__________________________________________________________________________________________________________________________________

EuropeanSafetySystemsLtd. Impress House, MansellRoad, Acton, LondonW37QHsales@e-2-s.com Tel: +44(0)208743 8880

www.e-2-s.com Fax: +44(0)2087404200

DocumentNo. IS2457-PIssue E12-03-10 Sheet3of 4

9) CableSelection

Whenselecting the cable size consideration mustbegivento

the inputcurrentthateach unit draws(seetable above), and

the length ofthe cableruns.

SAFETY WARNING: If the high outputBExDTS110D units are

used athighambienttemperatures,i.e. over+40ºC, then the

cable entrytemperature mayexceed +70ºCand therefore

suitable heat resistingcablesmustbeused, witharated

service temperatureofat least 110ºC.

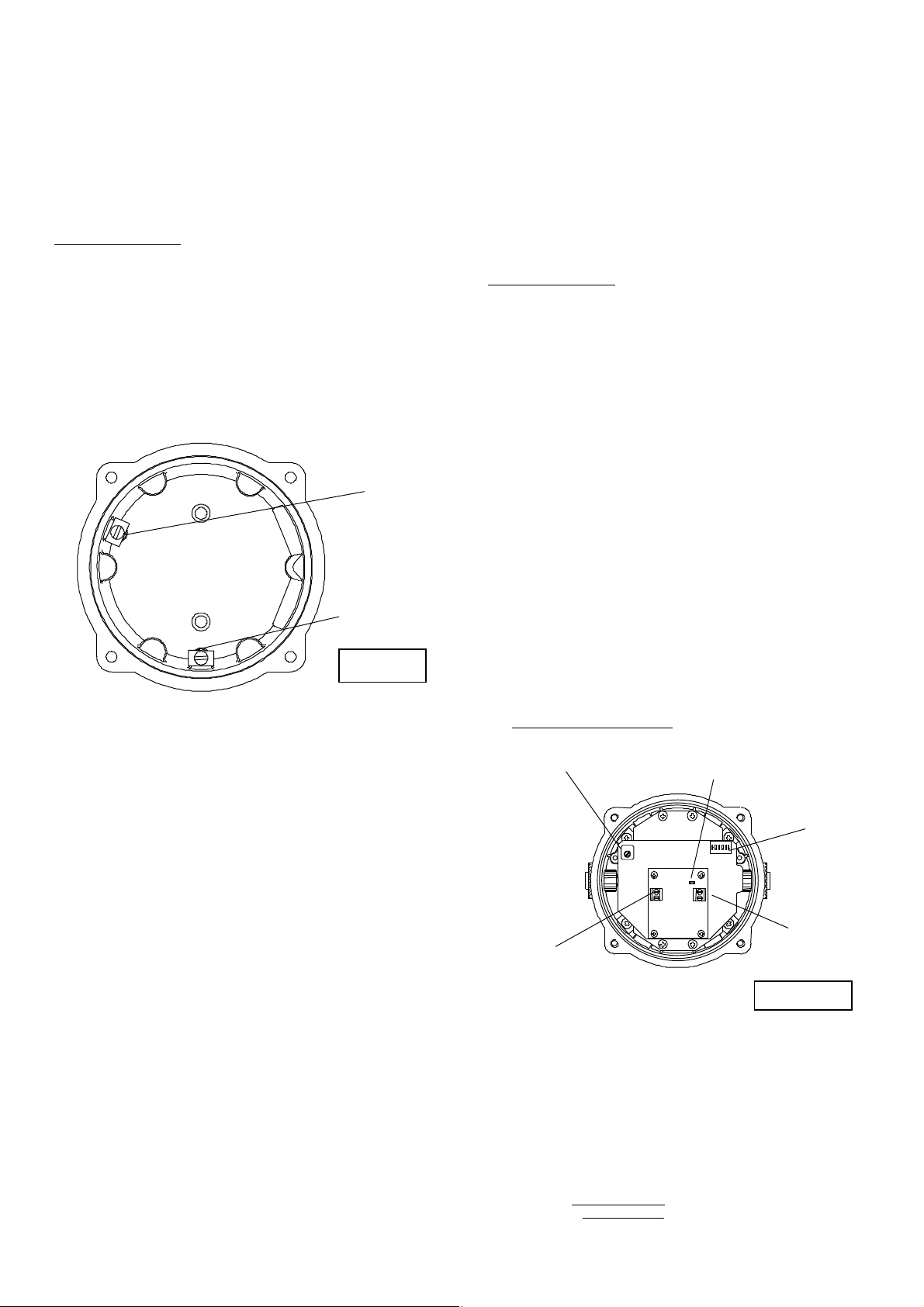

10) Earthing

The Sontelunits mustbeconnectedtoagood quality earth.

The unitsareprovidedwithinternal and externalearthing

terminalswhichare bothlocatedonthe terminalchamber

sectionoftheunit (seefigures 2and3).

Whenusingtheinternal earth terminalensure thatthe

stainlesssteelM4flat washer isbetweentheincoming earth

wireand the enclosure.

Whenusingtheinternal earth terminalensure thatthe

stainlesssteelM4flat washer isbetweentheincoming earth

wireand the enclosure.

When using theexternal earthterminal a cablecrimp lugmust

be used. Thecablelugshould be locatedbetween thetwoM5

stainlesssteelflat washers. TheM5stainlesssteel spring

washermust be fixed betweenthe outer flatwasher andthe

M5 stainless steel nut toensurethatthe cablelugissecured

againstlooseningand twisting.

The internalearthbondingwireensures that agoodquality

earth is maintained betweentheflameproofchambercasting

and the flameproofcovercasting.

11) CableGlands

The BExDTS110DSontelshave dual cableglandentries

whichhave an M20x1.5asstandard.Onlycable glands

approvedfor Ex‘d’applicationscan beused,which mustbe

suitable forthetype ofcablebeingusedand alsomeetthe

requirementsofthe Ex‘d’flameproof installationstandard

EN60079-14:2008/ IEC60079-14:2007.

Whenonly one cable entry isusedtheotherone mustbe

closed with an Ex ‘d’flameproofblankingplug,which mustbe

suitablyapprovedfortheinstallation requirements.

For combustibledust applications, the cableentry deviceand

blanking elementsshall be in type of explosionprotection

increasedsafety"e"or flameproof enclosure "d"andshall have

an IP 6Xratingaccording toEN 60529.

SAFETY WARNING: IftheBExDTS110D Sontelsareusedat

high ambienttemperatures,i.e.over+40ºC,thenthecable

entry temperaturemay exceed+70ºCand thereforesuitable

heatresisting cable glands mustbe used,with arated service

temperature of at least 110ºC.

12) CableConnections

The cableconnectionsaremadeinto theterminal blockson

the Sontelpcbassemblylocated in theflameproof enclosure.

Seesection7ofthismanualfor access totheflameproof

enclosure.Theprintedcircuitboardhastwoterminal blocks;

one for thepowersupply inputvoltageand onefor the

telephone signalinputcable(seefigures 4and 5). The power

input cableshouldenterthe enclosurevia oneofthe M20

cable entries and be connected to thesupply terminals (L and

N) AC units (+ve and –ve) DCunitsandthetelephonesignal

cable should entertheenclosure via theotherM20entryand

be connectedtothetelephone terminal.

A singlewire withacross sectionalarea ofup to 4mm² can be

connectedtoeachterminal way. Whenconnecting wires to the

terminalsgreat care should betakento dressthewire so that

whenthecoverisinsertedintothechamberthewires donot

exert excesspressureonthe terminalblocks. Thisis

particularlyimportantwhenusingcableswithlarge cross

sectional areassuchas2.5mm² andabove.

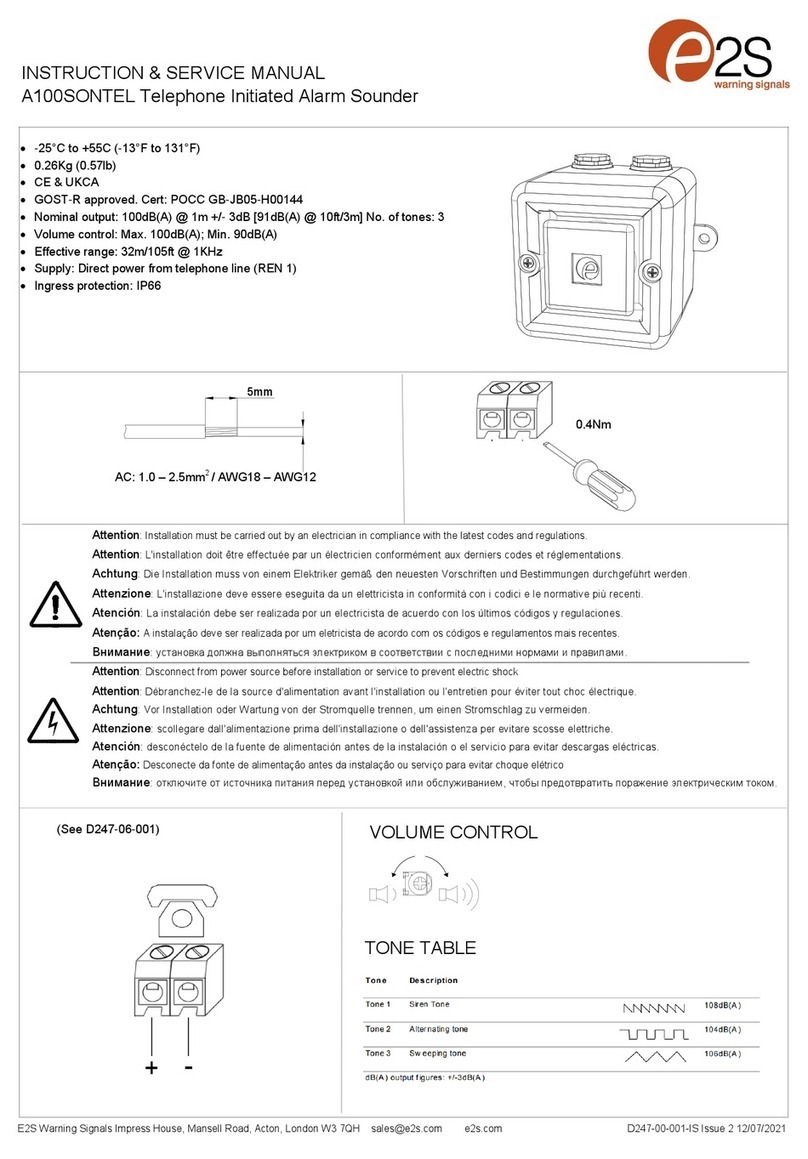

DIPSwitch

VolumeControl

Input Terminals

Input Terminals

Land N

CableEntries

Figure3

WireTerminal