10

6. DISPLAY & ALARM CONFIGURATION

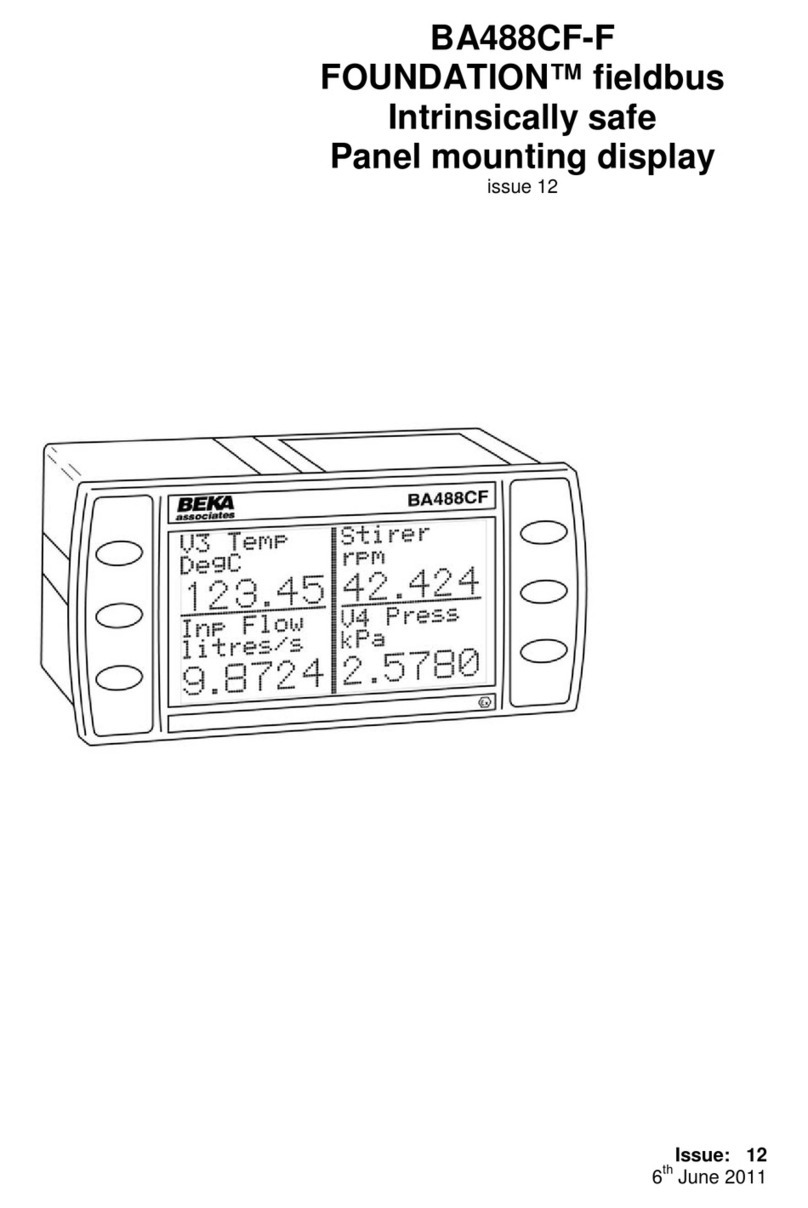

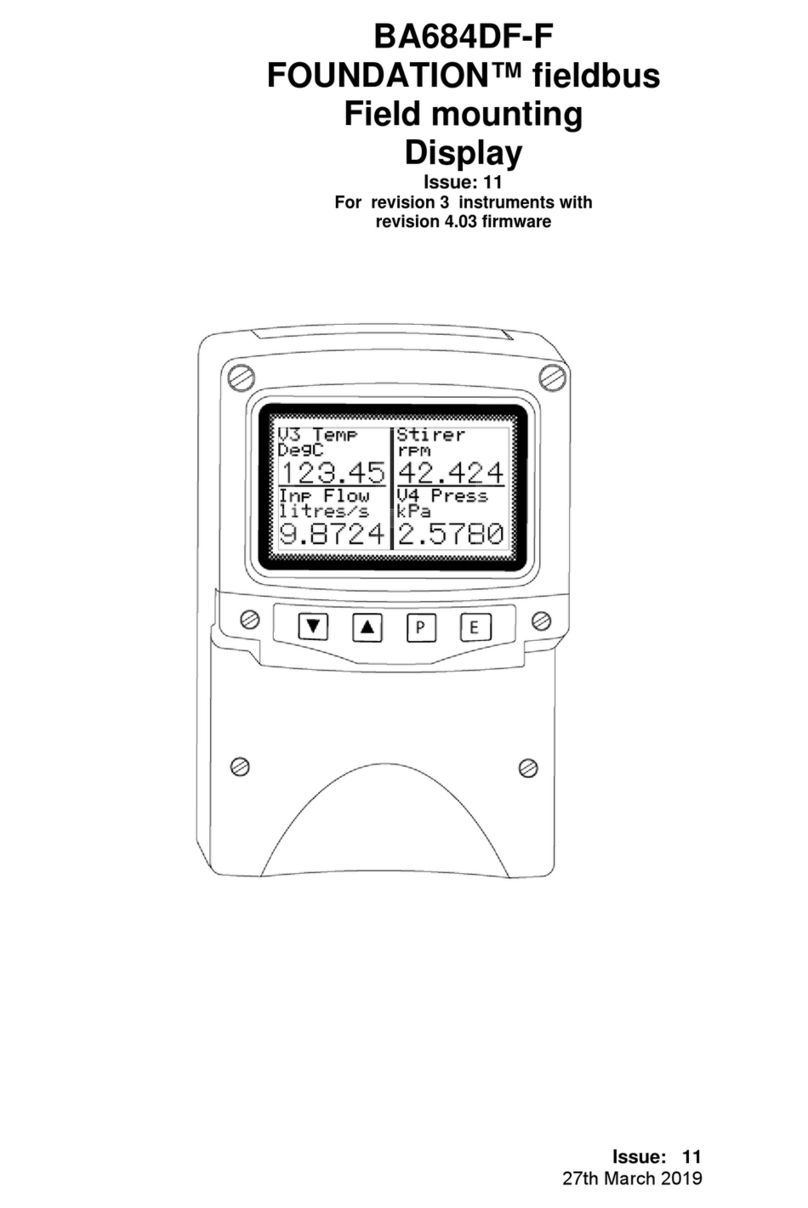

In addition to loading the BA488CF fieldbus

configuration files onto the system host and

defining up to eight fieldbus variables that are to

be displayed, the instrument display and alarms, if

fitted, have to be configured. How much of this

configuration can be done via the fieldbus

depends upon the instrument version and the

system host. Parameters that can not be

configured via the fielldbus, may be set via the six

front panel push buttons

All the display and alarm configuration functions

are contained in an easy to use menu that is

shown in Fig 7. Where necessary the sub-menus

contain on-screen prompts to guide the user

through each adjustment.

When navigating through the configuration menu,

the push button(s) should be held until the

required screen is displayed.

6.1 Default configuration

Unless otherwise requested at the time of

ordering, BA488CF Fieldbus Displays will be

supplied configured as follows:

Keys Both

Display brightness 100%

Display contrast 50%

Quick access menu On

Quick access menu code 0000

Configuration menu

access code. 0000

Screen Single variable

Number Format Auto

All alarms Disabled

Alarm activation Good data only

Alarm outputs N/C

Bargraph

Low 0

High 100

Input scaling

Zero offset 0

Gain factor 1

Fieldbus Foundation version

Revision Revision 2

(2 x IS function

blocks)

6.2 Accessing the display configuration

menu

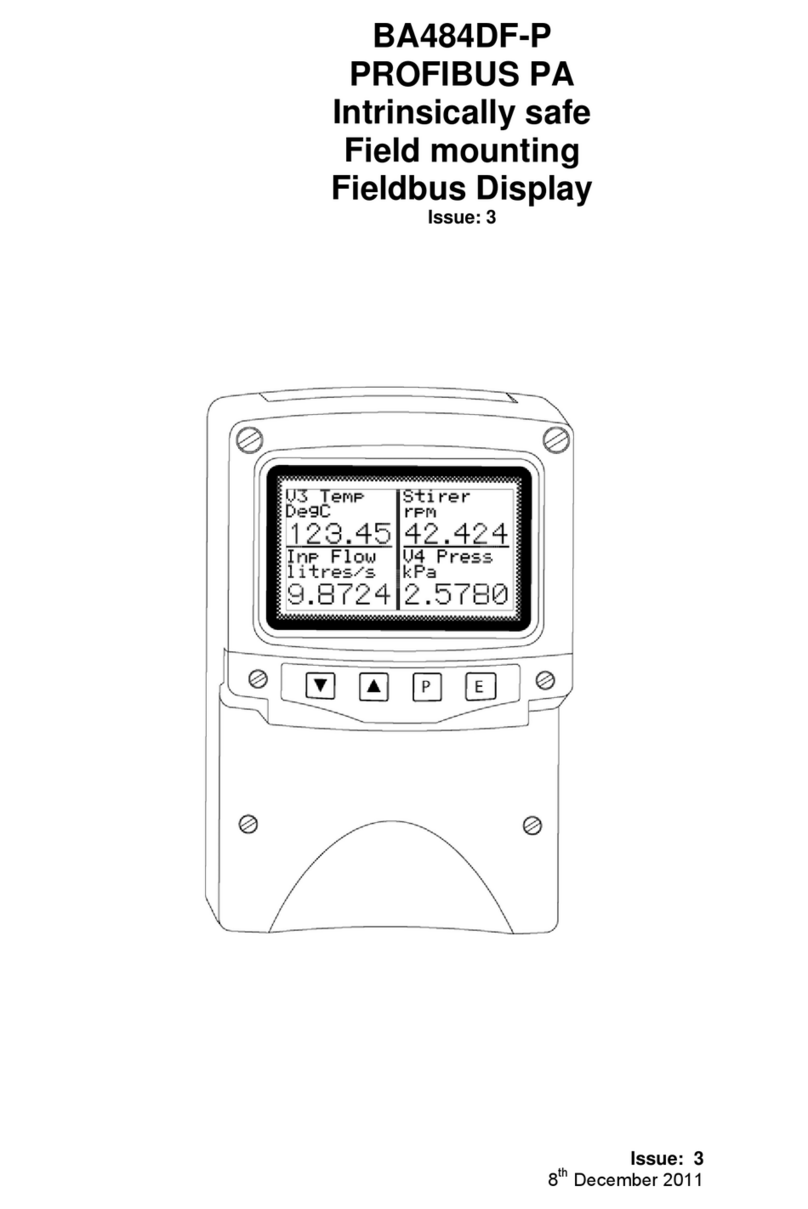

Throughout this manual push buttons are shown

in italics e.g. P or Up push button, and legends

displayed by the instrument are shown within

inverted commas e.g. 'Enter Access Code'.

Operating the Pand Epush buttons

simultaneously accesses the display configuration

menu. If the BA488CF is not protected by an

access code the main menu will be displayed. If

an access code other than the default code 0000

has already been entered, the BA488CF will

request that the access code be entered.

Using the Up or Down button set the first digit of

the code which will be flashing. Pressing Pwill

transfer control to the next digit, which should be

adjusted in the same way. When all four digits

have been set, pressing the Ebutton will enter the

access code. If the code is correct the main

menu will be displayed, if the code is incorrect

‘Invalid Code’ will be displayed.

When entering an access code, timeout will occur

and the instrument will automatically return to the

operating mode ten seconds after a push button

was last operated. In all other menus, timeout

occurs after sixty seconds.

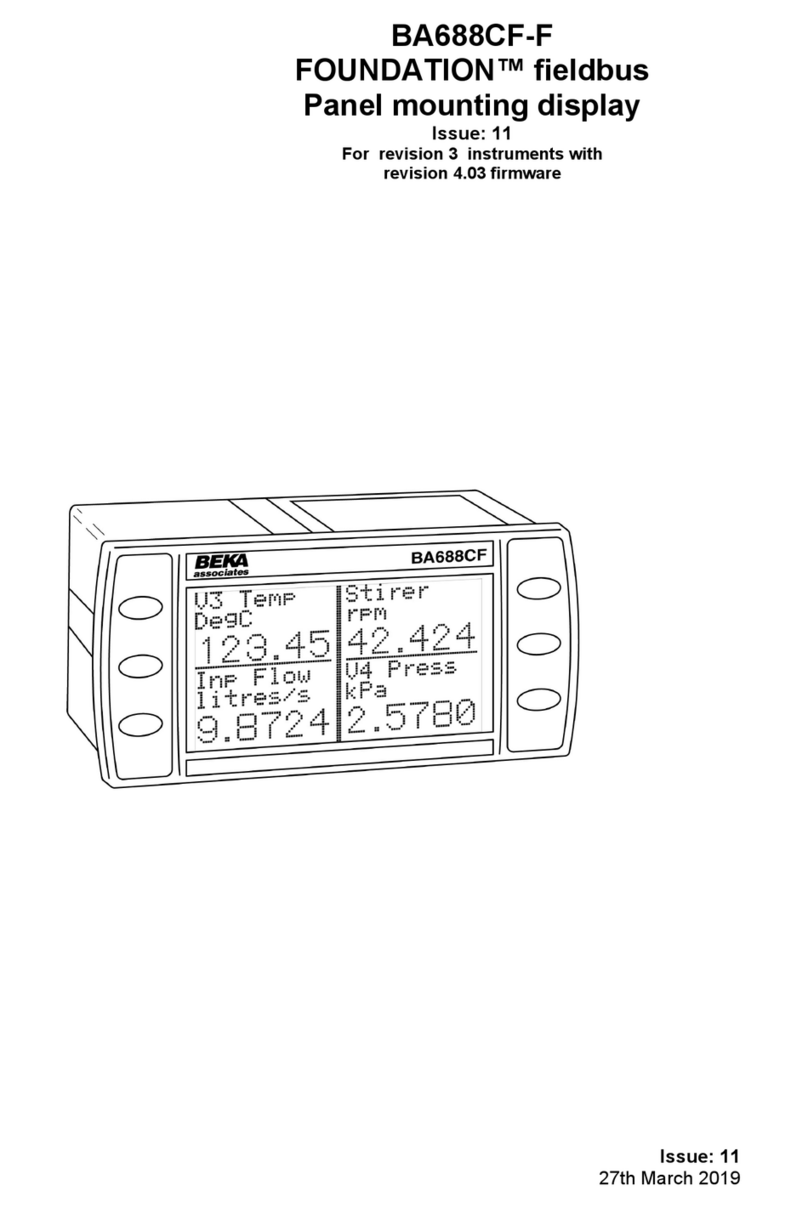

The structure of the display configuration menu is

shown in Fig 7. Navigation is achieved by

highlighting the required function using the Up and

Down buttons and then operating the Pbutton to

display the selected function sub-menu, from which

a further selection or adjustment may be made.

Operating the Ebutton moves the display back up

one level.

A flashing highlight indicates that an option or

alphanumeric character may be selected using the

Up and Down buttons and entered using the E

button. If only one entry or adjustment can be

made in a sub-menu, the display will automatically

move up one menu level when the adjustment is

entered. If more than one adjustment can be

made in a sub-menu, the highlight may be moved

to the second variable using the Up or Down

button after the first setting has been entered.

Operating the Pbutton allows the second variable

to be adjusted.

When multiple numeric or alpha characters are

adjusted e.g. an alarm setpoint or a tag legend, the

adjustment is made one digit at a time using the

Up and Down buttons. After the first flashing digit

has been set as required, the flashing highlight can

be moved to the next digit by operating the P

button. When all digits have been set, operating

the Ebutton will enter the setting.

Following completion of the instrument

configuration, the Ebutton should be operated to

step the display back to the main menu. One more

operation of the Ebutton will then return the

BA488CF to the operating mode.