Beghelli Bruno RM User manual

INSTRUCTIONS

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed including the following:

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS

2. Disconnect power before performing work on electrical equipment.

3. Do not use outdoors.

4. Use caution when servicing batteries.

5. Equipment should be mounted in locations and at heights where unauthorized personnel will not readily subject it to

tampering.

6. The use of accessory equipment not recommended by Beghelli Canada Inc., may cause an unsafe condition, and

will void the unit’s warranty.

7. Do not use this equipment for other than its intended purpose.

8. Servicing of this equipment should be performed by qualied service personnel.

9. SAVE THESE INSTRUCTIONS!

First, complete Common Mounting Steps (page 2) before proceeding to mounting options shown below.

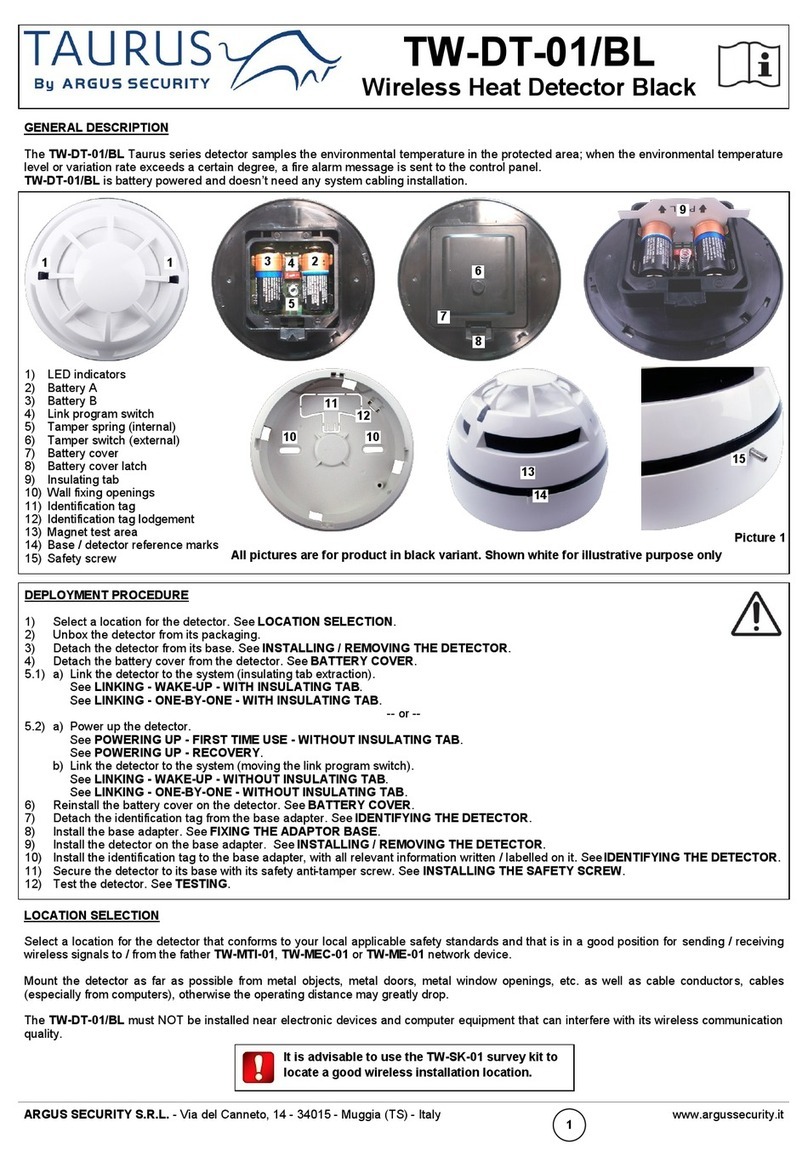

Bruno RM (BRU-RM)

Beghelli Canada Inc., 3900 14th Avenue, Markham, ON L3R 4R3 Tel: (905) 948-9500 Fax: (905) 948-8673

926000518 Page 1 of 7

Surface Ceiling Mounting,

See page 3

T-Bar Mounting,

See page 5

Surface End Mounting,

See page 4

Surface Wall Mounting,

See page 3

Ceiling Recessed Mounting,

See page 6

Wall Recessed Mounting,

See page 6

08/03/2019

Beghelli Canada Inc., 3900 14th Avenue, Markham, ON L3R 4R3 Tel: (905) 948-9500 Fax: (905) 948-8673

926000518 Page 2 of 7

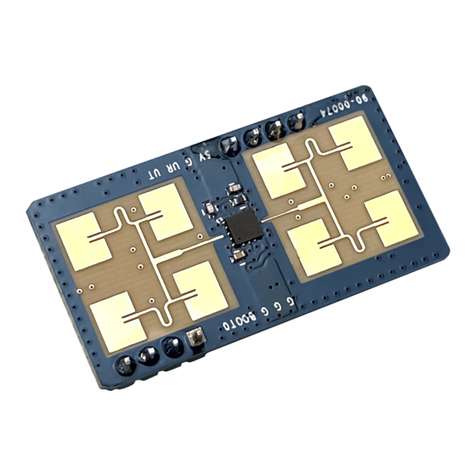

1

Box assembly

2

Back box

3

Trim plate

5

Pictograms

6

White insert

7

Angle bars (x4)

8

Bracket

9

Mounting bracket (x2)

10

Wedge

11

Canopy

12

¾" Bushing

13

6-32¾" Pan head screw (x2)

14

6-32½" Pan head screw (x2)

17

6-32 K-lock nut (x4)

16

6 " Pan head st screw (x2)

15

6-32¼" Flat head screw (x2)

18

4

Lens

19

Spider plate

20

Spider plate screw kit

21

8-32 K-lock nuts (x4)

22

#8 washer (x4)8-32 " Pan head screw (x4)

Components

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

Cover

Box assembly

Common Mounting Steps:

INSTALLATION

1. Remove cover from box assembly by removing screw on

end of box assembly.

5. Remove protective sleeve from LED strip.

6. For self-powered sign, plug battery into LED board.

7. Select pictogram. Install white insert or pictogram .

2. Knock out appropriate holes for mounting and install ¾" bushing

in entry hole and feed wires through.

3. For t-bar or ceiling recessed, knock out top holes.

4. For ceiling, knock out top, for surface end, knock out end, for

surface wall, knock out side.

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

Protective sleeve

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

Underneath pictogram,

insert at head screwdriver

to pop up button carefully

DETAIL A

SCALE .24:1

08/03/2019

Beghelli Canada Inc., 3900 14th Avenue, Markham, ON L3R 4R3 Tel: (905) 948-9500 Fax: (905) 948-8673

926000518 Page 3 of 7

8. Slide lens assembly into cover .

1. Install canopy to box using two ½" pan head screws

and k-lock nuts

.

2. Install cover and lens assembly into box.

Slide lens through

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

9. Secure using two ¾" pan head screws and k-lock nuts .

Secure with k-lock nuts

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

3. Secure with screw.

4. Thread wires through the spider plate.

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

Surface Ceiling Mounting:

Surface Wall Mounting:

1. Position wedge and canopy with the thick side of wedge

up.

2.

Secure with two ½" pan head

screws and k-lock nuts

.

3. Install cover and lens assembly into box.

1

1

2

2

A A

B B

SURFACE WALL MOUNT SURFACE END MOUNT

COMMON STEPS FOR RECESSED MOUNT

DETAIL A

SCALE .4

Wedge

Canopy

4. Secure with screw.

5. Make electrical connections (see Wiring Diagram, page 6).

6. Adjust the orientation of the spider plate to proper position.

5. Thread wires through the spider plate.

6. Make electrical connections (see Wiring Diagram, page 6).

7. Adjust the orientation of the spider plate to proper position.

19

20

19

20

Octagon

box

Octagon

box

08/03/2019

Beghelli Canada Inc., 3900 14th Avenue, Markham, ON L3R 4R3 Tel: (905) 948-9500 Fax: (905) 948-8673

926000518 Page 4 of 7

Surface End Mounting:

1. Position canopy .

2.

Secure with two ½" pan head

screws

and k-lock

nuts

.

4. Secure with screw.

3. Install cover and lens assembly into box.

1. Use back box as template cut opening.

1

1

2

2

A A

B B

SURFACE WALL MOUNT SURFACE END MOUNT

COMMON STEPS FOR RECESSED MOUNT

DETAIL A

SCALE .4

NOTE:

orientation

of canopy

“up”.

DETAIL A

SCALE .4

Common Steps for Recessed Mounting:

1

1

2

2

A A

B B

SURFACE WALL MOUNT SURFACE END MOUNT

COMMON STEPS FOR RECESSED MOUNT

DETAIL A

SCALE .4

Cut for

opening

2. Knock out entry hole in back box .

3. Install strain-relief (not supplied).

1

1

2

2

A A

B B

SURFACE WALL MOUNT SURFACE END MOUNT

COMMON STEPS FOR RECESSED MOUNT

DETAIL A

SCALE .4

Knock out one

entry hole

NOTE: Follow steps 1 through 8 in Common Mounting Steps before proceeding onto Common Steps for

Recessed Mounting.

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

1

1

2

2

A A

B B

SURFACE WALL MOUNT SURFACE END MOUNT

COMMON STEPS FOR RECESSED MOUNT

DETAIL A

SCALE .4

5. Thread wires through the spider plate.

6. Make electrical connections (see Wiring Diagram, page 6).

7. Adjust the orientation of the spider plate to proper position.

19

20

Octagon

box

08/03/2019

Beghelli Canada Inc., 3900 14th Avenue, Markham, ON L3R 4R3 Tel: (905) 948-9500 Fax: (905) 948-8673

926000518 Page 5 of 7

1. Install two mounting brackets to back box using four

" pan head screws , washer 22 , and K-lock nuts 21 .

NOTE: Mounting brackets can be installed on sides or ends

of backbox.

For Ceiling Recessed Mounting, follow T-Bar Mounting instructions and exclude angle bars .

T-Bar Mounting:

Ceiling Recessed Mounting:

2. Slide four angle bars into mounting brackets .

3. Install backbox assembly in ceiling.

4. Install bracket to top of box assembly using two ½"

pan head screws and k-lock nuts .

5. Install cover and lens assembly into box.

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

Bracket

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

Secure with k-lock nuts

Insert 3/8" pan head screws from

inside back box

6. Secure with screw.

7. Make electrical connections (see Wiring Diagram, page 6).

8. Position assembly up into back box and secure bracket

to back box using two " self tapping screws .

9. Slide trim plate over lens and secure with " flat head

screws .

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

DETAIL A

SCALE 0.24 : 1

A

1

1

2

2

A A

B B

COMMON STEPS SURFACE CEILING MOUNT

UNDERNEATH FIBER

INSERT FLAT HEAD SCREWDRIVER

TO POP UP BUTTON CAREFULLY

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

08/03/2019

Beghelli Canada Inc., 3900 14th Avenue, Markham, ON L3R 4R3 Tel: (905) 948-9500 Fax: (905) 948-8673

926000518 Page 6 of 7

1. Drill out three holes on trim plate . Use marks on trim

plate " diameter mounting holes and two " diameter

mounting holes.

5. Secure with screw.

6. Make electrical connections (see Wiring Diagram, page 6).

7. Position assembly to back box and secure using " flat

head screws .

Wall Recessed Mounting:

2. Position wedge and trim plate with thick side of

wedge up.

3. Secure with two " pan head screws

and k-lock nuts

.

4. Install cover lens assembly into box.

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

1

1

2

2

A A

B B

T-BAR MOUNT CEILING/WALL RECESSED MOUNT

WALL RECESSED MOUNT

Drill out holes

Wedge

K-lock nuts

Trim plate

Chassis GND LED Board

AC ONLY SIGN

Chassis GND

GREEN Ground

BLACK 120VAC

RED 347VAC or ORANGE 200-277VAC

WHITE Neutral

LED Board

AC & UNIVERSAL DC SIGN

YELLOW Positive 6 to 24VDC

PURPLE Negative

Emergency Supply

FROM Battery Pack

SELF-POWERED SIGN

Chassis GND

24 hours

Unswitched Supply

GREEN Ground

BLACK 105 to 360VAC

WHITE Neutral

LED Board

DUAL UNIVERSAL AC SIGN

From Generator OR

Emergency Supply

BROWN 105 to 360VAC

BLUE Neutral

NOTE: Cap unused AC Wire!

NOTE: Cap unused AC Wire!

24 hours

Unswitched Supply

GREEN Ground

BLACK 120VAC

RED 347VAC or ORANGE 200-277VAC

WHITE Neutral

24 hours

Unswitched Supply

Chassis GND LED Board

NOTE: Cap unused AC Wire!

GREEN Ground

BLACK 120VAC

RED 347VAC or ORANGE 200-277VAC

WHITE Neutral

24 hours

Unswitched Supply

Ni-Cd

Battery

Wiring Diagram

08/03/2019

MAINTENANCE

1. Code requires that the equipment be tested every 30 days for 30 seconds, and that written records be maintained.

Further, the equipment is to be tested once a year for the required time duration. The the equipment is to be

repaired whenever the equipment fails to operate as intended during the duration test. Written records of test results

and any repairs made must be maintained. Beghelli Canada Inc. strongly recommends compliance with these code requirements.

2. The lamps listed herein when used according to the instructions with this unit are in accordance with the requirements of CSA

Standard C22.2, No. 141 – Unit Equipment for Emergency Lighting.

3. Clean faceplates/lenses on a regular basis.

NOTE: Always turn off AC power before servicing. The servicing of any parts should be performed by qualied service personnel. The

use of replacement parts not furnished by Beghelli Canada Inc., may cause equipment failure and will void the warranty.

TROUBLESHOOTING

EXIT SIGN DOES NOT COME ON AT ALL

1. Check AC supply - be sure unit has 24 hour AC supply (unswitched).

2. AC supply is OK and indicator light is out, replace PC Board Assembly.

3. This could be the result of a switched AC supply to the unit (which has been turned off at some point).

SAVE THESE INSTRUCTIONS

Beghelli Canada Inc., 3900 14th Avenue, Markham, ON L3R 4R3 Tel: (905) 948-9500 Fax: (905) 948-8673

926000518 Page 7 of 7 08/03/2019

This manual suits for next models

2

Table of contents

Popular Security Sensor manuals by other brands

M-TI

M-TI ROGERS FREEDOM MICRO installation guide

Blackline Safety

Blackline Safety G7 BRIDGE Technical user's manual

Astral Pool

Astral Pool BASIC 37058 installation manual

E-matic

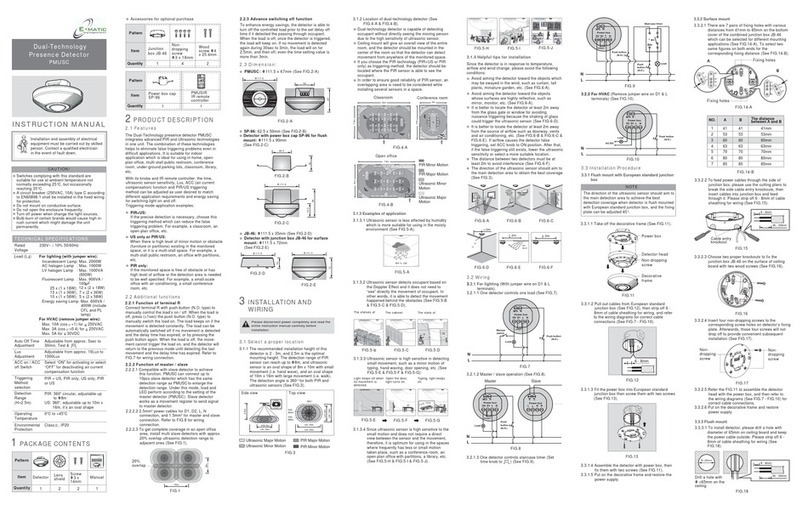

E-matic PMUSC instruction manual

M-TI

M-TI FREEDOM MICRO II product manual

Redline

Redline SMOKE PRO AIR COMPLETE 95-0051 Operation manual