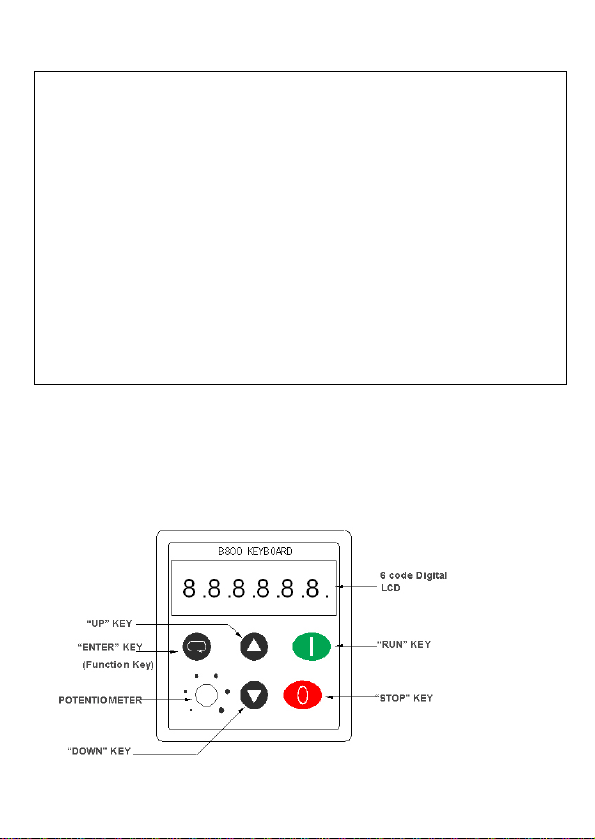

6.1 LCD and operation Key (B800 Series without potentiometer)

(B800-1 Series with potentiometer)

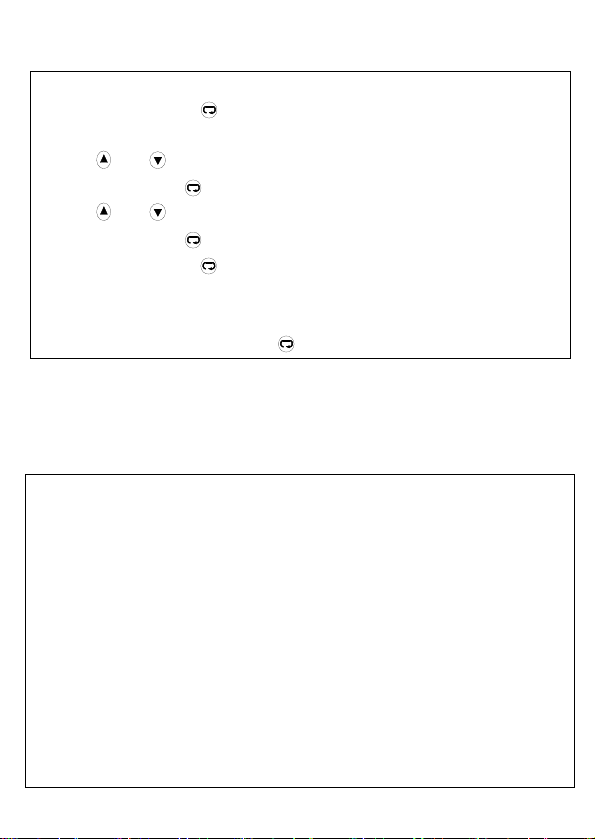

6.2 Utility for operation key

•When inverter ex-work, standard parameters are set as default.

•Press “Enter” key one second, then enter into check/modify

standard parameter group.

•Press or key to check the parameter group from F-01 to F-14

•Press “Enter” key again, which can read parameter value.

•Press or key, modify parameter value.

•Press “Enter” key again, Back to parameter group.

•If press “Enter” key more one second or standby more20 seconds,

Back to initial status prior to standard parameter group modification

•If want to enter into extended menu access(F-15-F-40),set F-14 to

“10”,and press “Enter” key .

7. Test operation

7.1 Master some relevant functions which may help you acquire more

ideal use effects

•Maximum and minimum output frequency F-01&F-02.

The maximum and minimum speed limitations are set according to

actual individual requirements.

•Accelerate and decelerate parameter F-03&F-04.

If linear acceleration time and linear deceleration time too short on

some occasions, which may cause inverter overcurrent and let inverter

trip, which cause motor stop working.

••Stop mode F-05.

When F-05=0, inverter would diminish motor’s speed according to

linear deceleration time.

If F-02≠0, when inverter start, motor would accelerate from mini

frequency we set (F-02), when inverter stops work, the motor linear

decelerate to ‘0’and then stop work.

If user want the motor stops work automatically (inertia stopping),

please sets F-05 to 1.

•V/F curve select F-06.

General loading F-06=0.

Such as fan, water pump etc. which are belonging to variable torque

loading, Pls set F-06=1, which will reduce the energy wastage when

motor run at low speed.

• Motor rated current, rated frequency and rated RPM(F-08, F-09, F-10).

Parameters should be set according to the nameplate on the motor.

When F-10 = 0, The Speed value appears with HZ.

If we set F-10 as motor rated RPM, which will help to improve slip

compensation function under different loading conditions

• Low speed voltage compensation (F-11).

Favorable to start motor smoothly, Maximum value of voltage

compensation up to 25%.

• Controlling methods select (F-12).

Terminal controlling method is for long distance control use.

Keyboard controlling method is for trial operation or handle manually.

• “Extended menu access” select(F-15~F-40)

“Extended menu access” is designed for inverter application experts,

engineers or technicians. General users don’t need to use it.

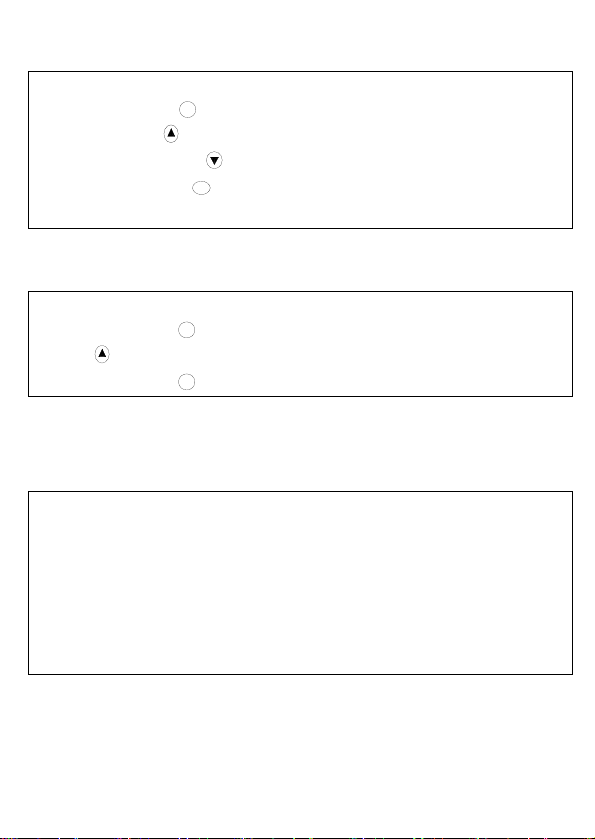

7.2 Keyboard operation mode( Default F-13=1 when ex-work)

•Put terminal 1, 2 open, the inverter appear to Stop

•Press “Run” Key 1,LCD appear to H0.0.

•Press “UP” Key ,frequency output increase.

•Press “DOWN” Key ,frequency output descends.

•Press “STOP” Key 0, Inverter stop frequency output, LCD appears to

stop.

7.3 Forward/Reverse operation on Keyboard

•Set F-12=2.

•Press “RUN” Key 1, LCD appears to H0.0.

•Press key,Speed increase.

•Press “RUN” Key 1again,Change motor rotary direction.

7.4 Terminal controlling operation mode

•Parameter F-12=0.

• Connect the start/stop switcher between terminal 1 and 2.

• Connect one potentiometer (1KΩ~10KΩ) among terminal 5, 6 and 7

• When “Start/Off” switcher ON, Turn potentiometer to change output

frequency (HZ) making the motor rotary

• When “Start/Off” switcher OFF or turn potentiometer to “0”, Inverter

stop work

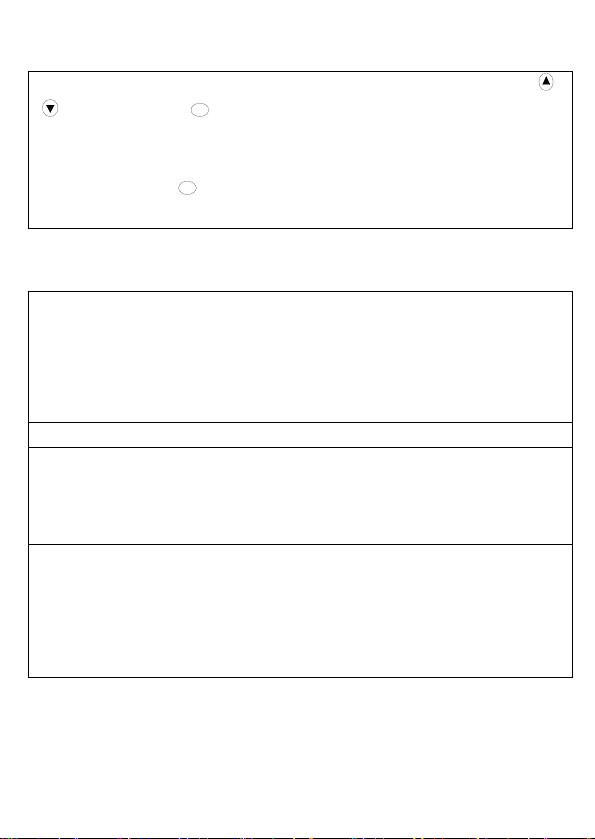

7.5 Parameters resume default (Parameters reset)

•When inverter stop and appear “Stop” on LCD, simultaneity press ,

and “Enter” Key 01 second

•LCD appears P-SET, which means all parameters have resumed to

default (ex-work value).

•Press “Enter” Key 0again, LCD appears “Stop”.

•Parameter F-37 would restore to 10, but F-39 and F-40 not change.

7.6 The saving condition after parameter modification

•As F-38=0 (Default), all parameters could be modified, they would be

saved in EEPROM when AC main power is cut off.

•As F-38=1, all parameters could also be modified, but they would not

be saved in EEPROM when AC main power is cut off.

•As F-38=2, all parameters couldn’t be modified, read only.

Notice

To prevent other persons modify parameters causally, please select any

number between 0 and 9999 for parameters F-37 (enter into “Extended

menu access” password).

•Under status of “Extended menu access” (expect F-00),LCD would

return to initial status if without any operation within 20 seconds.

•when set as F-00, LCD would return to initial status if without any

operation over 60 seconds.

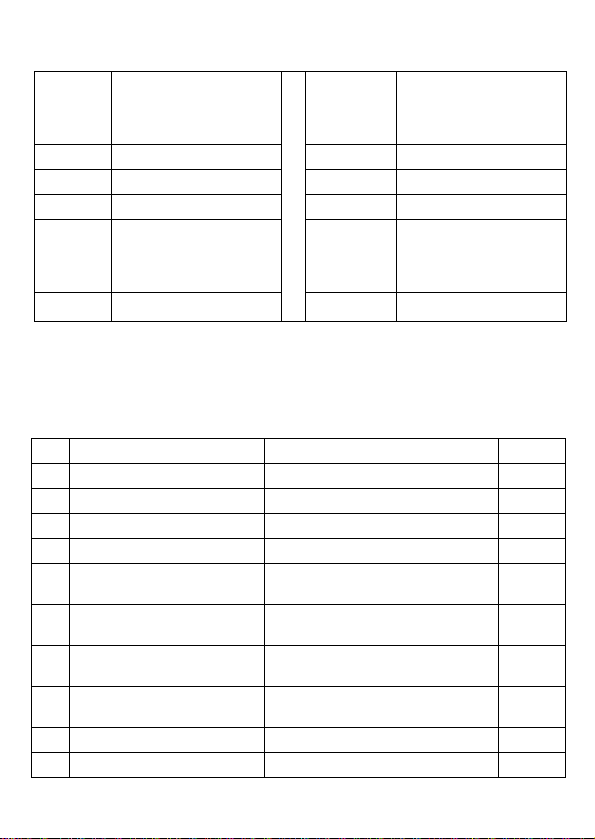

8. The symbol explanation on LCD

Symbol

on

LCD Explanation Symbol

on LCD Explanation

H50.0 Frequency output 50HZ A4.5 Output current 4.5A

1480 RPM 1480r/ min Stop Inverter stop work

F01 Parameter F-01 L Parameter lock (F-38)

E Parameter Error,

Modified only when

inverter stop

Radix

point

twinkling Inverter over-load

Stndby Standby

9. Parameter and datasheet

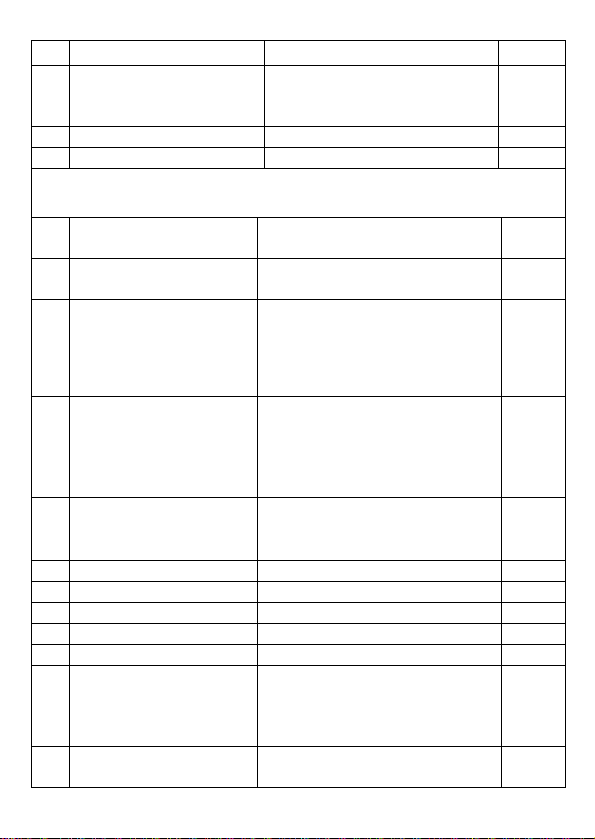

9.1 Parameter list

STANDARD PARAMETER

Par Description Range Default

F-01 Maximum speed F-02 to 5*F-09 (max 545Hz) 50Hz

F-02 Minimum speed 0 to F-01 (max 545Hz) 0Hz

F-03 Linear Accel time(s) 0.1 to 3,000s 5s

F-04 Linear Decel time(s) 0.1 to 3,000s 5s

F-05 Stop mode select 0, 2: linear stop (ramp stop)

1: inertia stop (coast to stop) 0

F-06 V/F characteristic 0: Constant torque, INDUSTRIAL

1: Pump/fan, HVAC 0

F-07 Rapid linear Decel time (s)

when power cut 0.0 to 25s. (Disabled when 0.0s) 0.0s

F-08 Motor rated current 25% -100% of drive current rating Drive

rating

F-09 Motor rated frequency 25Hz to 545Hz 50 Hz

F-10 Motor rated speed 0, F-09*12 to F-09*60 0

F-11 Voltage boost 0 to 25% of max output voltage 8%

F-12 Terminal or Keypad control 0: Terminal control

1: Keypad control –fwd only

2: Keypad control. fwd and rev 1

F-13 Trip log Last four trips stored Read only

F-14 Extended menu access Code 0 to 9999 0

EXTENDED PARAMETER SET

F-15 Motor rated voltage 220V product:80V to 250V

400V products:150V to 500V 0

F-16 Analog input format (V/mA) Voltage: 0-10V, 10-0V,-10V-10V

Current:4-20mA,0-20mA,20-4mA 0-10V

F-17

Effective power stage

switching frequency

(Carrier wave frequency

selection)

4,8, 16kHz 16 kHz

F-18 Relay output function

0: Drive enabled

1: Drive healthy

2: At set speed

3: Speed >zero

4: Motor at max speed (F-01)

1(Drive

healthy)

F-19 Multi-function contact input

selection 0 to 11 0

F-20 Preset /Jog speed 1 -F-01 (reverse) to F-01 50Hz

F-21 Preset /Jog speed 2 -F-01 (reverse) to F-01 0Hz

F-22 Preset /Jog speed 3 -F-01 (reverse) to F-01 0Hz

F-23 Preset /Jog speed 4 -F-01 (reverse) to F-01 0Hz

F-24 Slip compensation 20% to 250% 100%

F-25 Analog output function

(A) 0:Motor Speed

1:Motor current

(D) 2:Drive enabled

3: Set speed

0

F-26 V/F characteristic adjustment

factor 20% to 250% 100%

F-27

Skip freq /

speed 0 to F-01 (max) 0Hz

F-28 Skip freq /

speed band 0 to100% of rated speed/freq. F-09 0Hz

F-29 V/F characteristic

adjustment frequency 0 to base frequency (F-09)

(Function disabled when set to 0) 0Hz

F-30 Drive start mode

Edge-r: Close Digital input 1 after

power up to start drive

Auto-0: drive runs whenever digital

input 1 closed.

Auto-1-4: as Auto-0, except 1..4

Attempts to restart after a trip.

Auto-0

F-31 DC injection voltage 0.1 to 20% of max voltage 10%

F-32 DC injection braking time 0 to 250s 0s

F-33 DC injection on enable 0: Inactive 1: Enabled 0

F-34 External Brake Resistor

0: No brake resistor fitted

1: Optidrive braking resistor

2: Customer specified resistor

1

F-35 Speed reference scaling factor

(analog or digital) F09 * (1% to 500%) 100%

F-36 Drive address(s-comms) 0 to 63 1

F-37 Access code definition 0 to 9999 10

F-38 Parameter access lock

0: Parameters can be changed,

auto-saved on power down

1: Parameter changes not saved

on power down

2: Read-only. No changes allowed.

0

F-39 Hours run meter 0 to 99999 hours Read

only

F-40 Drive identifier Drive rating /Software version Read

only

Parameter explanation to only-read window

Parameter

No. Explanation to surveillance content

Range

of

setting

Factory

setting

value

F-00

1:Originalanaloginput %

2:Original analog input (F-35) Hz

3:Settingfrequency Hz

4: Output frequency Hz

5:Slipfrequency Hz

6:Stator frequency Hz

7:Motorvoltage VAC

8:DCbusvoltage VDC

9: Inside thermistor (NTC) 0~255

0~9 1

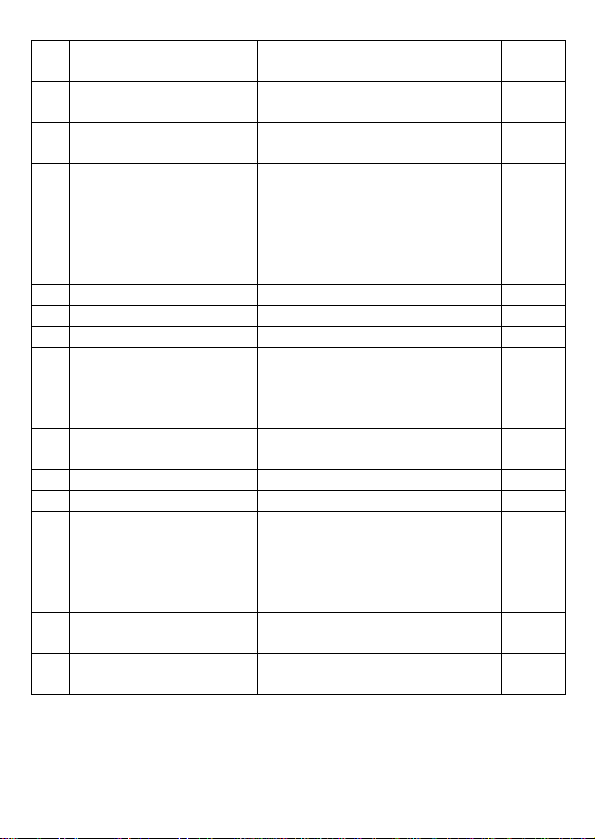

Multi-function contact input (Digital input)

F-19 Multi-function

Contact 2 Multi-function

Contact 3 Multi-function

Contact 4

0

Open: Stop (disable)

Closed: Run (enable) Open: Analog speed

reference

Closed: Preset /Jog Speed

1

Open: Voltage analog

input

Closed: Current analog

input

1 Open: Stop (disable)

Closed: Run (enable)

Open: Analog speed

reference

Closed: Preset /Jog Speed

1or 2, selected by Digital

input 4

Open: Preset /

Jog Speed 1

Closed: Preset /

Jog Speed 2

2 Open: Stop (disable)

Closed: Run (enable)

Digital Input 3 Open +Digital Input 4 Open =

Preset /Jog Speed 1

Digital Input 3 Closed +Digital Input 4 Open =

Preset /Jog Speed 2

Digital Input 3 Open +Digital Input 4 Closed =

Preset /Jog Speed 3

Digital Input 3 Closed +Digital Input 4 Closed =

Preset /Jog Speed 4

3

Open: Stop (disable)

Closed: Run (enable) External trip input:

Open: TRIP;

Closed: no trip.

Open: Analog speed

reference

Closed: Preset /

Jog Speed 1

4

Open: Stop (disable)

Closed: Run (enable) Open: Run forward

Closed: Run reverse

Open: Analog speed

reference

Closed: Preset /

Jog Speed 1

5

Open: Fwd Stop

(disable)

Closed: Fwd Run

(enable)

Open: Reverse Stop

(disable)

Closed: Reverse Run

(enable)

Open: Analog speed

reference

Closed: Preset /

Jog Speed 1

6 Open: Stop (disable)

Closed: Run (enable)

Open: Run forward

Closed: Run reverse

External trip input:

Open: TRIP;

Closed: no trip.

7

Open: Fwd Stop

(disable)

Closed: Fwd Run

(enable)

Open: Reverse Stop

(disable)

Closed: Reverse Run

(enable)

External trip input:

Open: TRIP;

Closed: no trip.

8

Open: Stop (disable)

Closed: Run (enable) Open: Run forward

Closed: Run reverse

Open: Preset /

Jog Speed 1

Closed: Preset /

Jog Speed 2

9

Open: Fwd Stop

(disable)

Closed: Fwd Run

(enable)

Open: Reverse Stop

(disable)

Closed: Reverse Run

(enable)

Open: Preset /

Jog Speed 1

Closed: Preset /

Jog Speed 2

10

Normally Open

(N.O.)

Momentary close to

run fwd

Normally Closed (N.C.)

Momentary open to Stop

(disable)

Open: Analog speed

reference

Closed: Preset /

Jog Speed 1

11

Normally Open

(N.O.)

Momentary close to

run fwd

Normally Closed (N.C.)

Momentary open to Stop

(disable)

Normally Open (N.O.)

Momentary close to run

reverse

• Forward means motor rotary along clockwise direction

• Multi-functions contact input selection “F-19” set to “0”

When multi-function contact 4 “OFF”,Analog input is voltage signal,

When multi-function contact 4 “ON”,Analog input is current signal,

The type of analog input signal can be set through parameter F-16.

If parameter F-19 set to 5 or 7 or 9, when use machine braking, multi-function contact

2 or 3 “OFF” or multi-function contact 3 or 4 “OFF”, Inverter not output, the motor

would be inertia stop.

•As F-19=6 or 7 and choose keyboard operating mode (F-12=1 or 2),External trip

function will be activated, when function contact is OFF, the inverter appear fault.

•Under keyboard operating mode, as F-12=1 or 2 and F-19=6, the rotary direction is

controlled by multi-functions contact 3, which means the inverter can be started in

reverse direction under the mode of keyboard operation.

•Under keyboard operating mode, as F-12=1 or 2 and F-19=7, multi-function contact 2

and 3 “ON” simultaneously which would activate the function of “Rapid linear

deceleration function (F-07).

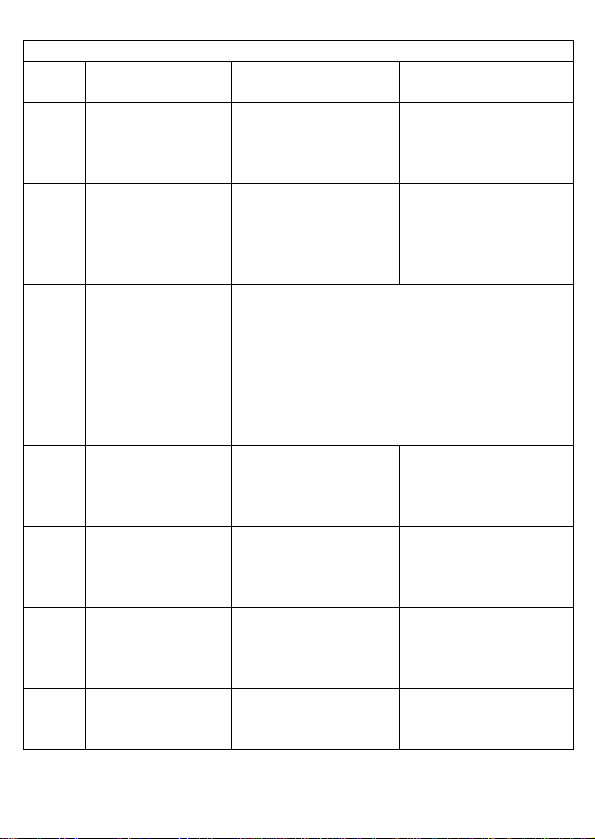

9.2 Parameter explanation

Standard parameter group

•F-01 max output frequency

Maximum frequency limitation

(Speed, refer to F-10)

•F-02 min output frequency

Minimum frequency limitation

(Speed, refer to F-10)

•F-03 linearAccel time(S).

The required time accelerate from 0 to max speed.

•F-04 linear Decel time(S).

The required time decelerate from max speed to 0

•F-05 stop mode select

0: Decelerate and stop according to parameter F-04;

2: Decelerate and stop according to parameter F-07;

1: Input “Stop” instruction, motor coast to stop (inertially).

This manual suits for next models

6

Table of contents

Other Bedford DC Drive manuals

Popular DC Drive manuals by other brands

GFA

GFA ELEKTROMAT SI 260.9-80,00 installation instructions

Efka

Efka DC 1550 instruction manual

FALK

FALK Ultramite UB Installation & maintenance instructions

LS

LS Starvert SV-iC5 Easy start guide

PS Automation

PS Automation PSF-Q Short operating instructions

YASKAWA

YASKAWA JVOP-181 Driver installation guide