BEIER-Electronic SV3-1-8Z User manual

Table of contents

Other BEIER-Electronic Controllers manuals

BEIER-Electronic

BEIER-Electronic UFR-1230 User manual

BEIER-Electronic

BEIER-Electronic SFR-1-HL User manual

BEIER-Electronic

BEIER-Electronic UFR-1230-D User manual

BEIER-Electronic

BEIER-Electronic SV1-2-10Z User manual

BEIER-Electronic

BEIER-Electronic SFR-1 User manual

BEIER-Electronic

BEIER-Electronic SFR-1-D User manual

Popular Controllers manuals by other brands

Eurotherm

Eurotherm epack user guide

Dwyer Instruments

Dwyer Instruments Mercoid EDA series Specifications-installation and operating instructions

Siemens

Siemens Acvatix SAS31.03 manual

Calpeda

Calpeda IDROMAT 5 quick start guide

Duff-Norton

Duff-Norton UM28632 Installation, operation and maintenance instructions

National Instruments

National Instruments CompactRIO cRIO-9072 User manual and specifications

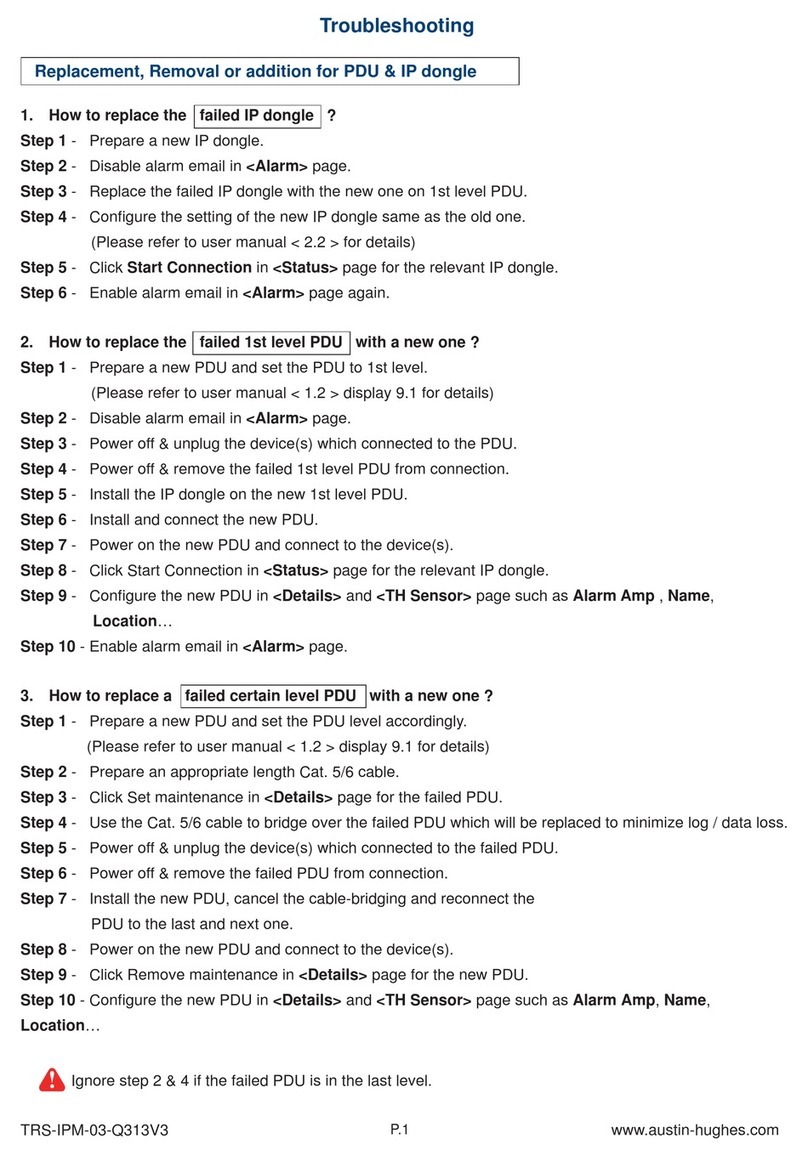

Austin Hughes

Austin Hughes InfraPower Manager IPM-03 Troubleshooting

Resol

Resol DeltaSol SLT Manual for the specialised craftsman

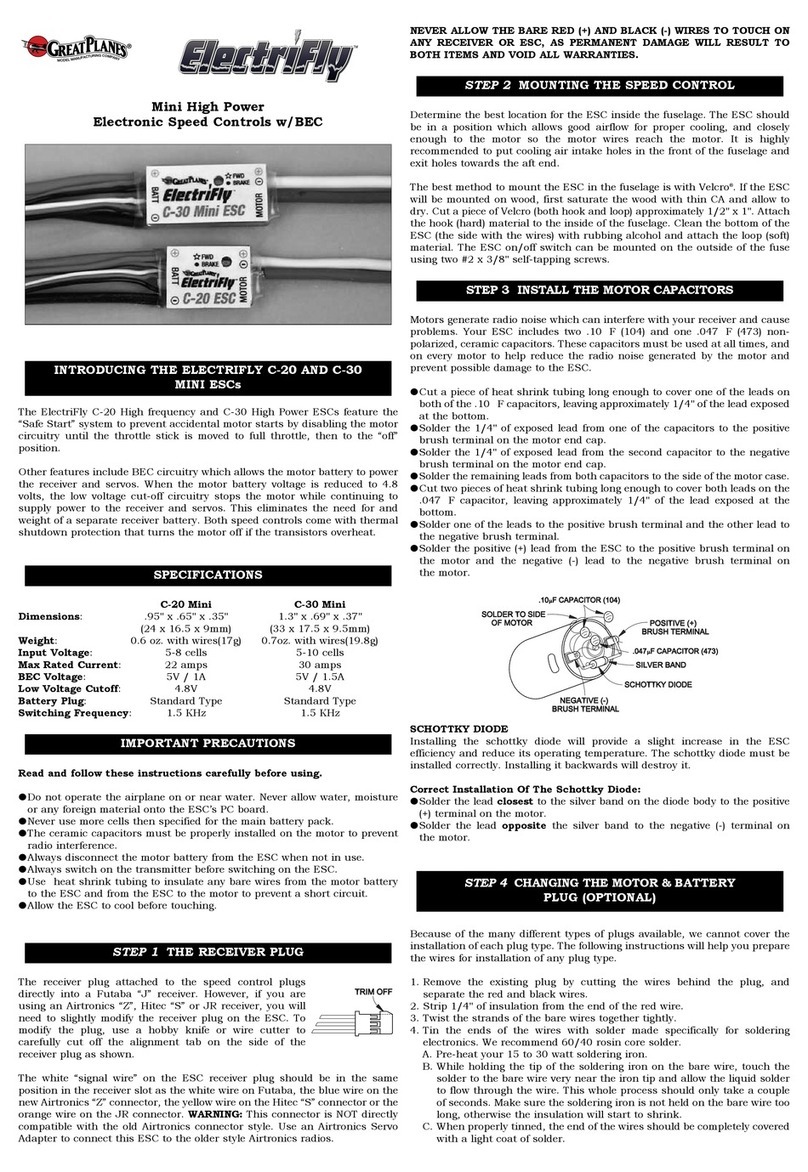

GREAT PLANES

GREAT PLANES ElectriFly C-30 Mini quick start guide

Motor Guard

Motor Guard MHT-7300 instructions

Kramer

Kramer SL-1 user manual

TREND

TREND AL0620-24-K installation instructions