Belimo AF24-LIN US User manual

AF24-LIN US Damper Linearizing Actuator

Damper actuator, Spring Return, 24 VAC/DC power, 2 to 10 VDC and 4 to 20 mA control signal.

Output signal of 2 to 10 VDC for position indication. Programmable rotation with respect to control signal.

I20652 - 04/-06 - Subject to change. © Belimo Aircontrols (USA), INC.

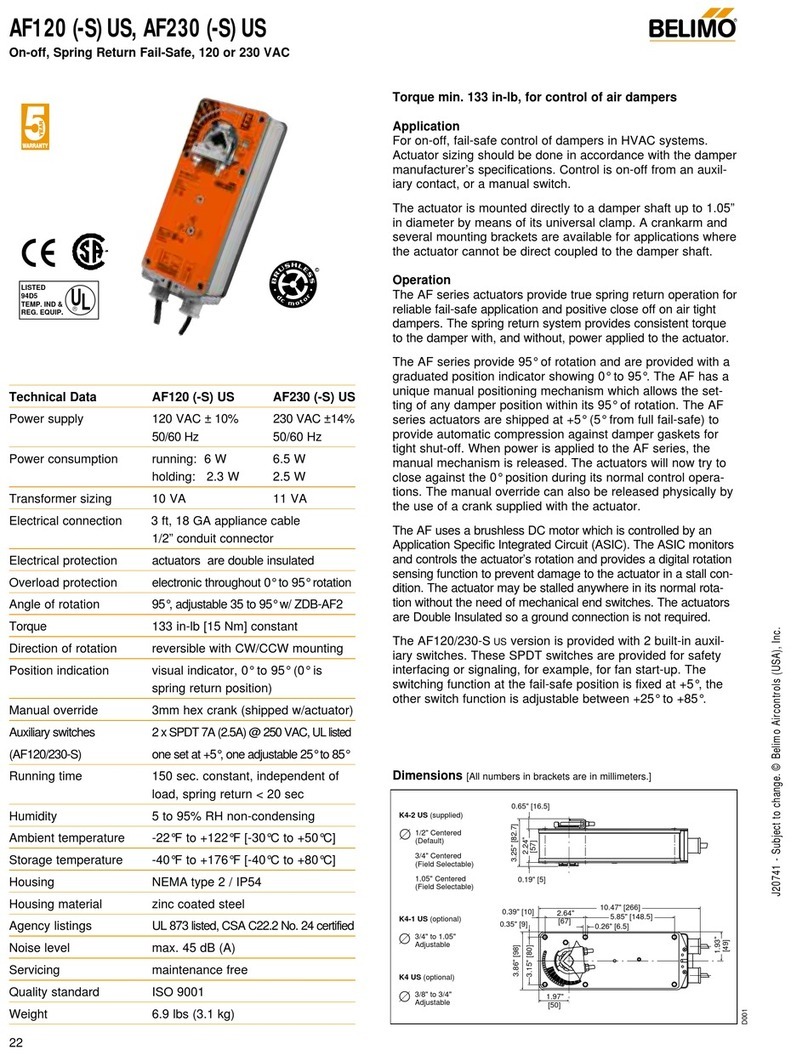

1.97"

3.15" [80]

3.86" [98] 3.10" [78]

2.24"

[57]

[50]

1.93"

[49]

2.64"

[67] 0.26" [6.5]

5.85" [148.5]

10.59" [269]

0.35" [9]

0.39" [10]

0.65" [16.5]

0.19" [5]

Standard:

1/2" to 1.05"

Optional*

3/8" to 3/4"

3/8" to 5/8"

*with K4 US

clamp

®

70635-00001

Torque min. 133 in-lb, for control of air dampers

Application

For proportional modulation of dampers where linear air flow

response with respect to input signal is required..

The concept of the linearizing actuator is based on the need

recognized in problem applications where the non-linearities of

dampers themselves, linkages or jackshafts, or other geomet-

ric effects cause severe modification of flow response.

The actuator operates in response to a 2 to 10 VDC, or with

the addition of a 500Ωresistor, a 4 to 20 mA control input

from an electronic controller or positioner. A 2 to 10 VDC

feedback signal is provided for position indication or master-

slave applications.

Operation

The AF24-LIN US series actuators provide true spring return

operation for reliable fail-safe application and positive close-off

on control dampers.The spring return system provides con-

stant torque to the damper with, and without, power applied to

the actuator.

The AF24-LIN US series provides 95° of rotation and is pro-

vided with a graduated position indicator showing 0 to 90°.

The AF24-LIN US has a manual positioning crank arm which

allows the setting of any damper position within its 95° of rota-

tion.

The actuator manual override allows pre-load to provide auto-

matic compression against damper gaskets for tight shut-off.

When power is applied, the manual mechanism is released

and the actuator drives toward the full fail-safe position. The

actuator will memorize the angle where it stops rotating and

use this point for its zero position for its normal control opera-

tions. The manual override can also be released physically by

the use of a crank supplied with the actuator.

The AF24-LIN US uses a brushless DC motor which is con-

trolled by a microprocessor. The actuator may be stalled any-

where in its normal rotation without damage.

The actuator is programmed using ZIP-RS232 hardware and

the laptop software embedded within an Excel® program. The

damper manufacturer provides a chart with the signal versus

required rotation that provides a linear air flow response with

respect to the signal. Alternately the TAB and control contrac-

tor can field adjust the program.

Dimensions [All numbers in brackets are in millimeters.]

Technical Data AF24-LIN US

Power supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power consumption running: 6 W ; holding: 2.5 W

Transformer sizing 10 VA (class 2 power source)

Electrical connection

Motor 3 ft, 18 GA 4 color leads (24V)

Auxiliary switches 3 ft, 18 GA appliance cable

1/2” conduit connector

Overload protection Electronic throughout 0 to 95° rotation

Operating rangeY 2to10VDC,4to20mA

Input impedance 100 kΩ(0.1 mA), 500Ωfor 4-20 mA

Feedback output U 2 to 10VDC (max.0.5 mA) for 95°

Angle of rotation Mechanically limited to 95°

Torque 133 in-lb [15 Nm] constant

Direction of rotation Spring return reversible with CW/CCW

mounting. The control direction switch

can be used to change the action from

direct to reverse.

Position indication Visual indicator, 0° to 90° (0° is default

spring return position)

Manual override 3mm hex crank (shipped w/actuator)

Running time 150 sec. constant, independent of load,

spring return 19 seconds nominal

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to +122°F [-30°C to +50°C]

Storage temperature -40°F to +176°F [-40°C to +80°C]

Gears Permanently lubricated

Housing NEMA type 2 / IP54

Housing material Zinc coated metal

Agency listings cULus listed to UL873 and CAN/CSA C22.2

No.24, CE

Noise level Maximum 45 dB (A)

Servicing Maintenance free

Quality standard ISO 9001, 5 year Belimo warranty

Weight 6.0 lbs (2.7 kg.)

MFT options Adjustable rotation per volt signal change

D004

1

I20652 - 04/-06 - Subject to change. © Belimo Aircontrols (USA), INC.

2

AF24-LIN US Damper Linearizing Actuator

Damper actuator, Spring Return, 24 VAC/DC power, 2 to 10 VDC and 4 to 20 mA control signal.

Mechanical Accessories

All AF series accessories may be employed:

IND-AF2 Damper position indicator

K4 US Universal clamp for 3/8” to 3/4” shafts

K4-1 US Universal clamp for up to 1.05” dia. jackshafts

K4-H Universal clamp for hexshafts 3/8” to 5/8”

KH-AF Crankarm for up to 3/4” round shaft (Series 2)

KH-AF-1 Crankarm for up to 1.05” jackshaft (Series 2)

KH-AFV V-bolt kit for KH-AF and KH-AF-1

Tool-01 10 mm wrench

SGA24 Min.and/or max. positioner in NEMA 4 housing

SGF24 Min.and/or max. positioner for flush panel mounting

ZDB-AF2 Angle of rotation limiter

ZG-100 Universal mounting bracket

ZG-101 Universal mounting bracket

ZG-102 Multiple actuator mounting bracket

ZG-103 Universal mounting bracket

ZG-104 Universal mounting bracket

ZG-106 Mounting bracket for Honeywell®Mod IV replace-

ment or new crankarm type installations

ZG-107 Mounting bracket for Honeywell®Mod III or Johnson®

Series 100 replacement or new crankarm type

installations

ZG-108 Mounting bracket for Barber Colman®MA 3../4..,

Honeywell®Mod III or IV or Johnson®Series 100

replacement or new crankarm type installations

ZG-AF Crankarm adaptor kit for AF/NF

ZG-AF108 Crankarm adaptor kit for AF/NF

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

ZS-260 Explosion-proof housing

ZS-300 NEMA 4X housing

For an overview of how to apply the accessories, see

Belimo Mechanical Accessories and refer to the Belimo

Mounting Methods Guide.

Go to www.belimo.us or www.belimo.ca. Then click on

“AF Linearizing Actuator” section for extensive details.

Wiring diagrams

1 Common

2 + Hot

3 Y1Input, 2 to 10V

5 U Output 2 to 10V

1

1

2

3

24 VAC Transformer

Provide overload protection and disconnect as required.

Actuators may be connected in parallel. Power consumption

and input impedance must be observed.

Actuator may also be powered by 24 VDC.

4The ZG-R01 500Ω resistor converts the 4 to 20mA.

Maximum 4 actuators parrelleled on 4 to 20 mA.

5Only connect common to neg. (—) leg of control circuits.

5

3

2

4

Control Signal (+)

4 to 20 mA

(–)

Feedback Signal

(+)

2 to 10VDC

(–)

Ω

500Ω

Line

Volts

Control Signal (+)

2 to 10VDC

(–)

1 Blk Com

2 Red + Hot

3 Wht Y1Input, 2 to 10V

5 Wht U Output 2 to 10V

1

2

3

24 VAC Transformer

AF24-LIN US

AF24-LIN US

Line

Volts

1

2

3

1

2

3

Provide overload protection and disconnect as required.

Actuators may be connected in parallel. Power consumption and input impedance must be observed.

Actuator may also be powered by 24 VDC.

4

4

5

The ZG-R01 500 resistor converts the 4 to 20 mA. Maximum 4 actuators paralleled on 4 to 20 mA.

Control Signal (+)

2 to 10VDC

(–)

1

2

3

5

1

1

2

3

24 VAC Transformer

AF24-LIN US

1

2

3

5

2

22

AF24-SR/MFT

Line

Volts

Control Signal (+)

4 to 20 mA

(–)

1

2

3

24 VAC Transformer

AF24-LIN US AF24-LIN US

Line

Volts

Mechanically paralleled actuators must be wired 5 to 3.

Electrically paralleled actuators may be wired 3 to 3 or 5 to 3.

Ω

500Ω

5

5

3

Specifications

Dampers on AH units…(name)…shall be linearized using Belimo

AF24-LIN US actuators. The control signal shall be 2-10V or 4-

20mA. Balancer shall confirm that the air flow quantity does not vary

more than ± 10% from linear with respect to the control signal.

Contractor shall provide damper manufacturer or Belimo with the fol-

lowing information:

(1) Closest AMCA figure number representing the geometry of

the installation.

(2) Damper type - Opposed Blade or Parallel Blade and presence

of jackshaft or linkage if any.

(3) Approximate authority of each damper.

Actuators shall be programmed for linearization of the damper by the

damper manufacturer or the contractor in the field as appropriate.

Safety Note

Screw a conduit fitting into the actuator’s metal bushing. Jacket the

actuator’s input and output wiring with suitable flexible conduit.

Properly terminate the conduit in a suitable junction box.

Go to to www.belimo.us or www.belimo.ca. Then click on “AF

Linearizing Actuator”for laptop program, tutorial, and other files.

W441

W442

®

Mechanically paralleled - piggyback (5 to 3)

and Electrically paralleled (3 to 3).

I20652 - 04/-06 - Subject to change. © Belimo Aircontrols (USA), INC.

3

Default Program

The feedback is set to allow slave actuators to follow accurate-

ly. It is for this reason that the feedback is 30%. If a standard

2-10V slave actuator is driven from wire 5, then that actuator

will position at the 4.5V position as calculated already.

In other words, a standard 2-10V actuator may be paralleled

with a LIN actuator if wire 5 is used to control the standard

actuator. If paralleling LIN actuators, wire 3 should be used as

input for both.

The default program outputs 8.6V at 100% open. (That is

(.94 x 8V) + 2V This AMCA application produces 100% flow

at 85% open, that is .85 x 90º. (See files.) 85º/95º= 94%.

The readings will vary slightly. For example, assume the LIN

master actuator is full closed at 0ºand the slave actuator is

full closed at -5º. In that case, the damper will position cor-

rectly for the flow, but the LIN actuator will be 80ºopen per

the indicator while the slave is 75ºaccording to the indicator.

Mechanically paralleled actuators.

While electrically paralleled actuators may be wired Signal to

3 to 3 to 3, etc., mechanically paralleled (“piggyback”) actua-

tors must be wired using Signal to 3, 5 to 3 to 3 to 3 (maxi-

mum 4 actuators). See Figure on page 1.

When the signal to a LIN increases and the actuator does not

move due to mechanical load, the wire 5 stops being a feed-

back after a few seconds. It then increases the voltage on wire

5 above the signal input for a few seconds.The follower actua-

tor then starts to move and the actuators track together.This

algorithm has been used for years by Belimo and works well.

Adaptation.

The LIN actuators do not adapt at startup or upon power inter-

ruption. If one needs the actuator to adapt, then rotate the

crank winder two times. The actuator will drive closed, then

drive to the full open position (typically limited by the damper

or linkage geometry), and then drives to the control signal

position.

The actuator will not adapt to be more open than the program

indicates.

For example, if the damper is limited to 80 degrees open and

the actuator is adapted, then 100% signal input (10V) will

cause the actuator to drive 80 degrees open. This changes

the actuator's position calculation for other points also.

If 6V (50% signal, 32% rotation) is applied, the actuator drives

.32 x 80º= 26º.That damper angle would produce 50% of

maximum airflow. Program adjustment would likely be needed.

The actuator has a default program as below. 5% refers to

the damper authority.

Actuator Functionality

Initial startup.

Upon powerup, the AF24-LIN US will drive back and find the

true damper 0 position. It sets the 0% (2V or 4mA) signal

position here.When the signal is increased beyond 2V, the

actuator drives to the programmed position for that signal

input. For example, if the signal is 6V, which is 50% in the pro-

gram, and the default program is active, then the actuator will

drive to 32% open. See the AMCA 5.2 OB 5% chart above.

In an AMCA 5.2 OB 5% Authority application, 32% open will

produce approximately 50% flow through the damper.

Feedback.

Continuing the example above:

The feedback will be 32% or about 4.5V when the signal input

is 6V or 50%. That is (.32 x 8V) + 2V.

For approximation in degrees, use 32% = .32 times 90º= 29º.

Instruments and actuators vary slightly, approximate accuracy

is sufficient.

®

AMCA 5.2 OB

damper authority 5%

Input Input Rotation Angle

Signal [V] Signal [%] [% of 95°]

20% 0%

312.5% 7%

425.0% 15%

537.5% 21%

650.0% 32%

762.5% 43%

875.0% 53%

987.5% 67%

10 100% 94%

Note that the rotation angle of the default linearization curve is

based on a 0 to 95°range, so 0% equals 0°, 100% equals 95°.

I20652 - 04/-06 - Subject to change. © Belimo Aircontrols (USA), INC.

Technical Data ZIP-RS232 US

Supply Voltage 24 VAC; Class II power supply

Power Consumption 1 W / 1.5 VA (without actuator)

Electrical protection MFT-XFMR is internally protected and

automatically resets

Connections Power supply; Stereo connector

Actuator; manual push button terminals

MP-Bus; Orange male connector, part

number ZKS-MP (Optional)

RS232; PC cable, sub-D, 9 pin,

female/female, included

Operating temperature 0°to +122°F

Storage temperature -40°F to +176°F

Electrical safety Class III

Weight <1.0 lb. (without actuator)

ZIP-RS232 US

For interfacing PC with…MFT US type actuators

®

Power supply

The MFT-XFMR accessory transformer is connected to the

unit, and supplies 24 VAC power to the ZIP-RS232 and up to

one connected actuator. The actuator on switch powers the

actuator. Separate actuator 24V may also be used.

RS232 connector

The ZIP-RS232 is connected via this RS232 connector to the PC

with a standard female-female 9-pin sub-D cable, provided.

LEDS

A Green LED is lit when 24 VAC is supplied.

Tx: LED flashes when data flows from ZIP-RS232 to actuator.

Rx: LED flashes when data flows from actuator to ZIP-RS232.

EN: LED is lit constantly when RS232 device is connected.

Accessories

Null modem serial cables can be used by switching the

ZIP-RS232 internal jumpers.

System Transformer Powered

1

2

3

5

Common

+ Hot

Control signal“Y”

U5 Diagnostics

…MFT US

RS232

D-Sub

RS232

D-Sub

ZIP-RS232

Actuator

ON

OFF 12 5

PC

24 VAC

_

T

+

~

_

T

+

~

UPP

Tx Rx EN

MP-BusSupply U5PP EN

T

24VAC/DC

50/60 Hz

1.5VA 1W

MFT-XFMR

Optional wiring via 24V

Class 2 transformer

Line voltage

Com

Hot

Standard jumper

setting Jumper setting for

null-modem cable

RS232

D-Sub

RS232

D-Sub

RS 232

ZIP-RS232

Actuator

ON

OFF

12 5

_

T

+

~

_

T

+

~

_

T

+

~

U

PP

1235

U

PP

MFT

AC 24V

DC 24V

!

Connect via

safety isolating

transformer.

Programming.

The LIN actuators do not have MFT program capacity.

The signal input is always 2-10V or 4-20mA.

Adjustable rotation with respect to signal programming.

Go to to www.belimo.us or www.belimo.ca. Then click on “AF

Linearizing Actuator”for laptop program, tutorial, and other files.

MFT-XFRM Powered

4

Other Belimo Controllers manuals

Belimo

Belimo SY-3-T-TS Series Quick start guide

Belimo

Belimo LF-2 Series User manual

Belimo

Belimo AFX24LON User manual

Belimo

Belimo AFRB24-SR Manual

Belimo

Belimo PR User manual

Belimo

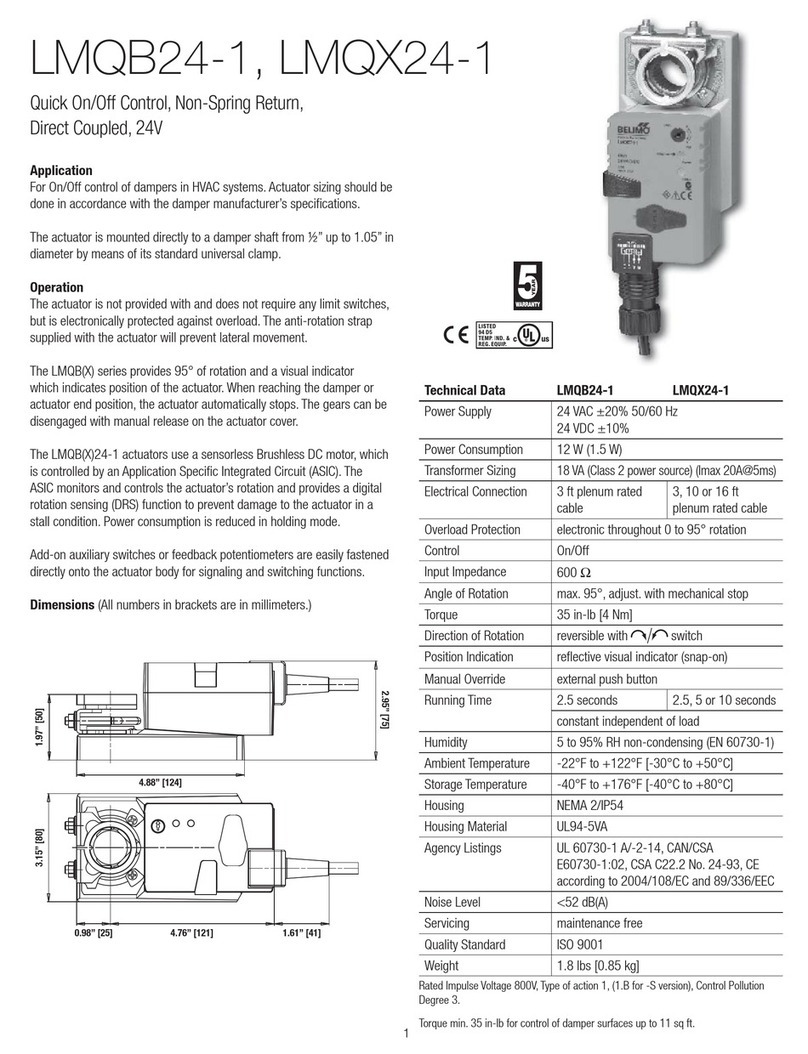

Belimo LMQB24-1 User manual

Belimo

Belimo NMQB24-MFT User manual

Belimo

Belimo LRB24-3 User manual

Belimo

Belimo FS Series Use and care manual

Belimo

Belimo AF24-SR US Parts list manual

Belimo

Belimo NF24A-SR-S2 Instruction Manual

Belimo

Belimo GM24 US User manual

Belimo

Belimo NM24A-MP Instruction Manual

Belimo

Belimo LonWorks NMX24-LON User manual

Belimo

Belimo TR24-SR User manual

Belimo

Belimo LMB series User manual

Belimo

Belimo NMB24-SR User manual

Belimo

Belimo CQB24-3 User manual

Belimo

Belimo AMB24-SR-X1 User manual

Belimo

Belimo TFC120-S US User manual