1. Introduction

1.1 About SGC 110............................................................................................................................................................................................................................ 4

1.2 Key functions............................................................................................................................................................................................................................... 4

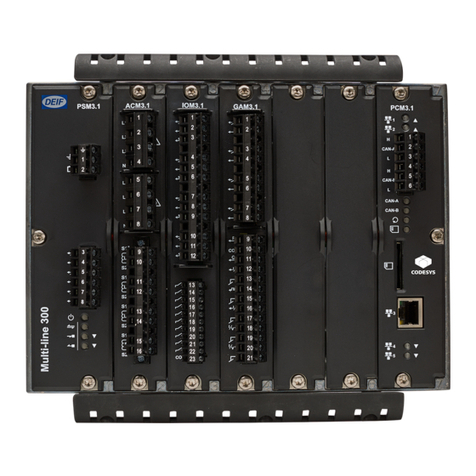

1.3 Product overview....................................................................................................................................................................................................................... 4

1.4 Passwords..................................................................................................................................................................................................................................... 5

1.5 Overview of controller buttons...........................................................................................................................................................................................5

1.6 Legal information.......................................................................................................................................................................................................................6

2. Safety instructions

2.1 General safety instructions.................................................................................................................................................................................................. 7

2.2 Electrical safety...........................................................................................................................................................................................................................7

2.3 In operation safety.....................................................................................................................................................................................................................7

3. Technical_specifications

3.1 Terminals........................................................................................................................................................................................................................................ 8

3.2 Power supply................................................................................................................................................................................................................................8

3.3 Genset voltage and frequency measurements..........................................................................................................................................................9

3.4 Digital inputs................................................................................................................................................................................................................................ 9

3.5 Analogue resistive sensor inputs.....................................................................................................................................................................................9

3.6 Analogue inputs used as digital inputs...................................................................................................................................................................... 10

3.7 D+ Charger alternator........................................................................................................................................................................................................... 10

3.8 Sensor common point...........................................................................................................................................................................................................11

3.9 Digital outputs...........................................................................................................................................................................................................................11

3.10 Communication ports.........................................................................................................................................................................................................11

4. Installation

4.1 Dimensions.................................................................................................................................................................................................................................12

4.2 Mounting in panel....................................................................................................................................................................................................................12

4.3 Terminal details........................................................................................................................................................................................................................ 13

4.4 Typical wiring diagram......................................................................................................................................................................................................... 15

5. Monitoring mode

5.1 Monitoring mode......................................................................................................................................................................................................................16

6. Configuration mode

6.1 Configuration mode............................................................................................................................................................................................................... 17

6.2 Configurable parameters.................................................................................................................................................................................................... 17

6.2.1 Configurable parameters..............................................................................................................................................................................................17

6.2.2 Module..................................................................................................................................................................................................................................18

6.2.3 Digital inputs...................................................................................................................................................................................................................... 18

6.2.4 Analogue inputs................................................................................................................................................................................................................19

6.2.5 Outputs.................................................................................................................................................................................................................................21

6.2.6 Timers...................................................................................................................................................................................................................................21

6.2.7 Generator............................................................................................................................................................................................................................22

6.2.8 Engine.................................................................................................................................................................................................................................. 23

6.2.9 Maintenance...................................................................................................................................................................................................................... 25

6.2.10 Password ID....................................................................................................................................................................................................................25

6.3 Digital input source selection...........................................................................................................................................................................................26

6.4 Digital output source selection........................................................................................................................................................................................26

7. Running modes

7.1 Remote start/stop mode...................................................................................................................................................................................................... 28

USER MANUAL 4189341228A UK Page 2 of 34