Belanger Chameleon Arch Series User manual

Chameleon® Arch Series

1MANUAL526 Rev02

Chameleon®Arch Series

®

Belanger Equipment Owner’s Manual

Chameleon® Arch Series

Copyright 2020

Belanger, Inc®

This manual and the accompanying equipment are protected by United States trademark, copyright, and patent laws. You

may make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form

whatsoever, in whole or in part, without the prior written permission of Belanger, Inc.®

The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is

for reference purposes only and does not imply sponsorship or approval of Belanger, Inc.®by these companies or any

companies affiliated with their respective owners.

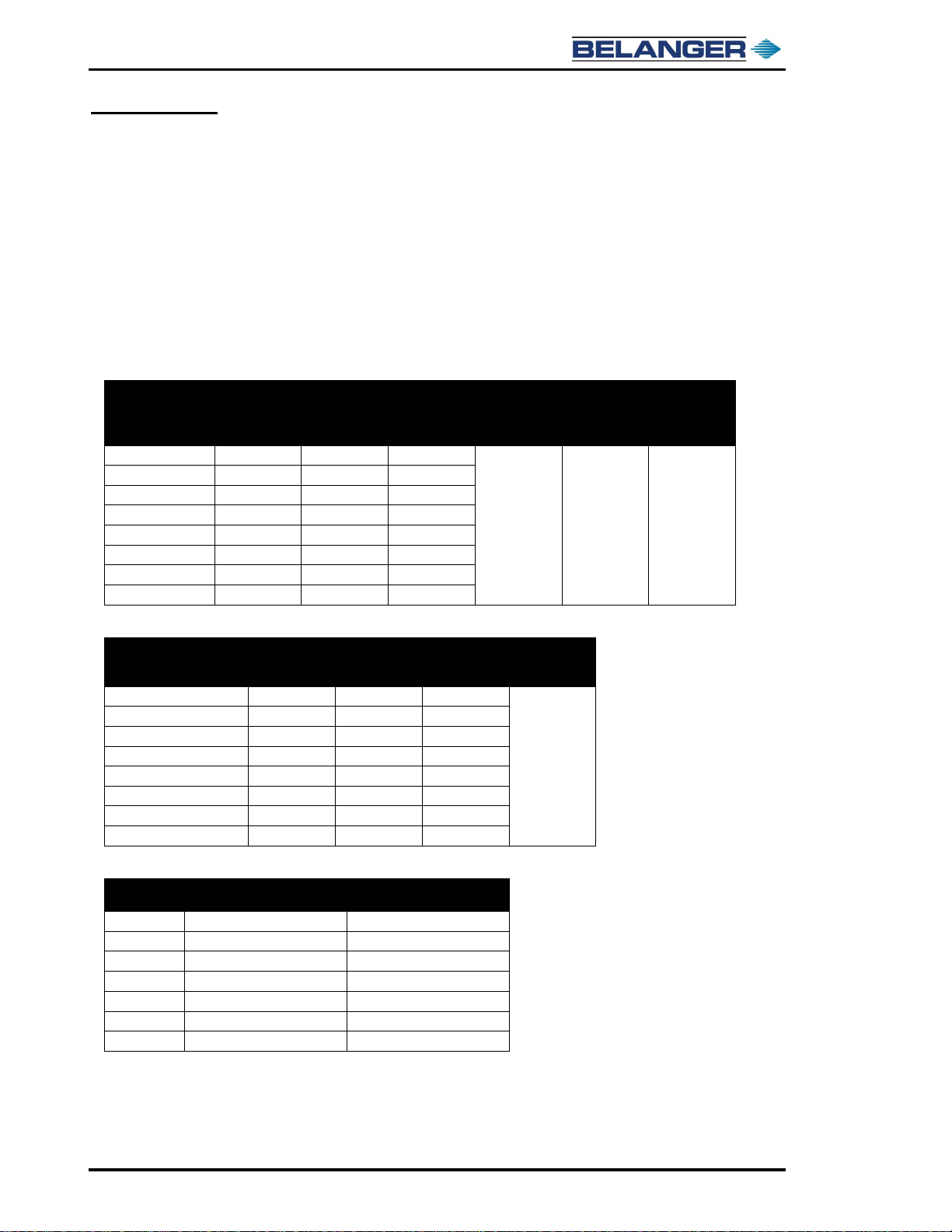

CURRENT REVISION LOG

Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Rev

Release

Date

Page

Description

02

04/13/2020

Manual

Revised manual to conform to CE Requirements

Manual

Updated Front Cover, Back Cover and Belanger®Logo

3

Updated Limited Warranty

3 & 8

Changed Bi-Flouride to Bi-fluoride

11

Updated Description of Chameleon®Arch added images

CHAMELEON® ARCH SERIES

1MANUL526 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1

Table of Contents

Belanger Incorporated® Limited Warranty.......................................................3

Introduction.........................................................................................................4

IMPORTANT Safety Information –MUST READ......................................................................4

Operational Warning..................................................................................................................8

Environmental Parameters ........................................................................................................9

Reasonable and Foreseeable Misuse .......................................................................................9

Do’s and Do Not’s ....................................................................................................................10

Description of Chameleon® Arch Series .................................................................................11

Before You Get Started............................................................................................................12

Equipment Included .................................................................................................................12

Specifications....................................................................................................14

Requirements...........................................................................................................................14

Output ......................................................................................................................................14

Dimensions ..............................................................................................................................15

Things You Should Know Before You Proceed..............................................16

Extrusion Styles .......................................................................................................................16

Installation.........................................................................................................17

Arch Assembly .........................................................................................................................17

Tunnel Placement....................................................................................................................21

Neon Strip Kit Installation and Electrical Connections.............................................................23

Water Feed Kit Installation.......................................................................................................29

Utility Arch Filler Strips.............................................................................................................30

Arch Final Assembly ................................................................................................................30

Additional Options: Side Pendants ..........................................................................................31

Additional Options: Foam Pods ...............................................................................................33

Additional Options: Rain Arch..................................................................................................43

Additional Options: Single K-Nozzle Manifolds........................................................................46

Additional Options: Dual K-Nozzle Manifolds ..........................................................................53

Leak Test / Nozzle Kit Installation (Applies only to the Spray Arch Option) ............................60

Nozzle Configuration Guide.....................................................................................................61

Maintenance ......................................................................................................64

Routine Procedures .................................................................................................................64

Trouble Shooting......................................................................................................................64

Powder Coating Repair............................................................................................................65

Replacement Parts...................................................................................................................67

Frame and Components ................................................................................................................................... 67

Manifold Components ....................................................................................................................................... 67

Frame Weldments Overview............................................................................................................................. 68

Spray Arch Frame Assembly ............................................................................................................................ 68

Utility Arch Frame Assembly ............................................................................................................................. 68

Pendant Part Numbers ..................................................................................................................................... 69

Spray Arch Filler Strips Overview ..................................................................................................................... 70

CHAMELEON® ARCH SERIES

2Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Table of Contents

Maintenance (continued)..................................................................................70

Spray Arch Filler Strips ..................................................................................................................................... 70

Utility Filler Strips Overview .............................................................................................................................. 71

Utility Arch Filler Strips...................................................................................................................................... 71

RGB Neon LED Light Kit: 111267 & 111271 (SpinLite®) ................................................................................. 72

RGB Neon LED C-Channels ............................................................................................................................ 72

Pendant Fasteners (Oval Cover Shown) .......................................................................................................... 73

Side Pendant Mounting Components ............................................................................................................... 73

Side Pendant Adaptor....................................................................................................................................... 74

Rain Arch Assembly: 109384 ........................................................................................................................... 74

Foam Pod Tri-Mount Assembly: 109384 .......................................................................................................... 74

Triple Foam Pod Manifold................................................................................................................................. 75

Misc Foam Pod Fittings .................................................................................................................................... 75

Foam Pod Mount Extension Kit: 107229 .......................................................................................................... 75

Single Foaming Pod ......................................................................................................................................... 76

Triple Foaming Pod .......................................................................................................................................... 77

K-Nozzle Manifolds........................................................................................................................................... 78

Misc K-Nozzle Clamp Assembly....................................................................................................................... 78

Nozzle Assembly .............................................................................................................................................. 79

Soap Foaming Air Panel #102029.................................................................................................................... 79

Flasher Box #105113........................................................................................................................................ 79

Appendix A: CE Information............................................................................80

Appendix B: De-Commissioning (Dismantling and Disposal)......................81

CHAMELEON® ARCH SERIES

1MANUL526 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 3

Belanger Incorporated® Limited Warranty

LIMITED WARRANTY:

Equipment:

Subject to the limitations stated below, Seller warrants that the Equipment sold hereunder, which is fabricated by

Seller, shall be free from defects in workmanship and material under normal use and service for a period of 1 year plus

30 days from the date of invoice - CATPumps will be warranted for 2 years from the date of invoice.

Parts:

Subject to the limitations stated below, Seller warrants that the Parts sold hereunder, shall be free from defects in

workmanship and material under normal use and service for a period of 30 days from the date of invoice.

Limitations on All Warranties:

The warranties contained in this Section 13 are subject to the following limitations: (1) they are void if the factory

specifications for operation and maintenance, found in original equipment manuals, and component manuals, are not

followed, or if other than factory authorized erection, alterations or modifications are made to any Parts or Equipment;

(2) defective Parts are warranted to the Purchaser only for repair or replacement through an authorized Purchaser or

Distributor of Seller, or direct with Seller for a period of 13 months from the date of invoice; however, this warranty

excludes all claims for failure resulting from normal wear and tear, improper installation, omission of factory specified

preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God and Purchaser agrees to

submit to and assist Seller or its authorized Purchaser or Distributor in conducting in-warranty inspections of the

Goods including inspection of any Equipment or Parts claimed to be defective by the Purchaser; (3) the cost of

providing labor or repair to replace Equipment and Parts warranted to Purchaser will be included within the warranty

only if such claim is made within 120 days from the date of invoice and then only during normal business hours

through an authorized Purchaser or Distributor of Seller, or direct with Seller, and labor and service provided beyond

the labor warranty period shall be subject to labor charges at the rates established by the local authorized Purchaser

or Distributor or direct with Seller; (4) the warranties shall be void for all Equipment failures and premature Part wear

caused by the use of corrosive chemicals in the wash process, and the following list includes some, but not all, of the

particularly corrosive chemicals that if used in conjunction with Equipment or Parts will void the warranty: Hydrofluoric

Acid, Ammonium Bi-fluoride, Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide,

Hydrochloric Acid, Sodium Hydroxide and Chlorinated Solvents; (5) Seller makes no warranty, express or implied, with

respect to the design or operation of any entire system, in which Seller’s Equipment or Parts sold hereunder are mere

components;(6) in no event shall Seller be liable for any incidental, special, consequential, punitive or exemplary

damages resulting from the furnishing, performance or use of any Goods or services sold pursuant hereto, whether

due to a breach of contract, breach of warranty, negligence or any other claim at law or equity. Seller shall not be

liable for any damages of any kind, including, but not limited to, loss of business; inconvenience, or property damage

of any kind; nor for any damages of whatever nature resulting in any way from the Purchaser’s selection and use of

any chemicals not manufactured exclusively by Seller but used with the purchased Equipment or Parts; or for any

service not expressly provided herein related to or arising from the Equipment or Parts sold. Seller shall not be liable

for damages resulting from Purchaser’s use of any engineering recommendations, sales representations, technical

assistance, advice or data other than that information contained in Belanger manuals; (7) all warranties, express,

implied, or statutory, pertaining to the Equipment and Parts apply to the Purchaser only; are not transferable; are fully

set forth herein; and no addition to or modification thereto shall be binding upon the Seller, unless made in writing and

signed by a duly authorized employee of Seller.

No Other Warranties:

THIS LIMITED WARRANTY FOR EQUIPMENT AND PARTS IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE –SALES ARE EXPRESSLY

DISCLAIMED.

Copyright© 2013 by Belanger, Inc.®All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage

or retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Belanger® reserves the right to

change or modify the Belanger, Inc.® Limited warranty without notice.

CHAMELEON® ARCH SERIES

4Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Introduction

IMPORTANT Safety Information –MUST READ

This section introduces the hazard and safety precautions associated with installing, maintaining or

servicing this product. Before performing any task on this product, read this safety information and

the applicable sections in this manual, where additional hazards and safety precautions for your task

may be found. Electrical shock could occur and cause death or serious injury if these safe service

procedures are not followed.

Safety Warnings Explanation

Throughout this manual, the following symbols are in effect:

The safety warning symbols used throughout the manual fall into the following categories:

Symbol Example

Definition

Yellow warning triangle/black graphical symbol indicates what the

hazard is.

Red circle-with-slash/black graphical symbol indicates a prohibited

action to avoid the hazard.

Blue mandatory action circles/white graphical symbol –indicates an

action to take to avoid the hazard.

Terms used throughout the manual are defined as follows:

DANGER - Indicates an imminently hazardous situation, which if not avoided, will result in

death or serious injury.

WARNING - Indicates a potentially hazardous situation, which if not avoided, could result in

death or serious injury.

CAUTION - Indicates a potentially hazardous situation, which if not avoided, may result in

minor or moderate injury.

Other helpful informational notes appear as follows:

!!IMPORTANT!!

Important information that has more impact than a note-not related to injury.

NOTE:

General and/or helpful information-not related to injury or damage.

Helpful tips.

CHAMELEON® ARCH SERIES

1MANUL526 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 5

Introduction

IMPORTANT Safety Information –MUST READ

CAUTION –BEFORE YOU BEGIN, ONLY TRAINED OR AUTHORIZED

INDIVIDUALS KNOWLEDGEABLE IN THE RELATED PROCEDURES SHOULD

INSTALL, INSPECT, MAINTAIN OR SERVICE THIS EQUIPMENT.

CAUTION - DO NOT USE THIS EQUIPMENT FOR ANY PURPOSE NOT

DESCRIBED IN THIS MANUAL.

Read the Manual

Safety Warnings

WARNING –LOCKOUT/TAGOUT ELECTRICAL PRIOR TO OPENING FOR

SERVICE.

WARNING –LOCK ELECTRICAL EQUIPMENT.

DANGER –DISCONNECT MAIN POWER SUPPLY PRIOR TO SERVICING OR

MAINTAINING EQUIPMENT!

WARNING –LOCKOUT/TAGOUT AND REDUCE PNUEMATIC PRESSURE TO

ZERO PRIOR TO SERVICING.

Belanger recommends that all workers observe the OSHA (U.S. Department of Labor Occupational Safety

& Health Administration) Lockout / Tagout procedure prior to performing service or maintenance on

machinery and equipment. Doing so will prevent unexpected energization, startup, or release of hazardous

energy while maintenance and servicing activities are being performed.

WARNING –BE SURE TO OBSERVE OPERATING ENVELOPE. EQUIPMENT

MAY START UNEXPECTICALLY.

CAUTION –DURING THE INSTALLATION PROCESS THE INSTALLER IS

RESPONSIBLE FOR THE RE-TIGHTENING ALL LUGS, SET SCREWS AND

TERMINALS LOCATED IN THE ELECTRICAL PANELS. COMPONENTS MAY

VIBRATE LOOSE DURING SHIPPING.

CAUTION –BE AWARE OF HAZARDS ASSOCIATED WITH EQUIPMENT

INSTALLED ON THE FLOOR THAT MAY BE A TRIP HAZARD.

WARNING - READ, UNDERSTAND AND FOLLOW THIS MANUAL AND ANY

OTHER LABELS OR RELATED MATERIALS SUPPLIED WITH THIS EQUIPMENT.

IF YOU DO NOT UNDERSTAND THE PROCEDURE, CALL A BELANGER, INC.

REPRESENTATIVE AT 248-349-7010. IT IS IMPERATIVE TO YOUR SAFETY

AND THE SAFETY OF OTHERS TO UNDERSTAND THE PROCEDURES BEFORE

BEGINNING WORK.

CHAMELEON® ARCH SERIES

6Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Introduction

IMPORTANT Safety Information –MUST READ

Safety Warnings

CAUTION –SERVICE PERSON SHOULD USE APPROPRIATE FOOTWEAR AND

USE SAFETY CONSCIOUSNESS WHEN WORKING IN THE WASH BAY AREA.

WARNING –DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE

SERVICING ANY EQUIPMENT!

WARNING –DO NOT OPERATE THIS EQUIPMENT FROM ANY POWER

SOURCE THAT DOES NOT MATCH THE VOLTAGE RATING LISTED ON THE

EQUIPMENT. REFER TO THE MANUFACTURER’S IDENTIFICATION LABEL FOR

OPERATIONAL REQUIREMENTS.

CAUTION –IT IS RECOMMENDED THAT A LICENSED ELECTRICIAN IS

CONTRACTED TO PERFORM ALL ELECTRICAL INSTALLATIONS.

CAUTION –A COMPRESSED AIR SYSTEM SHOULD BE SET CORRECTLY TO

SUPPORT 90 PSI / 620 kPa NECESSARY TO OPERATE EQUIPMENT BUT

SHOULD NEVER BE SET TO DELIVER MORE THAT 120 PSI / 827 kPa AIR

PRESSURE TO BELANGER® SPECIFIED EQUIPMENT. FIELD SUPPLIED

PNEUMATIC TUBING MUST HAVE A MINIMUM OF 2 TIMES THE BURST

STRENGTH OF SYSTEM PRESSURE.

CHAMELEON® ARCH SERIES

1MANUL526 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 7

Introduction

IMPORTANT Safety Information –MUST READ

It is imperative to your safety and the safety of others to always follow

safe work procedures.

WARNING –IT IS THE RESPONSIBILITY OF THE SITE OWNER TO PROPERLY

INSTRUCT THE WASH USER ON THE PROPER USE OF THE WASH AND TO

INSTRUCT THEM THAT THE WASH BEGINS AUTOMATICALLY AFTER

PROPERLY LOADING THE VEHICLE.

WARNING –ALL MACHINE COMPONENTS HANDLED

DURING INSTALLATION, MAINTENANCE AND/OR SERVICE

MUST BE HANDLED WITH A DEVICE APPROPRIATELY RATED

AND IN SUITABLE CONDITION TO LIFT AND/OR HANDLE

THE WEIGHT OF THE COMPONENT. WHEN COMPONENTS

ARE HANDLED BY HAND, USE PROPER LIFTING TECHNIQUES

TO AVOID INJURY.

WARNING –DO NOT ATTEMPT TO SERVICE AREAS OF THIS EQUIPMENT

ABOVE 1.8 M (6 FT) WITHOUT WEARING AN APPROVED SAFETY HARNESS.

DO NOT ATTEMPT TO ACCESS UPPER AREAS OF THIS EQUIPMENT EXCEPT BY

USING AN APPROVED SAFETY LADDER IN GOOD OPERATING CONDITION.

DO NOT USE TABLES, CHAIRS, OR OTHER NON-APPROVED CLIMBING

EQUIPMENT OTHER THAN AS STATED HEREIN.

CAUTION –ALWAYS WEAR SAFETY GLASSES WHEN PERFORMING

MAINTENANCE ON ANY EQUIPMENT.

CHAMELEON® ARCH SERIES

8Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Introduction

Operational Warning

Formulations containing the chemicals listed below are particularly dangerous and should not be

used even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-fluoride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc., does not endorse or condone the use of chemicals that are potentially dangerous to

human health, the environment or property. Belanger recognizes that it is the right and sole decision

of the end user operators of our equipment as to the type and dilution ratio of the chemicals used in

their facilities. We strongly recommend that the end user does not select products containing any of

the chemicals listed above as an ingredient in the wash solutions. The chemicals listed above are

potentially dangerous to human health, and have a detrimental, deteriorating effect on the equipment

and the facility. Be advised that a portion of, or all of your warranty will be voided if you determine to

use any of the chemicals listed above as an ingredient in the wash solutions in conjunction with your

Belanger automatic car wash equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger Terms and Conditions of

Sales describes the potential limitation of warranty due to your chemical selection:

(4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes

some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride, Bromic

Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, and

Chlorinated Solvents. The Purchaser also agrees to accept the responsibility and liability for

the selection and use of any chemicals listed above;

However, should the end user decide to use formulations containing any of the above ingredients,

the end user should institute a comprehensive training program and implement detailed operational

parameters within their organization for the proper handling and treatment of such products to

minimize the potential dangers involved. Consult your chemical supplier for assistance in

establishing operational guidelines in the use of their products. MSDS (Material Safety Data Sheet)

should be obtained from the chemical supplier before using any chemical formulation.

CAUTION –DO NOT USE CHEMICALS THAT ARE CORROSIVE, CONTAIN

CONTAMINANTS, FOREIGN PARTICLES, AND/OR CORROSIVE ADDITIVES. DOING

SO WILL VOID MACHINE WARRANTY. CHEMICAL USED MUST BE COMPATIBLE

WITH LOCAL CODE REQUIREMENTS AND NOT HARMFUL TO PERSONS,

ANIMALS, OR THE ENVIRONMENT.

CHAMELEON® ARCH SERIES

1MANUL526 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 9

Introduction

Environmental Parameters

•Operating Temperature. This equipment will operate correctly in its intended ambient, at a

minimum between +40ºF (+5ºC) and +104ºF (+40ºC).

•Relative Humidity. The equipment will operate correctly within an environment at 50% RH,

+104ºF (+40ºC). Higher RH may be allowed at lower temperatures. Measures shall be taken

by the Purchaser to avoid the harmful effects of occasional condensation.

•Altitude. This equipment will operate correctly up to 1000m above mean sea level.

•Transportation and Storage. This equipment will withstand, or has been protected against,

transportation and storage temperatures of -13ºF (-25ºC) to 131ºF (+55ºC) and for short

periods up to 158ºF (+70ºC). It has been packaged to prevent damage from the effects of

normal humidity, vibration and shock.

Reasonable and Foreseeable Misuse

The following conditions must be considered by the Owner Operator. It is his/her responsibility to

take precautions as described below.

•Do not allow users who are under the influence of alcohol, drugs, or controlled substances to

use the wash.

•Keep the wash bay clean and free of debris and objects that would confuse the user or

impede access into or out of the wash bay.

•Instruct the wash user to not enter the wash with the vehicle windows and/or vehicle

doors open and to keep windows and vehicle doors closed throughout the entire wash

process.

•Always instruct the wash user to remain in the vehicle throughout the wash process.

•Ensure that the wash bay is well lit so wash users can safely use the wash.

•Instruct the wash user to not use the wash if their vehicle has loose or broken parts that

may interfere with, damage, or result in unsafe operation of the wash.

•Instruct the wash user that the damage to or incidents caused by aftermarket vehicle

components is not the responsibility of the wash owner or manufacturer.

•Instruct the wash user to proceed slowly through the wash.

•Instruct the wash user to never back up inside the wash bay.

•Instruct personnel not to work on wash unless the entrance is blocked from vehicles

entering, this is in addition to all other safety precautions.

CHAMELEON® ARCH SERIES

10 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Introduction

Do’s and Do Not’s

DO

DO NOT

Read all manuals carefully and

completely prior to beginning the

process the manual describes.

DO NOT drill in top of any electrical enclosures.

Verify that all parts needed to perform a step

described in the manual are present prior to

beginning the process.

DO NOT install high voltage and low voltage supply

lines in the same conduit.

Study and understand all installation diagrams and

drawings.

DO NOT power-up controller without following

manual.

Carefully follow all instructions.

DO NOT operate machine without testing all

sensors for clearance and operation.

Use anti-seize lubricant on all threaded fasteners

(screws, bolts, nuts, etc.).

DO NOT operate machine until all safety features

are tested.

Use quality thread sealant on all plumbing

connections to eliminate leaking.

DO NOT service high- or low-pressure

pumps without turning main power off

and following Lock-Out/Tag-Out

Procedures. Severe injury could result.

Ask questions when they arise.

DO NOT service without turning main

power off and following Lock-Out/Tag-

Out procedures. Severe injury could

result.

Check all electrical boxes are closed prior to spraying

water.

DO NOT attempt to add components to machine.

Check incoming electrical supply voltage to ensure it

matches equipment order.

DO NOT substitute machine components.

Follow all maintenance schedules to ensure trouble-

free performance.

Periodically check all system stop circuits are

functional.

Table 1 Recommended General Practices to Do and Not Do when Installing, Maintaining, and/or Servicing Belanger® Equipment.

CHAMELEON® ARCH SERIES

1MANUL526 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 11

Introduction

Description of Chameleon® Arch Series

Congratulations on your purchase of the Belanger, Inc. Chameleon® Arch. The purpose of this

manual is to familiarize you with the way that the Chameleon® Arch is installed, the various ways in

which it can operate, and how to maintain it after installation.

The Installation section will be used in conjunction with specification sheets, location diagrams, Arch

Configuration sheets, and the Chameleon® Arch drawings. All these combined are your guide to

installation.

The Maintenance sections will be used to make sure you can keep your car wash component

looking and running like new.

Whether you have already operated a car wash, or you are new to our industry, you know the

importance of the appearance of a car wash and its equipment to the customer. Keeping the

equipment clean will not only make the equipment easier to maintain, it will act as an example to

your customer to keep their equipment (their automobile) clean as well. Replacing the cleaning

material as necessary, will also help the image of your wash and keep the customer coming back.

Read through the entire manual to familiarize yourself with the Chameleon® Arch before installation.

When installation is completed, you will want to keep this manual as a guide to proper maintenance.

The new Chameleon® Stiks and the Chameleon® Arch are available in 8 different frame work colors

(aluminum, white, green, black, red, yellow, orange, and blue), eight different filler strip colors (gray,

white, green, black, red, yellow, orange, and blue), and five different neon strip colors (red, yellow,

orange, blue, green), all of which can be mixed and matched with each other. The main Spray Arch

Manifolds are constructed with 1/2” (12.7 mm) schedule 10 stainless steel pipes and is supplied with

stainless steel fittings. The Chameleon® Arch Series consists of 12 nozzle holes which are flo-drilled

for 1/8” (3.18 mm) NPT and use the current Belanger nozzle kits.

With RO water, and approved acid and alkaline based chemicals. A 3/4” (19.1 mm) NPT fitting and

hose barb are included for the normal supply feeds. The feeds are in the center of the arch for

optimum and balanced flow.

CHAMELEON® ARCH SERIES

12 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Introduction

Before You Get Started

Tools needed for installation:

hammer drill with 1/2” (12.7 mm) bit

25 foot (8 m) extension cord

ladder

tape measure (25 foot / 8 m or greater)

tin snips

level

miscellaneous hand tools

work gloves

safety glasses

Silicone adhesive

Allen wrench set

Equipment Included

Belanger Part Numbers for Chameleon Spray Arch Frame Assembly:

Powder Coated

Color

(*) Not Powder

Coated

Long Head

Beam

Weldment

Short Head

Beam

Weldment

Leg

Weldment

(2)

Top Spray

Manifold

Side Spray

Manifold

(2)

Accessory

Box

*Aluminum

109451

109452

109450

109449

109448

109455

White

109457

109458

109456

Red

109473

109473

109471

Blue

109460

109461

109459

Black

109463

109464

109462

Green

109466

109467

109465

Orange

109469

109470

109468

Yellow

109475

19476

109474

Belanger Part Numbers for Chameleon Utility Arch Frame Assembly:

Powder Coated

Color

(*) Not Powder Coated

Long Head

Beam

Weldment

Short Head

Beam

Weldment

Leg

Weldment

(2)

Accessory

Box

*Aluminum

109424

109425

109423

109426

White

109428

109429

109427

Red

109431

109432

109430

Blue

109446

109447

109445

Black

109437

109438

109436

Green

109440

109441

109439

Orange

109434

109435

109433

Yellow

109443

109444

109442

Belanger Part Numbers for Chameleon Arch Filler Strip Kits:

Filler Strip

Color

Spray Arch Filler Strip Kit

Utility Arch Filler Strip Kit

Gray

109419

109408

Red

109420

109411

Blue

109421

109406

Black

109418

109407

Green

109417

109409

Orange

109416

109410

Yellow

109415

109412

CHAMELEON® ARCH SERIES

1MANUL526 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 13

Introduction

Equipment Included

Belanger Part Numbers for Chameleon Arch Neon Light Strip Kits:

Neon Strip Color

Neon Strip

Kit

Red

107209

Yellow

107210

Orange

107211

Blue

107212

Green

107213

Belanger Part Numbers for Chameleon Arch Nozzle Kits:

Nozzle Kit Description

Nozzle

Kit

For Pre-Soak

105270

For Wet Down

105273

For Rinse

105274

For Wax

105275

For Wax

105276

Check Body Set (12)

105280

Belanger Part Numbers for Chameleon Spray Arch Water Feed Kits:

Feed Kit Description

Feed Kit

Single Feed

109383

Dual Feed

109384

Long Dual Feed

109561

Optional Equipment:

Belanger Part Numbers for Chameleon Arch Optional Components:

Optional Component Description

Component Number

Rain Arch Kit

107230

Single Foam Pod Kit

107228

Triple Foam Pod Kit

107227

Single Foam Pod Tri-Mount Kit

107247

Foam Pod Extension Kit

107229

K-Nozzle Kit

107226

Dual K-Nozzle Kit

107248

CHAMELEON® ARCH SERIES

14 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL526

Specifications

Requirements

Physical

Tunnel space required

8” / 63.5 cm

Unit height

103-1/2” / 2.63 m (single feed)

Unit width

141” / 3.58 m (outside of leg to outside of leg)

Utility

Electrical

110VAC (for optional solenoid valve) @ .5 amps

Water

3/4” / 19.1 mm barbed hose fitting

Output

Physical

Vehicle clearance, height

90” / 2.29 m (with optional check-bodies)

Vehicle clearance, width

125” / 3.18 m (with optional check-bodies)

WARNING –DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE

SERVICING ANY EQUIPMENT!

CAUTION –ALWAYS WEAR SAFETY GLASSES WHEN PERFORMING

MAINTENANCE ON ANY EQUIPMENT.

CAUTION –IT IS RECOMMENDED THAT A LICENSED ELECTRICIAN IS

CONTRACTED TO PERFORM ALL ELECTRICAL INSTALLATIONS.

CAUTION –A COMPRESSED AIR SYSTEM SHOULD BE SET CORRECTLY TO

SUPPORT 90 PSI / 620 kPa NECESSARY TO OPERATE EQUIPMENT BUT

SHOULD NEVER BE SET TO DELIVER MORE THAT 120 PSI / 827 kPa AIR

PRESSURE TO BELANGER® SPECIFIED EQUIPMENT. FIELD SUPPLIED

PNEUMATIC TUBING MUST HAVE A MINIMUM OF 2 TIMES THE BURST

STRENGTH OF SYSTEM PRESSURE.

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

AL-KO

AL-KO Solo 7505 VR Instructions for use

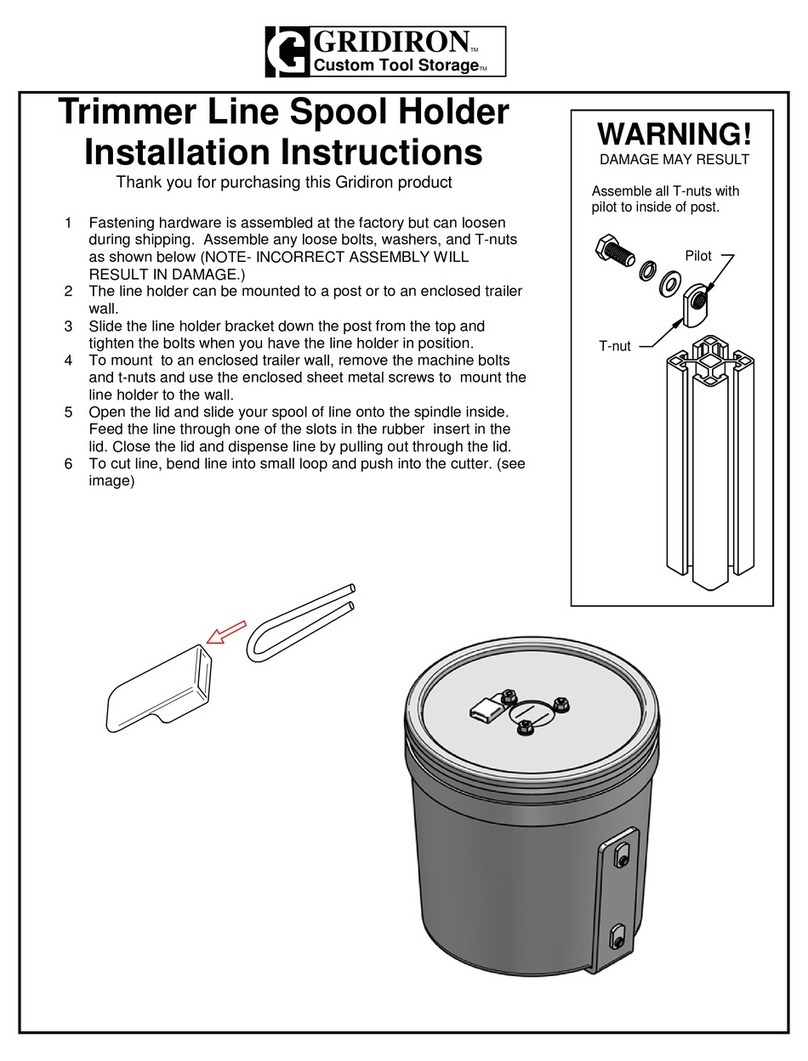

GRIDIRON

GRIDIRON TL-01 installation instructions

Schiller Grounds Care

Schiller Grounds Care RYAN JR SODCUTTER 744844H manual

Ecovim

Ecovim Eco 250 quick guide

Garden Furniture Direct

Garden Furniture Direct GARSDALE LOG & BOOT STORE Assembly instructions

Pond Pro

Pond Pro CAN-AIR MEGA owner's manual

Kärcher

Kärcher 6.997-355.0 manual

Somogyi

Somogyi Home IKM150 instruction manual

ENCLO

ENCLO Charleston Assembly instructions

Sealey

Sealey SPB27W instructions

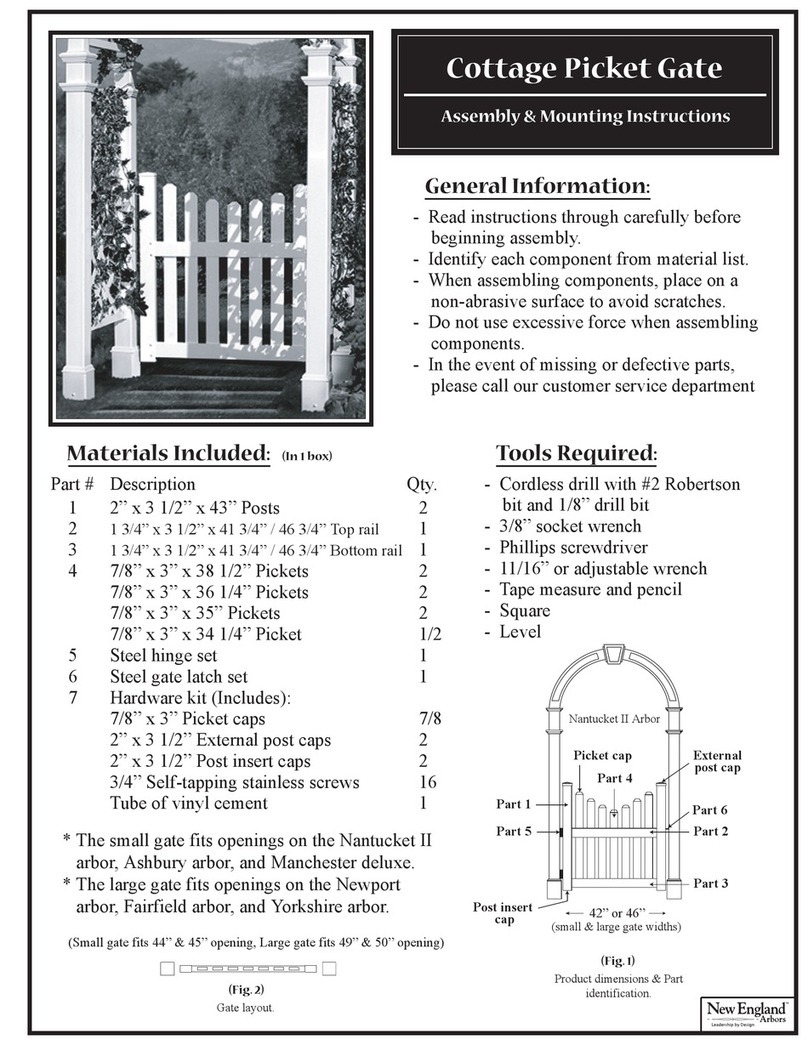

New England Arbors

New England Arbors Cottage Picket Gate Assembly/mounting instructions

Hitachi

Hitachi CH 10DL (CG) Technical data and service manual