Inhalt

METPOINT®SP11 3

Contents

1Pictograms and symbols ........................................................................................................................ 4

2Signal words in accordance with ISO 3864 and ANSI Z 535.................................................................4

3General information................................................................................................................................5

4Safety instructions ..................................................................................................................................6

5Proper use.............................................................................................................................................. 7

6Exclusion from the field of application....................................................................................................7

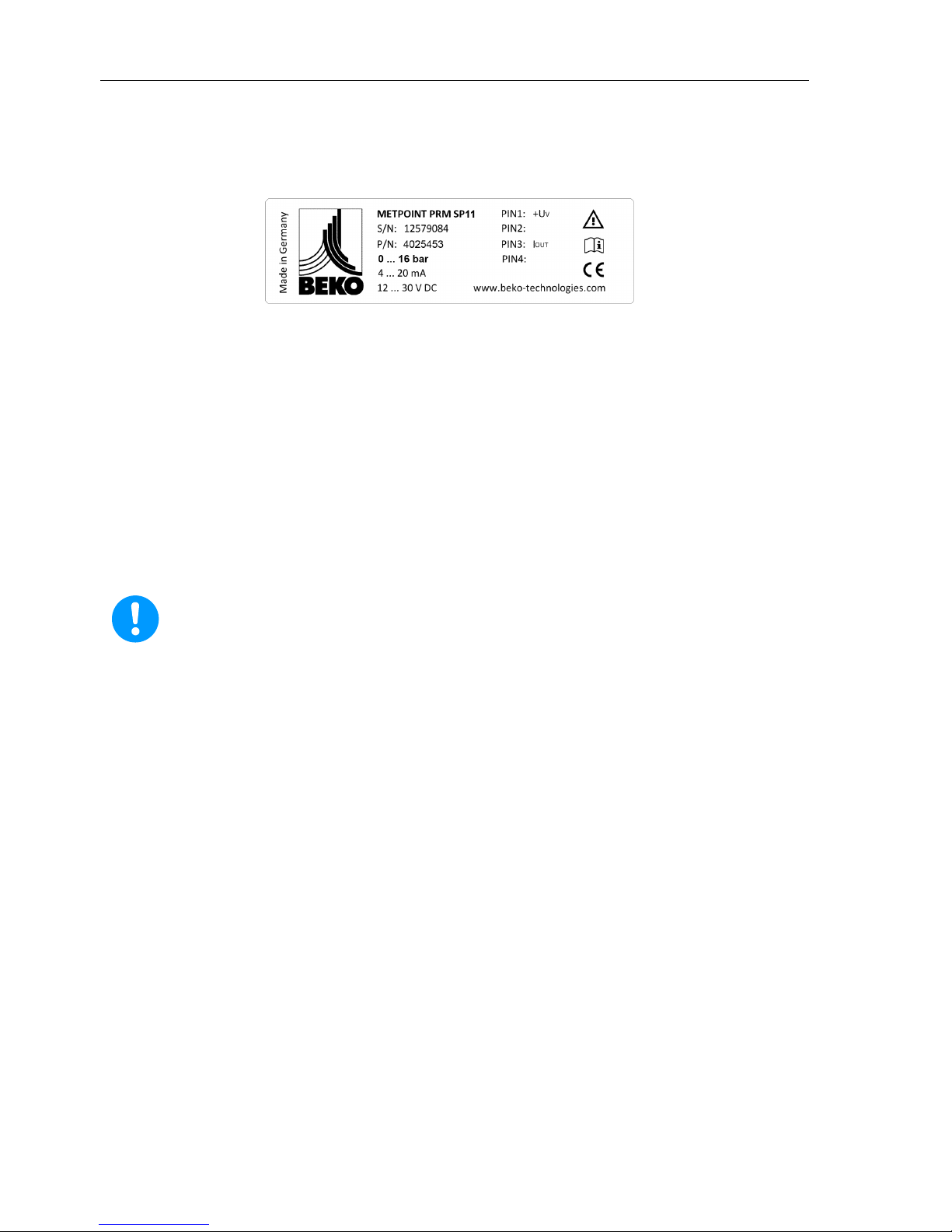

7Type plate...............................................................................................................................................8

8Technical data ........................................................................................................................................9

9Dimension drawings .............................................................................................................................12

10 Function................................................................................................................................................14

11 Installation ............................................................................................................................................15

11.1 Installation instructions .........................................................................................................................15

11.2 Preparing the thread at the measurement point ..................................................................................16

11.3 Installation example for connections in accordance with EN 837-1 with a cylindrical thread ..............16

12 Electrical installation.............................................................................................................................17

12.1 Pin assignment PRM SP11, 2-wire ......................................................................................................18

13 Maintenance and calibration ................................................................................................................20

13.1 Cleaning/decontamination....................................................................................................................21

14 Scope of delivery..................................................................................................................................22

15 Accessories ..........................................................................................................................................23

16 Dismantling and diposal .......................................................................................................................24

17 Trouble shooting and fault removal......................................................................................................25

18 Declaration of conformity .....................................................................................................................26

19 Index.....................................................................................................................................................27