BEHLMAN BL5000 Series Use and care manual

MNL106-676-500 REV-A DATE: 03/23/2022

USER'S GUIDE AND

TECHNICAL REFERENCE

BEHLMAN MODEL

BL5000 SERIES AC POWER SUPPLY

PART NO. 106-676-50x

FOR SERVICE ASSISTANCE

CONTACT BEHLMAN

CUSTOMER SERVICE DEPARTMENT

PHONE TOLL FREE 1-800-874-6727

OR WRITE

BEHLMAN

CUSTOMER ELECTRONICS DEPARTMENT

80 CABOT COURT

HAUPPAUGE, NY 11788

PHONE: (631) 435-0410

FAX : (631) 951-4341

FOR SALES INFORMATION:

PHONE: (631) 435-0410

USA : (800) 874-6727

FAX : (631) 951-4341

MNL106-676-500 REV-A DATE: 03/23/2022

LIMITED WARRANTY

Behlman Electronics, Inc. warrants, to the original purchaser, for a period of one (1) year from the

date of shipment from Behlman, each item to be free from defects in material and workmanship.

Bellman’s obligation and the Purchaser's sole remedy for any breach or violation of this agreement is

limited to adjustments, repair or replacement for parts which have been promptly reported by the

Purchaser as having been, in its opinion, defective and so found by Behlman upon inspection. All

replacement parts will become the property of Behlman on an exchange basis. This warranty will not

apply if such adjustments, repair, or parts replacement is required because of accident, neglect,

misuse, failure of environmental controls, transportation damage or causes other than normal use.

If during the warranty period a defect should impair the performance of the unit, Behlman agrees, at

its option, to repair or replace the unit or its defective components F.O.B. Behlman at 80 Cabot

Court, Hauppauge New York 11788 or at another Behlman service facility at Bellman’s option. To

obtain service under this warranty, the original Purchaser shall notify Behlman at the above address

or by Telephone at 631-435-0410 and provide information about the defect or impairment of

performance. Behlman will then supply the Purchaser a Return Material Authorization (RMA)

number. This number must be attached to the equipment sent back for warranty repair. Equipment

must be shipped back to Behlman prepaid. No collect shipments will be accepted.

Behlman shall be excused from supplying warranty service if the equipment covers have been

removed or if the unit has been subject to unauthorized repair. All service outside the scope of this

Warranty shall be paid for by the Purchaser at Bellman’s rates in effect at the time of repair. Behlman

will not perform any repairs outside of the Warranty without written authorization by the Purchaser.

If the repair is a warranty repair, Behlman will ship the unit back to the Purchaser, by a method

determined solely by Behlman, prepaid. If the Purchaser requests any other means of transportation

it shall be at the Purchaser's expense.

The use of the equipment shall be under the Purchaser's exclusive management and control. The

Purchaser will be responsible for assuring the proper installation, use, management, and supervision

of the equipment. Behlman will not be liable for personal injury or property damage.

The foregoing warranties are in lieu of all other warranties, expressed or implied including without

limitation warranties of merchantability and fitness for purpose.

In no event shall Behlman be liable for loss of profits, loss of use, or any other indirect, consequential,

or incidental damages. Purchaser agrees that Behlman will not be liable for any damages caused

by the Purchaser's failure to fulfill any of the Purchaser's responsibilities set forth herein.

MNL106-676-500 REV-A DATE: 03/23/2022

CLAIM FOR DAMAGE IN SHIPMENT

Under the FOB factory terms of sale, ownership and responsibility are transferred to the customer when the

equipment leaves the factory. Each Behlman instrument is shipped from the factory in proper operating condition.

Immediately upon receiving equipment, unpack and inspect it for evidence of damage incurred in shipment. I F

equipment is damaged, file a claim with the freight carrier. Forward a copy of the damage claim report to

Behlman. Include the model number, serial number, and date the shipment was received. Behlman will advise

the disposition of the equipment and will arrange for necessary repair or replacement.

RETURNING EQUIPMENT TO FACTORY

Do not return equipment to the factory without prior authorization from Behlman.

This equipment, like all precision electronic equipment, is susceptible to shipping damage. It contains heavy

magnetic components as well as delicate electronics components. If equipment is returned without prior

authorization, the shipment will be refused and the customer will be liable for all shipping, handling and repair

costs. When packing for reshipment, use the original shock absorbent material and shipping container to prevent

additional damage to the equipment.

Ensure that the return authorization numbers (RMA) is available on the container.

PACKING INSTRUCTIONS

RACK MOUNTED UNITS

I) Box(es) must be double wall with minimum 350 lbs. bursting test.

2) Box(es) must provide for a minimum of 2 to 3 inches of clearance around sides, top and bottom of

unit.

3) When packing unit, utilize either a foam-in-place system or high-density foam. Clearance provided

for above must be completely filled with foam.

FAILURE TO COMPLETELY SECURE UNIT IN BOX WILL ALLOW MOVEMENT

DURING SHIPPING, RESULTING IN DAMAGE.

DO NOT USE PEANUTS OR BUBBLE

WRAP

4) Secure box(es) to pallet(s). This is necessary to insure proper handling and protection during

shipping.

5) Place the following warning label on box(es)

DO NOT STACK

6) Ship unit using a freight cargo carrier; air or ground.

MNL106-676-500 REV-A DATE: 03/23/2022

SAFETY SUMMARY

The following safety precautions must be observed during all phases of operation,

service, and maintenance of this equipment. Failure to comply with these precautions

or with specific warnings elsewhere in the manual violates safety standards associated

with the design and intended use of this equipment. This manual forms an integral part

of the equipment and must be available to operating personnel.

GROUND THE EQUIPMENT

This equipment may have high leakage current to chassis due to EMI filtering requirements.

To minimize shock hazard, the equipment chassis(s) must be connected to an electrical safety

ground. This equipment is supplied with a three-conductor line connection for single phase

applications and/or a five-wire connection for three phase applications. Both types include an

earth terminal intended for safety ground connections. In addition, isolated installation sites

may require an AC output neutral to earth connections as per NEC section 250 (National

Electrical Code). Refer installation to licensed electrician or other qualified personnel.

DO NOT OPERATE IN EXPLOSIVE ATMOSPHERE

Do not operate the equipment in the presence of flammable gases or fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove equipment covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace components

with power applied. Under certain conditions, dangerous voltage may exist even with the

power removed. To avoid injuries, always disconnect power and discharge circuits before

touching them. During normal operation the operator does not have access to internal

hazardous voltages. However, depending on the user’s application configuration, HIGH

VOLTAGES HAZARDOUS TO HUMAN SAFETY may be normally generated at the output

terminals. The customer/user must ensure that the output power lines are labeled properly as

to the safety hazard and that any inadvertent contact is eliminated.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable of rendering first

aid and resuscitation is present.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install substitute parts or

perform any unauthorized modification to this equipment. Contact Behlman Electronics for

proper replacement parts and specific service information.

MNL106-676-500 REV-A DATE: 03/23/2022

DANGEROUS PROCEDURE WARNINGS !

Warnings will precede potentially dangerous procedures in this manual. Instructions contained

in the warning must be followed. Warnings will be preceded by the caution symbol (above).

RISK OF ELECTRIC SHOCK

This symbol warns personnel of hazardous conditions due to the exposure of hazardous

voltage that can cause injury to humans if contacted.

Neither Behlman Electronics, Hauppauge, NY, USA, nor any of the subsidiary sales

organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that may result from improper use of the equipment and/or accessories

provided.

For additional safety related technical information, contact the Behlman Electronics sales

department or local sales representative.

or call in N.Y.

631-435-0410

MNL106-676-500 REV-A DATE: 03/23/2022

TECHNICAL MANUAL BL5000 SERIES AC POWER SUPPLY

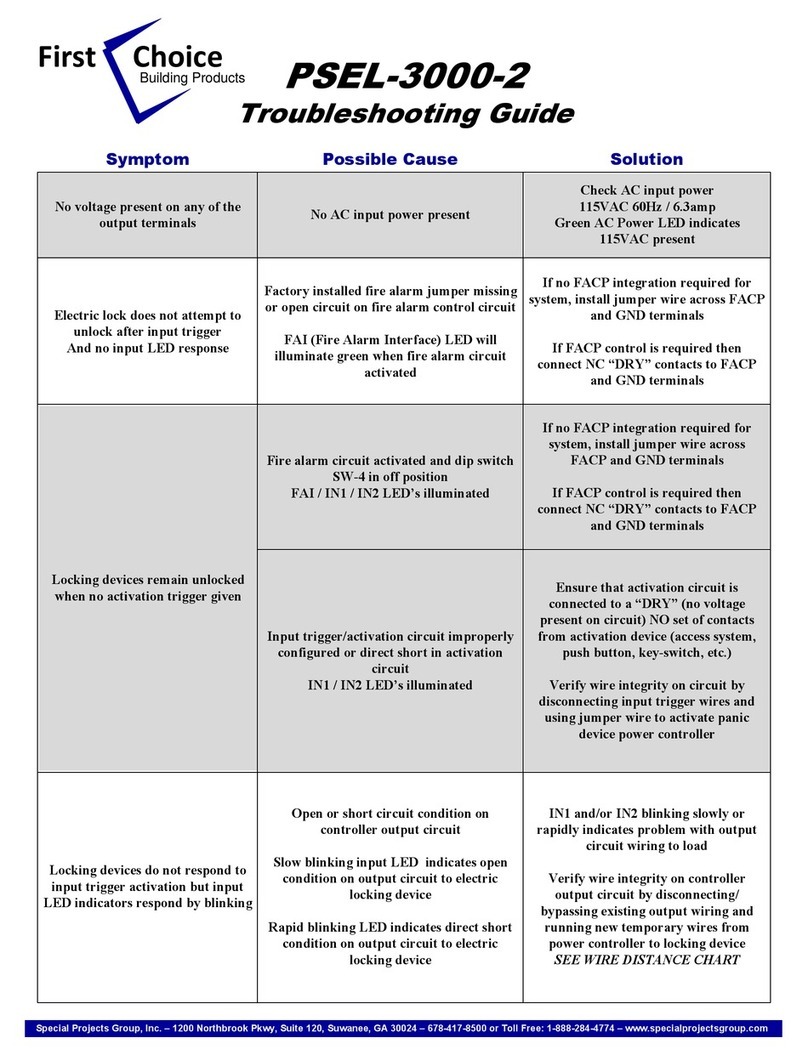

TABLE OF CONTENTS

Section Title

1.0 Introduction

1.1 Specifications

1.2 Available options

1.3 Unpacking & Inspection

2.0 Installation & Wiring

2.1 Installation

2.2 Input power Connections

2.3 Input Power Requirements

2.4-2.5 Output and Other Wiring

2.6 T5/T5D Transformer Options

3.0 Operation

3.1 Controls and Indicators

3.2 Operating Instructions

3.3 Analog Remote Control

3.4-3.10 Operational Considerations

4.0 Maintenance

4.2 Trouble Shooting

4.3 Performance Verification

4.4 Fuse Replacement

5.0 Mechanical Outline

A1 RS-232 Control Option *

B1 IEEE-488 Control Option *

* Optional appendix

MNL106-676-500 REV-A DATE: 03/23/2022

SECTION ONE

INTRODUCTION

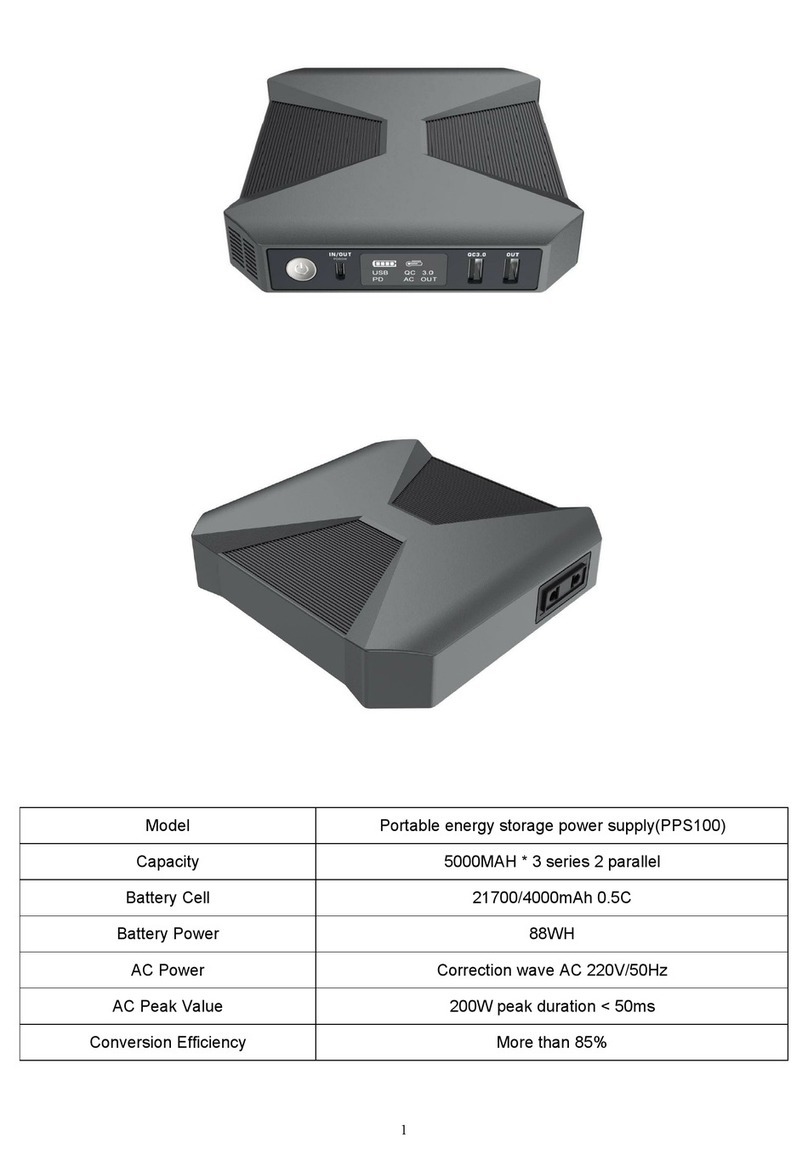

1.0The Behlman BL5000 series of AC power supplies are designed to provide regulated

AC power at frequencies and /or voltages not available from local utilities. All models

are completely solid state, PWM switching types that provide high efficiency and overall

reliability. These devices require very little maintenance and will provide years of

trouble-free service when used within their ratings. The models in this series include a

multi-pulse rectifier circuit to reduce input harmonics associated with the conversion

process used. These models are housed in an all metal, EIA rack mountable

enclosures.

The block diagram below illustrates the conversion process performed by this

equipment. AC power is applied and converted to DC by a multi-pulse transformer

rectifier arrangement. This DC is then used to provide raw power for 3 class D power

amplifiers. The amplifiers are driven from reference signals at the desired output

frequency and phase. The resulting amplified signals are applied to the output

connector via an internal relay that provides the output on/off function. Short circuit

protection and current limit are performed by the control electronics.

FIGURE 1-1, BLOCK DIAGRAM B5000-SERIES 3 PHASE POWER SUPPLY

MNL106-676-500 REV-A DATE: 03/23/2022

SECTION ONE

1.1 SPECIFICATIONS FOR AC POWER SUPPLY BL5000-CX-SERIES

INPUT POWER REQUIREMENTS: 3 Phase, 4 wire w/P.E.

(See table 1), 47-63Hz, 4 wire w/P.E.

AC OUTPUT POWER: 5000W total, continuous, @ 40C

OUTPUT CURRENT: 12.5 ARMS continuous per phase.

OUTPUT FREQUENCY: Variable from 45- 500Hz +/- 1%

AC OUTPUT VOLTAGE Variable from 0 -135VAC (L-N) 0 -232VAC L-L

AC OUTPUT REGULATION: less than 1 % No load to Full load, resistive

AC VOLTAGE DISTORTION: Less than 3% full resistive load 45-500Hz

AC REGULATION RESPONSE TIME 250 –300 mSec, typical.

METERING:

VOLTAGE: +/- (0.5% of reading + 1% of range), 1V res.

CURRENT: +/- (2% of reading + 1% of range), 0.1A res.

FREQUENCY: +/- (1% of reading + (+/- 1Hz) 1Hz res.

PHYSICAL: Comprised of two 19” chassis configured for

EIA standard rack-mount cabinets

POWER CHASSIS: 23.5” D, x 10.5” H, x 19” W

CONTROL CHASSIS: 23.5” D, x 7.0” H, x 19” W

WEIGHT (approximate): Power = 110 lbs. Control = 70 lbs.

OPERATING TEMPERATURE: 0 to +50 degrees Celsius.

STORAGE TEMPERATURE: -10 to +60 Degrees Celsius.

SAFETY: Evaluated to IEC-61010, general safety,

Class1, pollution level 2.

MNL106-676-500 REV-A DATE: 03/23/2022

1.2 AVAILABLE OPTIONS

This model series is available with several input and output voltage options. Other

customer specified options such as fixed voltage and/or fixed frequency operation can

be provided. Behlman also produces many semi-custom or “engineering special”

versions of this model. These will be identified by a four-digit suffix added to the model

number. Always refer to model/serial number labels located on the side of each chassis

for the actual unit configuration. Any question regarding options may be sent to

summarize available standard options.

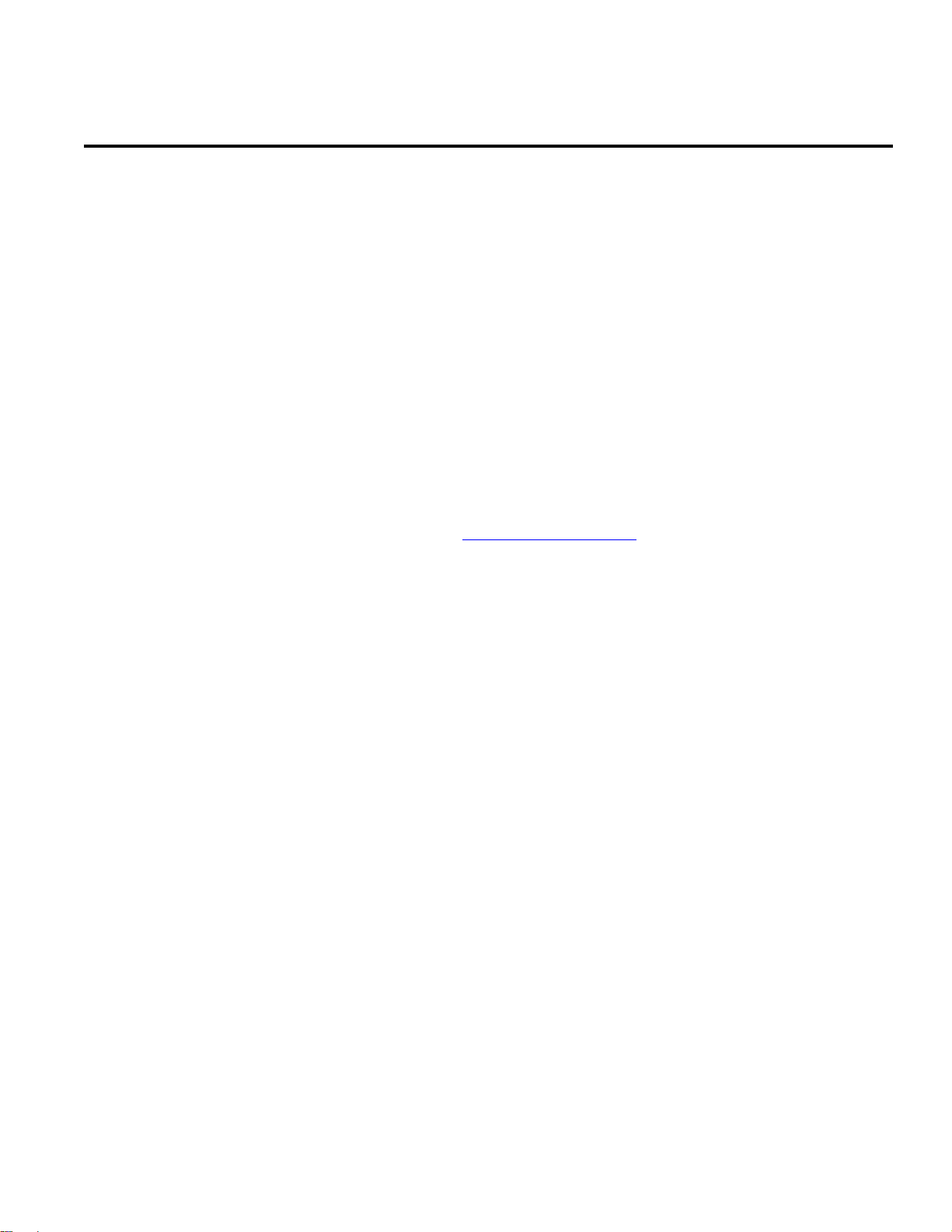

TABLE 1-1 INPUT VOLTAGE OPTIONS

BASE MODEL #

INPUT VOLTAGE

COMMENTS

BL5000C-1

120/208VAC, 3P, 4W, +PE +/-10%

47-63Hz

BL5000C-2

220/380VAC, 3P, 4W, +PE +/-10%

47-63Hz

BL5000C-3

277/480VAC, 3P, 4W, +PE +/-10%

47-63Hz

BL5000C-4

200V, 3P, 3W, +PE +/-10% DELTA

(220V or 240V taps available)

47-63Hz

BL5000C-5

346/600VAC, 3P 4W, +PE +/-10%

47-63Hz, incudes

additional internal fuses.

BL5000C-6

230/400VAC, 3P, 4W, +PE +/-10%

47-63Hz

BL5000C-7

240/415VAC, 3P, 4W, +PE +/-10%

47-63Hz

BL5000C-8

120V, 2 WIRE + PE +/-10%

47-63Hz single phase*

BL5000C-9

240V, 2 WIRE + PE +/-10%

47-63Hz single phase*

BL5000C-10

480V, 2 WIRE + PE +/-10%

47-63Hz single phase*

* Input power factor = 0.7 (approximate) 3 phase inputs = 0.9 (approximate)

TABLE 1-2 OUTPUT VOLTAGE OPTIONS

OPTION

OUTPUT VOLTAGE

COMMENTS

V -XXX

Fixed, xxx = voltage

Customer specified

F -XXX

Fixed, xxx = frequency

Customer specified

T5-270

0 –270V @ 6.2A/phase

Adds step-up transformer chassis

T5-300

0 –300V @ 5.5A/phase

Adds step-up transformer chassis

T5D-135/270

0-135 @ 12.5A & 0-270 @ 6.2A

Adds step-up transformer chassis*

T5D-150/300

0-150 @ 11A & 0-300 @ 5.5A

Adds step-up transformer chassis*

* Dual range units

MNL106-676-500 REV-A DATE: 03/23/2022

1.2 AVAILABLE OPTIONS (continued)

Other options not included in the tables on the previous page are listed below:

E = Extended output frequency range of 45 -1000Hz

I= Adds IEEE-488 compatible computer interface to control voltage and frequency.

IR = Adds RS-232 serial computer interface to control voltage and frequency.

L= Adds locking devices to front panel voltage and frequency controls

MA = Adds accessory mounting angle for support when mounting in EIA standard rack.

MT = Adds oversize output transistors to accommodate induction motor starting currents.

S= Adds factory mounted chassis slides for mounting in EIA standard rack.

21-00 = Adds 21” cabinet with casters.

Behlman can accommodate a wide range of user requested modifications such as special

control functions or output voltages not listed in the previous tables. Contact the factory for

specific information regarding special units or semi-custom version of this model.

MODEL NUMBER FORMAT EXAMPLES

BL5000C-1 = standard unit where X = input voltage

BL5000C-X- V120/F400 = standard unit with fixed voltage and frequency output

Base model options

BL5000C-1-IR = input voltage 120/208V with RS-232 control option.

BL5000C-3-T5-300-L = input voltage 277/480, output 0 -300V, with locking devices.

IMPORTANT NOTE FOR ALL MODELS IN THIS SERIES:

The information contained in this manual is subject to change without notice. Some of the

information may also not apply to older production as improvements and or changes have

been made over the life of this product. Special units may have additional information added or

a specific technical manual. When in doubt, consult the factory or Behlman Sales for the latest

information.

MNL106-676-500 REV-A DATE: 03/23/2022

SECTION ONE

1.3 UNPACKING AND INSPECTION

Remove the equipment from its packaging and inspect it for shipping damage. If the box

shows signs of damage, retain it in case a claim needs to be filed with the shipping

carrier. If the equipment shows signs of damage, DO NOT attempt to operate it. Contact

Behlman immediately and file a damage claim with the shipper. Prior authorization is

required before sending any equipment back to Behlman. This is in the form of a

Returned Material Authorization (RMA) number that must be obtained from Behlman.

Any shipment sent without an RMA # will be refused and the customer will be liable for

all shipping costs.

This equipment may ship with other accessories. Check the contents of any

shipments against the provided packing list. A copy of the user/technical manual is

provided in the shipping container. It is recommended that the serial number be verified

and retained in case of any warranty claims. The warranty for this unit is one year for

parts and labor. See the Warranty statement at the beginning of this document for

specific information. All warranty repairs must be performed by Behlman or one of its

warranty repair or non-warranty service.

MNL106-676-500 REV-A DATE: 03/23/2022

SECTION TWO

INSTALLATION AND WIRING

2.1 INSTALLATION

This device is designed primarily for a fixed installation site with non- user detachable

wiring. This model may be mounted in an EIA standard equipment rack using the

appropriate hardware (not provided). If the unit is to be rack mounted, it must be placed

so as not to block the cooling vents on the sides, front, and rear panels. Rear support

must also be provided. This may be in the form of internal support “rails” or chassis

slides. Many equipment rack manufacturers can supply generic support brackets or

shelves to be used with their racks. Racks that are completely sealed will require

ventilation to remove heat generated by the AC power supply’s exhaust.

The installation site must protect the power supply from moisture and any conductive

particulate matter. IN NO CASE should this unit be operated in the presence of dripping

or misting fluids.

WARNING !

INSTALLATION AND OPERATION

MAY EXPOSE PERSONNEL TO HAZARDOUS

VOLTAGE AND CURRENT LEVELS

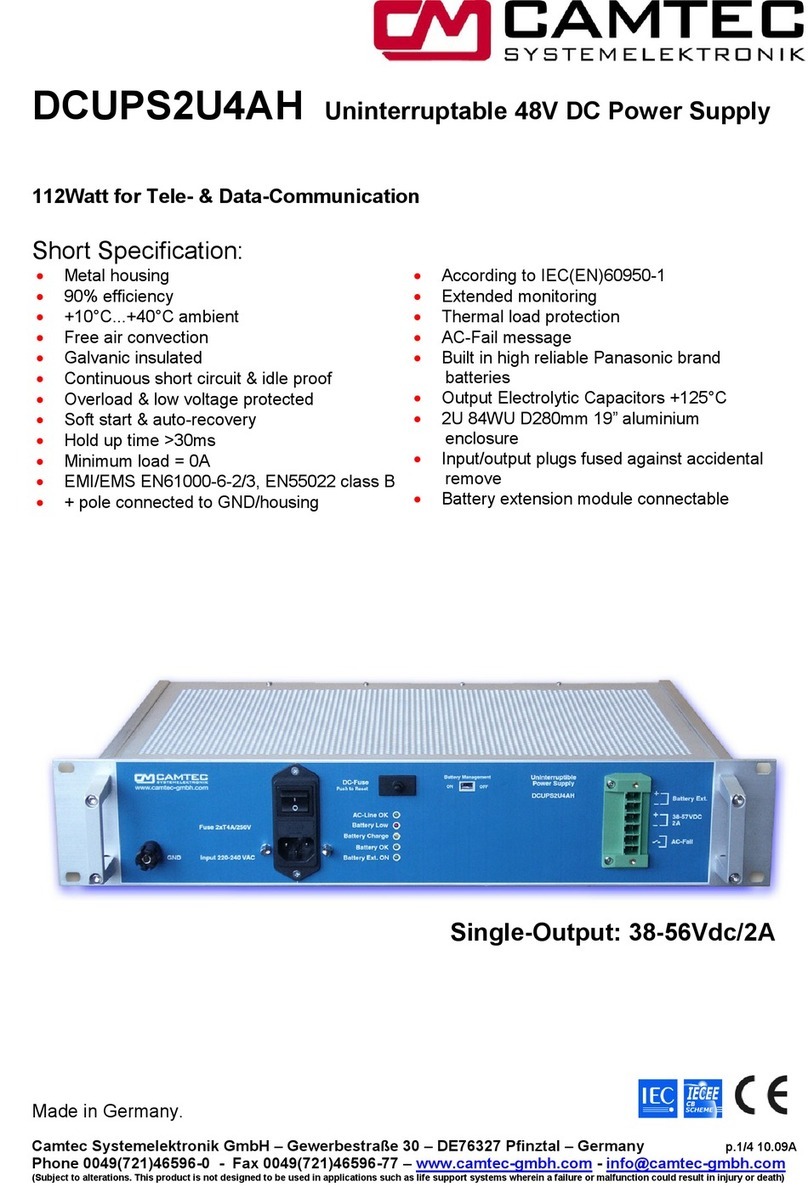

2.2 INPUT POWER CONNECTION

Input and output power connections are made to rear panel mounted terminal blocks

using ¼” diameter hardware. Ring lugs with a ¼” diameter are recommended for these

connections. IMPORTANT! Only the bottom row of screws for each terminal block can

be used for connections. The top row of screws attaches to internal hardware and

should not be removed for any reason. Attach input line phases to A, B, & C terminals

and the neutral to the “N” terminal. Note that the unit will function without the neutral,

however, if left unconnected there may be an increase in input current harmonics and

voltage stress on the input transformer. All EMC and safety testing apply to 4 wire

“WYE” with a grounded neutral conductor. The unit is not sensitive to phase sequence.

See figures 2-1 and 2-2. The SCCR for this device is 5KA or less.

WARNING

THIS DEVICE IS SUPPLIED WITH A 3 or 5 WIRE LINE CONNECTION THAT INCLUDES A

PROTECTIVE EARTH CONDUCTOR. THE P.E. CONNECTION IS CRITICAL TO OPERATOR SAFETY

AND MUST BE TIED TO THE INSTALLATION SITE PROTECTIVE EARTH. DUE TO COMPONENTS

USED FOR EMI REDUCTION, THIS DEVICE MAY PRODUCE LEAKAGE CURRENTS THAT ARE

HAZARDOUS. THE EARTH CONNECTION ALSO PROVIDES A RETURN PATH FOR THESE

CURRENTS.

MNL106-676-500 REV-A DATE: 03/23/2022

2.3 INPUT POWER REQUIREMENTS

This model uses an isolation type rectifier transformer. The maximum 3 phase input

power required for full output power into a resistive load is about 6000VA at nominal

voltage. Overload protection is provided via a front panel mounted circuit breaker and

other electronic methods. Single phase inputs have a lower power factor and can

require about 8000VA input at full load. All voltage ranges are: +/-10%, 47-63Hz. The

neutral wiring is the same for both 3 phase and single-phase versions.

Table 2-2 lists the estimated input current requirements for the BL5K series units versus the

rated input voltage. All values are calculated for 10% low input voltage and full resistive output

loads and will represent the worst-case power consumption. The actual current values will vary

depending on the characteristics of the supply voltage distribution system and applied load (if

other than resistive). The short circuit current rating of this equipment (SCCR) is assumed to be

5kA maximum. For proper short circuit protection coordination, current limiting fuses or circuit

breakers should be used in the circuit branch feeding this equipment.

MODEL

RATED AC LINE

CURRENT/PHASE

BL5000C-1

120/208V WYE

16A

BL5000C-2

220/380V WYE

9A

BL5000C-3

277/480V WYE

7A

BL5000C-4*

220V DELTA*

16A

BL5000C-5

346/600V WYE

5A

BL5000C-6

230/400V WYE

8A

BL5000C-7

240/415V WYE

8A

BL5000C-8

120VAC 1 PHASE

60-75A**

BL5000C-9

240VAC 1 PHASE

30-40A**

BL5000C-10

480VAC 1 PHASE

15-20A**

*C-4 units may also be tapped @ 200V or 240 L-L

** Actual current dependent on line impedance at site, PF = 0.7 (approx.)

!OPERATION OF WYE INPUT WITHOUT THE NEUTRAL CONNECTION

In many facilities using 3 phase power, the neutral conductor may not be available at the

installation site. Note that the neutral conductor is not and should not be treated the same as

the earth or P.E. conductor. The earth conductor is not intended to carry current during normal

operation. Although it is not the recommended situation, most of the BL5000 models can be

used without the input neutral. During operation, the phase currents will remain balanced

(typically within 5-10% At full load). While the unit will function properly, this connection method

will not provide the same level of safety and EMI performance to which this product has been

tested. This will also cause the harmonics associated with the neutral imbalance to circulate in

the transformer causing a small increase in losses. The transformer windings may also be

subjected to additional voltage stresses. The long-term effect may be reduced insulation life.

MNL106-676-500 REV-A DATE: 03/23/2022

The front panel circuit breakers used on this product are “slash” rated at 277/480VAC. This

applies to all models. This means they are only tested and approved for use on circuits where

the line to earth voltage is a maximum of 277VAC and is guaranteed under all fault conditions.

This is true of WYE connected systems that use a neutral or “grounded conductor”. It is not true

of certain delta or other un-grounded systems. As a precaution, back-up fuses rated to at least

the full voltage should be employed on ungrounded distribution systems with greater than 277V

line to line.

The figure 2-1 below illustrates typical 3 phase AC input wiring.

MNL106-676-500 REV-A DATE: 03/23/2022

2.4 AC OUTPUT LOAD CONNECTIONS

Connect the load to the rear panel AC output terminal block located on the control

chassis. Use only the lower row of screws for connection. Note that this device

produces output voltages that are hazardous under normal conditions. The end user

must make sure that all output wiring is installed in a way that prevents inadvertent

contact with operating personnel. The use of warning labels is highly recommended.

The output circuit of this device is direct coupled and floating with respect to the input

line. Likewise, the AC output Neutral terminal is isolated from the input Neutral. The

maximum continuous floating voltage between any output terminal and ground is

500VDC or peak AC. It is also permissible (and recommended for most applications)

that the output neutral be tied to earth or connected to the input neutral. See figure 2-1.

2.5 OTHER WIRING

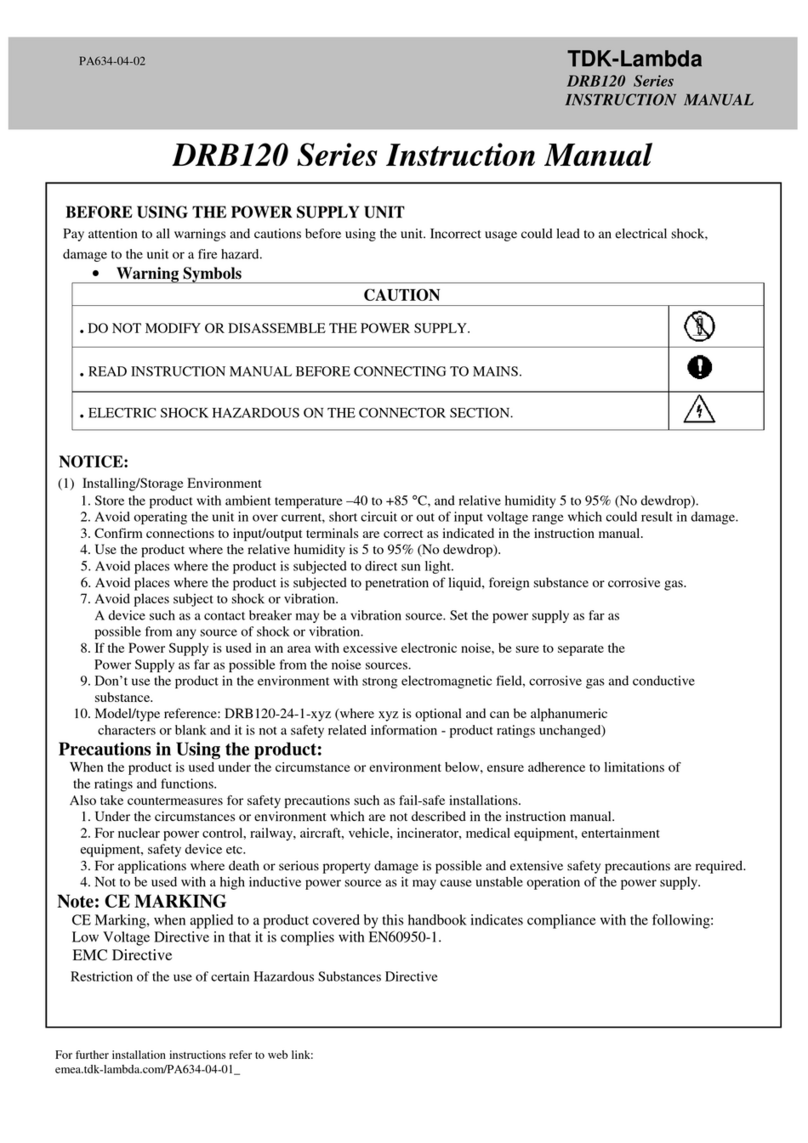

This model is made up of two 19” wide rackmount assemblies. A cable set is provided

to connect the DC output of the power chassis to DC input of the control chassis. Due to

EMI and operational considerations, the length of these cables should not be altered.

The connection details are provided here for reference. Always remove power and allow

several minutes for internal capacitors to discharge before removing or connecting DC

wires.

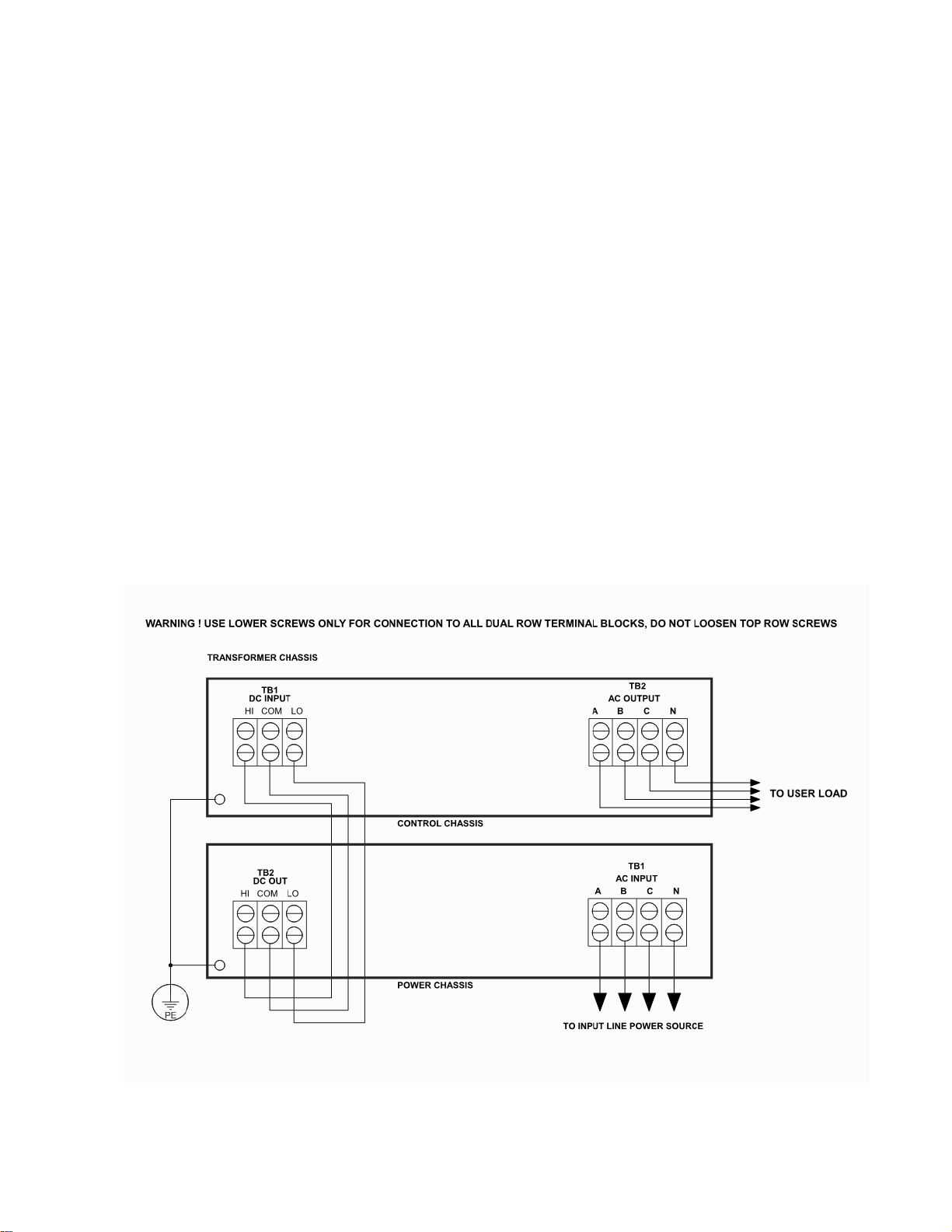

Figure 2-2 chassis inter-connection

MNL106-676-500 REV-A DATE: 03/23/2022

2.6 UNITS WITH TRANSFORMER OPTIONS

The BL5000 series models are available with optional transformer assemblies to

provide different output voltages. These are typically auto-transformers connected to

boost or lower the available 0-135VAC and match the user required load impedance.

T5 options provide a single range while T5D options provide a two-range output. Refer

to table 2-2 for a list of standard output configurations. Engineering specials may allow

other voltages not listed in the table. Refer to any addendum to operating instructions

that may have been provided with the special unit.

The wiring diagram below illustrates the interconnection of a BL5000 with a T5 or T5D

transformer chassis.

Figure 2-3 chassis inter-connect with T5 options

MNL106-676-500 REV-A DATE: 03/23/2022

SECTION THREE

OPERATION

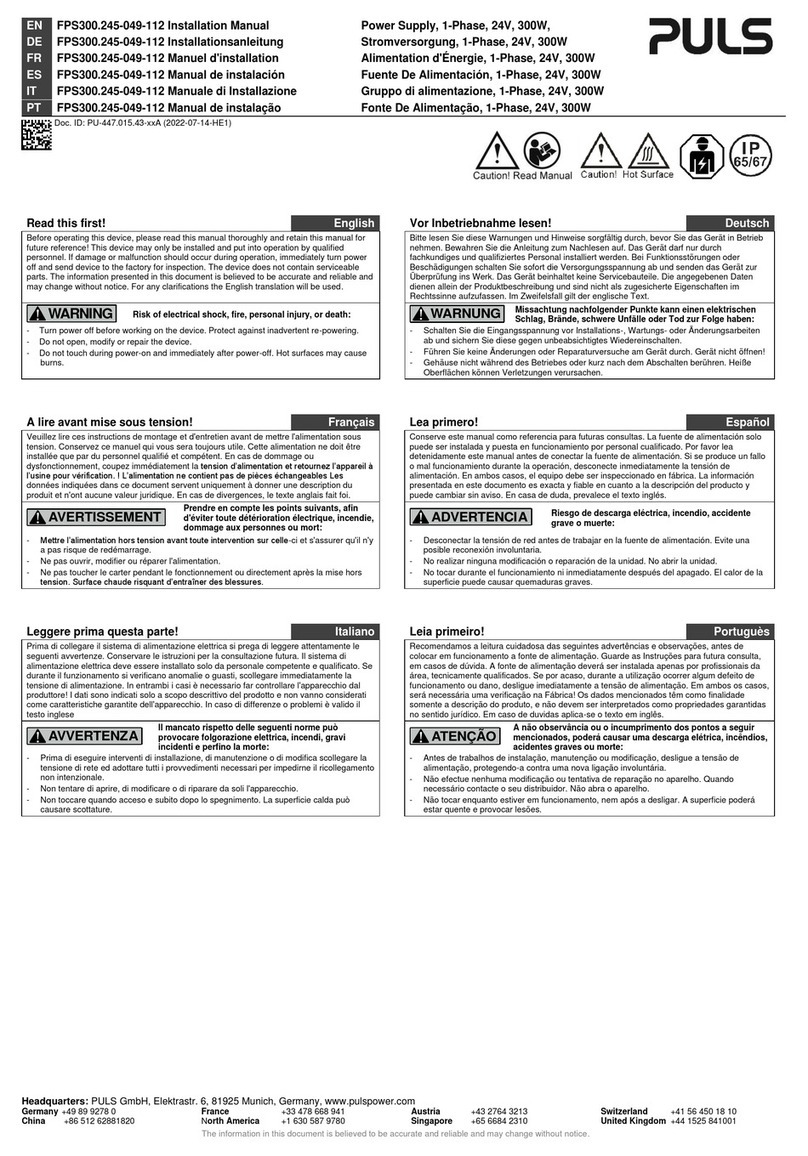

3.1 CONTROLS AND INDICATORS

Table 3-1 below lists the controls, indicators, and other features associated with the

model BL5000 AC power supply. Refer to figure 3-1 & 3-2 for locations.

ITEM

DESIGNATION

COMMENT/DESCRIPTION

1

AC Line ON/OFF

Input circuit breaker.

2

Power indicator

Green indicator lamp for line power

3

Digital Displays

3-digit LED readouts to display output volts, current

and frequency.

4

Display Select Switch

Selects the phase to be monitored by the displays.

Note: output voltage displayed is line to neutral.

5

Voltage Adjust

Multi-turn control provides continuous adjustment

of output voltage. Note: all 3 phases adjust

simultaneously. NOT INCLUDED on fixed voltage

versions.

6

LED Indicators

LED indicators for: Over Temp, Overload, or

Constant Current.

7

OUTPUT switch

Controls internal relay for application of AC output

to user load.

8

PHASE ADJUST trimmers

& LINE DROP COMP trimmers

Front panel “trimmers” that allow fine adjustment of

phase-to-phase angle and regulation over usable

frequency range. See operating instructions for

adjustment instructions.

9

FREQUENCY ADJUST

Multi-turn control provides continuous adjustment

of output frequency. Note: all 3 phases adjust

simultaneously. NOT INCLUDED on fixed voltage

versions.

10

TB2, Rear Panel AC Output

AC output terminal block.

11

TB1, AC Line input

AC input terminal block. See section 2 on input

wiring.

12

Remote interface

Analog remote control or optional RS-232 or IEEE-

488 type computer interface.

13

DC inter-connect (TB2 on input

chassis & TB1 on control unit.)

Connect DC cables between power and control

unit chassis. Caution! 500VDC high voltage.

MNL106-676-500 REV-A DATE: 03/23/2022

FIGURE 3-1 CONTROLS AND INDICATORS BL5000 MODEL SERIES

(FRONT VIEW)

1

2

3

4

5

6

7

8

9

MNL106-676-500 REV-A DATE: 03/23/2022

FIGURE 3-2 BL5000 MODEL SERIES

(REAR VIEW)

10

11

12

13

13

MNL106-676-500 REV-A DATE: 03/23/2022

3.2 OPERATING INSTRUCTIONS

1. Connect the unit to a source of AC power within the rated operating range for this

equipment. See sections 1 and 2 of this document.

2. Connect a suitable load to the AC output terminals (see section 2).

3. Set the output switch to off (recommended).

4. Set the front panel breaker to “ON”.

5. At this point, the front panel display will indicate some value and the sound of

cooling fans will be evident. The unit is now ready to use.

6. To energize the load, set the VOLTS and FREQ controls to provide the desired

output voltage and frequency. Note these controls are multi-turn types. If fitted with a

locking device (option L), make sure the device is un-locked prior to attempting

adjustments. Set the OUTPUT switch to “on” to connect the load. Set the load on

(assuming the load has its own switch or enabling device).

7. During operation, the METER SELECT switch can be set to display the voltage and

current of each phase. The meter displays line to neutral voltages and phase current.

8. To shut down, set the OUTPUT switch off, set the VOLTS control fully

counterclockwise, and set the front panel breaker to the OFF position. NOTE: No

damage to the power supply will occur if this procedure is not followed, however, this

sequence will provide a transient free output during switch on/off.

It is permissible to use the OUTPUT switch to turn the load on and off, however, certain

loads can cause the internal relay contacts to wear prematurely. This is especially true

for loads with capacitive or other high in-rush currents. When in doubt, use the

procedure outlined above. This procedure will provide a transient free output and

prolong the internal relay contact life.

It is also possible to have the output voltage set at zero, and then to turn on the

OUTPUT switch. The voltage can then be increased to the required operating point by

adjusting the VOLTS control clockwise. This method works best with linear loads and

may be desirable for certain applications (variable voltage versions only).

ADJUSTMENT OF LINE DROP COMPENSATION

This model provides a means of compensating for load current related voltage drops

associated with the output wiring. A LINE DROP COMP trim is located on the control

chassis front panel. One trimmer is provided for each phase. To adjust, proceed as

follows detailed in the following:

Other manuals for BL5000 Series

1

This manual suits for next models

10

Table of contents

Other BEHLMAN Power Supply manuals

BEHLMAN

BEHLMAN BL20000 Series Use and care manual

BEHLMAN

BEHLMAN PF1350 Series Use and care manual

BEHLMAN

BEHLMAN P1351 Use and care manual

BEHLMAN

BEHLMAN BL3300 Series Use and care manual

BEHLMAN

BEHLMAN PF1352 Series User manual

BEHLMAN

BEHLMAN BL15000 Series Use and care manual

BEHLMAN

BEHLMAN P1350 Use and care manual

BEHLMAN

BEHLMAN BL10000 Series Use and care manual