______________________________________________________________________________________

AVC634A-120 3

2. OPERATION PROCEDURE

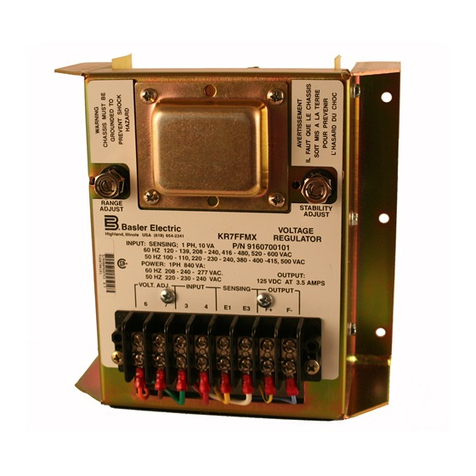

2.1 STABILITY ADJUST RHEOSTAT (STAB)

●An internal screwdriver adjustable potentiometer

provides adjustment to the response rate of the

generator output voltage to a change in load.

●Clockwise rotation of this adjustment provides an

increase in the response time and therefore

decreases the amount of voltage overshoot

(increased stability). Counter-clockwise rotation of

this adjustment provides a decrease in the

response time (faster response time) and

therefore increases the amount of voltage

overshoot (decreased stability).

2.2 OPERATION

The following system operation procedures provide

instructions for adjusting the AVC634A-120 voltage

regulator. Symptoms resulting from a faulty regulator and

certain generator system problems are included, together

with suggested remedies.

CAUTION !

Meggers and high potential test equipment must not

be used. Incorrect use of such equipment could

damage the semiconductors contained in the

regulator.

2.3 PRELIMINART SET-UP

1. Verify that the voltage regulator specifications

conform with the generator system requirements.

2. Ensure that the regulator wires are as follows:

●If the remote voltage adjust rheostat is not to be

connected, ensure terminals 6 and 7 are shorted

with a jumper.

●If a 55 Hz “corner frequency” for 60 Hz systems is

desired, ensure that the HZ1 and HZ2 terminals

are open. If a 45 Hz “corner frequency” for 50 Hz

systems is terminals are shorted together with a

jumper.

●For 120V nominal sensing, ensure that terminals

V1 and V2 are not connected. For 240V sensing,

ensure that terminals V1 and V2 are connected

together.

3. Ensure the voltage regulator is correctly

connected to the generator system.

4. Install the fuses as described in Fuses.

5. Set the regulator VAR and external VAR (if used)

as follows:

2.4 SYSTEM STAR-UP

1. Perform preliminary set-up as described in

the above paragraphs.

NOTE :

All voltage readings are to be taken with an average

reading voltmeter.

2. Start prime mover and bring up to rated speed.

RESULT :

Voltage should build up. If not, perform Field Flashing.

3. Slowly adjust the regulator VAR CW until the

generator output voltage reaches the nominal

value. If used, adjust the remote VAR to set the

generator voltage to the exact value desired.

RESULT:

Voltage should build up to rated value. If voltage

does not build up to rated value, check generator for

short or excessive load.

4. Check regulator normal operating and

loading conditions.

RESULT:

Voltage regulation should be better than ±1.0%

no-load to full-load. If regulation is not within this

range, perform the following steps:

●Voltage reduction under load may be due to

speed change from no load to full load. causing

the frequency compensation (U/F) circuit to

reduce voltage at lower frequencies.

●Replace voltage regulator.

2.5 OPERATIONAL TEST

1. Connect the test setup as shown in the following

figure, Operational Test. Do not apply power.

Ensure that the light bulb is rated for 120V and is

less than100Watts.

Complete the following steps before

proceeding with the system start-up.

SWITCH INITIAL SETTING

Regulator VAR Fully CCW

Remote VAR Centered