bell marine Viper S Series User manual

MORE POWER! MORE SPEED! MORE TORQUE!

USER GUIDE

www.bellmarine.com.au

1000 MICRO & RAPID

ELECTRIC ANCHOR WINCHES

Viper

‘S’ SERIES

bellmarine.com.au

WORLD CLASS STAINLESS STEEL BOATING CHANDLERY & PERFORMANCE BOATING ACCESSORIES

Whats Included In Your Viper Winch Bundle

Viper SSeries 1000 “MICRO” Anchor Winch Bundle

Viper Deluxe Anchor Roller (#30009)

Viper Deluxe Stainless Steel Anchor Swivel (#30001)

60 meters of Premium Blend Double Braid Anchor Rope

Pre Spliced to 6mtrs of 6mm Short Link Gal Anchor Chain (#30045)

200 Amp Reversing Solenoid (#30020)

Illuminated LED Up/Down Marine Rocker Switch (#90021)

Laser Etched LED Switch Cover

100 Amp Flush Mount Circuit Breaker Including Rubber Seal For Wall Mount (#90046)

Single Switch Stainless Steel Face Plate (#30051)

Combo Switch & Circuit Breaker Stainless Steel Face Plate (#30052)

5mm Stainless Steel Sandwich Plate

Emergency Manual Safety Release Tool

All Stainless Steel fixings, Bolt, Screws, Nuts, Washers, Heat-shrink etc Included

Viper User Guide, Wiring Diagram & Registration Card

Viper Wiring Loom Order Form

5 Year Manufacturers Warranty

Viper SSeries 1000 “RAPID” Anchor Winch Bundle

Viper Deluxe Anchor Roller (#30009)

Viper Deluxe Stainless Steel Anchor Swivel (#30001)

75 Meters of 8mm Premium Blend 3 strand Anchor Rope

Pre Spliced to 8mtrs of 6mm Short Link Gal Anchor Chain (#30010)

200 Amp Reversing Solenoid (#30020)

Illuminated LED Up/Down Marine Rocker Switch (#90021)

Laser Etched LED Switch Cover

100 Amp Flush Mount Circuit Breaker Including Rubber Seal For Wall Mount (#90046)

Single Switch Stainless Steel Face Plate (#30051)

Combo Switch & Circuit Breaker Stainless Steel Face Plate (#30052)

5mm Stainless Steel Sandwich Plate

Emergency Manual Safety Release Tool

All Stainless Steel fixings, Bolt, Screws, Nuts, Washers, Heat-shrink etc Included

Viper User Guide, Wiring Diagram & Registration Card

Viper Wiring Loom Order Form

5 Year Manufacturers Warranty

bellmarine.com.au

Please note: If there is any items missing from your winch bundle please contact Bell Marine on (03) 9708 2846 or email us at [email protected]

and we will express your items immediately

OPERATING INSTRUCTIONS

Viper S Series Anchor Drum Winch

How to get on your mark:

• Please make sure your engine is running while operating your winch.

• Engage the circuit breaker to power up your winch.

• Travel just past where you wish to anchor, place the boat in reverse in the idle position.

• Push the down switch whilst continuing to idle back.

• Continue to lower the anchor until the rope goes slack – your anchor has now hit the bottom take you finger off the button

and reverse your boat back a little bit to make sure your anchor rope is tight and to help bed your anchor into position. When

anchored your rope should not be straight under your boat, ideally it should be at least a 45-degree angle or more. If you are

in rough water and or windy conditions, release some more rope out to compensate for boat movement and water chop.

• Once you are in the right spot there is no need to tie off the rope while you are anchored.

• Disengage the circuit breaker to cut power from the winch. The Viper worm drive will automatically lock your winch in this

position once your finger is taken off the up/down LED switch.

Retrieving the anchor:

• Engage the circuit breaker to power up the winch.

• Start your engine, press the up button, there is no need to move forward to retrieve your anchor, in some cases the rope will

wind on better if it under some sort of resistance, if you drive to far forward the rope can wind onto the winch with less

resistance and can cause bunching up in the middle of the drum. Driving forward is at the discretion of the user and may or

may not be affective as an anchoring technic for your individual boat.

• Continue to push the UP switch until you can see the chain or your chain sock – Then slowly tap the switch to bring the

anchor up and lock into the Bow Sprit, a handy tip is to paint the last 2 meters of your chain or sock white to indicate when

the anchor is near the front of the boat, also handy at night under a light for increased visibility during the anchoring proce-

dure.

• Once the anchor is locked into the bow sprit/bow roller, you can disengage the circuit breaker to cut power to the winch

and your right to go. Disengaging the circuit breaker prevents any potential winch movement if the down button is accident-

ly pressed while the boat is underway (this technic is optional)

• When underway it is recommended to have a separate cord attached to your anchor chain and then tied off to a bollard or

solid point at the front of your boat, this can prevent any accidental releasing of the anchor either by mechanical failure of

the winch or again by pressing the down button by mistake, thus preventing the anchor from moving and potentially falling

down and hitting your boat while underway or while being towed on your trailer.

SAFETY SWITCH:

• The Viper Pro Series Winch has a safety switch (circuit breaker) located on the switch panel or under your dash.

• When traveling or anchored disengage the red lever on the circuit breaker to cut power to the winch. This will prevent

accidental use while anchored or traveling as outlined above

• No specific maintenance is required however a polish every 12 months and a quick check of your rope and anchor chain

before every trip is recommended. Also soaking your anchor rope in a bucket of warm water and fabric softener annually

will keep your anchor rope soft a subtle so it lays on nicely.

ELECTRICAL FAILURE:

• If your electrics fail or you flatten your battery/s and your winch is fitted with the Emergency Manual Safety Release

mechanism, use the provided spanner tool to undo the bolt device on the side of your gearbox turning the bolt in an

anticlockwise direction, once the bolt is taken all the way out the winch will drop the anchor down in a free fall manner, once

the anchor hits the ground, tie the rope off to a bollard to become anchored. Once safely anchored ring the coast guard or

your local marine rescue response team.

• If your winch does not have the emergency release system installed, then it is advised that a spare anchor, rope and chain

is available on your boat, so the anchor can be deployed for safety reasons.

bellmarine.com.au

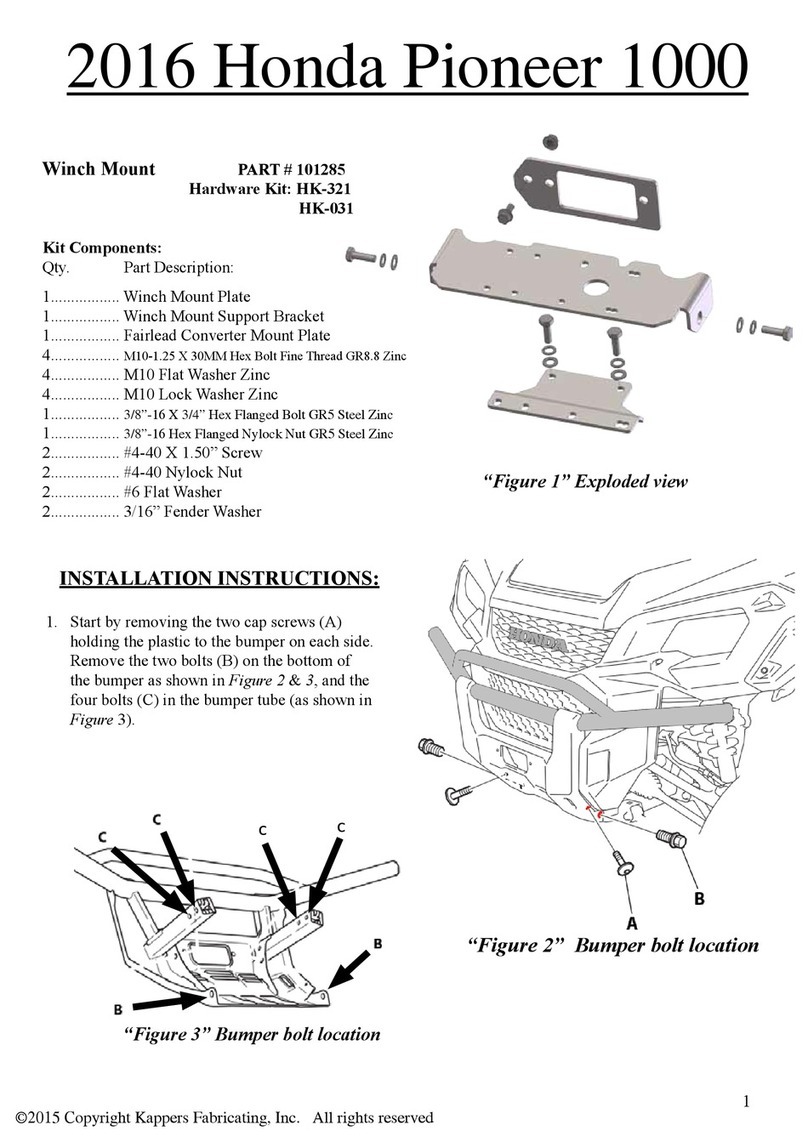

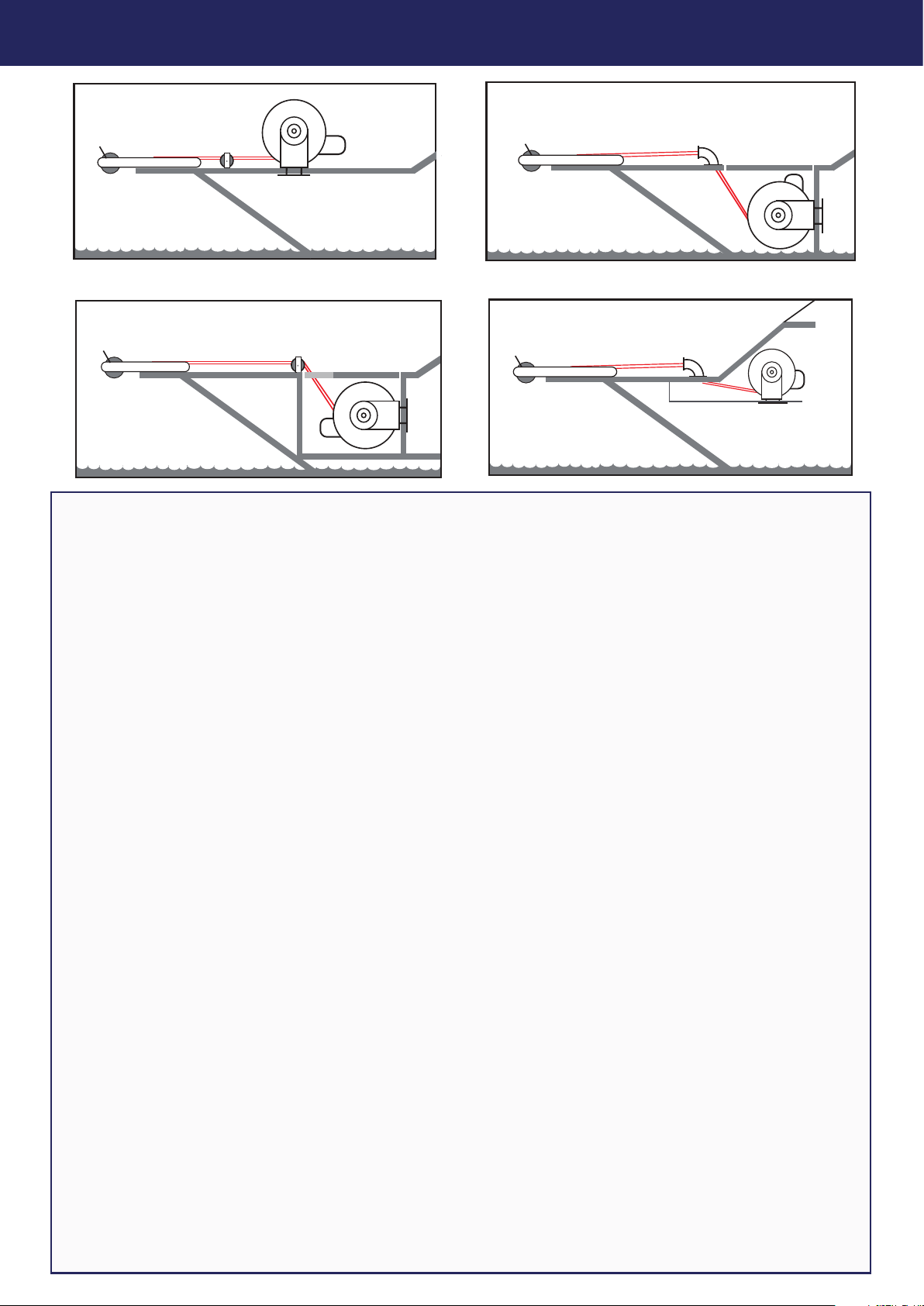

Deck Mount InstallationDiagram 1

Anchor Well Installation

Using An Anchor Roller

Diagram 2

Anchor Well Installation

using Hawse Pipe

Diagram 3

Cuddy Cab Installation

Diagram 4

Rope and Chain can also be mounted over the top of the drum

A.This Limited warranty is given by Bell Marine (the company) to the original purchaser (the “purchaser”) of a Bell Marine Viper Winch (the “Product”)

specified in this manual. This 5 Year limited warranty is not transferable to any other party.

B. Responsibilities of the Company under this Limited Warranty

1. Repair or replace (at the discretion of the Company) any part or parts of the Product found by the Company to be defective within a 5 year period

from the date of purchase.

2. The Company will pay the transportation charge for shipment back to the Purchaser of any Product received for legitimate Warranty repair.

C: Responsibilities of the purchaser under this warranty.

1. Complete (fully and accurately) and return to the Company, the Warranty card included in the box. Otherwise, Purchaser will have to show dated

proof of purchase to qualify for service under the provisions of the Limited Warranty.

2. Promptly notify the Seller or the Company of any claim hereunder.

3. At the Option of the Company, return the product to the company for inspection. Authorization must be given prior to any product return. Call the

Company 61 3 9708 2846 or write the Company at Factory 1, 2 Network Drive Carrum Downs Victoria Australia 3201,for authorization and complete

instructions on how to return the product directly to the company.

4. Use reasonable care in installation, maintenance, operation, use and storage of the Product.

5. Have Warranty work, installation performed by a authorized dealer or representative approved by the company if required.

6. Except as noted in B.2., transportation charges to return the unit back to the manufacturer are the responsibility of the Purchaser.

7. Labour costs incured at any authorised, non authorised service centre, shop, and or place or repair are not covered under the warranty, and are the sole

responsibilty of the owner/purchaser.

D. This Limited warranty covers:

1. Defects in workmanship or materials.

2. Any part or parts of the product sold or manufactured by the Company, excluding wearable components including but not limited to brushes, and or

bearings.

E: This limited warranty does not cover:

1. Any failure that results from improper installation of the Product.

2. Any failure that results from accident, purchaser’s abuse, neglect, modification, improper maintenance, or failure to operate and use the product in

accordance with Bell Marine.

3. Wearable components including but not limited to brushes, and or bearings, which are considered to be consumable items under normal working

conditions.

4: Rope and chain kit breakage, damage due to usage, age and or misconduct of boating activity for which the rope/chain was not designed for.

5: Labour costs incured at any authorised, non authorised service centre, shop, and or place of repair are not covered under the warranty, and are the sole

responsibilty of the owner/purchaser (as listed above in Sub Cat. C)

6: Any opening or attempt to open the winch motor and or gearbox will VOID warranty

F. There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular purpose are limited to one (1) year from date

of purchase. This is the exclusive remedy and any liability for any and all incidental or consequential damages or expenses whatsoever is excluded. Some states do

not allow limitations on how long an implied warranty lasts, or do not allow exclusion or limitation of incidental or consequential damages, the above limitations may

not apply to you. This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state. Bell Marine reserves the right to alter

specifications on any product without notice. All rights reserved. This publication or part thereof may not be reproduced in any form without written permission.

5 Year Limited Warranty

Typical Winch Installations Samples

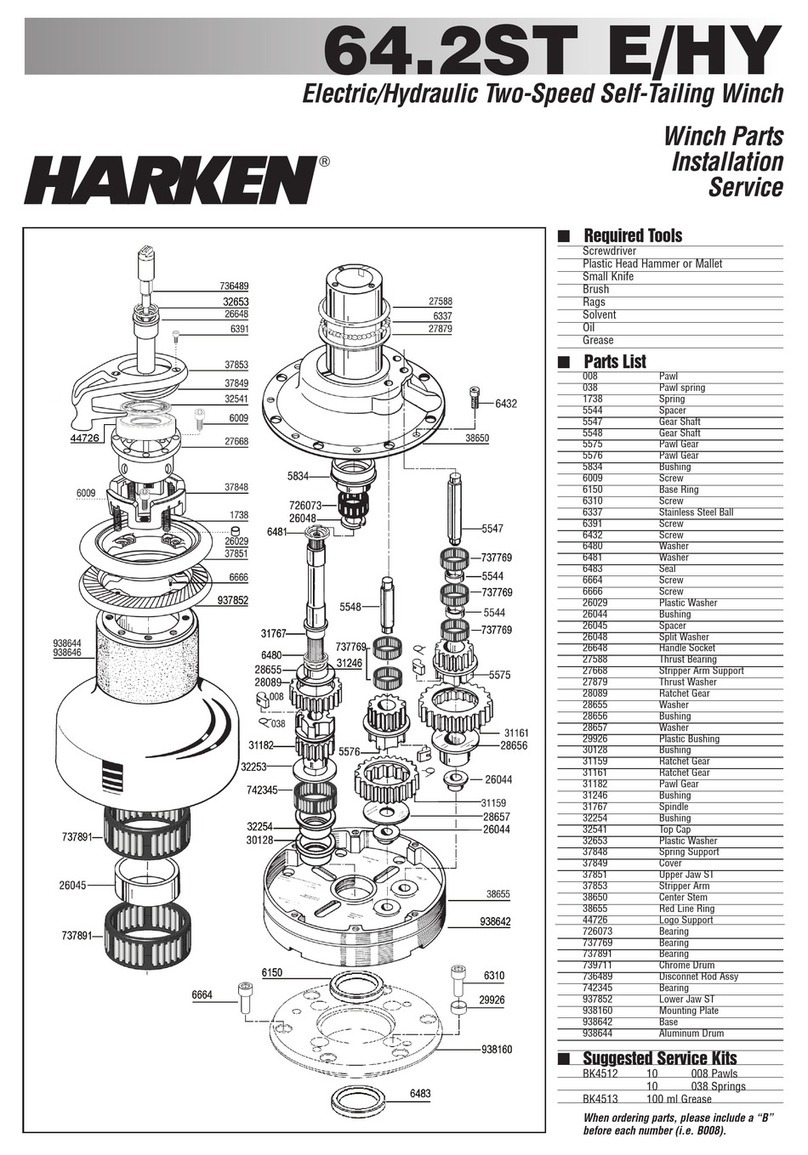

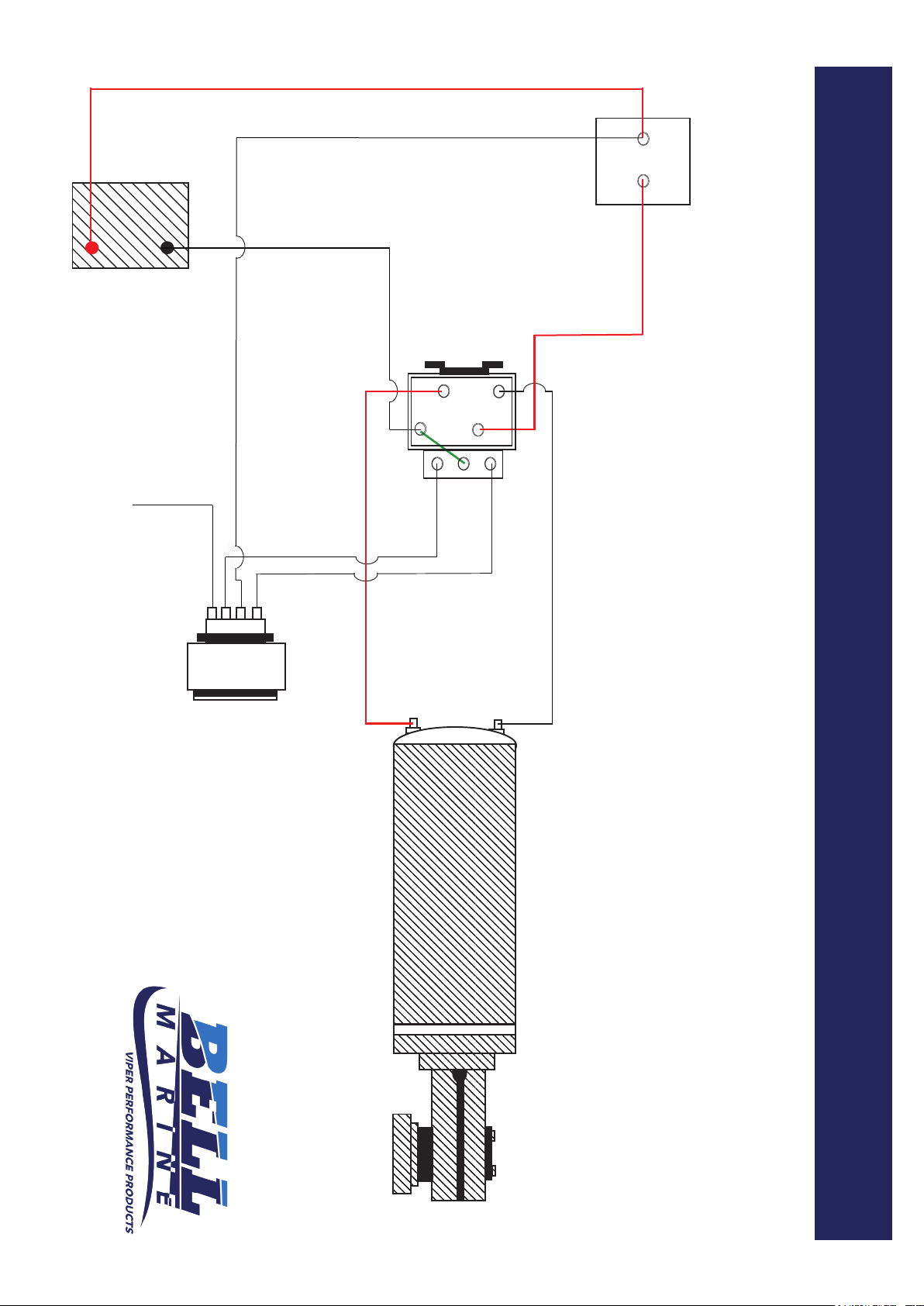

Anchor Winch Wiring Diagram A

Battery

Electric Winch Motor

Up Down

Switch

100 Amp Circuit Breaker

+

-

3 B&S Cable

Reversing

Solenoid

3 B&S Cable

3 B&S Cable

3 B&S Cable

4

BAT

AUX

1

3

2

RE: 01072016C

SSERIES 1000 MICRO/RAPID DRUM WINCH

To negative (-) enabling

LED indicator

7

Please note: solenoid must

be mounted with terminals

in the up position.

Polarity (+/-) only denotes

motor rotation direction

Only use 3 B&S Tinned Marine Cable = 25mm Sq Cable

All switch wire must be 1.5mm Tinned Marine Cable

WARNING: Remember never to connect your battery leads until your installation is complete!

PLEASE NOTE: Pull your wiring loom through your boat first to calculate the position of your

winch accessories before cutting any holes.

Please note: Do not remove the serial number sticker or dismantle the electric

motor under any circumstances as you will void your warranty as you could

cause yourself serious harm.

Every Viper winch electric motor is pressure tested and sealed in our factory to

ensure no water ingress into your electric motor.

Viper

A

B

C

12

3

GALVANISED & POLISHED STAINLESS STEEL ANCHORS

Designed by Bell Marine to suit most bow rollers and a must for

electric winch installations, these ploughs are guaranteed to hold

bottom in any weather conditions and will not damage your bow

roller on retrieval which prevents your rope from damage. You will

never need to go up to the bow of your boat ever again and kick

your anchor off, these plough anchors self-launching, each and

every-time and now come with stainless steel D shackle with

counter sunk allen key S/S bolt.

P/N 30015 10LB/5KG GALVANISED PLOUGH ANCHOR

P/N 30011 15LB/7KG GALVANISED PLOUGH ANCHOR

P/N 30012 20LB/9KG GALVANISED PLOUGH ANCHOR

P/N 30028 25LB/12KG GALVANISED PLOUGH ANCHOR

P/N 30029 35LB/16KG GALVANISED PLOUGH ANCHOR

“S” SERIES ALLOY BOAT FITMENT KIT

As the production of alloy boats increases, more and more winches are

being fitted to aluminum run abouts and Pro Series boats. The two (2)

biggest problems with fitting a full stainless steel winch or any stainless

fitting to an aluminum boats is the reaction between the 2 different

metals in a salt water environment.

The second issue is, if there is a 12V power supply to the equipment you

are fitting and unless you are 100% sure you have insulated all stainless

steel from your aluminum hull, deck or dash, electrolysis will eat

everything away.

The Alloy fitment kit includes 2 HD plastic winch sandwich plates,

anchor roller insulation, insulation spacers for each bolt, aluminum

switch face plate. RECOMMENDED FOR EVERY ALLOY BOAT!

P/N 30038-A ALLOY FITMENT KIT FOR VIPER S SERIES MICRO WINCH

P/N 30021-A ALLOY FITMENT KIT FOR VIPER S SERIES RAPID WINCH

P/N 30072-A ALLOY FITMENT KIT FOR VIPER S SERIES GRAVITY FEED

P/N 30003-A ALLOY FITMENT KIT FOR VIPER S SERIES 1500 WINCH

NEW

RELEASE!

“Recommened for all aluminum boats”

PRO SERIES MARINE GRADE WIRING LOOMS

FOR MICRO/RAPID/GRAVITY FEED

& 1500 WINCHES

Viper

Viper

P/N 30034 MARINE WIRING LOOM FOR BOATS

UP TO 6 MTR (MICRO/1000)

P/N 30035 MARINE WIRING LOOM FOR BOATS

UP TO 8 MTRS (MICRO/1000)

P/N 30060 MARINE WIRING LOOM FOR BOATS

9MTRS & UNDER- (SERIES 1500)

P/N 30061 CUSTOM MADE WIRING LOOM

Anchor Winch Options

PRO SERIES HAWSE PIPES

Viper

Viper

PRO SERIES DELUXE ANCHOR SWIVELS

Bell Marine deluxe anchor swivels are normally attached between

your chain and anchor, reducing the chance of your rope and chain

getting twisted and your anchor spinning on the way up and

damaging your hull. The 316 stainless steel joint allows for perfect

transition through your anchor rollers with no risk of damage to

any components on your boat - rated to 200kgs/440lbs

.

P/N 30019

VIPER PRO SERIES DELUXE ANCHOR SWIVEL

LARGE SUIT 8-12MM CHAIN

P/N 30001

VIPER PRO SERIES DELUXE ANCHOR

SWIVEL SMALL SUIT 6 - 8MM CHAIN

PRO SERIES DELUXE STAINLESS STEEL BOW ROLLERS

P/N 30006

VIPER PRO SERIES DELUXE

SINGLE ROLLER BOW ROLLER

P/N 30007 VIPER PRO SERIES DELUXE BOW ROLLER LARGE

W70 X L370 X H210MM (MOUNT AREA 210 X 70MM)

W100 X L500 X H 250MM

(MOUNT AREA 300 X 100MM)

P/N 30016

VIPER PRO SERIES

DELUXE BOW ROLLER SMALL

ORIGINAL AND THE BEST CHAIN SOCKS - AUST MADE

P/N 30053 VIPER CHAIN SOCK TO SUIT 6MM SHORT LINK CHAIN-8MTRS

P/N 30053G VIPER CHAIN SOCK TO SUIT 6MM SHORT LINK CHAIN-8MTRS

P/N 30036 VIPER CHAIN SOCK TO SUIT 6MM SHORT LINK CHAIN-10MTRS

P/N 30036G VIPER CHAIN SOCK TO SUIT 6MM SHORT LINK CHAIN-10MTRS

P/N 30037 VIPER CHAIN SOCK TO SUIT 8MM SHORT LINK CHAIN-12MTRS

Viper

bellmarine.com.au

ALSO AVAILABLE

IN FLURO GREEN

30023 - VIPER PRO SERIES HAWSE PIPE SMALL

Opening W90 x 55mm

Flange W158 X D97mm

Cut Out W120 X 65mm

Overall Height 78mm

30031

VIPER PRO SERIES HAWSE PIPE

LARGE

Opening W195 X H100mm

Flange W220 X D120mm

Cut Out W190 X 85mm

Overall Height 130mm

NEW

VERSION!

P/N 30013 5kg S/S PLOUGH ANCHOR

P/N 30014 7kg S/S PLOUGH ANCHOR

P/N 30030 9kg S/S PLOUGH ANCHOR

Table of contents

Other bell marine Winch manuals

Popular Winch manuals by other brands

Mile Marker

Mile Marker HI9000 Installation and operator's manual

Kolpin Outdoors

Kolpin Outdoors KAWASAKI MULE QUICK-MOUNT 4500 Assembly & owners manual

Pfaff

Pfaff BGV C 1 operating instructions

Comeup

Comeup DS-9.5i instruction manual

BRADEN

BRADEN CH SERIES Installation maintenance and service manual

Antal

Antal W6 Installation and maintenance manual