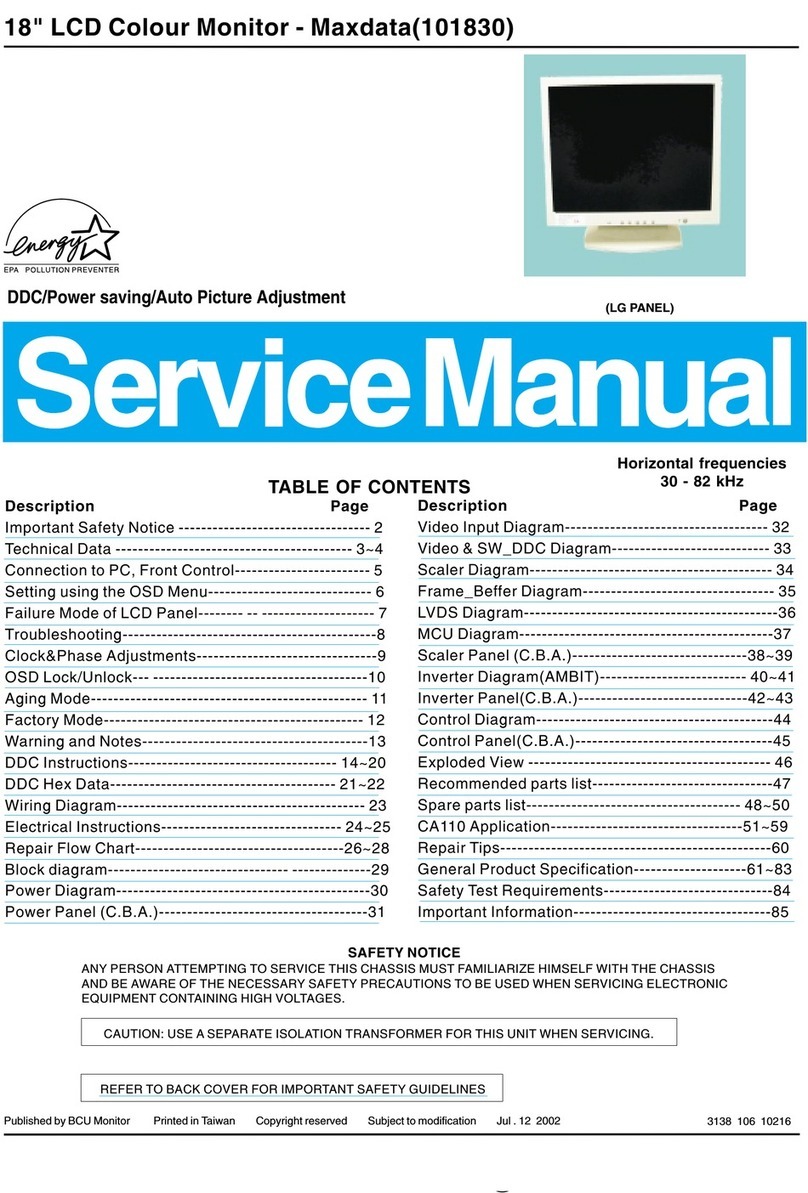

BELINEA 10 55 70 User manual

Notes

Belinea

IO

55 70 Service Manual

??

Preface

??

Before You Start

General Safety Precautions

1.

2.

3.

Use an isolation transformer in

the

power line and AC

supply to troubleshoot.

When servicing, observe the original lead dress, espe-

cially in the high voltage circuits. If a short circuit is

found, replace all parts which have been overheated or

damaged.

Before turing the display on, measure the resistance

between B+ line and chassis ground. Connect the nega-

tive side of an ohmmeter to the B+ lines and the positive

side to chassis ground. Each line should have more

resisstance

than the following specifications:

B+ Line Minimum Resistance

+2oov

119.5am

+75v

a.77m

4.

Potentials, as high as

25kV

are present when this display

is in operation. Operation of the display without the rear

cover involves the danger of a shock hazard from the

display power supply. Servicing should not be at-

tempted by anyone who is not thoroughly familiar with

the precautions necessary when working on high volt-

age equipment. Always discharge the anode of the pic-

ture tube to the display chassis before handling the tube.

5.

After servicing, be sure to check the items listed in the

Safety Checkout, below before returning the serviced

unit to the customer.

Safety Checkout

The following checks must be made after correcting

the

original service problem and before the unit is returned to the

customer.

1.

2.

3.

4.

5.

6.

7.

8.

Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface for

solder splashes and bridges.

Check the inter board wiring to ensure that no wires are

pinched or coated

with

high-wattage resistors.

Check that all control knobs, shields, covers, ground

straps and mounting hardware have been replaced.

Makde absolutely sure you have replaced all the

insula-

t0l-S.

Look for any unauthorized replacement parts, particu-

larly transistors, that may have been installed dueing a

previous repair. Point

them

out to the

cusstomer

land

recommend their replacement.

Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

Check the line cord for

cracks

and abrasion. Recom-

mend the replacement of any such line cord to the

customer.

After making any repair, check the B+ and HV to see

whether they are at the values specified. Make sure your

instruments are accurate; if your HV meter always

shows a low HV, check the meter

lo

ensure it is not

malfunctioning.

Carry out the leakage current checks as detailed below

overleaf.

Leakage Current Cold Check

1.

Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Turn on the display power switch.

3.

Use an ohmmeter to measure

the

resistance value

bc-

twcen

the

jumpered

AC plug and

each

exposed metallic

cabint part on the display, such as screwheads, terminals

control shafts.

etc.

When

an

exposed

metallic

part has a

return path to the chassis, the reading should be bctwccn

240k and

5.2M.

When exposed metal does not

have

a

return

path

lo

the chassis,

the

reading must be.

Leakage Current Hot Check How to Find A Good Earth

1.

Plug the AC cord into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a

1.5k,

10 watt resistor in parallel with a 0.15F

capacitor between each exposed metallic part on the set

and a good earth ground (see How to Find a Good Earth,

below) as shown in the diagram below.

A cold water pipe is a guaranteed earth ground; the cover plate

retaining screw on most AC outlet boxes is also at earth

ground. If the retaining screw is to be used as your earth

ground, verify that it is at ground by measuring the resistance

between it and a cold water pipe with an ohmmeter. The

reading should be zero (0) ohms. If a cold water pipe is not

accessible, connect a 60-100 watt trouble light (not a neon

lamp) between the hot side of an AC power receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot

side of the line. The lamp should light at

normal

brilliance if

the screw is at ground potential

r

.

Leakage Current Hot-Chedc Circuit

AC

VOLTMETER

Example of Leakage Current Hot-Check Circuit

3.

4.

5.

6.

Use an AC voltmeter with 1000 ohms/volt or more

sensitivity to measure the potential across the resistor.

Check each exposed metallic part, and measure the

voltage at each point.

Reverse the polarity of the AC plug in the AC outlet and

repeat the above measurements.

The potential at any point should not exceed 0.75 volt

RMS. A leakage current tester (Simpson Model 229,

RCA WT-540A or equivalent) may be used to make the

hot checks.

Trouble light

Cold water

pipe

How to Check for Earth Ground

Leakage current must not exceed 0.5 milliarnp. If a measure-

ment is outside of the specified limit, there is a possibility of

a shock hazard and the monitor should be repaired and re-

checked before it is returned to the customer.

cm

i-

Disassembly Instructions

r

PaH

1.

VA Version

.-

2.1.

Removing the Rear Cover. . . . . . . . . . . . . . . . . . . . .

2-1

2.2.

internal Disassembly (Right Side). . . . . . . . . . . . . . .

2-l

2.3.

Internal Disassembly (Left Side). . . . . . . . . . . . . . .

O

2-l

2.4.

Removing the Neck Board and Main Board . . . . . . .

2-2

2.5.

Removing the Control Board. . . . . . . . . . . . . . . . . . .

2-2

.-

Part 2. Non-VA Version

2.6.

Removing the Rear Cover. .................... 2-3

2.7.

Internal Disassembly (Right Side). ..............

2-3

2.8.

Internal Disassembly (Left Side). ...............

2-3

2.9.

Removing the Neck Board and Main Board ....... 2-4

2.10.

Removing the Control Board. .................. 2-4

??

VA Version

2.1. Removing the Rear Cover

1.

Turn the display so it is resting face downwards on the

work surface. Be sure to place a cloth or other soft

material on the work surface to avoid scratching the

screen surface.

2.

Remove the four screws at the rear of the display. Refer

to the figure 2-l (A).

3.

Remove the rear cover.

Figure

2-1

Remove the Rear Cover

2.2. Internal Disassembly (Right Side)

The neck board is plugged on to the CRT neck and is enclosed

in a metal shielding.

1.

Disconnect the two ground wires from the Neck Shield.

Refer to the figure 2-2 (A).

Figure 2-2

internal

Disassembly (Right Side)

2.

Remove the connected pin from the Neck Board. Refer

to the figure 2-2 (B).

3.

Remove the screw at the rear chassis. Refer to the figure

2-2 (C).

4. Cut the two cable ties indicated to free the cables. Refer

to the figure 2-2 (D).

5.

Disconnect the degaussing coil from the Main Board.

Refer to the figure 2-2

Q.

6.

Release the cable wire indicated to free the cables. Refer

to the figure 2-2

(F).

7.

Remove the nylon revets holding from Bezel. Refer to

the figure 2-2 (G).

2.3. Internal Disassembly (Left Side)

1.

Cut the four cable ties indicated to free the cables. Refer

to the figure 2-3 (A).

2. Disconnect the three ground wires from the Neck

Shield. Refer to the figure 2-3 (B).

3.

Remove the screw at the FBT cover. Refer to the figure

2-3 (C).

4.

Remove the nylon revets holding from fix plate. Refer

to the figure 2-3 (D).

5.

Remove the connected pin from the Logic Board. Refer

to the figure 2-3 (E).

6. Remove Logic Board.

7.

Remove the connected pin from the Connector Board.

Refer to the figure 2-3

(F).

8.

Remove the two connected pins from the Main Board.

Refer to the figure 2-3 (G).

Figure 2-3 Internal Disassembly (Left side)

2-l

cr

E

c

-

To avoid risk of electric shock, before

re-

moving the anode cap, made sure tdhe

a&

ode has been completely discharged as

high voltage may remain on the anode for

extended time after power off.

9.

Remove the anode cap from the CRT. Refer to the figure

2-3

(H).

10. Remove the nylon revets holding from Bezel. Refer to

the figure 2-3 (I).

2.4. Removing the Neck Board

&

Main Board

1.

Remove the screw from

U

Bracket. Refer to the figure

2-4

(A).

figure

2-4 Remove the Control Panel

Figure

Z-5

Remove the Neck Board and Main

Board

2Remove the two Lock Caps from the

nylon ties.

Refer to

the figure 2-5 (A).

3.

Remove the two ground wires from the Neck Shield.

Refer to the figure 2-5 (B).

4.

Remove the Neck Shield.

5.

Remove Neck Board.

6.

Remove the Main Board.

2.5.

Remove the Control Board

1.

Remove the two screws from Control Panel. Refer to

the figure

2-4 (B).

2.

Remove the Control Panel.

3.

Remove the six screws from the Control

Board.

Refer

to the figure 2-6 (A).

4.

Remove the Control Board.

Figure Z-6

Remove

the

Control

Board

-

2-2

UPart

2.

??

con-VA

Version

2.6.

Removing the Rear Cover

1.

Remove the four screws at the rear of the display, and

lift the cover vertically away from the monitor. Refer to

the figure 2-7

(A).

2. 1

Xemove the rear cover.

Figure 2-7 Remove the Rear Cover

2.7. Internal Disassembly

(Right Side)

The neck board is plugged on to the CRT neck and is enclosed

in a metal shielding.

1.

Disconnect the ground wires from the metal casing of

the neck board. Refer to the figure 2-8 (A).

Figure 2-8 Internal Disassembly (Right Side)

2.8.

Internal Disassembly (Left Side)

1.

2.

3.

Disconnect the ground wires from the metal

casing

of’

the neck board. Refer to the figure 2-9 (A).

Remove the two screws from the

PBT

cover and U

bracket. Refer to the figure 2-9 (B).

Rmove the ground pin from the neck board. Refer to the

figure 2-9 (C).

4.

Cut the cable tie indicated to free the cables. Refer to the

figure 2-9

0).

5.

Remove the nylon revets holding from Bezel. Refer to

the figure 2-9 (E).

6.

7.

8.

9.

Disconnect the ribbon cable from the Logic Board and

the cable from the CRT connected to the rear side of the

logic board. Refer to the figure 2-9

(P).

Remove the Logic Board.

Remove the connected pin from the Connector Board.

Refer to the figure 2-9 (G).

Remove the connected pin from

the

Main Board. Refer

to the figure 2-9 (H).

2.

Disconnect the degaussing coil from the main board.

Refer to the figure 2-8 (B).

3.

Removing the screw from the chassis mat. Refer to the

figure 2-8 (C).

4.

Place the display flat on

its

face and remove the nylon

revets holding the main board in place on the frame.

Refer to the figure 2-8 (D).

10. Remove the connected from Main Board, and the con-

nected from Main Board to Earphone Board.. Refer to

the figure 2-9 (I).

To avoid risk

of

electric shock, before re-

moving the anode cap, made sure tdhe an-

1

ode has been completely discharged as

high voltage may remain on the anode for

extended time after power off.

0

A[

@

Figure 2-9 Internal Disassembly (Lift Side)

2-3

1

c

F

I-

-.

-

-

11.

Remove the CRT anode cap. Refer

to the figure 2-9

(J).

12. Place the diiplay flat on its face and remove the nylon

revets

holding the main board in place on the frame.

Refer to the figure 2-9 (K).

2.9.

Removing the Neck

Board and

Main Board

1. Disconnect the three ground wires from the metal casing

of the neck board. Refer to the figure 2-10 (A).

2.

Remove the two

Lock

Caps from the nylon ties. Refer

to the figure 2-10 (B).

3.

Remove the Neck Board from the CRT.

4.

Remove the Main Board.

Figure

Z-10

Removing the Main Board

2.10. Removing the Control PCB

1.

Remove the

two

screws from Backet Cover. Refer to the

figure 2- 10 (C).

2.

Remove the seven screws from Control Panel. Refer to

the figure 2-11 (A).

3.

Remove

the Control Board.

Figure

2-11

Removing the Control PCB

2-4

Notes

c

1.

2-5

I

-

Part

7.

VA Version

3.1.

3.2.

3.3.

3.4.

3.5.

Switching Power Supply .......................

3-1

The Deflection Circuit ........................

3-3

Video Amplifier

.................

I

...........

3-11

Microprocessor and Sync Processing. ...........

3-12

Audio Amplifier .............................

3-12

Part 2. Non-VA Version

3.6. Sw.itching

Power Supply ......................

3-13

3.7.

The Deflection Circuit ........................

3-15

3.8. Video Amplifier

.............................

3-23

3.9.

Microprocessor and Sync Processing. ........... 3-24

3.10.

Audio Amplifier .............................

3-25

??

Part 1.

bA

Version

3.1. Switching Power Supply

The switching power supply (SPS) used in this display is a

15OW flyback mode type. The power supply provides seven

outputs (B+, 75V,

lN,

-15V, 6.3V ,+12V and +5V). Please

refer to schematic diagram for details of the circuit layout. The

input voltage is from

85VAC

-

UOVAC

with an input

frequency of

47Hz

-

63Hz, as shown in Figure 3-

1.

The current first passes through the EMI control circuit and

is regulated to DC by the bridge diodes

(BDl)

and filter

capacitor (C9). During rectification a large current surge is

generated and as C9 has a very low impedance while being

charged the fuse, on/off switch and bridge diode are all liable

to be damaged. For this reason, a thermal resistor (THh4ER)

is added before the bridge diode in order to limit the large

current surge generated during the charging of the capacitor.

During rectification, Cl2 is charged through R7, R12 and

42.

When Cl2 is charged to 16V, IC2 3842A starts to operate (for

details, of the functions of this IC, please refer to the relevant

data sheet) and outputs a pulse signal from Pin 6 to set the

transistor Q6 in the ON state. At this time, transformer T3.

which is connected in parallel, starts to store power. When the

current passing through the resistor R45, and the supplemen-

tary current from R39, R41 and R27 (Pin 4 to Pin 3) into Pin

3 of IC2 reaches 1.1 V, IC2 is reset, causing the energy stored

by the transformer to reach the rated value. In order to prevent

the transformer from being saturated and causing damage to

the transistor, when transistor

46

is in the OFF state, the

energy stored in the transformer T3 is released into the secon-

dary coil and is regulated through the various output loops and

filters and converted to the required DC output. In addition to

this, at the appropriate time, the windings pin 1

-

pin2 supply

Pin 7 of IC2 with a fixed power supply for normal operation.

Also, when windings pin1

-

pin3 are in power saving active

state, power is supplied to Pin 7 of IC2 for normal operation.

In any of the above cased, the output pulse is terminated and

the FET is turned off, causing the voltage on the output of the

FET to rise rapidly, and the voltage across the winding of the

primary to reverse in polarity, thus tending to reset the flux

within the core. At this point, the diodes D16-D19, D22 and

D24 on the secondary supply winding become forward biased

and begin to conduct, thus transferring energy from primary

to the secondary, and charging the secondary capacitors.

There is also secondary winding the primary side of the power

supply which, through diode D8 and Q5 recharges the control

IC reservoir capacitor C12. This supply then keeps the IC

running. In the event of a secondary short circuit, the supply

fails to recharge, thus the voltage across Cl2 drops to a

threshold limit below which the IC cuts out and returns to its

low current load operation.

During normal operation, the supply rails charge until the

error amplifier realized by IC4 on the secondary begins to turn

on the opto-coupler,

PHl.

At this point, the photo-transistor

of this opto-coupler on the primary side begins to conduct.

draining current from the primary control IC supply through

diode D6. This reverse biased the gate of the thyristor

42.

As

POWER

XFORMER

O/P

RECTIFIER

FILTER CIRCUIT

--,

75v

-›,

15v

-b

12v

+

-15v

-b

6.3V

--b

5v

E

-.

-

-

E

,

.

i

FM MONITOR H.V. FEEDBACK

Figure

3-7

Switching Power Supply Block Diagram

3-1

the anode of

42

is fed from an alternating source, once the

gate is reverse biased, this device is then turned off until the

c

current in the opto-coupler drops to zero, thus eliminating the

power that would otherwise be washed in the start-up resis-

tors, R7 and R12.

b

Under normal operation IC4 regulates the current flow

through

PH 1, and hence determines the output voltage of the

error ampliier internal to IC2. Various passive components

around IC4 and IC2 set the gain compensation for optimum

stability and regulation characteristics.

In the event of a fault condition occurring, either Q4 may be

turned on by the lack of voltage at pin2 of IC2 or zener diode

-

ZDl

may conduct, due to excessive voltage on the primary IC

supply. In the latter case, the triac

43

will fire, thus dragging

down the output of the control IC error amplifier, which in

turn will limit the duty cycle and reduce the output voltage. It

will stay in this mode until the AC input power is removed.

--

When the

feedback

signal passing through the main 75V

output is completed, the transistor’s duty cycle is adjusted

through the transfer to Pin 2 of IC2 3842 of the primary coil

by

PH14N35

and IC4 TL431, stabilizing the output current.

At this time, it is important to note that before the feedback

signal is established, the charge level of Cl5 cannot trigger

43

SCR or it will cause a faulty power startup. In addition, in

order to synchronize the supply power and mdtiitor and reduce

noise that will cause interference to the display, in the area

Dll the monitor’s feedback transformer gets a feedback

signal in order to ensure synchronization between the power

supply and monitor, with synchronization in the range 3OkHz

-

69kHz. Because the power operating frequency changes

with the monitor causing changes in the value of IP, (the value

of LP is fixed while the value of IP increase or decreases

according to the frequency), this affects the test value of Pin

3 of IC2 3842A. This causes the total power supplied to vary

according to the frequency, so a compensation value is pro-

vided by D12 in order to reduce the difference in total power

for different frequencies. In addition, because the AC input

ranges from 85VAC to 270VAC, this causes the value of the

direct current on the DC bus to vary, affecting the rise rate of

IP, the oscillator and the duty cycle, and causing the test value

obtained at Pin 3 of IC2 to vary. To resolve this, a compensa-

tion value is provided by R39 and R41 which reduces the

difference resulting from the different input voltages.

3.1

.l.

Auto-degaussing

.

-

When Pin29 of

P2

connector is in high state, the

transistor Ql

2SC945P

is on, causing the relay to

jump from Normal Open (N.O.) to Normal Close (N.

C.) to perform auto-degaussing operations. The du-

ration of this operation is controlled

by

a logic pulse

and lasts approximately 6 (six) seconds. When tran-

sistor Ql enters the OFF stale and the relay returns

to N.O. to terminate the auto-degaussing operation is

completed.

3.1.2. Suspend Mode Operation

Two feedback ratios can be selected, both sensing

from the 75V rail. In the event of

QX

being turned on

by micro processor, additional current is drawn from

the virtual earth node of IC4, thus causing the power

supply to serve the rail to a high voltage, nominally

75V. This is trimmed by resistor

VRl.

The other

supply rail are predetermined ratios of this winging,

being

+15V,-15V&.3V

and

+2OOV

nominally. In

addition, a low voltage primary side winding feeds

the control IC directly through D7 turning off the

control IC supply through Q5, which would other-

wise dissipate excessively.

When Q8 is turned off, the 75V rail drop to around

17V.

In this case, the primary control supply fed

through D7 drops to a value that is below the level

needed to sustain operation. Instead, Q5 begins to

conduct and the higher voltage supply winding taken

via D8 is used to keep the primary side powered up

with minimal power losses.

The

5V

power supply is driven by one of two sources,

In normal operation when the 75V is present, the

5V

regulator, IC6, is fed from the 15V rail through diode

D21. When switched to standby mode (75V rail

drops to 12V) then the 15V rail drops too low to

supply IC6. In this case QIO and Ql 1 take over and

maintains the supply to IC6 at around 9V.

In addition to the

5V

regulated supply, in normal

operation there is also a 12V regulated supply take

from the 12V rail.

To ensure that micro processor gets a good 5V power

supply, there is a power good detection circuit

formed by IC3. This monitors the supply going into

the

5V

rail (not the

5V

rail directly). It detects

whether there is sufficient voltage to enable the

5V

regulator to work effectively. It

is

not a detection of

the

5V

rail itself, but relies upon the premise that the

regulator is not faulty and that there is no faulty load

condition on the 5V.

During power up, there is a delay to the signal at the

output of the threshold comparator IC3 a caused by

R57 and C3

1,

in order to allow the micro circuit time

to stabilize. The threshold is chosen such that the

RESET line drops low at least 25ms before the

5V

drop out of regulation.

Finally a synchronization pulse taken from the hori-

zontal output stage maintains the SMPS operating

frequency in sync with the horizontal scan. Dl 1

injects a pulse which prematurely triggers the oscil-

lator within IC2 which would

othcrwisc

run at a

frequency lower than the minimum

required

sync

frequency.

DC to DC Circuit

Another special characteristic of this power supply is

the addition of a DC to DC circuit to the output. In

order to support the monitor at different frequencies,

a similar high voltage is required (26kV). To accom-

modate this requirement, a buck loop has been added

to the 200V output. The synchronization signal is got

3-2

from the monitor H.D. area, and after getting syn-

chronization through

QPl

trigger pin2 of

ICP2,

a

high voltage feedback signal ( FB). is input to QP2

to obtain the DC level. A comparison is carried out

between pin5 of ICP2 and ICP3 to establish the duty

cycle of transistor QP3 so that even under different

frequencies, a similar high voltage value is still ob-

tained.

3.2. The Deflection Circuit

9.

10.

11.

Please refer to the block diagram of the deflection circuit and

video circuit and logic circuit as shown in Figure 3-2.

36.1.

IC308

UPC1883

12.

13.

1.

2.

3.

4.

5.

6.

7.

8.

IC308

UPC1883 is a horizontal and vertical

processor. The horizontal section consists of a

‘ITL interface, two comparators and an oscilla-

tor. The vertical section consists of a

TlL

input

interface and an oscillator. This IC includes a

voltage stabilizer to provide about 5V.

When sync is input as a

TIL

level, this causes

a negative edge trigger. Pin 26 serves as the

H-sync input point and Pin 27 as the V-sync

input point.

14.

15.

16.

Pin 18 is the horizontal output. The output

current is too small to drive

T301,

therefore

4374 and 4375 are added as a buffer followed

by a transistor

43

10.

17.

Pin 20 and 22 provide the external control of

the horizontal oscillator free run. Free run is

controlled by changing the resistance value of

R479 and C431 to obtain different DC voltage

levels. By adding an external F/V on Pin 19, the

difference between a variety of input frequen-

cies and free run is maintained at a similar lenel.

In this way, when different timing modes are

input, if the ration between the active display

and total display is similar, then the position of

the phase will also be similar.

3.2.2. Vertical Deflection Circuit

1.

X202

TDA8172 consists of a flyback gener-

ator, voltage stabilizer, drive circuit and verti-

cal output amplifier.

2.

The vertical oscillator circuit

(a) The frequency and phase of

rhe

vertical

oscillator circuit is generated by the vertical

synchronization signal.

The parallelogram of different modes can be

individually adjusted by changing the VDC

level at pin 4.

The pin-balance of different modes can be in-

dividually adjusted by changing the VDC level

at pin 5.

The vertical size of different mode can be indi-

vidually adjusted by changing the VDC level

at pin8.

The vertical center of different modes can be

individually adjusted by changing the VDC

level at pin 11.

The vertical linerarity of different modes can

be individually adjusted by changing the VDC

level at pin 12 and 13.

The horizontal phase of different modes can be

individually adjusted by changing the VDC

level at pin 25.

The horizontal duty of different modes can be

individually adjusted by changing the VDC

level at pin 23.

When it is not use for pin 1 to pin 5, it shall be

connected to Vcc (9V).

The pin 2 and pin 4 are setting the trapezoid or

parallelogram and output waveforms from the

pin 28. pin 3 and pin 5 are setting the side pin

or side pin balance and output waveforms from

the pin 10.

Pins 6 provides the external control of the ver-

tical oscillator free run. Free run is controlled

by changing the

capcitance

value of C432 to

obtain different DC voltage levels. It does not

need an external F/V control because this IC

can keep vertical synchronization. Pin7 pro-

vides vertical A.G.C function.

The pin-comer of different modes can be indi-

vidually adjusted by changing the VDC

level

at pinl.

The trapezoid of different modes can be indi-

vidually adjusted by changing

the

VDC

level

at pin2.

The pincushion of different modes can be indi-

vidually adjusted by changing the VDC level

at pin3.

(b) The synchronization signal is input from

Pin 27 of

LC308

UPC1883, after being proc-

essed by the synchronization circuit, is sent to

the vertical synchronization oscillator circuit to

trigger the vertical oscillator and synchronize

the oscillator frequency with Ihe external syn-

chronization signal. The frequency of its inter-

nal free

osciilalion

is set by the time constant

of C432. It

dots

not

need

an cxrernal

F/V

control

because

this

IC308

can

keep

vertical

synchronization. Pin 7 provides vertical A.G.C

function, so the pin 7 of IC308 is use to main-

tain the difference between the free oscillation

frequency and external synchonization signal

frequency at a similar level and make the saw-

tooth wave amplitude from pin 9 of IC308 the

same.

t

-.

L

1

:

’

L.

3-3

II

,

t’

-

I

1

PAWCS)

AMPI

IFICR

I

1

I

-

???

?

????

??????????

?

???????

CtRCUIT

lC503

IYcu-TI@

b

SYNC ON GREEN

ClRCUlT

IC504

v

moo

I

.

.

OSD CiRCUlT

IC502,Q511 ,Q512,Q513

L_,

1

I

t

RGA’N

:

7

DAC CIRCUIT

-

II

G

GAIN

0PM-

@GM

.

IC505TDA8444

SBuIcowRol

c

Gl

I

(

-18OV)

I

II

WV

BLANKING

1

1

HRET

--------iv

.

WET

ICIRCUIT

Q503,Q505,Q509

.

A

X-RAY CONTROL

I I.

4

I

]

CIRCUIT

Q370.Q371

.

L

I

I

I

II t

‘H

SdC

1

HSYNC+

7

c>-

COMBINE0

HORKONTAL

6

MRTICAL

PRoCESSof?

WrTH

GEOMETRY

CONTRol-”

DYNAMIC

Pocus

CIRCUIT

T401,CMlO

4420

+-

H-WIOTH

CONTROL CS CONTROL

CtRCUlT

E>-

CIRCUIT

IC302,4360

.

-t>-

4350,4302,Q309

Q353.Q354,Q355 RL301

,Q347,0348

I

B*

CONTROL CIRCUIT

4

QPl

,QPZ,QP3,QP4,

R-SIDE

ic,

CNO

!o,/-

AUDIO PREAMPLIFIER

CIRCUIT

ICQOl

L

?

L-SIDE

3;

1

lJPc1408HA

A

W

b

3.

Vertical Si Control

The pulse voltage output by the oscillator is

sent to the sawtooth wave generator. The size

and amplitude of the voltage of the sawtooth

wave generation can bc changed by DC value

which output from Pin

IO,1

1 of IC306 and the

vertical size can thus be controlled. This saw-

tooth wave voltage passes through a buffer and

is output from Pin 9 of IC308 to pin 1 of IC202

TDA8172 of the vertical drive circuit.

The verticai ramp and DC offset are also con-

trolled by DAC output. The vertical ramp gen-

erated across C432 is buffered internally to

IC308

by DC controlled variable gain stage.

The voltage is derived by sum of 2 DAC output,

VSIZEl

and

VSIZE2.

which are summed to-

gether to give 128 bit resolution.

4. Vertical Drive Circuit

(a) It is not sufficient to rely solely on the

oscillator circuit output to ensure the stability

of the vertical output, so a first or second level

amplifier circuit must be inserted between the

oscillator circuit and the output. This circuit is

called the drive amplifier and in

-addition

to

amplifying the sawtooth wave also corrects the

vertical linearity.

After adding the drive circuit, because the level

of amplification can be considerable, enough

negative feedback can be added to correct ver-

tical linearity and increase the stability of the

circuit.

(b) If the current of the sawtooth wave flowing

through the deflection yoke is distorted, then

the top and bottom portions of the display will

be expanded or compressed, resulting in poor

linearity. In order to solve this problem, correc-

tion of the linearity of the sawtooth wave can

be carried out before the drive level.

5.

IC202

TDA8172

Vertical Drive Circuit

The IC202 uses a double power source, so it

can be viewed as an OCL drive ampiification

circuit.

In order

that

the DC coupled output stage accu-

rate DC reference, a DC reference voltage is

taken from IC308 from

pin 12.

This used as the

reference voltage (via divider resisdtors, R497

and R499) for the DC coupled power amplifier,

IC202. This is 8 simple voltage to current in-

verting amplifier, using R203 to derive a volt-

age proportional to the current in the dcflcction

winding of the yoke. This voltage is fed back

to the virtual signal earth inverting input of the

power amplifier(pin1) by R204. This back to

back diode feedback network modifies the

linearity of the transfer characteristic in order

to give precept “S” correction linearity. in ad-

dition to the variable correction in the ramp

generator.

The vertical output amplifier has a voltage

boost circuit to triple the positive supply volt-

age during retrace in order to speed up flyback.

It does this by charging capacitor C202 through

diode D212 during the normal forward scan.

Pin6 of the IC is the voltage supply to the power

output stage. When

flyback

occurs, pin3 is

switched to the positive supply rail on

pi&

thus adding the voltage across C202 to that of

the supply rail, effective doubling the supply

momentarily.

6.

Vertical Centering Adjustment

Since IC202 functions as an OCL circuit, VDC

is output from Pin 7 of IC202, so the central

current can be changed to shift the on-screen

display up or down to prevent voltage

fluctua-

tion. After adjusting the power stabilizer at Pin

14 of IC308 UPC1883 (about 5V) and pin 11

of

IC308

with R487, R497 and R499 this is

input to Pin 7 of IC202 to change the value of

the vertical center.

The DC operating point of the amplifier can be

varied by the VPOS DAC output which adds

or subtracts an offset into the output, thus vary-

ing the DC offset of the scan and hence the

vertical centring.

3.2.3. Pincushion Correction Circuit

1.

If the width of the border in the center of the

screen is insufficient, the waveform

shown

in

Figure 3-3 below,

can

be used to add to hori-

zontal deflection B+ in order to change the

deflection of the horizontal deflection circuit.

%

This waveform is the parabola obtained after

regulation of the vertical period, and is created to

perform amplitude modulation on the horizontal

deflection current, as shown in Figure 3-4.

/-J&J&

Figure 3-3

Vdtage

Correction Wave

-

FH: Horizontal Frequency

FW Vertical Frequency

Figure 3-4 Current Correction Wave

3-5

--

e

I.

tor output, is added to horizontal B+

to provide

pincushion distortion correction.

‘Ihe

diode modulator pm-amplifier provides

this filtering action. The op amp IC302 is con-

figured with 4353

to

provide a current source

output at the collector of 4353 . The

PWM

parabola is filtered to remove horizontal rate

harmonics by 657.

r

3.2.4. Structure of Horizontal Deflection Circuit

The function of the horizontal deflection circuit is to

cause left/right scanning of the electron beam using

the sawtooth wave current flowing through the hori-

zontal deflection yoke, and is made up of the hori-

zontal oscillator circuit, horizontal drive circuit,

horizontal output circuit. synchronous AFC circuit

and high voltage generator circuit.

!--

1.

Horizontal Drive Amplifier

In order to rapidly saturate the output transistor

(ON) or cut it off (OFF), a sufficient basic

current must be provided. Because of this, an

amplifier circuit is added between the oscillator

circuit and the output circuit to amplify the

pulse voltage. At the same time, after the wave-

form has been regulated, by adding this circuit

to the

output circuit, this amplification circuit

functions as a drive amplifier.

:

I-

2.

The

sawtooth wave is Atput from Pin

.lO

of

IC308 and

through C354 and R360 and input

to Pin 2 of IC302. It

is then output from Pin 1

of IC302 and after being sent to Q353’s collec-

2.

IC UPC1883 consists of a vertical sawtooth

wave generator, horizontal sawtooth wave gen-

erator, horizontal oscillator circuit, vertical os-

cillator circuit, AFC circuit, phase regulator

circuit, geometry control circuit and drive am-

plification circuit. This IC includes the vertical

and horizontal circuits combined in one pack-

age.

When the synchronization signal input to Logic

circuit and pin 26 of

IC308.

The pin 18 of

IC308 output horizontal frequency is achieved

by the pin 12 and pin 13 of

IC306

(D.A.C

control) and flyback

pulse

from

pin 6 of T302

(A.F.C) fed to pin 17 of IC308, so the pin 18 of

IC308

output horizontal frequency through

4374,

4375.

Q3

10

and

I301

provide a hori-

zontal output transistor base current of

430

1.

The horizontal output transistor base drive

is

taken from a conventional base

drive

trans-

former stage. This circuit

as in a similar manner

to

a

flyback power supply. The square wave

horizontal oscillator output signal is coupled

into the base of base drive stage transistor,

Q310,

via C334,

C330,

D333, R326,

R325,

Q3

10

turns on and connects the primary wind-

ing of transformer ‘I301 across the +15V and

-

15V supplies. This causes the primary current

to increase linearly until such time as 4310

turns off, hence storing a predetermined

amount of flux energy in the transformer. As

43

10 tums off, and the primary current falls to

zero, the secondary voltage is driven above the

threshold of the base-emitter junction voltage

of the horizontal output transistor, 4301. Cur-

rent flows through

R304,

R457, R329 and

D3 12 into the base of 4301 hence turning this

device on. The high base current of around

1.lA.

Lamps is so high

that

4301 is driven

heavily into saturation. This is important in

order that the collector voltage should be as low

as low as possible whilst conducting the high

peak currents that flow through the horizontal

deflection winding. In turn.

this is vital to limit

dissipation.

At the required time as determined by the hori-

zontal oscillator, the base drive transistor is

turned back on. The voltage at 4310 collector

fall rapidly back towards the -15V rail. How-

ever, the secondary current still remains flow-

ing in a positive direction for a short time, due

to the finite leakage inductance of T301. Also,

due to the heavy saturation of Q301, the base

voltage remains at around IV. The current in

the secondary winding rapidly reverses and

goes sharply negative as the charge stored

within the base region of

4301

is removed

Diode D312 helps to speed up this charge re-

moval. Note that during this time, the collector

output of the

4301

is still turned on, even

though the base current is flowing out of the

base.

This period of time is known as the storage time

of the device and may take between

2-3~s

depending upon peak collector current and

temperature and various other design factors.

Finally, when all charge in the base region of

4301

is dissipated the base current suddenly

stops, and the secondary current drops almost

instantly to

zero. At

that point, the device now

become non conducting and the collector cur-

rent flow also terminates. The secondary volt-

age on T30

I

drops to it’s unloaded voltage and

the current flow in the primary settles to it

initial value once more.

3.

Horizontal Output Circuit

The horizontal output circuit uses the switch

operation of a transistor and a damping diode,

and provides a sawtooth wave current to the

dcllection

yoke.

The horizontal deflection yoke

is made up of

the

L

value

on

the

coil and

resistance

r

inside the coil connected in series.

Its resistance is extremely small, and the time

constant

(Vr)

is extremely

large.

Because of

this

the voltage at

the

two

terminals

of

the coil

cause rapid variation in the current flowing in

the coil still will slowly vary, creating a saw-

3-6

tooth current.

‘l%e

basic circuit and equivalent

circuit are shown in Figures 3-5 and 3-6.

Damping diode

figure

3-5 The Basic Deflection Circuit

Figure 3-5 Equivalent Circuit

4.

Horizontal Output Equivalent Circuit

Operation

Refer to Figure 3-7 above for the current wave

of the voltage of the horizontal output circuit

during operation.

(a)

tl-

t2

Period

The base of the output transistor is added to the

forward bias voltage. As the current through

the base is very large, it will cause the output

transistor to be saturated, corresponding to the

ON state of S 1 in the equivalent circuit. At this

time the deflection yoke contains a current flow

and because the time constant is large. the

current will slowly show a linear increase as

shown in Figures 3-7 (b) and 3-8 (a).

(b) t2-t3 Period

At

t2.

a negative load is applied to the to the

base and the output transistor changes to OFF

(Sl

in open state). There is no current passing

through the transistor at this time and the L and

C components of the deflection yoke become

independent oscillation circuits. If the current

is suddenly cut off, then the polarity of the

inverse voltage generated at L will be as shown

in Figure 3-8 (b). This voltage is viewed as the

source voltage and will cause current

to

flow,

at which time the current flowing to C is as

shown in Figure 3-7 (d). At time

13

this current

is 0 but the voltage at the two capacitor termi-

nals is at maximum. This waveform is known

as flyback pulse, and is

shown in Figure 3-7

(0.

(c)

(U

-

t4) Period

The energy accumulated in C is released to the

deflection yoke, the direction of the current

flow being shown in Figure

3-8 (c). The current

increases as the voltage

onC

decreases, and at

time t4, the voltage of C is 0, at which time the

current is at maximum, which means the cur-

rent flowing into the deflection yoke is also

maximum.

C is then charged and if a damping

resistor is not

co~ected, the

energy between L

and C will be reversed, which is the oscillation

frequency set by the oscillator at L and C.

(d) t4

-

t5

Period

At

t4,

the voltage of C is 0. After this it is

recharged in the opposite direction and this

voltage exceeds the voltage of the power source

at time 14. At this time the damping diode is ON

and the L and C circuits are shorted out and stop

oscillating. Because of this the time constant of

r and L in the damping diode is large so the

current flowing

in

the deflection yoke does not

suddenly become 0. The current shows a linear

decrease, and when it becomes 0 at time

t.5

the

transistor is ON and the operation described

above is repeated.

As described above, the current flowing in the

deflection yoke during scanning is the sum of

the current which has passed through the tran-

sistor and the damping diode current. Please

refer to Figure 3-7 (e).

(e) Horizontal output operation:

The actual output stage differs from the simple

model described in a number of ways. Refer to

the basic schematic of the major components in

Figure 3-9 on the following page.

The main inductance

L

is now divided into the

primary winding of the Flyback Transformer

(FBT), T302 and the deflection yoke winding.

The deflecting yoke is coupled through a ca-

pacitor C3

11,

which has two function. Primar-

ily it prevents DC unwanted DC currents

flowing through the deflection yoke which

would otherwise cause an undesirable deflec-

tion of the CRT beam.

Secondly, the voltage drop across it due to the

AC ramp current flowing causes a parabolic

modulation in the slope of the ramp, leading to

a progressive curve in the ramp, symmetrical

about the zero current value as shown in Figure

3-10, below. This intentional distortion of the

linear

ramp is required to compensate for the

‘S’.

or symmetric

linearity

distortion in the

CRT.

In series with C3

1

I and the deflection yoke is

another indicter, L303. This is a saturating in-

dictor that is biased with a permanent magnet.

Consequently this device has a linearity that is

higher for current flow in one direction than in

the opposite direction. This function provides

compensation for resistive losses that would

otherwise cause an undesirable exponential

3-7

Transistor ON

/

(a) Base Input voltage

(b) Current through transistor

(c) Current through diode

(d) Capacitor current

(e) Current through deflection yoke

(9

Voltage generated in deflection yoke

Figure

3-7 Horizontal Output Voltage/Current Waves

curve to the linear ramp, resulting in

asymmet-

rical

linearity errors in the displayed image.

In addition to the AC coupling of the deflection

yoke, another major difference is that the

damper diode is split into two diodes. A second

resonant circuit comprising of

C307

and

L304

are connected at this point. This second reso-

nant circuit acts exactly as a smaller version of

the

flyback

circuit. A ramp current is set up in

L304,

proportional to the voltage at the output

of the diode modulator circuit, VDM. A small

flyback

voltage is also created across

C307

as

a result of this. Consequently, the voltage seen

across the yoke winding is the difference

bc-

tween the constant heigh main

flyback

pulse

seen across

Q301

and

the

smaller, variable

flyback

pulse seen across

C307.

As the current

flowing in the yoke is proportion to this differ-

ence, the deflection current (and therefore the

VDM. This voltage is derived from the output

of 4353 after buffering by a unity voltage gain

amplifier formed by 4354 and 4355.

The voltage seen in the output stage require

special attention. The B+ supply can varying

between

60-

180. The main

flyback

pulse seen

across

4301

and associated components is

around 1200V. Consequently, appropriate pre-

cautionary measures must be taken when serv-

icing the monitor.

In addition to the basic topology as

dcscribcd

above,

there

arc a

number

of

other

additional

dcviccs.

4302

and 4309 can bc

indepcndcntly

turned

on or off

under

logic control.

These

devices

switch addition capacitors, C3 I3 and

C324 in parallel with C3

I

I to alter the amount

of ‘S’ correction at different horizontal scan

frequencies.

displayed image width) can hence

bc

modu- D308 and D309 set up a positive and a negative

lated

by varying the diode modulator voltage, supply rail with respect to the main B+ supply.

3-8

(a) Second half of scanning period (tl

-

C?)

*

I~+-

(b) First half of return line period

(t2

-

t3)

+

-t/

+T

A

=J

1

I/

P

I

-

xi

(c) Second half of return line period (t3

-

t4), (d) First half of scanning period (t4

-

t5)

Figure 3-8 Polarity of Transformer Voltage

current into

L303.

‘Ihis

current flows into the

deflection yoke and adds a variable DC offset

to allow image raster entering to be achieved.

The B+ supply is configured so as to maintain

a constant anode voltage. The anode voltage

is

derived from the

flyback

transformer,

T302.

As

the

flyback

voltage across the primary is

al-

ready a high voltage pulse of around

1.2kV,

it

requires only a modest turns ratio to step this

pulse up to around

26kV.

the working voltage

of the CRT.

Figure 3-9 Basic Horizontal Output Circuit

Parabolic voltage

acrOSS

(2311

s’txmeckd

ov

_

-

Lineard

amp

--

The

flyback

pulse at the primary of

T302

is

proportional to the

both

frequency and the sup-

ply rail, B+. In order to maintain the anode

voltage at a constant 26kV a regulation system

is required. This is achieved

using a buck regu-

lation stage formed by a

ICP2

driving a

FET,

synchronized by the horizontal oscillator. The

ICP2

has an error amplifier that generates an

error signal from the feedback network formed

by the high voltage bleed resistor (it is internal

to

T302).

Resistors

VRPl,

RP14 and RP13 set

the DC feedback ratio, and by adjustment of

VRP

I,

this ratio can be adjusted at

setup

to set

the high

voltage

at it’s nominal

value

of 26kV.

The

AC

frcqucncy

rcsponsc

of

the

scrvc

loop

is set by CPI 1 and RP21 for optimum stability

and relegation

characteristics.

Figure 3-10 Linear Ramp Distortion

Q352 acts as a constant current source that can

be programmed under logic control. This cur-

rent source drives the transistor pair

Q304

and

4305

which thus drive an adjustable constant

The output of

the

error

amplifier

which can bc

observed on ICP2 of pin 5 is

internally

com-

pared with a DC voltage. This DC is produced

across.

CP4, charge by

RW.

The voltage across this

capacitor is periodically discharged by

QPl

which is fed by a pulse from the horizontal

3-9

Table of contents

Other BELINEA Monitor manuals

BELINEA

BELINEA 101910 User manual

BELINEA

BELINEA 10 User manual

BELINEA

BELINEA 10 User manual

BELINEA

BELINEA 2025 S1 User manual

BELINEA

BELINEA 101910 User manual

BELINEA

BELINEA 10 80 80 User manual

BELINEA

BELINEA 101911 User manual

BELINEA

BELINEA 10 60 65 User manual

BELINEA

BELINEA 101915 User manual

BELINEA

BELINEA Belinea 2025 S1W User manual

BELINEA

BELINEA 102015 User manual

BELINEA

BELINEA 2225 S1W User manual

BELINEA

BELINEA 10 User manual

BELINEA

BELINEA 10 18 30 User manual

BELINEA

BELINEA 101555 User manual

BELINEA

BELINEA 1945 G1 User manual

BELINEA

BELINEA 101830 User manual

BELINEA

BELINEA 101901 User manual

BELINEA

BELINEA 10 User manual

BELINEA

BELINEA 10 30 55 User manual