Sisis BRUSH-PRO User manual

BRUSH-PRO

RIDE-ON BRUSH SYSTEM

INSTRUCTION MANUAL

R

SP20017_REV_1

02/15

BRUSH-PRO FEB ‘15

2

Certicate of Conformity

Brush-Pro ride-on brush system powered by Honda GX Petrol Engine

Manufacturer:- Howardson Ltd, Howardson Works, Kirk Langley, Derby, DE6 4NJ. UK

Owner of Technical Document:- Mr I.D. Howard, Howardson Ltd, Howardson Works Kirk Langley, Derby, DE6 4NJ, UK

Notied Body:- AV Technology Ltd, AVTECH house, Arkle Avenue, Stanley Green Trading Estate, Handforth, Cheshire,

SK9 3RW, UK

I the under signed Declare that these machines:-

Tested at:- Howardson Works test site September 2011

Complies with the applicable requirements of:-

- Machine Directive 2006/42/EC

- Noise Directive 2000/14/EC (Annex VI Procedure 1)

Managing Director

Ian Howard

The reliability and quality of performance of the BRUSH-PRO depends upon some simple care maintenance carried out

regularly. This manual has been prepared to allow the user to carry out all such work.

It is advisable to read the instructions carefully. Proper care and attention will enable the machine to give a continuous,

satisfactory, and reliable service. Failure to carry out regular lubrication and maintenance as outlined in this manual may

render any guarantee or warranty invalid.

In the case of any difculty, or if further information or advice is required, our Service Department is always at your call. In

the interests of speed and accuracy of information please quote the serial numbers of the machine and engine when

making enquiries.

For the BRUSH-PRO, this is to be found on a plate attached to the side frame. The engine number is stamped on either

the crank case or the gear casing facing towards the front of the machine. We suggest you write the numbers on

the front page of this book.

Introduction

Serial Numbers

MACHINE SERIAL NUMBER

MAKE A NOTE OF THE SERIAL NUMBERS OF YOUR MACHINE & ENGINE AND ALWAYS

QUOTE THEM IN ANY COMMUNICATION WITH PERSONNEL AT DENNIS.

NOTE

ENGINE SERIAL NUMBER

BRUSH-PRO FEB ‘15

3

Contents

Page

Certicate of Conformity....................................................................................................................................................... 2

Serial Numbers..................................................................................................................................................................... 2

Introduction........................................................................................................................................................................... 2

Technical Data...................................................................................................................................................................... 3

Machine Description............................................................................................................................................................. 4

Important Safety Instructions................................................................................................................................................ 5

Operating Instructions ..................................................................................................................................................... 6 - 7

Parts Listings................................................................................................................................................................. 8 - 13

Technical Data

Model Brush-Pro

A - Width (M) 1.5

B - Length (M) 2.1

C - Height (M) 1.1

D - Width - Brushes Down (mm) 3.0

Weight (Kg) 350

Engine Honda GXV390 - 7.6kW

Drive System Hydrostatic Transaxle

Measured Sound Power Level dB(A) LWA 91

Guaranteed Sound Power Level dB(A) LWA 94

A

BC

D

BRUSH-PRO FEB ‘15

4

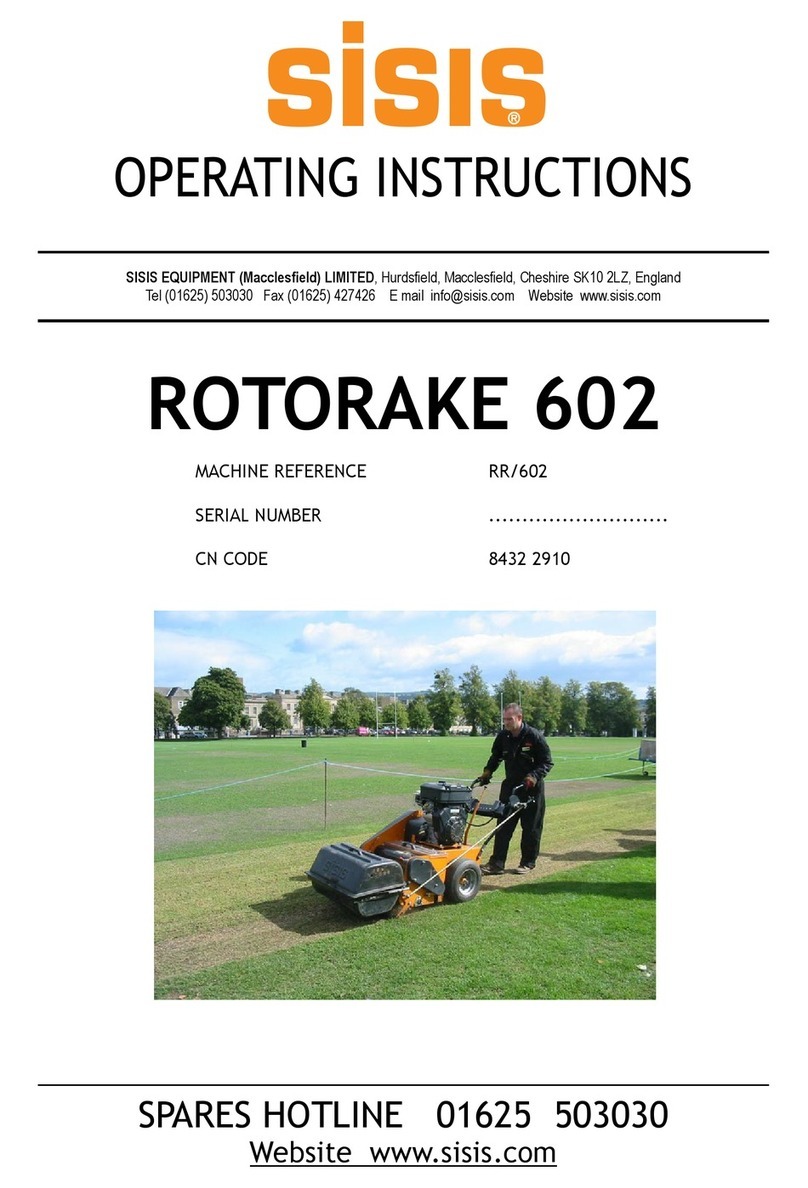

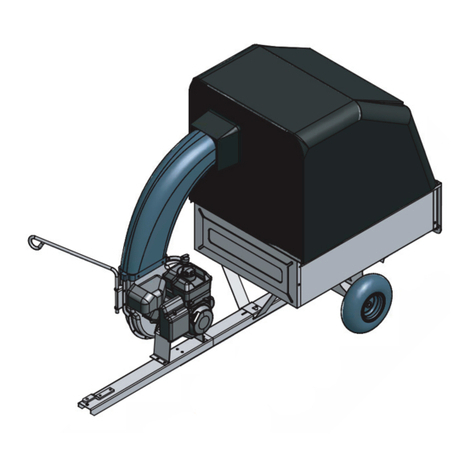

Machine Description

The SISIS Brush-Pro has been designed for use on articial surfaces to re-distribute the inll and keep the inll

material from compacting and migrating, whilst also brushing/grooming the carpet pile. The Brush Pro is powered by a

7.6 kW (10.2 Hp) air cooled 4-stroke single cylinder engine.

The Brush-Pro has 2 mid mounted oscillating brushes and a rear drag brush, both sets are lifted and lowered by

electrically operated rams and which also allow for any increase in ground clearance. The centre brushes oscillate to

loosen the inll and the rear drag brushes follow to settle and nish the inll. The rear brushes have two wing/outer

brushes which are attached to gas springs to ensure constant and even pressure over the contact surface. The rear

brushes are used daily to maintain the surface to redistribute the inll material and groom the synthetic surface.

1. Centre Brushes 7. Operator Seat

2. Rear Brushes 8. Operator Controls

3. Air Filter 9. Steering Column Release

4. Fuel Tank 10. Axle Drive Engage Rod

5. Foot Pedal 11. Exhaust

6. Steering Wheel

1

2

3

8

4

5

6

7

2

9

10

11

BRUSH-PRO FEB ‘15

5

Machine Description Important Safety Instructions

In order to operate the machine safely please follow these Health and Safety guidelines.

TRAINING

READ THE INSTRUCTIONS CONTAINED IN THIS MANUAL WITH CARE. IF YOU ARE IN

ANY DOUBT PLEASE ASK YOUR EMPLOYER OR CONTACT US DIRECT AT SISIS.

CAUTION

• Be familiar with the controls and the proper use of the equipment.

• Never allow children or people unfamiliar with these instructions to use the Brush-Pro. Local regulations or insurance

may restrict the age of the operator.

• Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their

property.

PREPARATION

PETROL IS HIGHLY FLAMMABLE AND WILL DAMAGE GRASS IF SPILT.

WARNING

A) Store fuel in containers specically designed for this purpose.

B) Refuel out doors and do not refuel whilst smoking.

C) Add fuel before starting the engine. Never remove the cap of the fuel tank or add petrol while the engine is running or

when the engine is hot.

D) If petrol is spilled do not attempt to start the engine but move the machine away from the area of spill and avoid

creating any sources of ignition until the vapours have dissipated.

• Replace damaged or faulty silencers.

• Before using the machine always inspect the safety devices including the cut off switch and the blades for excessive

wear or damage. Replace if necessary.

OPERATION

• Do not operate the engine in a conned space where dangerous CARBON MONOXIDE fumes can collect.

• Use extreme caution when reversing or pulling the machine towards you.

BRUSH-PRO FEB ‘15

6

Operating Instructions

OPERATING INSTRUCTIONS

Before operating the Brush-Pro ensure the drive enage lever is pushed in fully to disenage

the rear drive axle (See Figure 1). This allows safe starting of the motor whether the user is

seated or standing at the side of the machine. The engine will not start if the operator is

unseated with the drive engage lever in the enaged position, fully out. Check that the brake is

on (See Figure 2) and that the centre and rear brushes (Item 1 & 2, Machine Description)

are off the ground, see ‘Operating the Brushes’ and disenaged with the brush engage lever in

the off position.

The Honda GXV390 is equipped with electric key start or recoil start at the engine. Before

starting the Brush-Pro ensure the drive engage lever (Item 10, Machine Description)

is pushed in fully to disenage the rear drive axle. Once seated the drive engage lever

can be pulled out fully to engage drive, this fully activates the foot pedal.

To start the engine from cold pull the throttle lever back to the choke position

(See Figure 2), and turn the ignition key. Release the key once the engine has started

and allow the engine to warm up. To stop the engine turn the ignition switch to the off

position. Use the recoil start if the battery is not charged sufciently to start the engine.

Once the engine is warm release the brake lever to the off position (See Figure 3) and

depress the Operator’s Pedal (Item 5, Machine Description).

The Brush-Pro is driven by a Hydrostatic Axle, with the axle engaged (lever fully out)

pressing the top of the pedal gives forward motion and pressing the bottom of the pedal

puts the Brush-Pro into reverse. Releasing the pedal stops the Brush-Pro. The drive is

proportional to the travel of the pedal.

The engine will cutout if the pedal is pressed signicantly without releasing the brake

lever, thus protecting the rear axle brake.

OPERATING THE BRUSHES

The Brush-Pro is tted with oscillating centre

brushes and a set of rear nishing brushes.

The rear brushes have two outer wing brushes

which can be lowered into place giving a wide

nishing width and even ground pressure

(See Figure 4). Both the centre and rear

brushes are height controlled via electric rams,

with two rocker switches on the control panel,

(See Figure 5). The centre brushes can also be

used as drag brushes or by enaging drive in oscillating motion to aggrevate and

redistribute the inll material.

To enage the oscillating motion pull the centre brush drive lever back to the on position,

(See Figure 5). Both the mechanisms that control the brushes compensate for ground

clearance allowing them to be fully lowered onto the ground. The engine will cutout if

the centre brush drive is engaged with the brake lever in the on position, thus protecting

the centre brush oscillating mechanism.

BEFORE YOU OPERATE THIS MACHINE YOU MUST READ AND STUDY THIS MANUAL.

IF YOU ARE IN ANY DOUBT PLEASE ASK YOUR EMPLOYER OR CONTACT US DIRECT.

CAUTION

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

BRUSH-PRO FEB ‘15

7

Operating Instructions

TRANSPORT

Disengage the rear wheel drive by pushing in the drive engage lever fully in (See Figure 6).

This allows the machine to be manoeuvred for transportation. When moving the machine by

hand best practice is to hold the machine by the oor tubes, of if towing use the front

bumper tube.

MAINTENANCE

Engine - Honda GXV390 7.6kW 10.2 HP

Engine Oil - SAE 10w-40

Hydrostatic Axle Oil - SAE 10W-30

Tyre Pressures - Front 25 PSI, Rear 25 PSI

Battery - 12 VDC

Drive - Hydrostatic transaxle - rear axle

Centre Brush Drive - Belt drive

Operating Instructions

CHECK TYRES ARE AT THE CORRECT PRESSURE, SEE ABOVE. CHECK ENGINE OIL

LEVEL. CHECK BRUSHES FOR WEAR OR DAMAGE.

NOTE

• For access to the battery remove the left side top cover by loosening the screws as shown (See Figure 7).

• For access to the controls and tensioning cables remove the right side top cover (See Figure 8).

• For access to the centre brush mechanism remove all side covers (See Figure 9).

• For access to the machine drive mechanisms remove the front cover and seat plate (See Figure 9).

Figure 6

Figure 7 Figure 8 Figure 9

BELT TENSIONING

The Brush-Pro uses two tensioning cables for the engagement of the belt drive and rear hydrostatic axle brake. Remove

the right side cover to get access to the tensioning nuts for tension adjustment (See Figure 8).

BRUSH-PRO FEB ‘15

8

Item No. Part No. Description Quantity

1 228054 Spirol Pin (M8 x 50) 2

2 401206 Bearing Spacer 2

3 401229 Plate Actuator Link 2

4 401242 Brush Holder Assembly 1

5 401255 Angle Lift Plate WA 1

6 401257 Centre Brush Shaft 1

7 401301 Centre Brush Frame Assembly 1

8 401302 Brush Holder Assembly 1

9 401303 Spacer Rod End 1

10 401304 Crank Arm 1

11 401337 Boss Actuator 2

12 401338 Angle Lift Plate WA 1

13 401634 Pivot Arm Brush 2

14 401659 Spacer Bearing 4

15 BA1009 Bush Oilite Al1218 4

16 D8154 Grub Screw M8 x 16 2

17 D8173 Bearing 6001 2RS 8

18 D8802 M6 x 40 Caphead 2

19 D8956 Insert 50 x 25 4

20 E1-1062 M8 Spring Washer 8

21 E1-1110 Hex Set Screw M8 x 40 3

22 SP06021 Bearing 2 Bolt Flange 16ID 1

23 F21582 Bearing PB Asahi BPP 5.Z 2

24 F21706 Ball Joint 4

25 F22121 Rod End 1

26 F22320 Linear Actuator 100mm 1

27 F37340 Spacer 2

28 F37575 Centre Brush (Black) 2

28 SP24003 Centre Brush (Yellow) 2

29 SP01020 Hex Set Screw M10 x 40 4

30 SP01022 Hex Set Screw M8 x 50 1

31 SP01028 Hex Set Screw M6 x 20 2

32 SP01129 Cap Head M12 x 65 2

33 SP01122 Rod M10 x 50 2

34 SP02004 Nut M6 Nyloc 4

35 SP02006 Nut M8 Nyloc (T) 4

36 SP02008 Nut M10 Nyloc (T) 6

37 SP02010 Nut M12 Nyloc (T) 6

1.01 Centre Brushes

Item No. Part No. Description Quantity

38 SP03008 Washer M8 Form A 8

39 SP03012 Washer M12 Form A 3

40 SP06017 Bearing 6004-2RS 4

41 SP14013 Lobe Knob M8 x 55 8

32

12

37

33

24

36 1

16

6

29

23

2

36

16

37

1

3

21

35

11

30

32

35

15

7

28

17

40

17

34

13

27

34

40

18

10

31

22

37

25

14

39

37

17 38

20

19

41

8

BRUSH-PRO FEB ‘15

9

47

29

21

7

34

12 30

24

8

28

50

49

45 43

44

4

36

46

40

55

15

53

2

54 34

32

3

27

1

32

18

20

26

50

51

22

56

32

17

19

59

32

37 42

25

38

23

14

11

61

58

13

32

57

52

2.01 Controls

Item No. Part No. Description Quantity

1 229167 Clutch Spring 2

2 229378 Cutter Drive Clutch Cable 1

3 230170 Lever R.H. W.A. 2

4 240140 Throttle Lever W.A. Sport 1

5 240169 Sensor Angle Plate 2

6 240171 Cutter Control Plate 2

7 260135 Battery Positive Connector 1

8 260136 Battery Negative Connector 1

9 260145 Battery Eyelet 6mm 1

10 260146 Battery Eyelet 6mm 1

11 260147 Relay 1

12 401266 Control Panel Inner 1

13 401267 Control Panel Outer 1

14 401268 Control Panel Top 1

15 401275 Throttle Brake Bracket WA 1

16 401360 Battery Clamp Side 1

17 401361 Side Panel Angled 1

18 401362 Side Panel Angled LH 1

19 401363 Side Panel Cover 1

20 401364 Side Panel Cover LH 1

21 401423 Panel Outer LH 1

22 401424 Panel Inner LH 1

23 401425 Panel Top LH 1

24 D8712 Cable Earth 1

25 F20096 Cap Head M6 x 20 1

26 F22327 Rocker Switch 2

27 J20017 Knob - Red 3

28 SP12057 Battery Negative Cable 1

29 SP12058 Battery Positive Cable 1

30 MD407 Battery (015) 1

31 MD674 Battery Clamp 1

32 SP01009 Hex Set Screw M8 x 20 43

33 SP01019 Button Head M6 x 16 4

34 SP01029 Shoulder Bolt 12 x 25 M10 1

35 SP01069 Button Head M5 x 12 4

36 SP01070 Cap Head M2 x 12 4

37 SP02002 Nut M5 Nyloc (T) 5

Item No. Part No. Description Quantity

38 SP02004 Nut M6 Nyloc 5

39 SP02006 Nut M8 Nyloc (T) 5

40 SP02032 Nut M2 Std 4

41 SP02044 Rivnut Hex M8 (0.5-3.0) [No Head] 25

42 SP03010 Washer M6 Form A 5

43 SP03012 Washer M12 Form A 1

44 SP03019 Washer M12 Wave 1

45 SP03020 Shim 12 x 18 x 1 2

46 SP03027 Washer M2 4

47 SP06009 Bush Lever Pivot 2

48 SP12030 Battery Positive Insulation Boot 1

49 SP12031 Battery Negative Insulation Boot 1

50 SP12044 Red Indicator Led 12V 1

51 SP12045 Ignition Switch 1

52 SP12046 Terminal Insulation Cover 1

53 SP14014 Throttle Cable Brush Pro 1

54 SP14015 Belt Tensioner Cable Brush Pro 1

55 SP14016 Clamp Throttle Cable 1

56 SP18006 Decal Brush-Pro 2

57 SP18007 Decal SISIS Black 2

58 SP18008 Decal Brake Brush Brush Pro 1

59 SP18009 Decal Throttle Brush Pro 1

60 SP18010 Decal Brush Up Brush Pro 1

61 SP18011 Decal Brush Down Brush Pro 1

BRUSH-PRO FEB ‘15

10

Item No. Part No. Description Quantity

1 401279 Front Tube WA 1

2 401285 Front Tube LH WA 1

3 401287 Front Corner Floor Plate 1

4 401288 Front Corner Floor Plate LH 1

5 401289 Floor Strip LH 1

6 401290 Floor Strip 1

7 401291 Rear Tube WA 1

8 401295 Rear Tube LH WA 1

9 401352 Pedal WA 1

10 401356 Pedal Axle 1

11 401357 Pedal Spacer 1

12 401358 Pedal Support Plate 1

13 401365 Rear Mudguard 1

14 401366 Rear Mudguard LH 1

15 401384 Front Tube WA 1

16 401387 Front Centre Cover 1

17 401388 Front Cover 1

18 401389 Front Cover Bracket 1

19 BA1009 Bush Oilite Al1218 2

20 SP01009 Hex Set Screw M8 x 20 43

21 SP01045 Hex Set Screw M8 x 25 8

22 SP02006 Nut M8 Nyloc (T) 29

23 SP02044 Rivnut Hex M8 (0.5-3.0) [No Head] 18

24 SP03008 Washer M8 Form A 18

25 SP03015 Washer M8 Form C 5

3.01 Floor Assembly

13

20 24

22

22

24

14

20

22

6

24

20

73

21

20

25

22

12

21 24

22

10 11

25

22

19

1

922

15

21

2

4

22

20

20

23

8

17

20

22

18

5

20

16

24

BRUSH-PRO FEB ‘15

11

4.01 Rear Brushes

Item No. Part No. Description Quantity

1 401215 Rear Brush Support Frame 1

2 401216 Bottom Pivot Arm 1

3 401219 Top Pivot Arm WA 1

4 401225 Lift Arm Link 2

5 401229 Plate Actuator Link 2

6 401336 Boss Angle Plate 3

7 401337 Boss Actuator 2

8 D8032 Bearing Flange 25ID 2

9 D8955 Tube Bung 40 x 40 1

10 D8956 Insert 50 x 25 4

11 E1-1110 Hex Set Screw M8 x 40 3

12 E1-1181 M16 x 130 Hex Bolt 5

13 SP06021 Bearing 2 Bolt Flange 16ID 10

14 F22314 Gas Strut 2

15 F22319 Linear Actuator 130 1

16 F37330 Rear Side Brush Frame WA (Black) 2

16 403135 Rear Side Brush Frame WA (Yellow) 2

17 F37332 Rear Brush Frame WA (Black) 1

17 403130 Rear Brush Frame WA (Yellow) 1

18 F37598 Rear Side Brush (Black) 2

18 SP24006 Rear Side Brush (Yellow) 2

19 F37599 Rear Brush (Black) 1

19A 403134 Rear Brush (Yellow) 1

19B SP24006 Rear Brush (Yellow) 1

20 SP01005 Hex Set Screw M8 x 30 4

21 SP01009 Hex Set Screw M8 x 20 4

22 SP01022 Hex Set Screw M8 x 50 1

23 SP01022 Hex Set Screw M8 x 50 3

24 SP01023 Hex Set Screw M8 x 60 10

25 SP01028 Hex Set Screw M6 x 20 20

26 SP02002 Nut M5 Nyloc (T) 20

27 SP02006 Nut M8 Nyloc (T) 29

28 SP02028 Nut M16 Nyloc (T) 5

29 SP03008 Washer M8 Form A 10

30 SP12032 Connector Bulgin Skt 2W 1

31 SP12033 Chassis Connector Bulgin Pin 2W 1

32 SP12034 Pin Contact 2W Bulgin Soldered 2

33 SP12035 Socket Contact 2W Bulgin Soldered 2

12

29

20

27

5

15

7

27

29

35 33

30

5

11

4

6

4

29

7

23

28

18

12

9

10

12

13

25 26

10

21

8

27

3

26

25

13

10 24

27

19

27

32

31

34

14

27

26

13

12

25

16

36

17

1

19A

19B

19B

Item No. Part No. Description Quantity

34 SP12036 Cap Sealing Chassis Connector 1

35 SP12037 Cap Sealing Connector 1

36 403137 Bush Lift Arm 1

BRUSH-PRO FEB ‘15

12

Item No. Part No. Description Quantity

1 229011 Pinion Shaft 11T 1

2 401230 Suspension Arm Assembly 1

3 401263 Stub WA 2 1

4 401265 Stub WA 1 1

5 401274 Steer Rack WA 1

6 401323 Steering Frame WA 1

7 401330 Steering Side Plate 2

8 401368 Steering Upper Bush WA 1

9 401371 Steering Column WA 1

10 401376 Steering Column Cover 1

11 401377 Column Pivot Cover WA 1

12 401391 Steering Connecting Shaft 1

13 401392 Steering Wheel Shaft 1

14 401393 Column Pivot Spigot 2

15 401394 Centre Cover 1

16 401395 Centre Pocket Cover 1

17 F35835 Shaft Washer 4

18 401430 Steering Connecting Rod 1

19 401431 Steering Rod 1

20 401525 Latch Pivot Pin 1

21 401606 Bracket Spring Lower 1

22 401607 Steering UJ Machined 1

23 401620 Steering Bearing Housing 1

24 401623 Steering Plate 1

25 401635 Latch Arm WA 1

26 401639 Latch Foot Pin 1

27 BA1009 Bush Oilite AL1218 2

28 D1376 Spring 1/2” Bore x 14 Swg x 3 1

29 D1947 Grease Nipple M6 2

30 D8032 Bearing Flange 25Id 2

31 D8035 Key Parallel 5 x 5 x 25 1

32 F20384 Caphead M8 x 25 2

33 F21706 Ball Joint 4

34 F21739 Bobbin M8 Rubber 5

35 F22396 Oilite Bush 25 x 30 x 25 Flanged 4

36 J20052 Bearing 6204-2RS 3 4

37 SP01009 Hex Set Screw M8 x 20 4

38 SP01015 Hex Set Screw M6 x 25 4

5.01 Steering Assembly

Item No. Part No. Description Quantity

39 SP01035 Hex Set Screw M10 x 25 2

40 SP01045 Hex Set Screw M8 x 25 28

41 SP01049 Cap Head M8 x 20 2

42 SP01076 Hex Set Screw M8 x 16 2

43 SP01105 Hex Set Screw M10 x 30 4

44 SP02004 Nut M6 Nyloc 4

45 SP02005 Nut M8 Std 2

46 SP02006 Nut M8 Nyloc (T) 30

47 SP02008 Nut M10 Nyloc (T) 7

48 SP02013 Nut M10 Lock (Thin) 1

49 SP02044 Rivnut Hex M8 (0.5-3.0) [No Head] 29

50 SP03008 Washer M8 Form A 4

51 SP03016 Washer M10 Form C 5

52 SP03029 Washer M8 Spring Lock 13

53 SP05008 Pin Spirol M5 x 50 2

54 SP05013 Pin Spirol M5 x 30 1

55 SP06006 Bush Oilite AI2026 - 25 1

56 SP06018 Bush Oilite Flanged Al1620 - 25 2

57 SP07006 Circlip D1400 - 20 1

58 SP14012 Steering Wheel 12” Plastic 1

47

52

56

27

29

25

22

53

11

42

46

40

10

9

55

13

15

52

40

40

16

31

58

51

7

44

6

43

51

47

8

34

46

40

38

14

39

46

34

52

32

33

19

33

18

48

36

34

46

52

17

29

2

46

35

17

40

30

24

46

29

36

23

37

1

5

12

54

57

41

14

38

26

28

21

40

46

BRUSH-PRO FEB ‘15

13

6.01 Main Chassis

Item No. Part No. Description Quantity

1 20194 Key 1/4” x 1/4” x 2” Rd End 1

2 240169 Sensor Angle Plate 1

3 401200 Engine Plate 1

4 401204 Frame Weldment LH 1

5 401205 Frame Weldment RH 1

6 401209 Upper Lower Drive Plate 2

7 401239 Backplate WA 1

8 401269 Control Panel Post 4

9 401277 Seat Rail Boss 4

10 401278 Tensioner Offset Plate 1

11 401297 Rear Tube Face Plate 2

12 401299 Chassis Front Cover 1

13 401300 Battery Support Bracket 1

14 401319 Speed Connecting Rod WA 1

15 401322 Pedal Connecting WA 1

16 401342 Belt Tensioner WA 1

17 401347 Tensioner Bracket WA 1

18 401348 Belt Finger Brush Pulley 2

19 401349 Belt Finger Cable Bracket 1

20 401350 Brake Cable Brcket 1

21 401351 Axle Engage Rod 1

22 401367 Wheel Hub 2

23 401428 Sprocket Drive Shaft WA 1

24 401429 Pulley Drive Shaft 1

25 401432 Brake Link 1

26 401433 Axle Hose 3/4” 1

27 401434 Tank Hose 5/8” 1

28 401590 Pulley 80Pcd A Rosca 1

29 401591 Pulley Belt Disc 1

30 401601 Tube Axle 2

31 401602 Axle Support Bracket 1

32 401608 Centre Cover 1

33 401611 Belt Guide 2

34 401616 Bracket Ms Drive Engage 1

35 401788 Crank Drive Engage WA 1

36 401789 Rod Drive Engage 1

37 D1989 Grub Screw M6 x 10 2

38 D7094 Wheel Bolt M12 8

39 D8032 Bearing Flange 25ID 3

40 D8048 Bearing Flange Mounted 20 Bore 1

41 SP11035 Pulley 1

41A 403138 Pulley Spacer 1

42 D8907 Washer Copper 1/4” Bsp 2

43 E1-1062 M8 Spring Washer 8

44 E1-1063 M10 Spring Washer 6

45 E1-1134 Hex Set Screw M10 x 80 4

46 F20664 Reservoir 1

47 F21623 Jubilee Clip 1A 2

48 F21706 Ball Joint 5

50 F21774 Belt V 1EJ Cotton A50 1300 1

51 F21784 Key 8 x 7 x 30 2

52 F21922 Vibration Mount 4

Item No. Part No. Description Quantity

53 F22078 15T Sprocket 1

54 F22269 Gearbox 1

55 F22326 57T Sprocket 1

56 F35835 Washer 2

57 F37300 250PCD Pulley 1

58 F37302 12T 0.5P Sprocket 1

59 F37358 Spider Coupling MC From 22329 1

60 F37611 Hydaulic Hose Assy 1

61 J20017 Knob - Red 1

62 J209085 Bush Oilite Am1216 - 20 4

63 J209104 Pin Spirol M6 x 50 1

64 MD919 Key 1/4” x 1/4” x 1 3/4” Rd End 2

65 SP01005 Hex Set Screw M8 x 30 3

66 SP01009 Hex Set Screw M8 x 20 45

67 SP01013 Hex Set Screw 3/8” UNF x 2” 1

68 SP01015 Hex Set Screw M6 x 25 2

69 SP01035 Hex Set Screw M10 x 25 6

70 SP01036 Hex Set Screw M8 x 35 8

71 SP01045 Hex Set Screw M8 x 25 5

72 SP01049 Cap Head M8 x 20 1

73 SP01069 Button Head M5 x 12 2

74 SP01070 Cap Head M2 x 12 2

75 SP01108 Hex Set Screw M6 x 40 1

76 SP01123 Csk Socket Screw M5 x 12 3

77 SP02002 Nut M5 Nyloc (T) 4

78 SP02003 Nut M6 Std 1

79 SP02004 Nut M6 Nyloc 3

80 SP02006 Nut M8 Nyloc (T) 45

81 SP02008 Nut M10 Nyloc (T) 4

82 SP02010 Nut M12 Nyloc (T) 8

83 SP02012 M8 Thin Lock Nut 1

84 SP02013 Nut M10 Lock (Thin) 2

85 SP02018 Nut 3/8” Unf Nyloc (T) 1

86 SP02028 Nut M16 Nyloc (T) 1

87 SP02032 Nut M2 Std 2

88 SP02044 Rivnut Hex M8 (0.5-3.0) [No Head] 14

89 SP03008 Washer M8 Form A 4

90 SP03011 Washer M10 Form A 2

91 SP03015 Washer M8 Form C 7

92 SP03029 Washer M8 Spring Lock 2

93 SP10005 Key 6 x 6 x 30 Rd End 1

94 SP11008 Tensioner Arm SE15 1

95 SP11026 Tapered Bush 2012 - 25mm 1

96 SP12008 Micro Switch Wheel 1

97 SP13005 Spring Tension 0.91 x 11.1 x 63.5 1

98 SP15002 Engine Honda GXV390 1

99 SP26006 Hose Reducer 3/4” To 5/8” 1

100 F22358 Seat 1

101 F20783 Wheel Assembly (Smooth) 2

101 SP09004 Wheel Assembly (Treaded) 2

102 F22269A Connector 1

41

47

66

14

42

63

60

15

47

38

22

30

64

80

26

99

68

79

46

27

48

1

50

59

76

29

28 37

71

7

33

52

3

51

66 72

43

94

53

81

69

80

66

80

40

10

90

65

39

97

86

23

66

12

65

24

18

66

51

93

58

55

95

66

6

57

98

32

70

9

19

39

56

43

75

20

44 69

80

25

71

8

66 11

80

35

62

80

91

77

62

80

85

16

17

74

73

34

87

31

66

47

21

78

80

80

66

80

84

2

61

36

13

66

92

47

66

101

100

102

R

Table of contents

Other Sisis Lawn And Garden Equipment manuals