1. DESCRIPTION

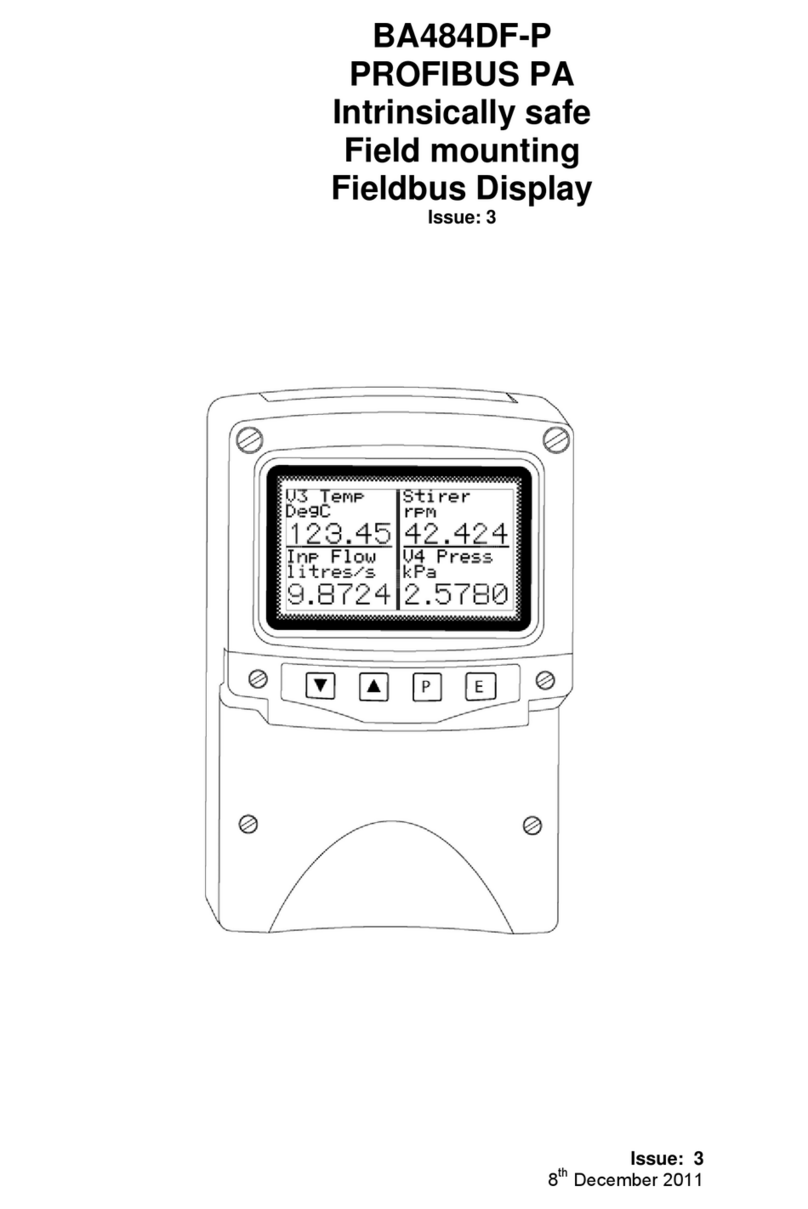

The BA484DF-F display is an intrinsically safe

instrument that can simultaneously display up to

eight FOUNDATION™ fieldbus process variables,

together with their units of measurement and tag

information. The instrument is bus powered so no

additional power supply is required.

The instrument’s communication protocol is shown

on a label inside the terminal cover. The ‘-F’ order

code suffix also indicates the protocol but is not

shown on the instrument certification label. There

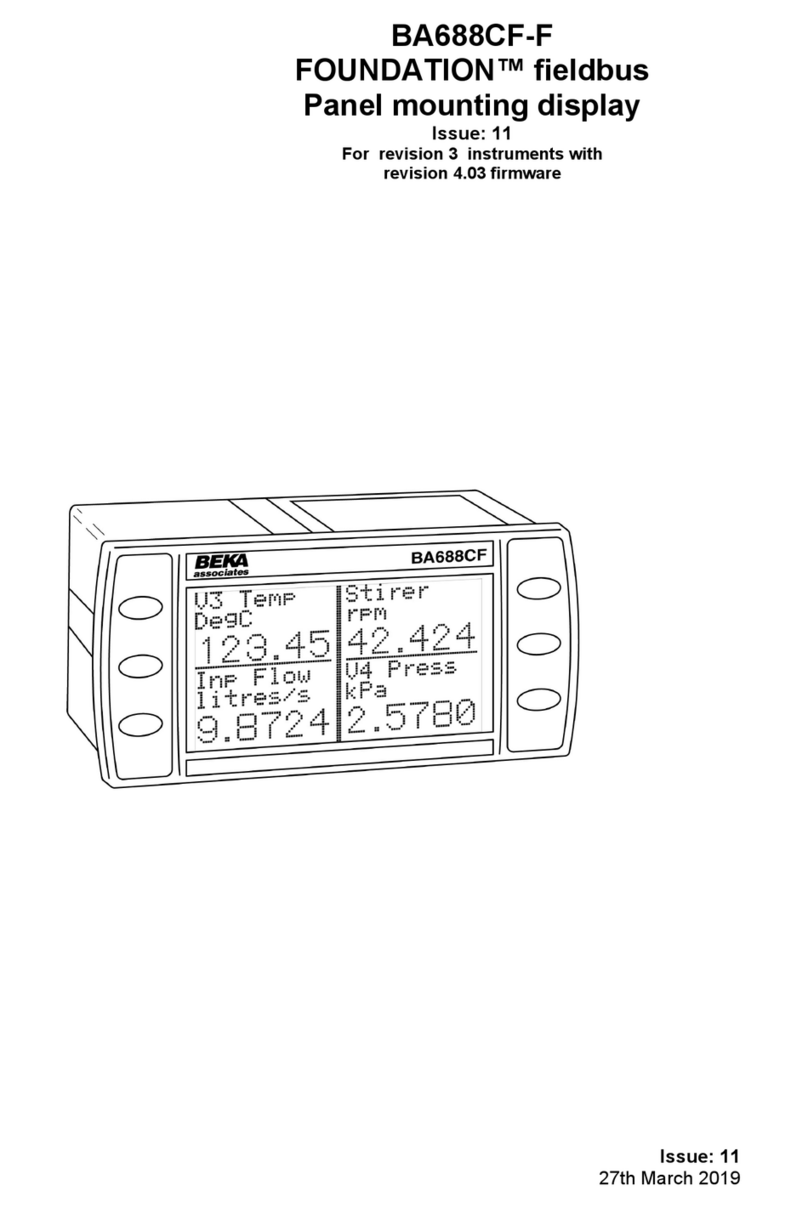

is an alternative version of the fieldbus display,

order code BA484DF-P for use on PROFIBUS PA

networks.

This instruction manual describes revision 3

BA484DF-F Foundation fieldbus displays which

were introduced in January 2019. Revision 3

displays have been verified in the FieldComm Labs

as compliant with ITK 6.3.

Instruction manuals for the earlier revision 1 and 2

instruments may be downloaded from the

superseded documentation section of the BEKA

website.

Most of the BA484DF-F display parameters are

configured on-site via the fieldbus. Screen format

selection and alarm configuration is performed

using an internal menu and the instrument's front

panel push buttons.

Up to eight process variables can be displayed

using the two Input Selector function blocks.

The required Device Description files, which may

be downloaded from either the FieldComm or the

BEKA websites, depend upon which BA484DF-F

FOUNDATION™ fieldbus display revision is

selected.

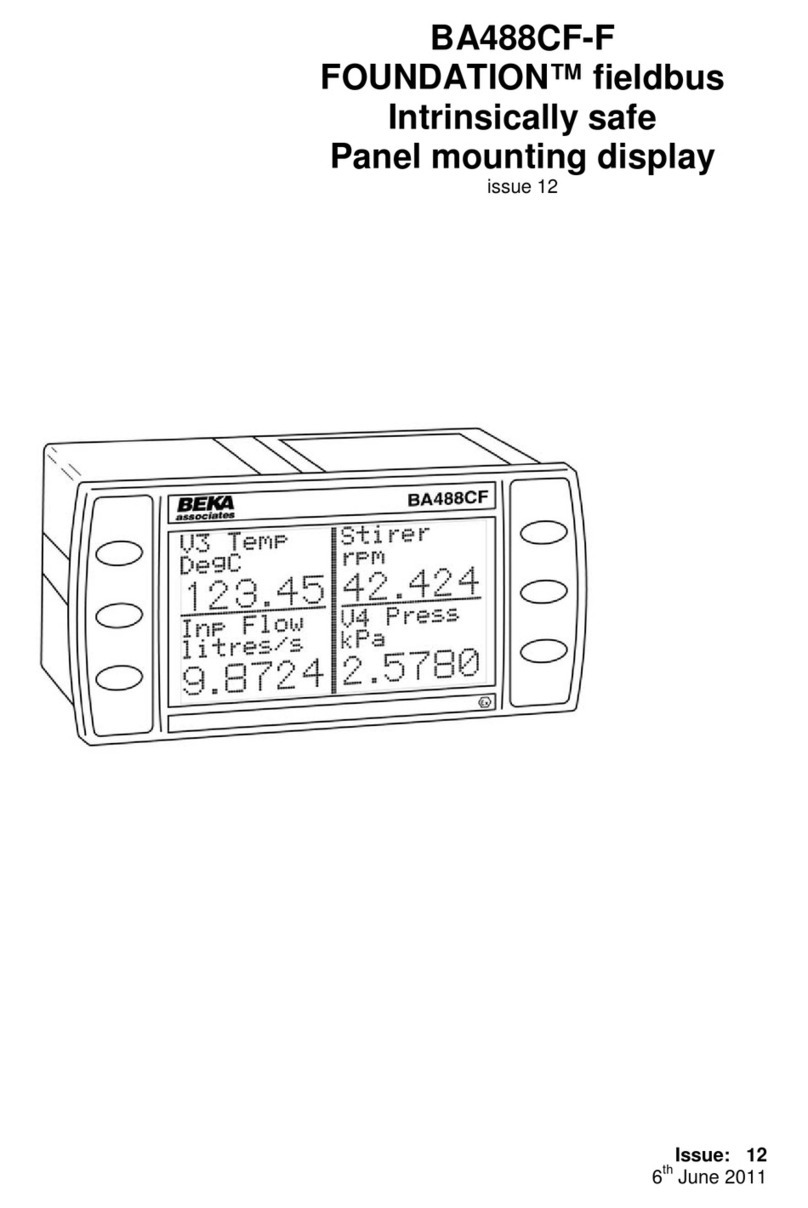

Eleven selectable standard display screen formats

enable one, two, three, four or eight process

variables, some with bargraphs to be displayed on

one screen.

The BA484DF-F FOUNDATION™ fieldbus display

can be supplied with six optional alarm outputs that

may be linked to any of the displayed fieldbus

variables. These alarm outputs are locally

activated from the fieldbus variables and are

configured via the instrument menu and push

buttons. They cannot be controlled via the

fieldbus.

The instrument has been issued with an EC-Type

Examination Certificate by Notified Body Intertek

Testing and Certification Ltd for gas and dust

atmospheres which has been used to confirm

compliance with the European Potentially

Explosive Atmospheres Directive 2014/34/EU.

For use in the USA the instrument has intrinsic

safety and nonincendive FM Approval – see

Appendix 2, plus IECEx intrinsic safety approval

for international applications – see Appendix 3.

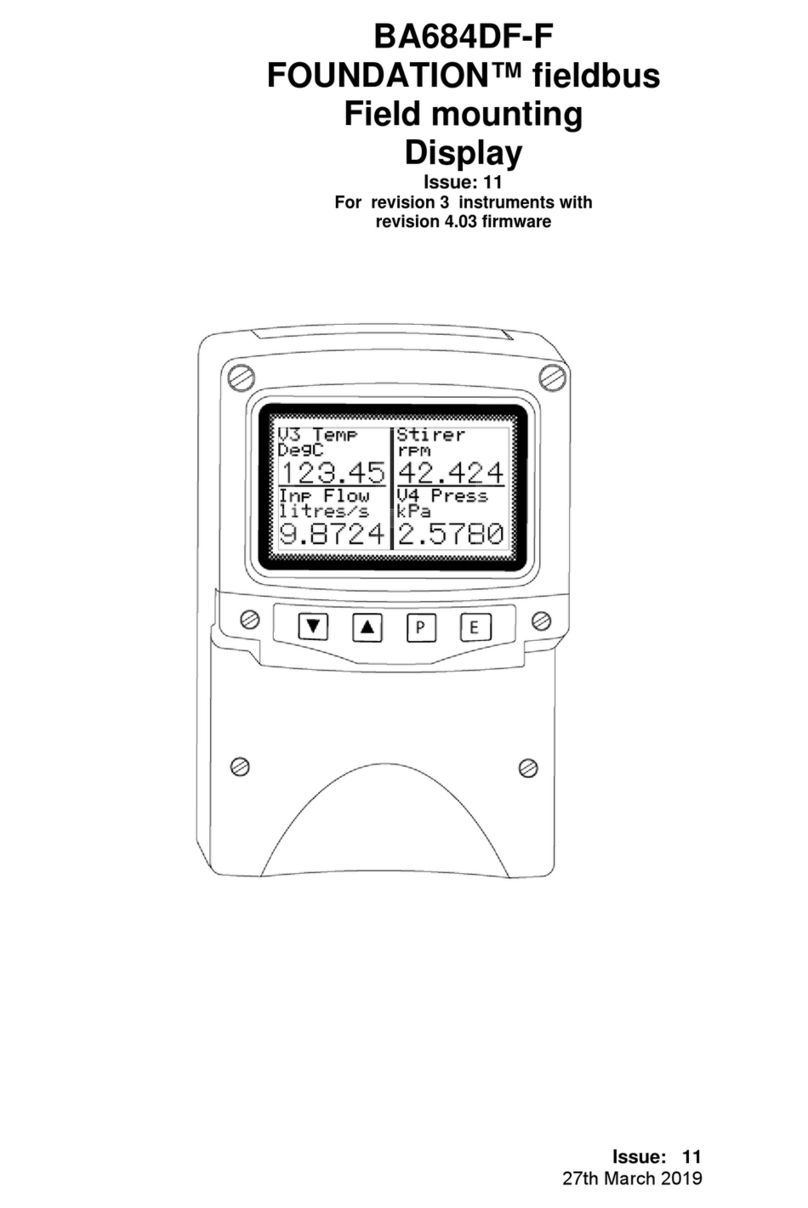

Housed in a robust IP66 glass reinforced polyester

(GRP) enclosure with a toughened glass window,

the BA484DF-F FOUNDATION™ fieldbus display

is surface mounting, or may be pipe mounted

using one of the accessory kits.

1.1 Documentation

This instruction manual describes system design,

conditioning and installation of the BA484DF-F

FOUNDATION™ fieldbus display. For detailed

commissioning information please refer to the

FOUNDATION™ fieldbus Interface Guide that can

be downloaded from the BEKA website

www.beka.co.uk

1.2 Version 4.03 firmware

Updated firmware was released in January 2019

which includes the following key features:

11 standard screens

Multiple bargraph limits

Individual input scaling

Two 4-input Input Selector function blocks:

Last variable parameter prevents display of

unused inputs.

Fieldbus compliance verified to ITK 6.3

Option added to remove status text from

single variable screens.

The instrument’s firmware version can be

established using the ‘Unit Info’ function in the

main configuration menu – see section 6.7.8 of this

manual.

3