BEINAT BX308xp User manual

Belonging to

Important: Assembly / maintenance of the appliance must be carried out by qualified personnel and in

accordance with applicable laws and regulations.

The manufacturer assumes no responsibility for the use of products that have to comply with particular

environmental and / or installation standards.

Important note

Before connecting the equipment, it is recommended that you read the instruction manual carefully and

keep it for future reference. It is also recommended to perform the electrical connections correctly as

per enclosed drawings, observing the instructions and the Standards.

N.B. Refer to the documentation in all cases where the symbol is on the side

Channel: Beinat gas solutions

Electricconnections alsoavailable on

CONFORMITY

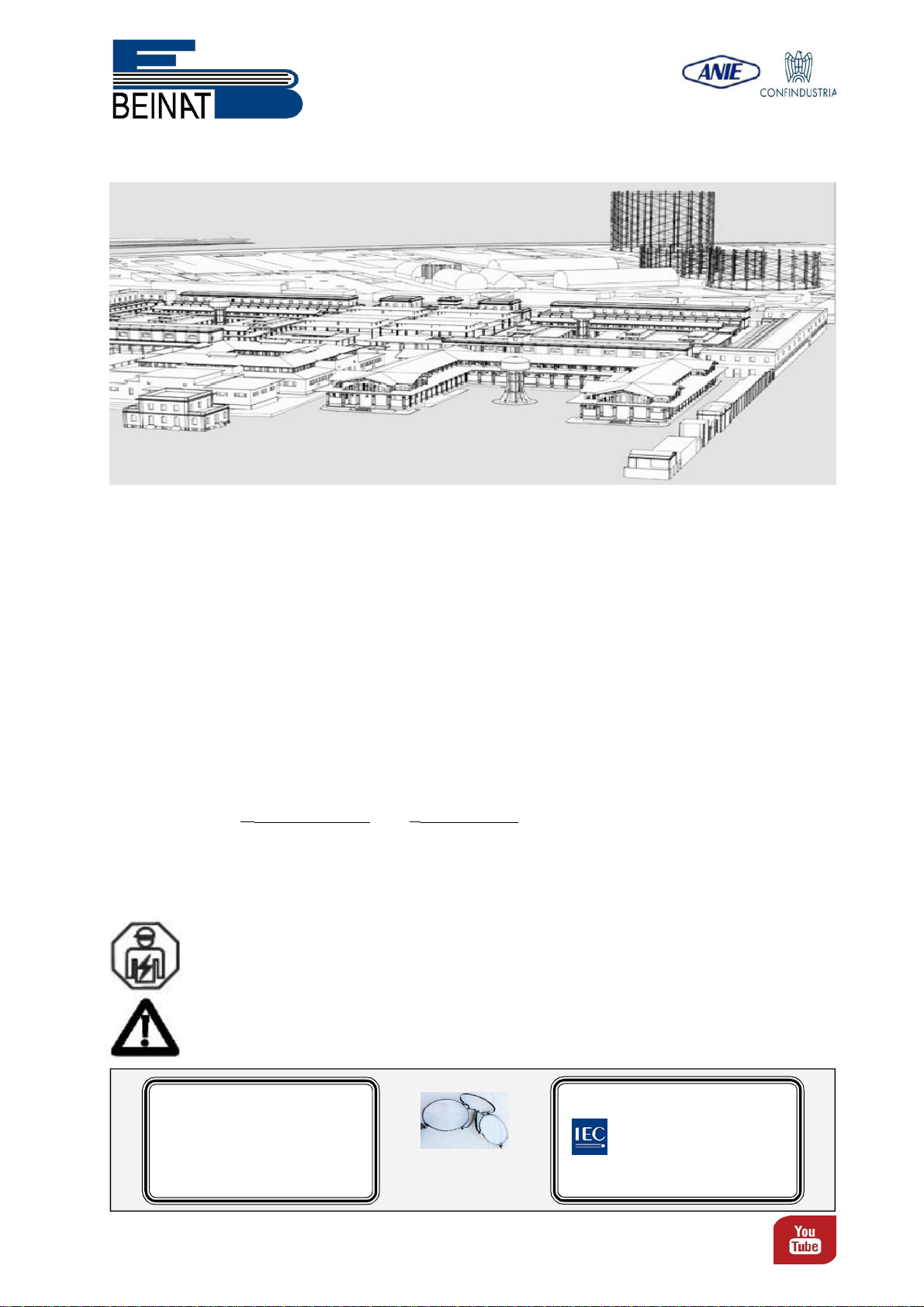

Installation

and user guide

Theexperience and the knowledge acquiredover the yearswithinindustrial sectorand markettogether withthe prestige

that has always made BEINAT S.r.l. stand out from its competitors comes to the new Gas Control Unit “BX308/xp”

aimed at checking, by means of probes coupled to it, the presence of gas: toxic, explosive, and Oxygen.

Cutting-edge technologies enable the Gas detection control unit to be installed in industrial environments and

underground parking spaces.

Thecontrolunit BX308xphas been designed and built tomeet the current requirementsof the Market andincompliance

with European Standard for checking gas presence in a versatile and innovative using: With conventional sensors.

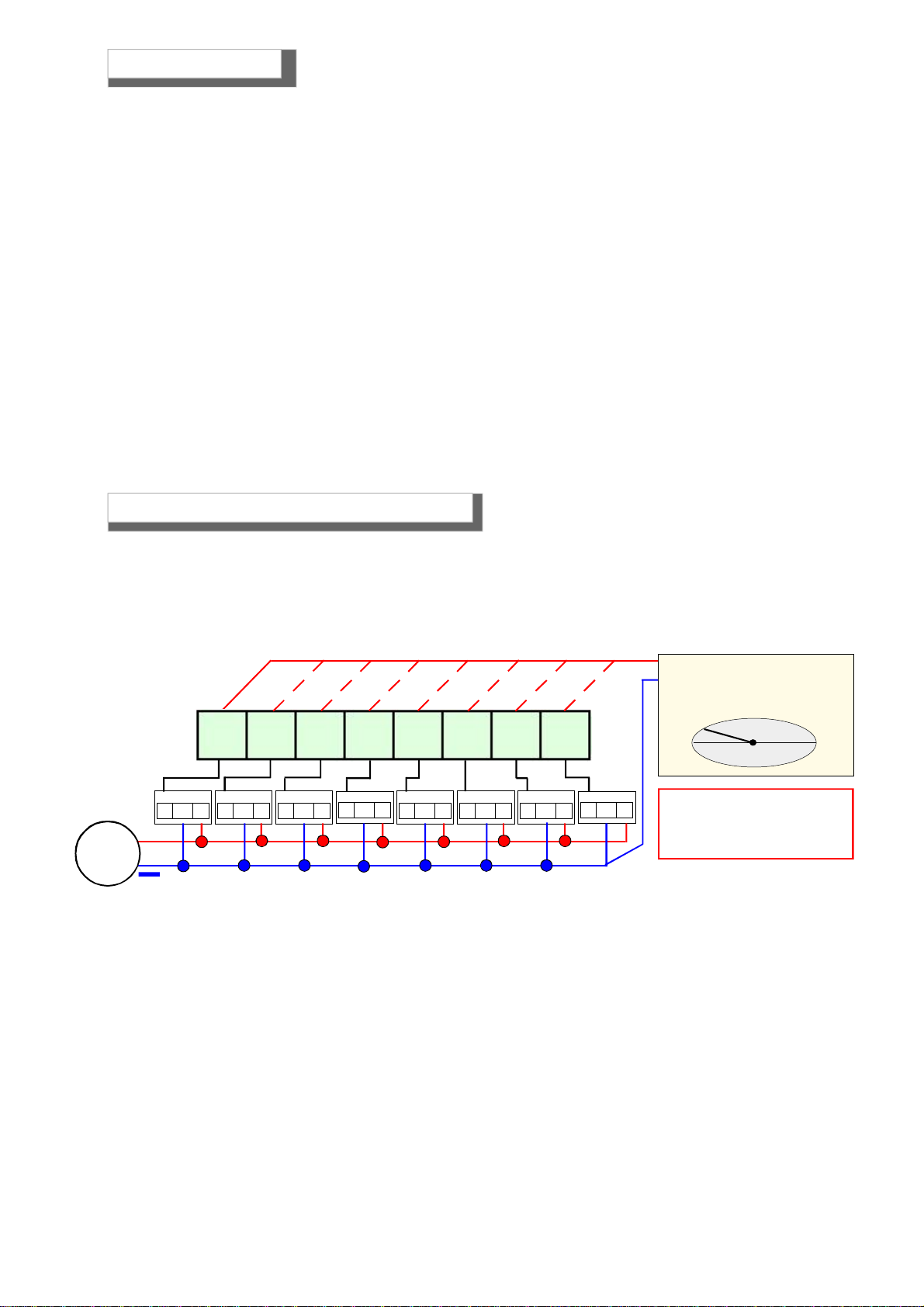

Up to 8 remote probes Conventional from 4 to 20 mA can be connected in conventional mode for a single zone.

Gas concentration measured by every probe sequentially is shown directly on display, with a description of its origin.

When one of the coupled probes exceeds the pre-alarm setpoint, the controlunit generatesa proportional sound signal,

depending on the concentration of gas measured, and shows on the display the number of the probe, the amount of

gas measured and its origin; the alarm triggered is saved in a memory (Datalogger). Should it be necessary,the data

stored can be printed (up to maximum 50 events).

The control unit features two levels of hazard:

1stLEVEL, pre-alarm.Thisdataisvariable.Thetechniciancanmodifypre-alarminterventionforeveryprobeaccording

to the type of plant to be controlled.

The level can be selected from 3% to 16% of L.E.L. or from 45 to 240 ppm

2nd LEVEL, general alarm. it is set to 20 % of L.E.L. or 300ppm

The control unit is equipped with two general alarm relays with/without Positive Safety Switch to enable further

independent control of two solenoid valves. Finally, the Control Unit allows the user to control the actual operation

of the probes coupled.

ALARMS Oxygen: < Oxygen deficiency, and >Oxygen excess

Expansion Cards

CARD-RLS4. Relay card: each card has 4 relays, it can connect up to 16 cards

CARD-BMS16. Current Voltage

EN50194

EN 45544-1-3

EN 50270

EN 61010-1

Compliant EN 60079-29-1

Installation EN60079-29-2

Reports issued by TUV Italia

INSTALL IN SAFE

AREA, NO ATEX

Control Unit from 1 to 8 Conventional sensors BX308xp

Rev. 3

Page 2

Set: Date and time

Select: The number of probes, and their disablement

Select: The Operating range of the probes, from 0 to 20%, or 0-100 of L.E.L.

Select: The type of gas that the probe must detect “Toxic or Explosive”

Set: The Pre-Alarm level, for every probe from 3% to 16%

Select: The quantity of zones, “1-2” divisible 8 probes per zone

Select: The operation of the relay “ pulsed or continuous”

Select: The function of Positive Safety Switch

Select: The function of saving the alarm triggered

Select: The exclusion or insertion of “external siren”

Select: The exclusion or insertion of “internal buzzer” if an alarm is triggered

Read: The history of alarms (data logger), failures or any

important detection , up to maximum 50 events.

Connection. Of a portable printer via USB port

LCD display in normal operating condition

Display: the Brand and the serial number

Display: Date and Time

Display: the probe being monitored

Display: automatic Explosive Gas and Operating range L.E.L. or Toxic Gas ppm

Display: the chart of the amount of gas detected

Display: Warm up on Display appears the “count-down” time

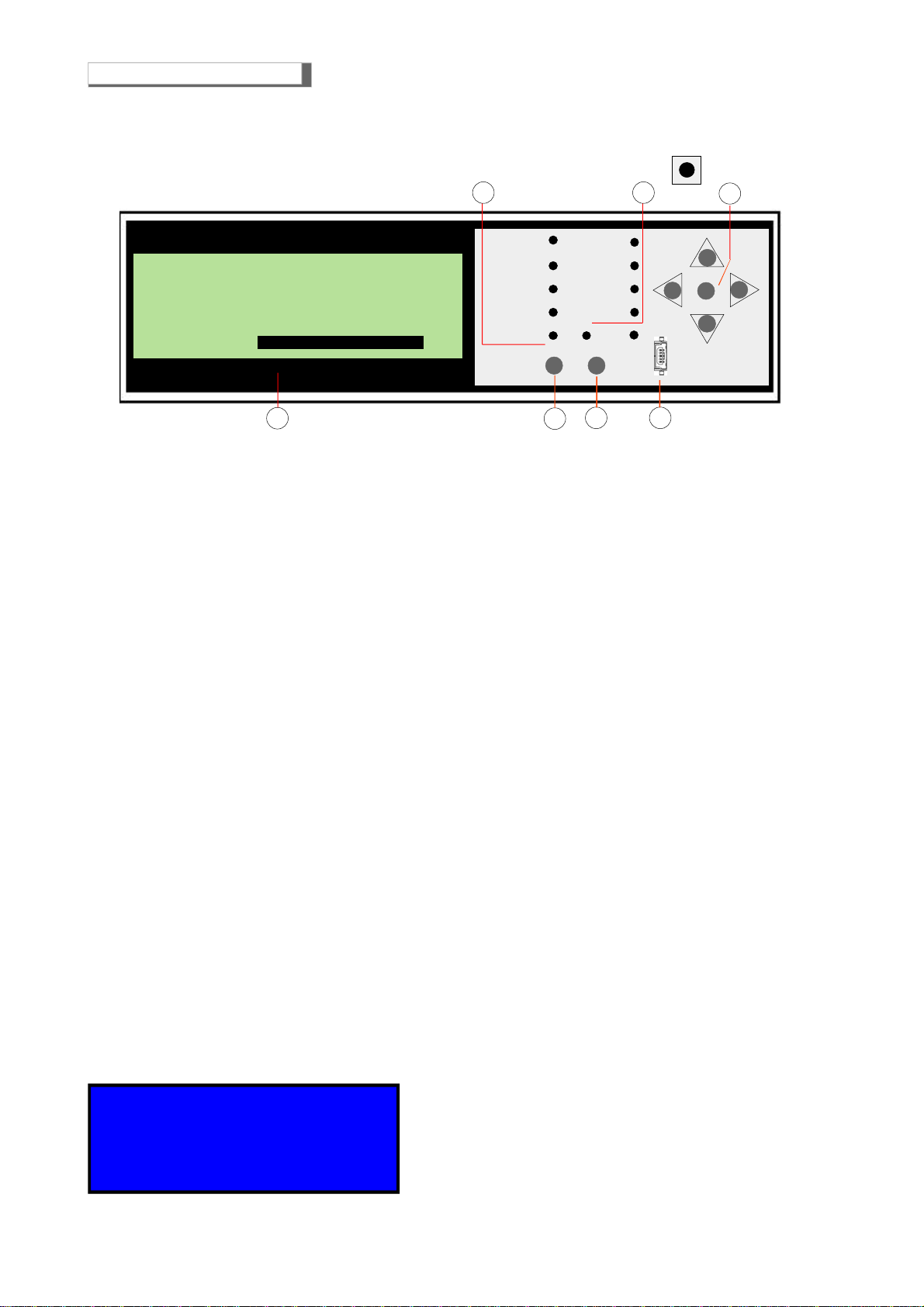

Front Panel

Push-buttons for navigation and confirmation of data set

Test push-buttons for total control of BX308xp that check the performance of both the control unit and the probes

connected to it.

Reset button used to reset alarm and failure memories

LED that displays the silenced external siren. This operation can be performed by entering the Password

All operation and alarm LEDs: read page 4 to find out their functions

LED that displays the charge status of Buffer battery

Main Power Supply

unboxed version

.........................................................................12/15 V ± 10%

Main Power Supply

boxed version

................................................................ 110/230VAC 50/60Hz ±10%

Secondary power supply via battery Max 2,2 Ah (not supplied) ....................................... 12,7 V ± 10%

Battery Charger Max 2,2 Ah ...................................................................................................... controlled

Max power demand in alarm with 8 probes connected .................................................. 15W Max @ 12 V

Max power demand in alarm with 8 probes connected ..................................................... 19W Max 240VAC

Relay Contact Range ..................................................................................................... 10A 250V resistive

ALARMS

1st Pre-Alarm ............................ adjustable for every probe from 3% (450ppm) to 16% (240ppm) of L.E.L.

2nd Final alarm for every active area .............................................. set to 20% of LEL or 300 ppm CO

Monitored Gas Indication .................................................................................. Through illuminated display

ALARMS Oxygen .......................................................... <Oxygen deficiency and > Oxygen excess See page7

INDICATIONS

Indicate the percentage of gas detected......................................................................... seen on display

Indication of mains power supplied

, alarms, battery state, probe and battery over load, faults

Manual alarm

indication

........................................................................................................... built-in

Siren ON

indication

................................................................................................................. built-in

Duration of pre-heating phase via count-down ..................................................................... 90 seconds

Manual test .......................................................................................................................... built-in

External siren and internal Buzzer silencing ......................................................... via software operation

ALARM AND PROBES ZONES

Number of Selectable zones ................................................................................................................. 1

Number of connectable Sensors ............................................................................................................. 8

Probes connection/disconnection ............................................................................. via software operation

Connectable probes ............................. Semi-conductor, Catalytic, Electrochemical cell, Pellistore, Infrared Rays

Faults detected by failure circuit ............................................................. Interruption , short circuit or failure

Input signal ..................................................................................................... 4 ÷ 20 mA over 150 Ohm

Operating Range ............................................................................................. 0-20% or 0-100% of L.E.L.

Equipment precision .................................................................................................................... 1% FS

Response time ............................................................................................................................... < 2"

CONNECTIONS

Printer ......................................................................................................... through dedicated USB port

CARD-RLS4 Relay expansion card ............................................................................ each card has 4 relays

CARD-BMS16 .................................................................................................. Converter Current Voltage

GENERALINFORMATION

Operating temperature .................................................................................................... -10°C ÷ + 60°C

Maximum distance between probes and control unit ............................................................................100 m

Cable diameter for connecting probes ............................................................................................. 1 mm2

Connection:

The cable of connection of the probe must not be installed together with the power cables.

Otherwise, make sure to use a shielded cable

Omega bar dimensions DIN EN 50092 9 modules .................................................................. 158x90x58 mm

Degree of Protection ............................................................................................................. in air IP20

Dimensions installed on the “Boxed” ............................................................................... 340*280*160 mm

Degree of Protection on the “Boxed”............................................................................................... IP65

Main specification

Technical specification

Page3

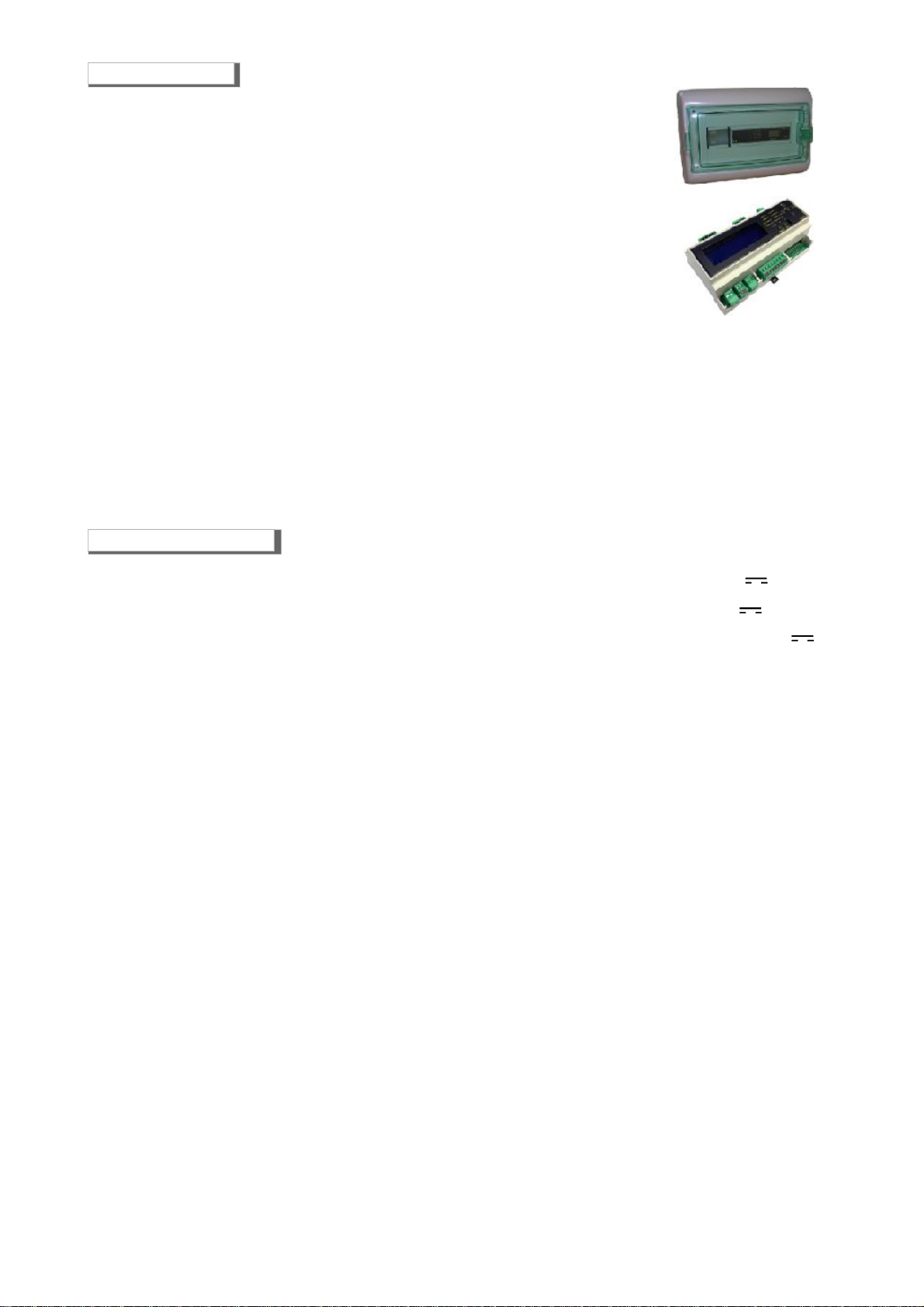

CHECK the integrity of the probe after having removed it from the box.

Check that the data written on the box correspond to the type of gas used.

When doing the electrical connections, follow the drawing closely.

Any use of thedetectorforpurposesotherthanthe intendedone isconsideredimproper,and asa resultof whichBEINAT

S.r.l. therefore disclaims any responsibility for possible damages caused to people, animals or objects.

TERMS and EXPECTATIONS: The installation of the BX308xp, its ordinary and extraordinary maintenance, and its

out of service removal at the end of the functional life guaranteed by the manufacturer, must be carried out by

authorizedand/orspecializedpersonnel.

Do not allow it to become wet.

Do not drop it.

Heavy knocks or falls during transportation or installation can damage the appliance.

Avoid abrupttemperature fluctuations.

Sudden temperature variations can cause condensation and the probe could work poorly.

Cleaning

Never clean the device with chemical products. If necessary, wash with a moist cloth.

Absolutely avoid using any cloth dipped in thinners, alcohol and chemical detergents.

Disposal of the device

Concerning the conservation, the protection and the improvement of the quality of the environment, as well as for the

protection of human health and the careful and rational use of natural resources, the device has to be the object of

aselective collectionfor he disposalof electronic equipments and can not be disposed with the common domestic waste.

The user thus has the obligation to separate the device of the other waste to ensure that it is recycled in a sure way

for preserving the environment For more details on the sites that are involved in the collection, contact the local

administration or the distributor of this product.

Useful Information

Main Compatible Probes

MAINTENANCE

The user periodically (every 6 months) must perform a check of the operation of the control unit by spraying

a suitable test gas at the base of the probes connected until the alarm condition is reached.

• At least once a year make a more accurate check by a specialist technician.

• Disabling the detector must be carried out by qualified personnel.

The installation of the gas detection system does not exonerate. From the observance of all the rules regarding the

characteristics, the installation and the use of the gas appliances. The ventilation of the premises and the discharge of the

combustion products prescribed by the UNI standards as per ART. 3 LAW 1083/71 and the relevant provisions of law.

SG500 Catalytic IP30 Domestic Use CH4-LPG 0÷100% LEL 4÷20 mA ±5 % NO NO

SG544 Catalytic IP44 Tertiary CH4-LPG 0÷100% LEL 4÷20 mA ±5 % NO NO

SGM595 Catalytic IP55 Tertiary See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SGM595/A Catalytic IP66 Zone 2 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SGM533 Catalytic IP55 Tertiary See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes Yes

SG800 Catalytic IP66 Zone 2 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes Yes

HCF100 SemiCondut IP55 Tertiary FREON 0÷300% ppm 4÷20 mA ±5 % NO Yes

SG895 Pellistor ATEX Zone 1 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SG580 Catalytic IP66 Zone 2 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SGF100 Catalytic IP64 Zone 2 Methane 0÷100% LEL 4÷20 mA ±5 % Yes Yes

SGF102 Catalytic IP64 Zone 2 LPG 0÷100% LEL 4÷20 mA ±5 % Yes Yes

SGF104 Optical Fluores IP64 Zone 2 Oxygen In % 4÷20 mA ±5 % Yes Yes

SGF106 SemiCondut IP64 Zone 2 FREON 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SGF108 Elettrochimica IP64 Zone 2 H2S 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SGF110 Electrochemical IP64 Zone 2 CO 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SGF112 Catalytic IP64 Zone 2 Hydrogen 0÷100% LEL 4÷20 mA ±5 % Yes Yes

CO100r Electrochemical IP55 Tertiary CO 0÷300% ppm 4÷20 mA ±5 % Yes Yes

CO100Ar Electrochemical IP66 Zone 2 CO 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SG800duct Catalytic IP66 Zone 2 CH4LPG 0÷100% LEL 4÷20 mA ±5 % Yes Yes

CO200duct Electrochemical IP66 Zone 2 CO 0÷300% ppm 4÷20 mA ±5 % Yes Yes

Application in:

Domestic: family accommodation. Local boilers up to 70 kW-h

Tertiary Areas: Large Rooms Boilers, Workshops, Material Deposits, Industrial Kitchens, Large Buildings, Buildings.

Zone 2 - Mixed IP66 ATEX: High probability of escape, high risk locations, premises for which applicable regulations apply.

Zone 1 - Hazardous Area, High Risk Hazards, Rooms for Which Regulations, Tanks, Control Valves are in force.

Probe Sensor Degree Suitable for Gas Range Output Precis. Calibration Relay

Protec. Detected Working Automatic

Sensor

Page 4

BEINAT S/N AD012G

16/010/17 10:10

= = BX308xp ver. 3.0 = =

Count Down 90”

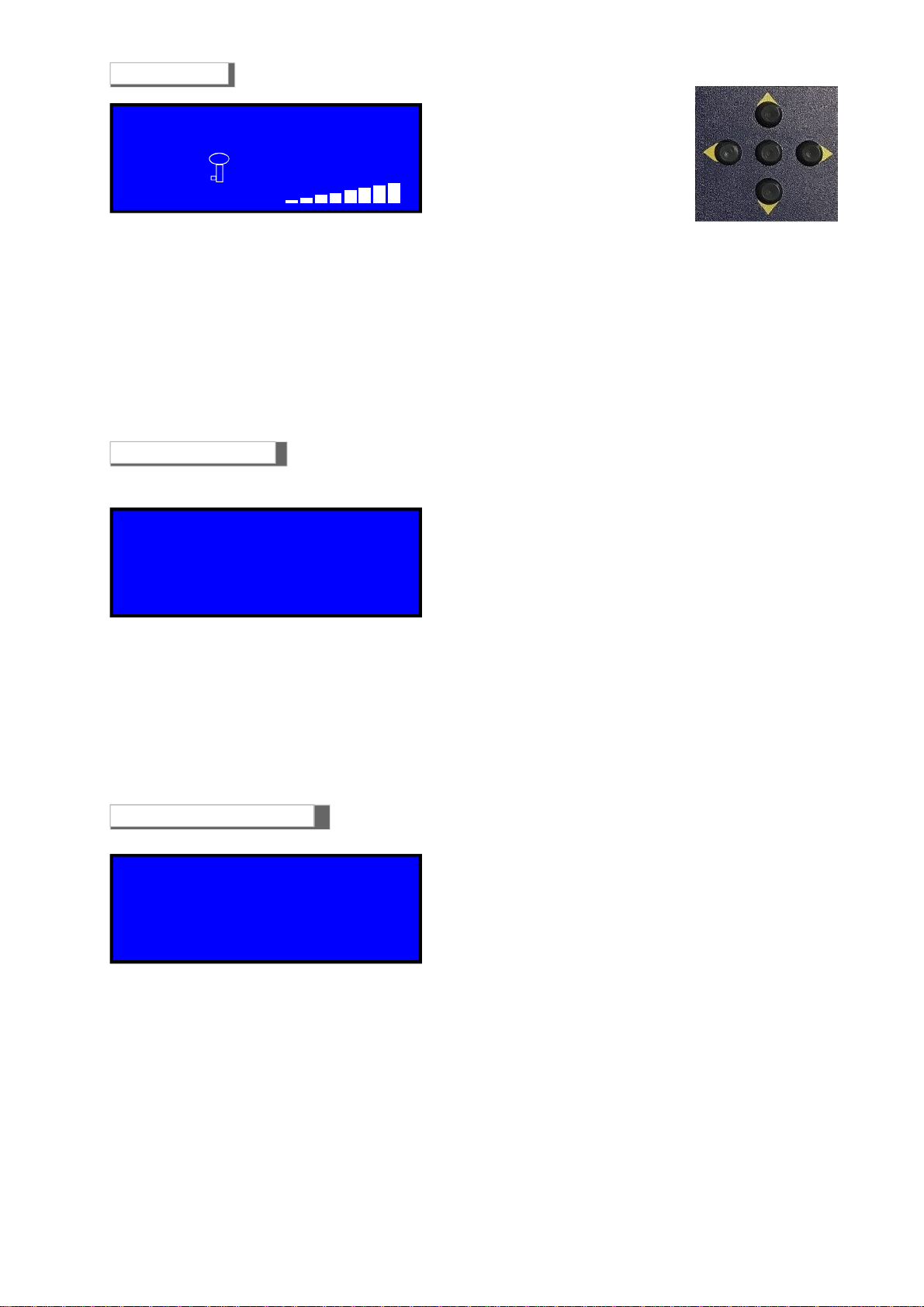

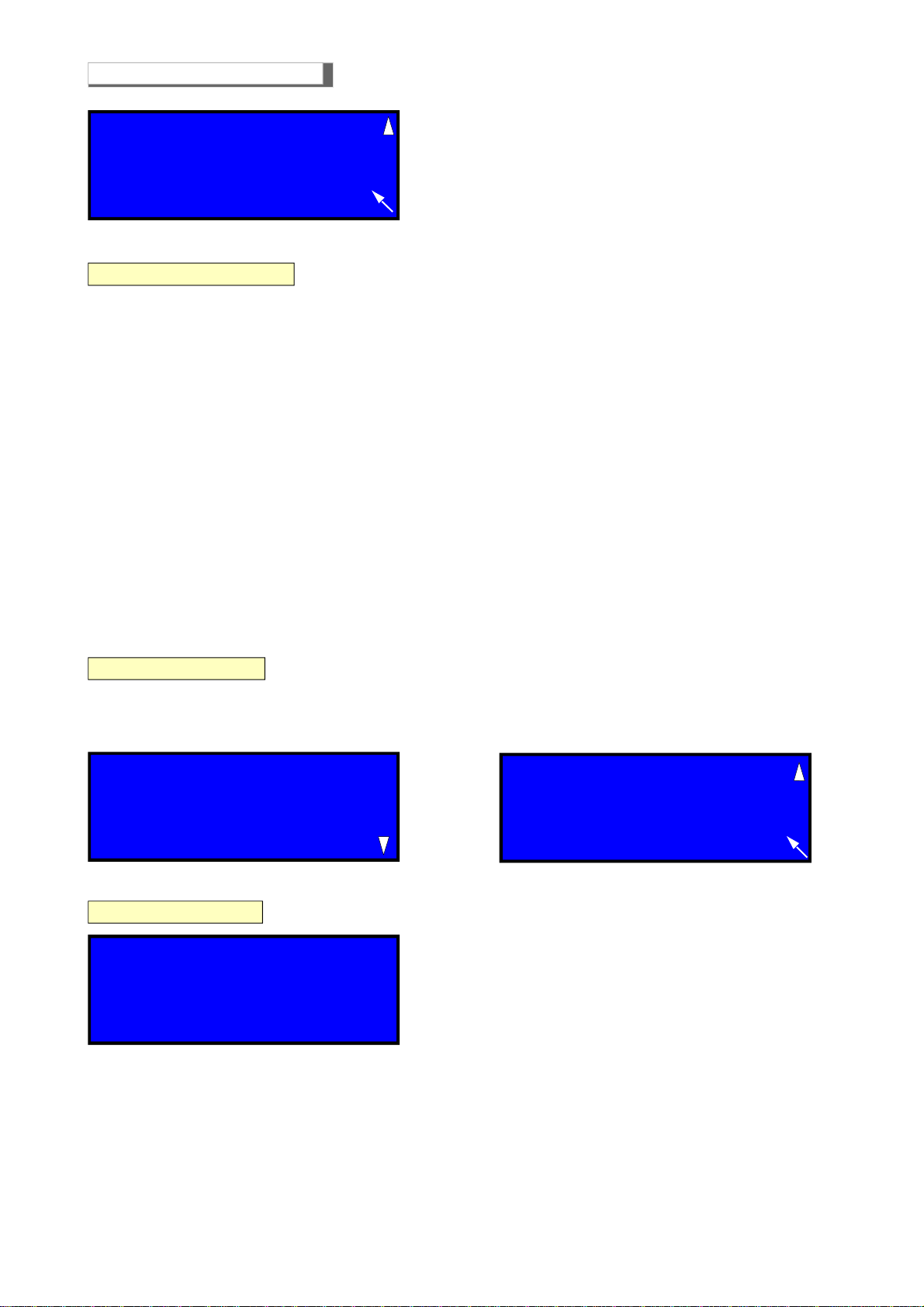

Screen displayed when turning on the BX308/xp.

This screen remains on for 90 seconds.

SN B0205 06/Jan/2013

State 15:48

Probe 05 18% LEL

Enabled

Power

Battery

OL Probes

OLBattery

Fault

PreAlarm

MainAlarm

Exit Alarm

SirenStatus Enter

Test Reset

123

456

Reset Hardware

7

1) Signaling LEDS

a) MAINS LED. It turns on when network voltage is inserted.

b) Battery LED. It turns on when the equipment is powered by battery.

When the LED starts to flash it means that the battery is low.

c) The control unit is equipped with electronic safety devices called OVER LOAD, that are used to prevent

permanent damage of the same. When these LEDs turn on it does not mean that the control unit is not working;

it means that the equipment coupled to it (or the relative connections) are not working.

PROBE OVER LOAD LED: if this LED turns on, it indicates a short circuit or a high absorption of current by the

probes and the relative connection cables. Check the battery and the connection cables.

BATTERY OVER LOAD LED: if this LED turns on it shows that the battery is connected incorrectly or there is

an abnormal current absorption. Check the battery and the connection cables.

d) FAULT LED. This LED turns on and flashes when one of the probes coupled is damaged or the connection

cables are interrupted or there is a connection error. When this LED is turned on, the equipment can no longer

detect the gas and it activates the relays of both threshold levels (the 1st and the 2nd).

To restore operation, the probe must be repaired or removed by pressing RESET using the setting program.

2) Alarm LEDS

a) PRE-ALARM LED(PRE-ALARM). This LED turns on when gas concentration level reaches the pre-alarm

value; the latter can be set from 8 to 16% of L.E.L. and closes the relay contact of 1st THRESHOLD.

b) MAIN ALARM (GENERAL ALARM) LED. This LED turns on when gas concentration reaches a value of 20 %

of L.E.L. and closes the GENERAL ALARM relay contact.

c) MANUAL ALARM LED. This LED turns on when the remote alarm button is pressed.

d) LED for activating the EXTERNAL SIREN. It turns RED when the external siren is disconnected.

Push-Buttons

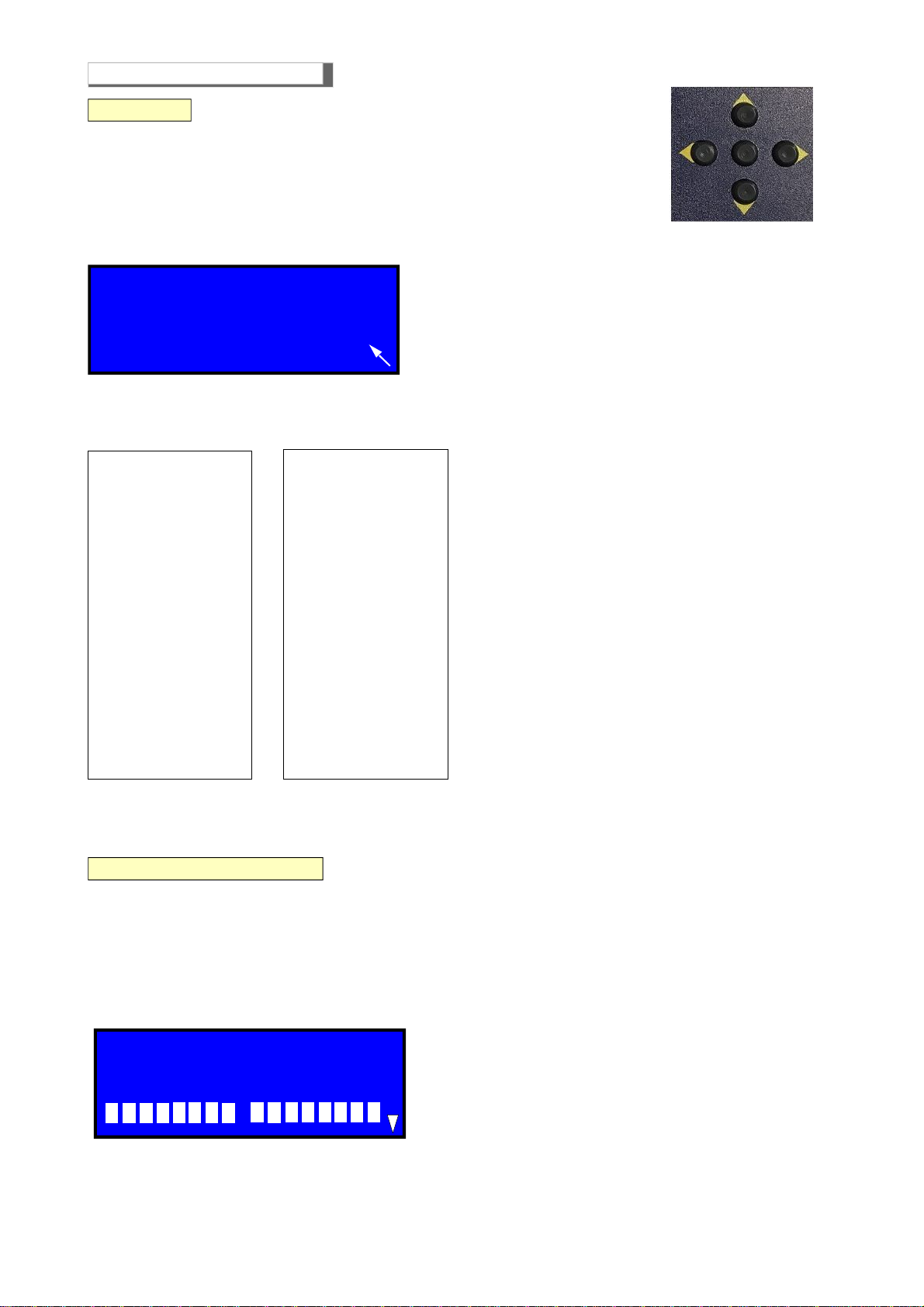

3) Navigation buttons group. These buttons are used to set the operation of the control unit.

4) RESET button. Press this button to reset all memories.

5) TEST button. By keeping this button steadily pressed you will simulate a gas leak.

6) Printer USB port. Connection for printing the data stored in the memory.

7) Display.

The instrument is equipped with a high performance alphanumeric display with 4 lines for every 20 characters

to facilitate reading all the events. Display background will always be lit up.

Components and comands

Page 5

SN AD012G 16/Ago/16

Single Zone 10:10

Probe 07 Esp. 020% 100%

20,0% LEL

To access the BX308xp setting program you should press the “ENTER” button for 5 seconds.

In normal functioning state, the display shows the following information:

a) Registration number

b) Current date and time

c) Currently detected zone

d) The currently monitored probe, and the type of gas, explosive and/or toxic.

Each connected probe is shown every 8 seconds.

To accelerate the display of the probes press the Left and Right buttons.

To stop the sequence of probes, and analyse the functioning of a specific probe, press “ENTER”.

On the display you will see a key. To unlock it, press again “ENTER”.

e) Display of the percentage of L.E.L. or ppm detected by the probe, and the bar graph of the quantity of gas.

To continue you should enter a password.

The “password” is 1-2-3-4.

Note. The password can be changed by accessing the “Advanced Functions” in the “General Functions” section.

Use the Left and Right buttons to reach the desired number, and press “ENTER”.

Each time you enter a number you will see an a star, until all four a stars appear.

If the password is correct you will see “Password accepted”

If you made a code input mistake, you will see “Wrong password”.

You should re-enter the password. If you do not press any key, you will return to the previous screen.

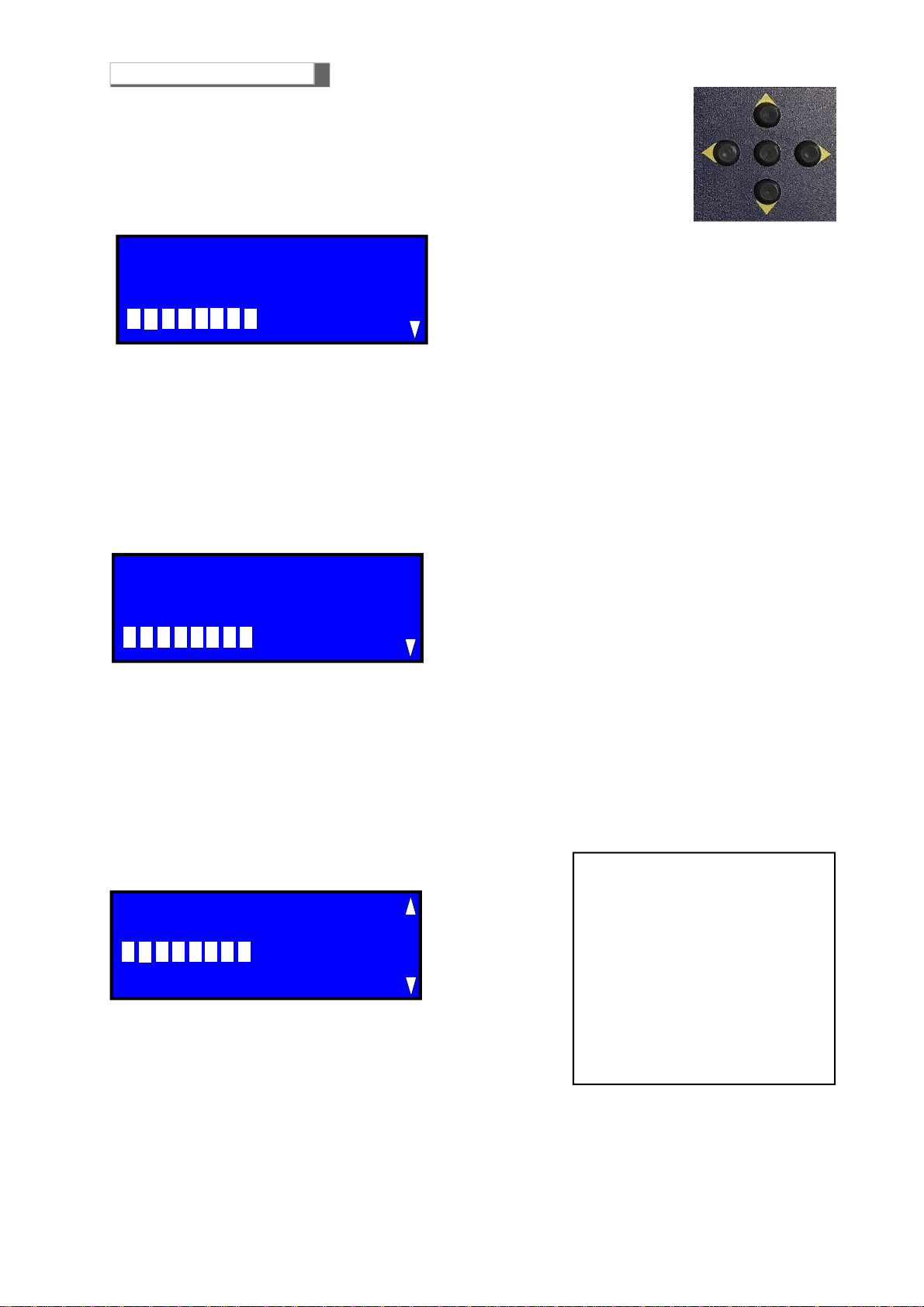

DATE and TIME SETTING

Use the Left and Right buttons to select “Time Setting”, and press “ENTER”. You will access the current

date and time setting program.

PROBE SETTING

Use the Left and Right buttons to select “Probe Setting”, and press “ENTER”.

You will access the program to select the quantity of zones (1-2-single).

Set the quantity of probes that can be connected, the type the pre-alarm gas percentage and the operative

range of each probe.

GENERAL FUNCTIONS

Use the Left and Right buttons to select “General Functions”, and press “ENTER” to access the program

to select: relay functioning mode, intrinsic safety function activation, activation of the zone alarm lachting

function, activation of the external siren in silent mode, and “Advanced Functions” menu.

By selecting “Advanced Functions” you can access a program to: change the password, read the

datalogger, print the events, and test the probes.

To select Exit to return to the initial program

Initial Screen

Control unit setting

Selection of the setting

Giù

Sù

SX DX

ENTER

Time setting

Probe setting

General Functions

Exit

Input Password

0 1 2 3 4 5 6 7 8 9

* * * *

Password accepted

Page 6

To set the date and time, proceed as follows:

1) Use the RIGHT and LEFT buttons to select day, month, year, hour, minutes.

2) Use the ENTER button to find the desired day, month, year, hour, minutes.

Note. In case of blackout the BX308xp, the set data are not lost.

If the backup clock battery is too low, you will get this error message “Err. bat. Clock” during the warmup phase.

EXITbutton

To exit the program, select “ Return Arrow ”.

Date and Time Setting

Probe Setting

Inserting or Disconnecting Probes, and Selecting the Type Gas, Explosive, Toxic, and Oxygen

Pressing the DOWN button starts blinking the probe 1,each time you press the"ENTER" button, a rectangle will appear

with the text:

Activation/deactivation of probes, and type of gas selection: Explosive or Toxic

Press DOWN to get probe 1 blinking.

Now, each time you press “ENTER” you will get the following box:

E, you have enabled a probe for explosive gas

T, you have enabled a probe for toxic gas

O, you have enabled a probe for oxygen gas

* you have disabled the probe

Use the RIGHT and LEFT buttons to select the desired probe, and repeat the operation outlined above.

This operation should be performed on all probes to be activated.

Use the arrow down to the right and press “ENTER” to access the setting program for the pre-alarm gas percentage.

Giù

Sù

SX DX

ENTER

Date time

16/oct/2017 15:10

1 2 3 4 5 6 7 8

T * T O * * E T T T T T E E E E

Configurazione sonde

Explosive Gas Setting

Page7

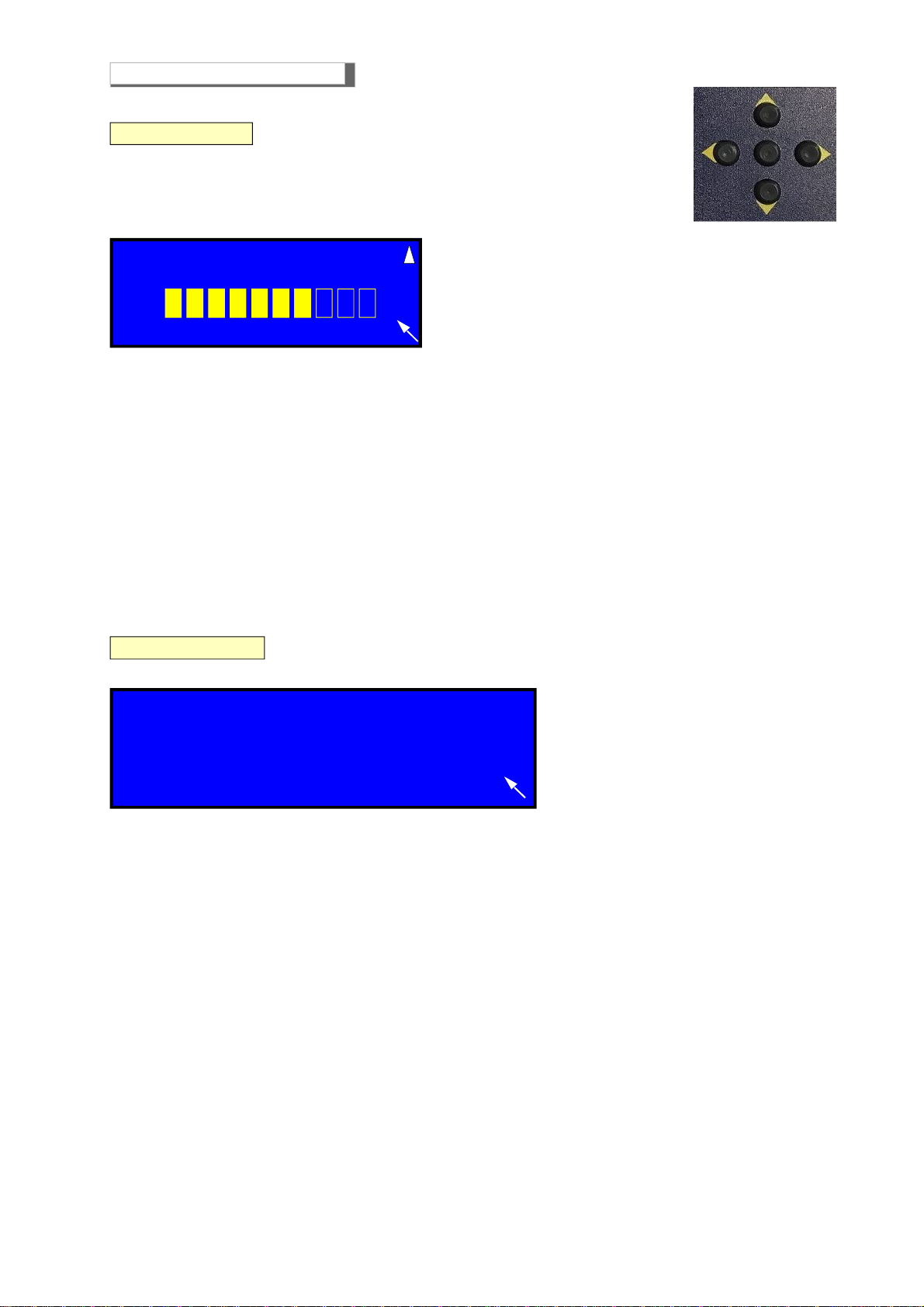

Setting pre-alarm percentage

The BX308xp program allows a different pre-alarm threshold per each

connected probe.

Toxic gas Setting

To set other probes, use the RIGHT and LEFT buttons to move to probe 7 (in this case) (“E”). On the first line you

will see the gas percentage of “10% LEL”.

To change the percentage press “ENTER”.

The percentage is increased each time of 1%, starting from 3% of LEL up to a maximum of 16% of L.E.L.

The percentages are increased cyclically.

Use the arrow up to the right and press “ENTER” to return to the previous program.

When this screen appears, the cursor goes on probe 1, (in this case (“T”). On the first

line you will see the gas percentage of “150 ppm”.

To change the percentage press “ENTER”. The percentage is increased each time of 15

ppm, starting from 45 ppm up to a maximum of 240 ppm.

The percentages are increased cyclically.

Probe Setting (continue)

1 2 3 4 5 6 7 8

T * T O * * E T T T T T E E E E

Configurazione sonde

Oxygen Gas Setting

pre alarm

main alarm

Key:

< Oxygen depletion

> Oxygen excess

< 19.9 %

> 21.9 %

< 18.5 %

> 23.5 %

To set Oxygen probes, move with the DX and SX buttons in our case on

probe 4, ("O"). All Oxygen probes have both pre-alarm and alarm fixed

settings.

See the threshold table at the side.

Use the arrow down to the right and press “ENTER” to access the setting program for the “OPERARTIVE RANGE”.

Giù

Sù

SX DX

ENTER

1 2 3 4 5 6 7 8

T * T O * * E E T T T T E E E E

Configurazione sonde

Pre-Al. 10% LEL

1 2 3 4 5 6 7 8

T * T O * * E O

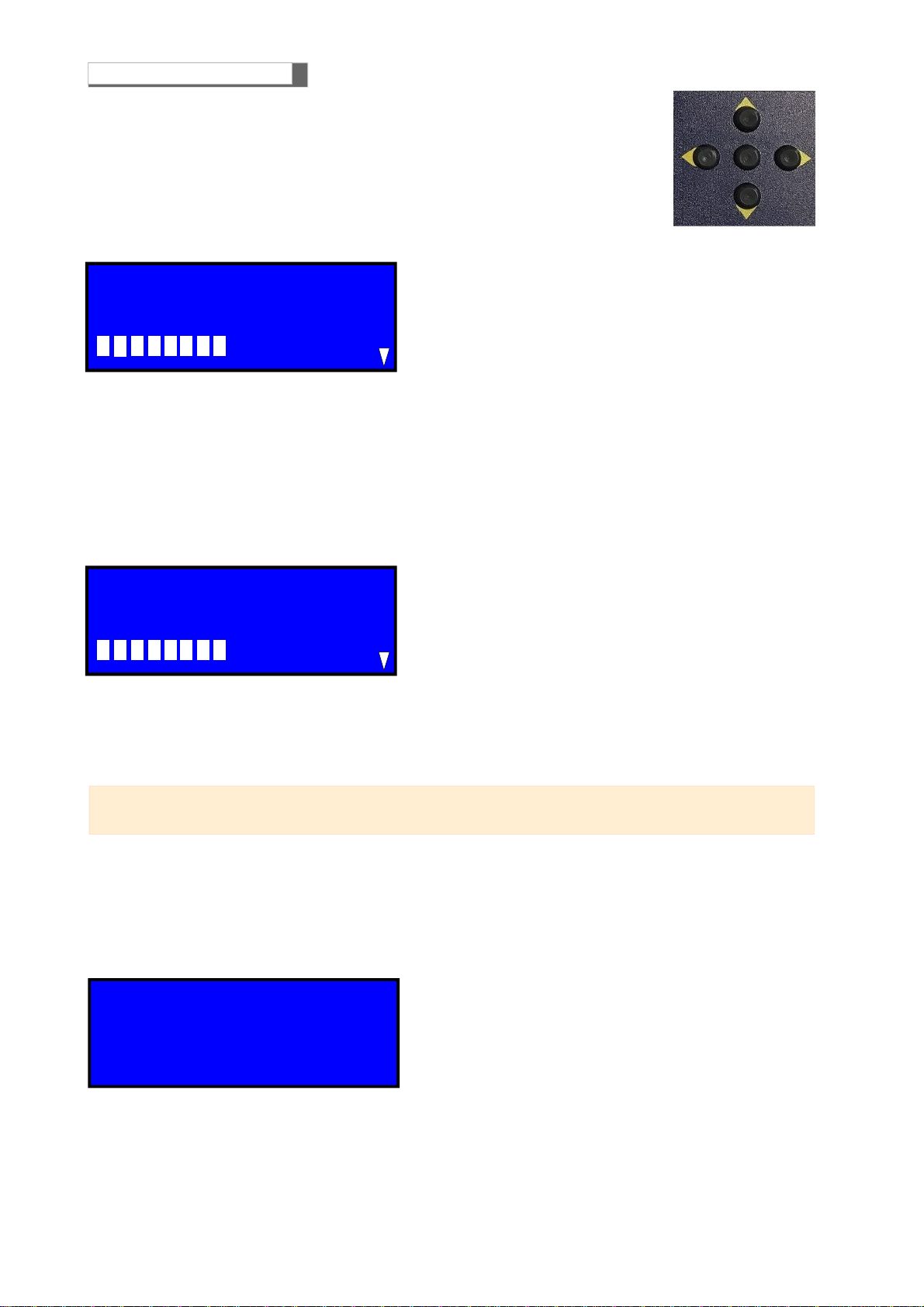

Page 8

Toxic Gas

When this page is displayed, it the cursor is moved to probe

1, “T” in our case

The message “Range Op 0-20% -100% L.E.L.” is not displayed

because the Operating range cannot be modified.

Explosive Gas

Press DOWN and use RIGHT and LEFT buttons to the select the desined probe whict change the Operative

Range. If you are on probe 7 (in this case “E”) on the first line you will see the operative range of “0-

20%L.E.L.”.

To change the value press “ENTER”:every time you press the button the percentage changes from “ Range

Op 0-20%L.E.L.” to “ Range Op 0-100%L.E.L.” and vice versa.

N.B. Please keep in mind that when this operation is peformed, the relative probes must also be setted to the

same range.

Select the top right arrow and press “ENTER” to return to the previous program.

Due to the sheer importance of this operation any change to the operative range shall be confirmed

END: to the exit program, select the “Back Arrow”.

Probe Setting (continue)

Giù

Sù

SX DX

ENTER

Setting the Percentage of Prealarm

The program of the control unit provides that each connected probe may have a pre-alarm

threshold different one from the other. This operation is reserved exclusively for explosive gas.

Range Op

1 2 3 4 5 6 7 8

T * T O * * E T T T T T E E E E

Configurazione sonde

1 2 3 4 5 6 7 8

T * T O * * E E T T T T E E E E

Configurazione sonde

This will change the

operative range !

Are you sure ? Yes No

Page9

Selecting memorisation of Main Alarm

According to the type of installation, you can select the activation or deactivation of the Main Alarm Latching.

By selecting the Latching function, the relay remains closed until the RESET button is pressed.

By unselecting the Latching function, the relay won’t remains closed when the alarm stops.

Note. The memorisation is subdivided in three ways:

1) Memorisation of single zone

2) Memorisation of first zone

3) Memorisation of second zone

Selection

Use the UP and DOWN buttons to select Latching (memorization).

Each time you press “ENTER” the ON/OFF message is changed.

In the “ON” position, the latching function is enabled.

In the “OFF” position, the latching function is disabled.

Once you have selected it, use the UP and DOWN buttons to move to the next selection.

Selecting the functioning mode of the Main Alarm Relay

According to the type of installation, you can select the relay functioning mode.

The relay functioning modes are two: continuous and impulse.

In the “Continuous” position, the relay remains closed until the alarm status continues, or until the alarm

stops.

In the “Impulse” position, the relay remains closed for 20 seconds, and then disenergizes afterwards.

Selection

Use the UP and DOWN buttons to select Relay.

Each time you press “ENTER” the Continuous/Impulse message is changed.

Once you have selected it, use the UP and DOWN buttons to move to the next selection.

Selecting the Positive Safety

According to the type of installation, you can select the Positive Safety function.

Selection

Use the UP and DOWN buttons to select Positive Safety.

Each time you press “ENTER” the ON/OFF message is changed.

In the “ON” position, the Positive safety function is enabled.

In the “OFF” position, the Positive safety function is disabled.

Once you have selected it, use the UP and DOWN buttons to move to the next selection.

General Functions

Giù

Sù

SX DX

ENTER

Relay: Continuous Impulse

Positive Safe: ON OFF

Latch Zone 1: ON OFF

Latch Zone 2: ON OFF

Page 10

Use the UP and DOWN buttons to select: Change Password - Datalogger - Print - Test Probes, and press

“ENTER”.

Now you can change the factory set password (1234), and enter your own.

Use the RIGHT and LEFT buttons to reach the desired number, and press “ENTER”.

Each time you enter a number you will see the selected number, until all four numbers appear.

Once you have entered it, you will get the “CONFIRMED” message.

The program returns to the previous screen after 5 seconds.

Save the password and do not forget it.

From now on you should enter the new password to access the BX308xp programming.

If you forget the password, you can find the “PUK” number in the warranty certificate.

Password Change

Advanced Functions

Siren and Buzzer Silent

Selecting the External Siren Silent Mode

The BX308xp program allows the silent mode for the external siren.

The siren could be annoying during test phases, or extensive alarms.

The silencing is indicated by a red LED on the front panel.

Red LED on, means siren silenced - Red LED off, means siren working

Selection Use the UP and DOWN buttons to select Siren Silent Mode.

Each time you press “ENTER” the ON/OFF message is changed.

In the “ON” position, the siren is enabled.

In the “OFF” position, the siren is disabled.

Selecting the Buzzer Silent Mode

Selection Use the UP and DOWN buttons to select Buzzer Silent Mode.

Each time you press “ENTER” the ON/OFF message is changed.

In the “ON” position, the siren is enabled.

In the “OFF” position, the siren is disabled.

Select Arrow and press “Enter” to return to the Menu.

General Functions (continue)

Siren Active: ON OFF

Buzzer Active: ON OFF

Advanced feat.

New Password

Confirmed

0 1 2 3 4 5 6 7 8 9

3 4 7 9

Password Change

Datalogger

Print

Test probes

Factory Reset

Page 11

To view the other screens, use the UP and DOWN buttons to select the arrows on the right.

Datalogger

Use the UP and DOWN buttons to select Datalogger, and press “ENTER”.

You will get the screen displaying the last 50 detected events.

The displayed events, one per screen, are:

Pre-Alarm, Alarm, Fault, Blackout, Reset, Low Battery, Probe Enabled, Probe

Disabled, Hard Reset.

- Event 06 -

--/---/-- --:--

Retrieving data ...

- Event 05 -

--/---/-- --:--

Retrieving data ...

- Event 02 -

--/---/-- --:--

Retrieving data ...

- Event 04 -

--/---/-- --:--

Retrieving data ...

- Event 03 -

--/---/-- --:--

Retrieving data ...

- Event 01 -

--/---/-- --:--

Retrieving data ...

- Event 06 -

25/Lug/13 08:15

Low Battery

Vbatt= 03.3 V.

- Event 05 -

24/Lug/13 09:15

Reset

- Event 01 -

24/Lug/13 15:28

Probe 16 Pre-Alarm

V=02.6 V I=17,3 mA

- Event 02 -

24/Lug/13 15:28

Probe 12 Alarm

V=02.6 V I=17,3 mA

- Event 03 -

24/Lug/13 08:15

Probe 01 Fault

V=00.o V I=00,2 mA

- Event 04 -

24/Lug/13 08:15

Black-out

General Functions (continue)

Giù

Sù

SX DX

ENTER

Page 12

Print

Use the UP and DOWN buttons to select Print, and press “ENTER”.

Now you can print the following:

The events on the current state of the BX308xp for all probes.

All the events in the datalogger.

Select arrow and press “Enter”

to return to the Menu.

Select arrow and press “Enter” to return to the Menu.

Test Conventional Probes

Use the UP and DOWN buttons to select Test Probes, and press “ENTER”.

Check voltage of probes

This screen is used by technicians to check the voltage detection state compared to the room gas concentration.

The cursor goes on probe 1. The voltage and current detected by the probe are shown.

To read other probes, use the RIGHT and LEFT buttons to reach the desired probe.

General Functions (continue)

Giù

Sù

SX DX

ENTER

Print status

Print datalogger

1 2 3 4 5 6 7 8

T * T T * * E E

1 2 3 4 5 6 7 8

T T T T E E E E

Zone 1 Zone 2

V. 3,2 I=20,2 mA

BEINAT

== BX308/xp ==

Ver: 1.0 S/N Sample

Serial number: 0102

Date Hour

07/oct/17 10:00

State probes

-------------------------

Probe 01 Zone 1

Gas Type: Explosive

Gas Level: 02.9 LEL

Meas.Current: 06.2 mA

Status: Normal

-------------------------

Probe 02 Zone 1

Disabled

------------------------

Probe 03 Zone 1

Disabled

-------------------------

Probe 04 Zone 1

Disabled

-------------------------

Probe 05 Zone 1

Disabled

-------------------------

Probe 06 Zone 1

Disabled

BEINAT

== BX308/xp ==

Ver: 1.0 S/N Sample

Serial number: 0102

Date Hour

07/oct/17 10:00

Datalogger

-----------------------

- Event 01 -

06/jun/2010 08:27

Reset

------------------------

- Event 02 -

07/jun/2010 10:11

Hard Reset

------------------------

- Event 03 -

07/jun/2010 10:27

Vbat=11.8V

----------------------

- Event 04 -

07/jun/2010 11:27

Black-out

------------------------

-Event 05-

06/jun/2010 09:27

Probe 16 Fault

V=00.1 V I=01.1 mA

Page 13

Select “Factory Reset”. Pressing “ENTER” the message starts blinking.

By holding the “ENTER” button for 4 seconds, you will view a frame with 10 empty rectangles that will gradually

fill. At the end, the BX308xp will be totally reset and a new countdown of 90 seconds will begin.

Use the arrow down to the right and press “ENTER” to return to the previous program

Factory Reset

Before proceeding be sure to want to do it, all previously set data will be

reseted.

Expansion cards

CARD-RLS4: 02 (Address card) 03,04.. 16

Relay: 01 02 03 04

Funct.:NOT USED PREALARM ALARM FAULT

Sonda: 01 02, 03, 04 ...16

General Functions (continue)

The control unit can be operate with up to 16 Expansion Relay cards (code: CARD-RLS4).

On each card there are 4 relays which can be associated with the desired probes range.

Each relay may be assigned to one of the following functions: Pre-alarm, Alarm, Fault or Not Used

Each relay may be assigned a range of probes from 1 to 16.

Display

CARD-RLS4- Indicates the hardware address set in the card (read information).

To change the current expansion card press “ENTER”. The expansion card address is pointed cyclically to the

next available.

Relay. Press “ENTER” to choose the relay, from 1 to 4, to be associated to a function.

Function. Press “ENTER” to choose the function of the selected relay between:

NOT USED – PRE-ALARM – ALARM - FAULT

PROBES. Use the “RIGHT” and “LEFT” buttons to select the field “from” or “to”. Press “ENTER” to choose

the probe belonging to the desired range.

To exit the program and save the changes, select “Return Arrow”.

Giù

Sù

SX DX

ENTER

16/10/17

Factory Reset

Page 14

30 cm Light Gases

30 cm Heavy Gases

Middle Height Volatile Gases

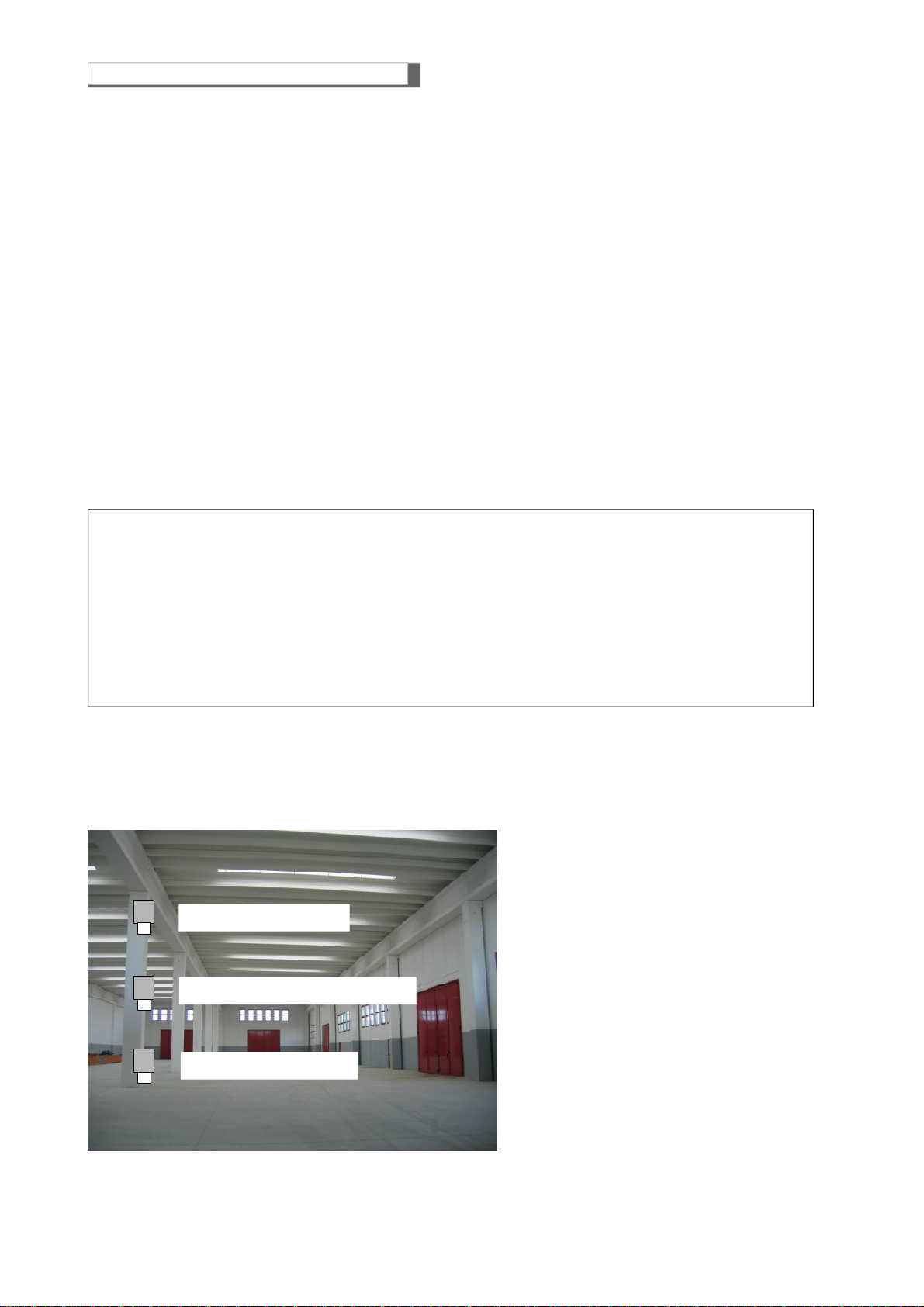

PROBE INSTALLATION INFORMATION

Installation and positioning of the probe

The BX308xp control unit belongs to group II and must be installed in a safe area;

Outside the ATEX zone, however, not in boiler rooms or engine room.

The control unit must be accessible and visible to the user.

The BX308xphas an Omega Bar enclosureand is a device suitable for mounting on pre-assembled quads and has IP20

protection. powered at 15 VDC

The BX308xp / boxed complete cabinet is an equipmentsuitable for wall mounting and is powered by 110/240VAC

with IP65 protection

When installing, it is good to use the normal care that an electronic equipment requires:

- Install the equipment away from excessive heat sources.

- Avoid liquids coming into contact with the control unit, remembering that its external structure has IP20 degree of

protection if installed on the Boxed version (cabinet) supplied to the source is IP65.

The probes must be selected with an IP degree depending on the area to be controlled (Kitchens, Boiler

Rooms, Laboratory, etc.) by selecting one of the probes from Beinat from IP30 to ATEX. see page 3

Position of the detection probes

You can connect many types of remote probes to this unit. Therefore, they should be positioned at different heights

depending on the type of gas to be detected.

These heights are:

- 30 cm from the lowest point of the floor in order to detect: Heavy gases (L.P.G. etc.)

- 30 cm from the highest point of the ceiling in order to detect: light gases (Methane, etc.)

- 160 cm from the lowest point of the floor in order to detect: volatile gases (CO, etc.)

It is importanttonote that the remote probes should be installed according to the following restrictions:

1) The probes should not be placed near the appliances to be controlled (boilers, burners, industrial kitchens, etc.)

but on the opposite side.

2) The probes should not be affected by smoke, vapour, and moving air, as they could distort their measurement.

3) The probes should not be placed near sources of heat, ventilators or fans.

It should be noted that the internal GAS sensors of the probe are perishable components with a variable average

life span from 5 to 6 years (you can request the relative table). Therefore, after this period of time has elapsed it

is advisable to replace them.

4) The control of operation and maintenance and / or extraordinary must be carried at least once a year. good

to keep

When turning on leds fault is necessary make the replacement of the probe by a specialized technician.

If the device does not start up.

Check that the power supply is correctly connected. If powered by the battery, check that the is power is correctly

connected.

If the Fault LED lights up.

Check that the connecting cables from the BX308xp to the probes are intact, that the probes are properly powered,

and that the signal cable is correctly connected.

If the Over Load Probe LED lights up.

Check: that the power polarity has not been inverted,that no short-circuit ispresent,that the probes were not damaged

during installation, that no excessive current absorption is present.

If the Over Load Battery LED lights up.

Check that the connection cables are not short-circuited, that the polarity has not been inverted, or that the battery

is not damaged.

If the control unit is repeatedly issuingan alarm.

Check that there are no gas leaks.

If the alarm signal and the FAULT indicator light turn on together, check the probes.

If the control unit is issuing an alarm and does not shut off the devices connected to it.

Check that the wiring is correct and that the jumper that carries power to the relay has been set properly. All relays

must be free from electrical power. Check the drawing of the connections.

If a 12Vdc solenoid valve , is connected to the BX308/xp, which does not work well

Direct connection of 12Vdc solenoid valves or sirens to the BX308xp is not permitted.

An external power unit must always be used.

The BX308xp gives a max current of 200mA.

If other problems arise, a specialised and/or authorised technician and/or the Distributor of BEINAT S.r.l.

should be contacted directly.

1) Apply power using the proper external switch. This switch should be fitted with protection fuses.

2) You will notice that some LEDs will light up in turn for about 20 seconds.

3) The display will start the COUNT DOWN of about 90 seconds (warm up). At the end the control unit is ready

for detection.

4) Pressing and holding down the TEST button, you can obtain a gas leakage simulation.

The control unit will carry out the following:

- It will light up the 13% LEL or the 200ppm (with reference to CO) LED, and the PRE-ALARM LED, switching

the 1st threshold relay. The buzzer will issue a low frequency sound.

- Later, it will light up the 20% LEL or the 300ppm (with reference to CO) LED, the MAIN ALARM LED. In addition

to maintaining the PRE-ALARM relay switched, it will also switch the MAIN ALARM relay. The MAIN ALARM LED

will start blinking and the buzzer will issue a higher frequency sound.

When releasing the TEST button, you will see the opposite: Only the blinking MAIN ALARM and the 20% L.E.L.

LEDs will remain ON.

When the latching is enabled, the main alarm will continue until the RESET button is pressed, clearing the alarm

from the memory.

5) To complete the test, carefully read the probe instruction manual and perform the sensor test by issuing

gas from a pre-calibrated gas bottle.

6) If you want to simulate a zone FAULT, you only need to disconnect the return cable of one or all the probes.

The control unit will carry out the following:

- The FAULT and MAIN ALARM LEDs will light up and blink;

- The buzzer will issue a continuous sound;

- The FAULT and MAIN ALARM relays will switch.

Reconnect the return cable and press RESET to restore the control unit functioning.

Beforecallingatechnician,check...

Turn-on

Page 15

0

1

3

2

1,1

V.

Voltmeter

WARNING.

This measurement should

be performed in clean air.

0,6

1 2 3 4 5 6 7 8

3 2 1

Probe 1 3 2 1

Probe 2 3 2 1

Probe 3 3 2 1

Probe 4 3 2 1

Probe 5 3 2 1

Probe 6 3 2 1

Probe 7 3 2 1

Probe 8

15VDC+

Page 16

WARNING.

Before connecting to the mains power, ensure the voltage is correct.

Carefully follow the instructions and the connections according to Regulations inforce, keeping in mind that

the signal cables should be laid separate from the power cables.

An automatic cut-off switch (appropriately identified as devicesectioning of the detector) should be

incorporated in the electrical system, adequatelylocated and easily accessible.

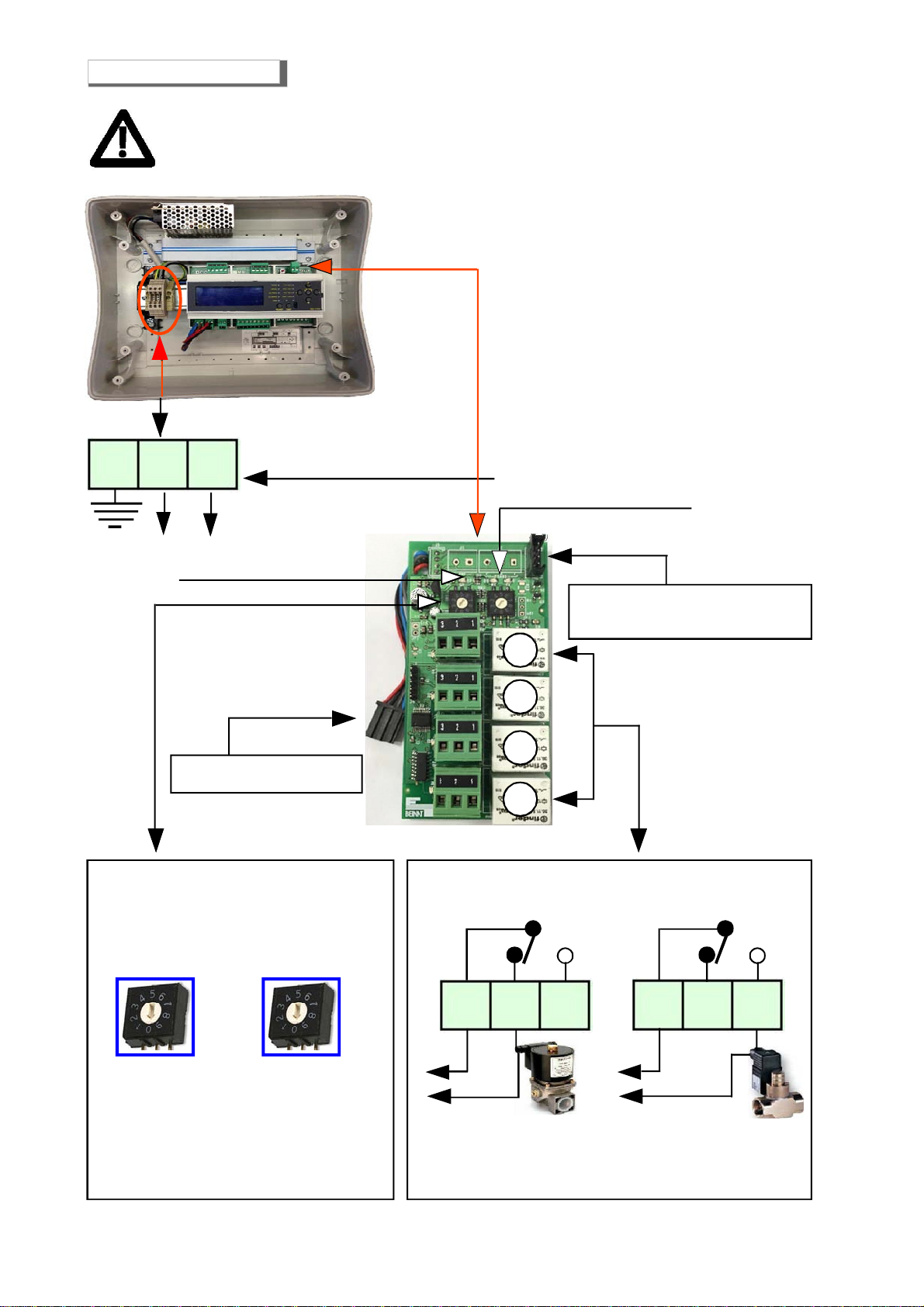

Electrical Connections

Main power 110/240 VAC

1 2 3

Ph N

Connection port forconnecting a

new card

Connection plug to the

control unit

RL1

RL2

RL4

RL3

Green led, voltage switched

Yellowled, transmission

Tens Unit

Example to select an address

Turn the Switch of tenths until you find the

desired tenth. For example: 0

Turn the Switch of units until you find the

desired unit. For example: 6

In this way you will set the address “ 6

Eachconnectedboardmusthaveanaddress

unique to avoid conflicts in the data

transmission.

Toentertheaddresses ofeachCARD-RLS4you

have to act through the rotary switches that

each CARD possesses, with them you can

select the desired address from 1 to 16

3 2 1

C

NO

NC

230 VAC

N

Ph

3 2 1

C

NO

NC

N

Ph

230 VAC

EV NC 230 VAC EV NA 230 VAC

Each relay can be coupled to the selected probe and now

you can match all the functions you want

Note!

All relays are voltage free.

Capacity Contacts 10A 230VDC resistive

Page 17

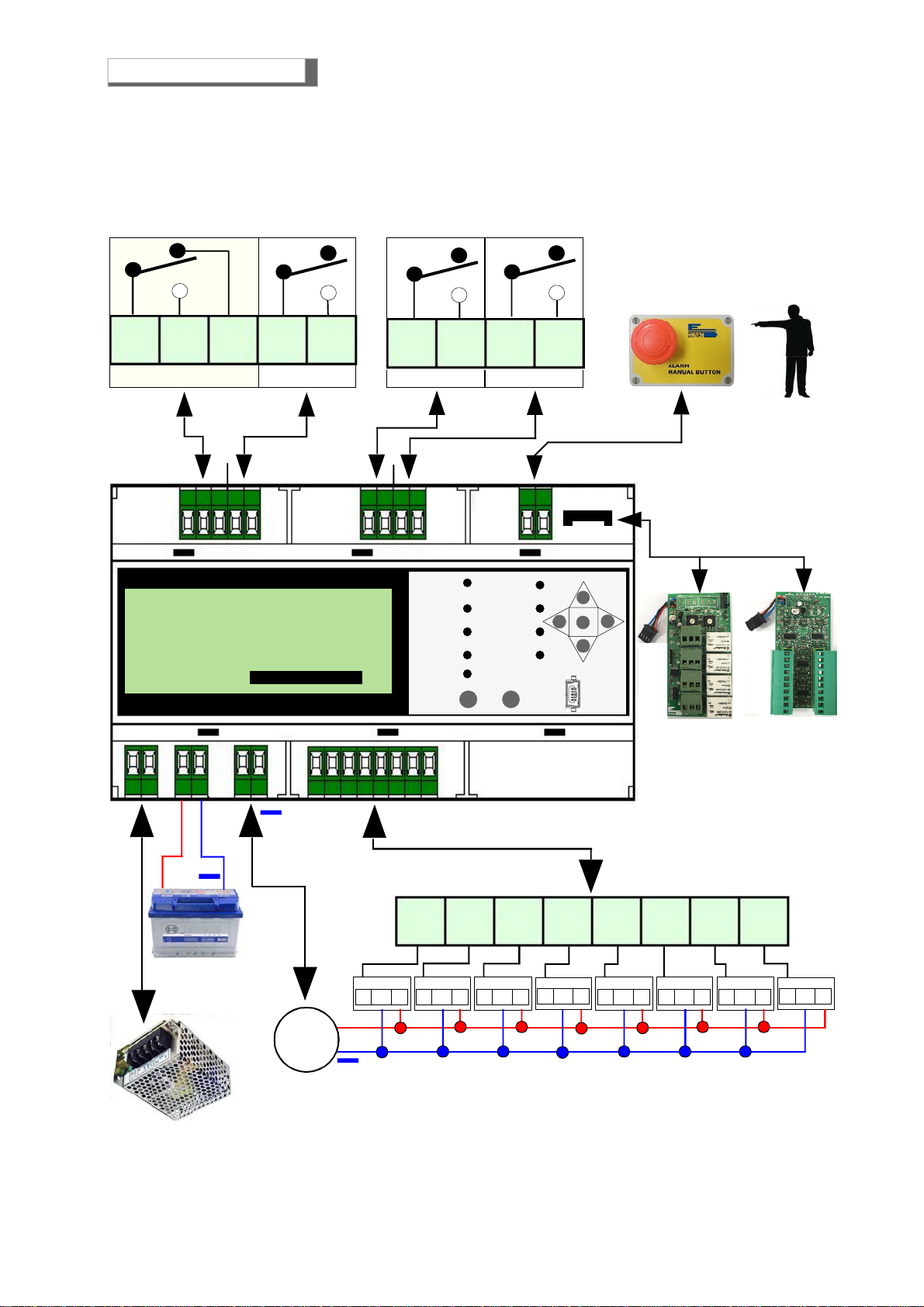

ElectricalConnections

Warning!! All relays are voltage free. Contact capacity 10 A resistives

SN B0205 06/Jan/2015

State 15:48

Probe 05 18% LEL

Enabled

Power

Battery

OL Probes

OLBattery

Fault

PreAlarm

MainAlarm

Exit Alarm

SirenStatus

Test Reset

CNC

NO

CNC

NO

Prealarm

Main Alarm

1 2 3 4 5

CNC

NO

CNC

NO

Fault Sirena Ext

6 7 8 9

Manual alarm PAM-NC

1 2 3 4 5 6 7 8

3 2 1

Sonda 1 3 2 1

Sonda 2 3 2 1

Sonda 3 3 2 1

Sonda 4 3 2 1

Sonda 5 3 2 1

Sonda 6 3 2 1

Sonda 7 3 2 1

Sonda 8

15VDC+

Characteristics standard switching power supply 230 VAC 15

N.B. Power supply included in the box version

+

+

Cards

Relay Conversion

12 V

Page 18

NC NC

Connecting solenoid valve Normally Closed with Positive Safety

Connecting aSolenoid valvewith sirens to12VDC, throughapower switcing.The powersupply should

be adequate to the consumption of the components

Electrical connections

Connecting a solenoid valveNormally Closed without Positive Safety

CNC

NO

CNC

NO

CNC

NO

CNC

NO

1 2 3 4 5 6 7 8 9

NA NC

Power supply Switching

Ph

N

12 VDc

+

Power supply

110/240 VAC

Solenoid valves Prealarm Fault Siren ext

Ph

N

230 VAC

C

NO

C

NO

CNC

NO

CNC

NO

1 2 3 4 5 6 7 8 9

Solenoid valve Prealarm Fault Siren ext

NC

Ph

N

CNC

NO

CNC

NO

CNC

NO

CNC

NO

1 2 3 4 5 6 7 8 9

Solenoid valves Prealarm Fault Siren ext

NA NC

230 VAC

Page 19

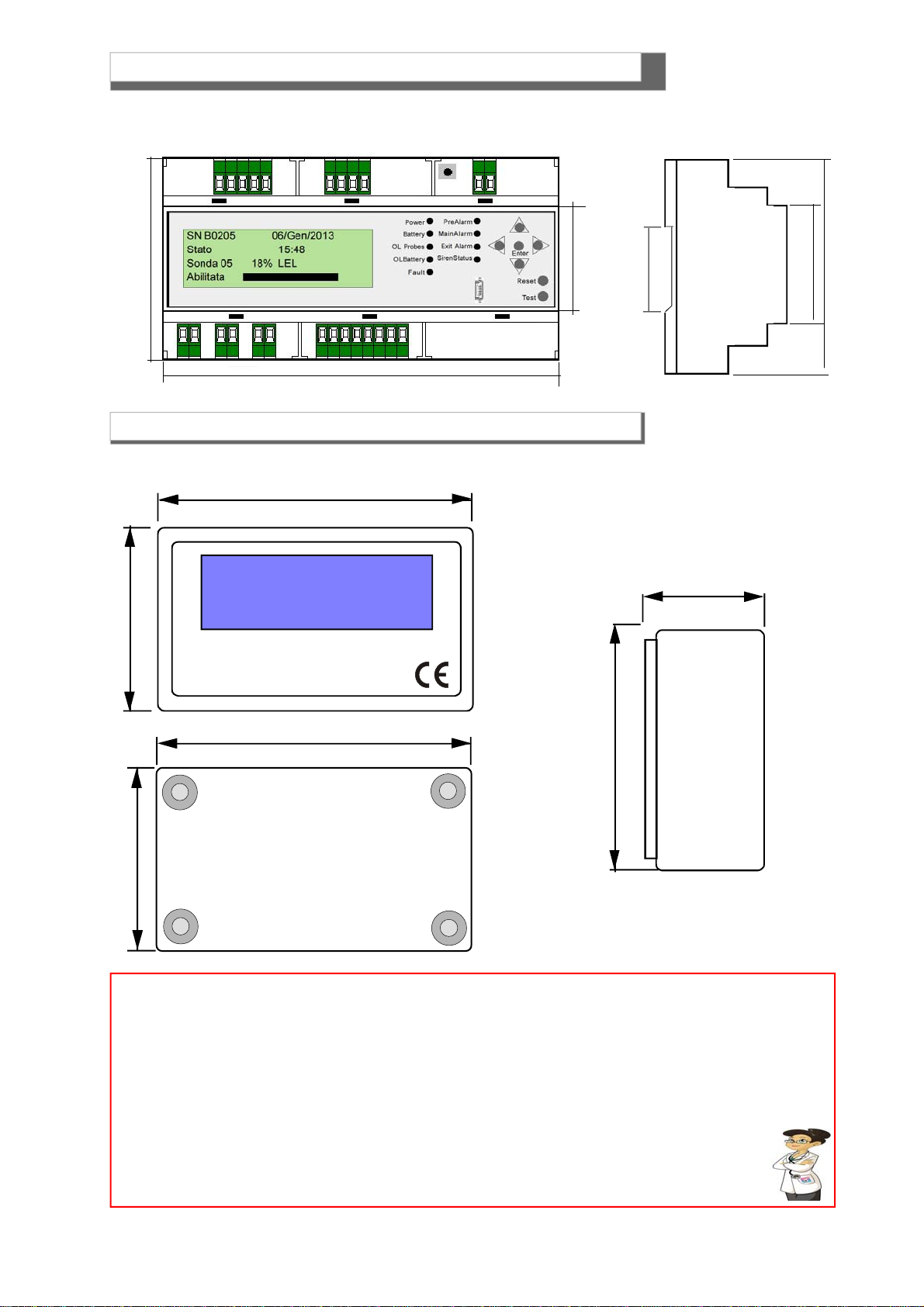

90 mm

45 mm

37 mm

90 mm

45 mm

159 mm

Measurements anddimensions of the controlunit in box IP65

Dimension ofthe9modulesOmega-typesize DIN EN50092

340

280

280

160

WARNING! Actions to be taken in case of alarm

Gas

1) Put out all free flames.

2) Close the main gas tap or the LPG cylinder tap.

3) Do not turn any lights on or off; do not turn on any electrical device or appliance.

4) Open windows and doors in order to increase ventilation.

If the alarm stops, its cause must be found and the relevant consequent measures taken.

If the alarm continues and the cause of gas presence cannot be found or removed, abandon the building and call

the emergency services when outside (fire department, distributors, etc.)

IMPORTANT: The operation test should not be carried out with the gas tap as this does not guarantee a

sufficient concentration to activate the general alarm.

Warning !!

If you have the following symptoms: vomiting, sleepiness, or else, go to the closest first aid station

and inform the operators that you could have been poisoned by Carbon Monoxide, or by an excess

or deficiency of oxygen

340

280

BEINAT S/N AD012G

21/10/15 10:10

= = BX308 ver. 1.0 = =

Count Down 90”

BX308/xp

Registration number

Stamp and signature of the dealer

Lo styling è della b & b design

In agreement with its continuous development policy, we reserve the right to modify its products without notice.

Purchase date

Control Unit BX308/xp

Madein Italy

IP65

BEINAT S.r.l. Via Fatebenefratelli 122/C

10077, S. Maurizio C/se (TO) - ITALY

Tel. 011.921.04.84 - Fax 011.921.14.77

http:// www.beinat.com

Help Desk - laboratorio@beinat.com

INSURANCE. This device is insured by the SOCIETÀ REALE MUTUA for the PRODUCT'S GENERAL LIABILITY up to a maximum

of 1,500,000.00 EURO against damages caused by the device in case of failures in functioning.

WARRANTY. The warranty term is 3 years from manufacturing date, in agreement with the following conditions. The

components acknowledged as faulty will be replaced free of charge, excluding the replacement of plastic or aluminium cases,

bags, packing, batteries and technical reports.

The device must arrive free of shipment charges to BEINAT S.r.l.

Defects caused by unauthorized personnel tampering, incorrect installation and negligence resulting from phenomena

outside normal functioning shall be excluded from the warranty.

BEINAT S.r.l. is not liable for possible damage, direct or indirect, to people, animals, or things; from product faults and from

its enforced suspension of use.

DISPOSAL OF OLD ELECTRICAL & ELECTRONIC EQUIPMENT.

This symbol on the product or its packaging to indicates that this product shall not be treated as household waste. Instead, it shall be handed

over to the applicable collection point for the recycling of electrical and electronic equipment, such as for example:

- sales points, in case you buy a new and similar product

- local collection points (waste collection center, local recycling center, etc...).

By ensuring this product is disposed of correctly, you will help prevent potential negative consequence for the environment and human health,

which could otherwise be caused by inappropriate waste handing of this product. The recycling of materials will help to conserve natural

resources. For more detailed information about recycling of this product, please contact your local city office, your household waste disposal

service or the shop where you purchased the product.

Attention: in some countries of the European Union, the product is not included in the field of application of the National Law that applies

the European Directive 2002/96/EC and therefore these countries have no obligation to carry out a separate collection at the “end of life”

of the product.

BE-V.3 43 17

Table of contents

Other BEINAT Control Unit manuals