CFT

4

A2529-2.0 en/de/frHBM

Safety instructions

The supply connection, as well as the signal and sense leads, must be

installed in such a way that electromagnetic interference does not adversely

affect device functionality (HBM recommendation: ”Greenline shielding

design”, downloadable from the Internet at http://www.hbm.com/Greenline).

Automation equipment and devices must be covered over in such a way that

adequate protection or locking against unintentional actuation is provided

(such as access checks, password protection, etc.).

When devices are working in a network, these networks must be designed in

such a way that malfunctions in individual nodes can be detected and shut

down.

Safety precautions must be taken both in terms of hardware and software, so

that a line break or other interruptions to signal transmission, such as via the

bus interfaces, do not cause undefined states or loss of data in the

automation device.

Appropriate use

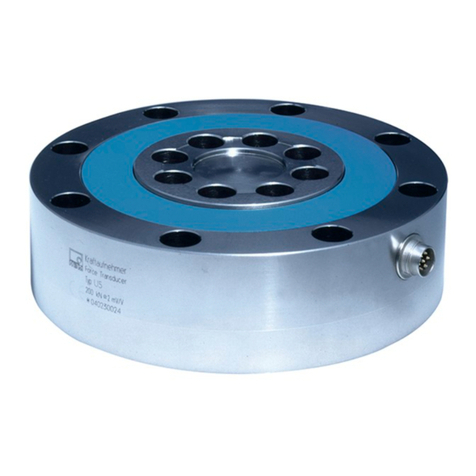

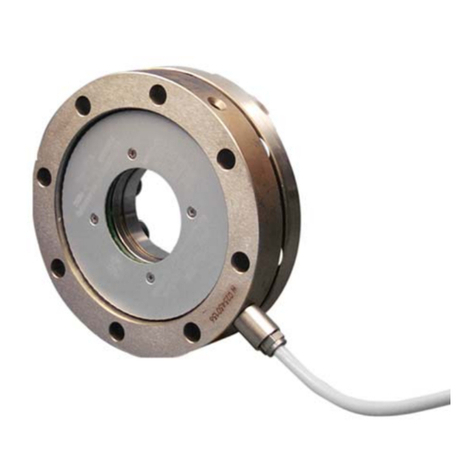

The CFT piezoelectric force transducer is intended for compressive force

measurements in test benches, press‐fit processes, test and inspection

equipment and presses. Use for any additional purpose shall be deemed to

be not appropriate.

In the interests of safety, the transducer should only be operated as described

in the Mounting Instructions. It is also essential to comply with the legal and

safety requirements for the application concerned during use. The same

applies to the use of accessories.

The force transducer is not a safety element within the meaning of appropriate

use. For safe and trouble‐free operation, this transducer must not only be

correctly transported, stored, sited and mounted but must also be carefully

operated and maintained.

Each time, before starting up the equipment, you must first run a project

planning and risk analysis that takes into account all the safety aspects of

automation technology. This particularly concerns personal and machine

protection.

Additional safety precautions must be taken in plants where malfunctions

could cause major damage, loss of data or even personal injury. In the event

of a fault, these precautions establish safe operating conditions.

This can be done, for example, by mechanical interlocking, error signaling,

limit value switches, etc.