Bell Sound Systems RT-204 User manual

PnoToFAcr* FolJ.t

$

ao

zcl

e*

o4

laJ

.Et

fo

Hg

En

e=

lll r

-

'la

pO

1F

irZ

o9

$

GENERAL I NFORMAT ION

The Bell Model RT-204 is designed to record and play back two tracks of material on

standard width recording tape (/ 4"), which doubles the playing time of a standard 5r' or ?rt

reelof tape withno loss of frequencyresponseorquality. Recordings canbe made from a radio,

television receiver or phonograph, in addition to those made directly from the microphone.

Recordings can be played back through the self-contained speaker or external speaker through

use of the External Speaker Jack.

The Bell Model RT-204 has two tape speeds, 7 / 2rt and 3 3/ 4t'per second. Using both

tracks, the recording time is as followed:

Size Reel 3 3/ 4r'Speed 7 V 2" Speed

5'' (600 ft. )

7" (1200 ft. )I hour

2 hours I/ 2 hour

I hour

The Bell Model RT-204 is designed to operate on 60 cycle, 110-I20 volts, AC supply only"

Manufactured by:

BELL SOUND SYSTEMS, INC.

A SUBSIDIARY OF THOMPSON PRODUCTS, INC.

555 MAR ION ROAD

COLUMBUS, OH IO

fhis molerial compiled ond published by

HOWARD W. SAtS & CO., lNC., !NDIANAPOIIS, INDIANA

Copyrioh0 t957 . All Righb Rcrcrvcd

$ff367

BELL SOUND

MODET RT-2O4

llITE g -57 FOIDER 5

I

FIGURE I

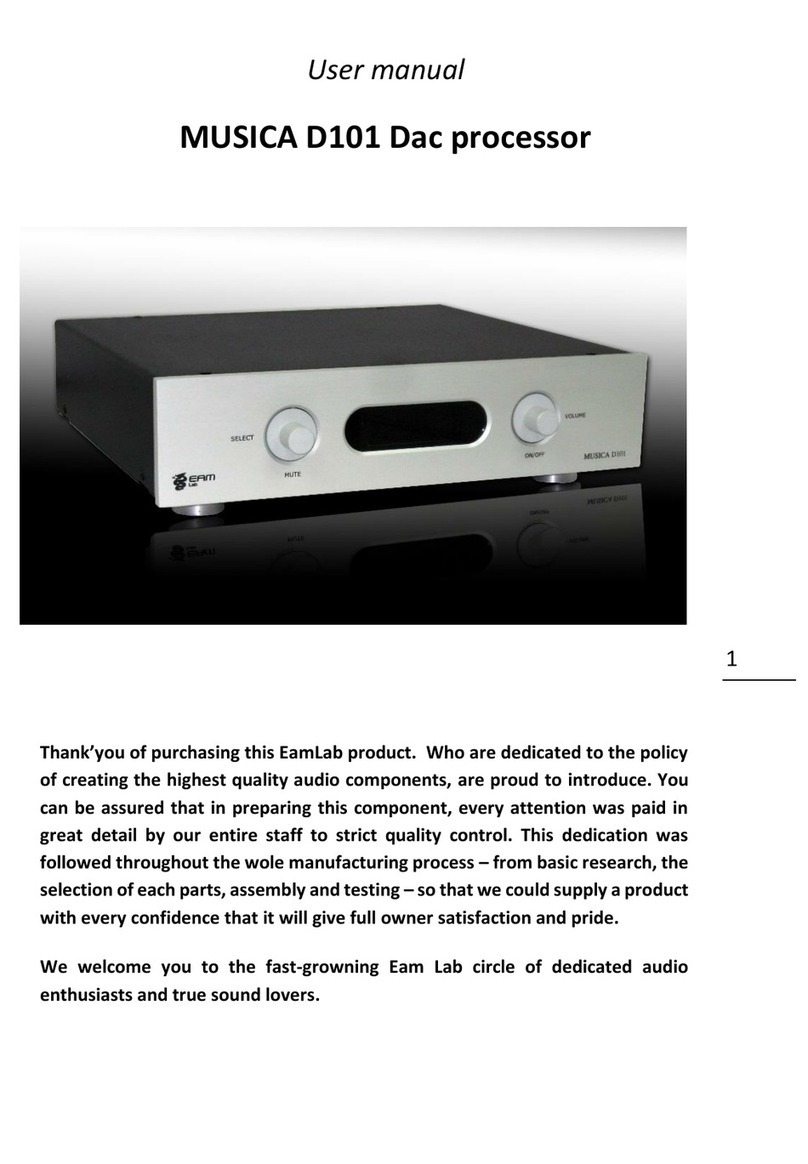

GENERAL DESCRIPTION

The BeU Model RT-204 is a dua.l track tape re- Recordings may be monitored through high or

corder having seven piano-type key6 for controlling lon' impedance headphones, external gpeaker, or an

tape speed, record, play, rewind, forv'/ard, and stop external amplifier.

modes' Built in interlocks prevent the operator from

placing the machine in more than one mode at a Ume.

This Bell Tape Recorder has been designed to The 'stop" key mu6t be depressed belore going from,

ellminate adjustments which may ""o"" . p"o6lu- i" 9i mode to arother, except when changing speed'

the use and servicing of tris malhine. Thiee motors This prevents tape brea-kage, spillage, and accldental

are used, relvind, capstan, arld taleup, As a result, elasure'

moving parts on the transport mechanism have been A remova.ble cover plate otr the bottom of the

held to a minimum- cabinet allows eaay acceas to tubes, motors, and hum

adjustment.

Two output jacks permit us€ of an external ModelRT-2o4is designedto operate on 80 cycle,

speaker or high fidelitir ampllfler system. When the 110-120 volts, AC supply only. Severe Damage Will

speaker iack i8 used, the self-contained slrealrer is Result U Connectiqr Is Mad€ To A Direct Current

automatically discqrnected. (DC) LINE.

SPECIFICATIONS

i

Frequency Response: 30to 10p00 cycles at? l/2inches Fast Forward: 5" reel - 25 *2 second.

per second. ?" reel - 45 +5 second.

Fast Rewind: 5" reel - 25 +2 second.

7" reel - 45 +b second.

Speeds (two): PIay or record. 7 L/2 or 3 3/4inches Wow and Flutter: Less than.3%atl L/2I.P.S.

ter secodd. Less than . i% at J g/4I.p.S.

PAGE 2

OPERATI NG INSTRUCTIONS

Preparing For Qperation -

1. Open and remove the lid by sliding it to the

right of the hinges. Place the recorder on a hard flat

surface so that the feet will allow air to enter the

bottom grille for ventilation.

2. Insert the AC power cord plug into a con-

venient 110-120 volt, 60 cycle AC ouilet.

Threading The Tape -

Place a reel of ''A" wind tape (glossy side out)

on the supply reel platform (2). T\rrn the reel while

pressing down lightly so that the three slots in the

reel hub engage the three keys on the reel platform.

Place an empty reel on the take-up reel platform (3)

and draw the endof the tape acrossand into the hub of

the empty reel. Insert the end of the tape into one of

the slots in the hub of the empty reel and rotate reel

counter clockwise until tape is secured to hub. Drop

the tape intothe tape slot andtake up slack in tape be-

fore turning unit on.

NOTE: This machine will operate in either a horizontal

or vertical position. When operating with the

front panel in a vertical position, use the two

rubber reel spindle tips to hold the reels firmly

on the spindles. Remove these (pull off) when

loading tape on machine.

To Record From Microphone -

Depress the "Stop" key, then turn on the re-

corder by rotating the "Tone" control clockwise. De-

press the desired speed key and allow approximately

30 seconds for the unit to warm up. Insertthe micro-

phone plug into the Mic. jack. Next, pull the record

lock (30) toward the front of the case and depress the

red record key. The tape will move and all sounds

striking the microphone will be recorded on the tape

if the "Volume" control is turned up sufficiently, The

correct volume control setting is that which causes

the record level lamp (Iocated under the "Volume"

control lnob) to flash on peak sounds. If the lamp

fails to light, volume is too low. If the lamp flashes

constantly, volume is too high, The "Volume" control

should be set f.rom L/2 to 3/4 of. maximum.

To Record From Radio. Phono or TV -

The most satisfactory method is to connect the

'Radio" input ofthe recorder tothe radio or TV voice

coil terminals.

In the case of an AM-FM Tuner, connect to the

tuner output where there are no tone controls in the

circuit. If this is not feasible, be sure tone controls

are in a flat position. AIso, cut out any loudness con-

trols since these accentuate bass and treble fre-

quencies.

To record from a phonograph equipped with a

crystal cartridge, connect the cartridge directly into

the 'Radio" input on the reeorder. When using a

magnetic cartridge, connect a preamp between the

cartridge and 'R.adio" input on the recorder.

After the proper connections are maderproceed

with the recording as described under "To Record

From Microphone ".

NOTE: In order to obtain the best recording quality,

volume control on the RT-204 should be at a

50S setting or above when the record level

lamp flashes on peak sounds. If the volume

control, when recording, must be turneddown

to a low setting (say L/4 of the way up or 25$)

to obtainproper flashing of the lamp,it means

that the signal being fed into the recorder is

too high. To avoid possible distortion, place

the microphone farther away fromthe source,

or turndown thevolume ofthe radioor phono-

graph so that the RT-204 volume control can

be advanced to 50% or higher for proper re-

cording leveI.

DuaI Track Operation -

When recording has used up the full tape length,

except for a few turns on the supply reel (left hand

side),turn reelsover and exchangeend for endplacing

the now full reel on the supply platform and the now

empty reel (except for a few turns) on the take-up

platform. Proceed with the recording as described

under "To Record From Microphone".

Either track may be played back at any time by

turning the reels over and exchanging platforms.

To Rewind -

After recording is made, press the "Stop" key

all the way down, then depress the 'lRewind" key.

When desired portion of tape is rewound, push down

'Stop" key. Wait for the tape to stop before pressing

the '1Play" key.

To PIay a Recording -

1. To play back a tape recorded on the RT-204

or to play a commercial pre-recorded tape, install

reels on platforms and thread as for recording. Turn

unit "On", select proper speed, and depress "Play"

key. Adjust "Volume" and "Tone" controls for de-

sired listening level. After playing, depress t h e

'Stop" key.

2. To play back second track, turn reels over

and place on opposite reel platforms. This may be

done at any time during playback.

To Use External Speaker -

Recordings may be played back through an ex-

ternal speaker by inserting a phoneplug inthe speaker

jack. This jack when used, disconnects the built-in

speaker.

To Use External Amplifier -

Recordings may be played back through a Hi-Fi

system by connecting to the "Ampl." output jack. To

silence internal speaker while in "Play" position, insert

a phone plug, miniature type, into the "Spkr," output

E*

s=

'la

FO

1F

*'Z

o('

5

PAGE 3

jack. For best results, the phone plug should be ter-

minated in a 6 ohm resistor.

Fast Forward -

In playback, it is sometimes desirable to skip

portions of tape to a particular spot. To do this, push

down "Forward" key untiltape arrives at desiredspot;

thendepress 'Stop" key. Be surekeys arepressed all

theway down. Wait forthetape to stopbeforepressing

the 'Play" key.

FIGURE 2

D I SASSEMBLY I NSTRUCTIONS

AD J U STMENTS

To Monitor Recordings -

Any signal being recorded may be monitored by

plugging high or low impedance phones into the "Spkr."

output jack.

An external amplifier may be used to monitor

any signals being recorded if connectedto the "Amp."

jack. An external speaker may also be used. Use

"Spkr." output jack.

To Remove Recorder From Cabinet -

Remove the four Phillips-head screws located at

the edgesof the top deck plateand lift theunit straight up from the case. Disconnect speaker leads from

speaker before lifting unit completely out of case.

Head And Pressure Pad Adiustments -

To properly check rread azimuth alignment it is

necessary to have a pre-recorded 1 mil alighment tape

which results in a ?500 cycle per second signal when

operated at 7 l/2 inches per second. PIay alignment

tape back through recorder with an AC VTVM connected

across the speaker or 6Qload.

CAUTION: Be sure recorder is in "Play" position to

prevent erasure of alignment tape.

Three things can cause low meter readings (pro-

viding amplifier and tubes are working properly).

These are, dirty headrimproper pressure pad pres -

PAGE 4

sure, or wrong head alignment angle. Check these

things as follows:

1. Check head to besure there is no dirt on the

pole pieces or bakelite portion. Dirt holds the tape

away from the pole pieces and lowers output. If head

is dirty, clean with head cleaning solvent or alcohol.

Wipe dry immediately after cleaning.

2. Check that pressure pads (22 and 23) cover

the head pole faces. The pressure at the spring side

of the play-record pad (23) should be 30 grams and

thepressure at the spring sideoferase pad(22) should

be 20 grams. Bend pad springs only when necessary,

avoiding odd-appearing kinks in the springs.

FIGURE 3tE

etr

lll r

-

'ta

pO

:{C

irZ

oE'

5

3. To adjust head alignment by means of tape

guide heights without destroying the correct nominal

tape height at the head, proceed as follows:

Set both left and right tape guides (29) to .486"

(at top surface) off of panel. With head fully seated,

run the ?500 cycle alignment tape through the machine

withthe "Volume'l and "Tone" controls full on. Adjust

the left tape guide by rotating not more than plus or

minus L/2 twn (*.016'). If this fails to produce a

peak voltage reading on the AC vacuum tube voltmeter,

adjust the right tape guide by not more than +1/4 turn

(+.008'). This amount of adjustment will tilt the tape

by morethan the normal head mis-alignment andif no

peak is reached either the head is not fully seated or

the head mounting plate (1a) is bent, or the head itself

is worn. Tape position must be such that, when playing

back a tape having the opposite track recorded to

normal level no crosstalk will be audible in the play -

back (slight crosstalk may be audible in ideal listening

conditions).

ReeI Platform Adjustment -

The reel platforms (2 and 3) must clear the deck

plate by l/32" minimum - t/16" maximum and both

reel platforms must be the same height on a given

machine. Adjustment is made by loosening set screw

(a) and positioning reel platform (2) or (3) to the cor-

rect height. After adjustment is made, tighten set

screw (4).

Hum Adjustments -

The hum balance control (R3) on the amplifier

should be adjusted first for minimum amplifier hum

but wiII probably have to be slightly re-adjusted for

Iowest overall hum, i.e., the hum voltage will help

cancel hum induction into the head from the power

transformer and motors. Minimum hum voltage in

playback is obtained by correctly polarizingthe power

transformer and motors, correctly polarizing the line

cord plug, adjusting the hum balance pot for minimum

hum, and selectingthe pre-amp tube (V1) if necessary.

Procedure for Motor Fhasing - in "PIay" Position But

Without Tape.

1. With aII motors disconnected and the head

shorted, the amplifier should have only a 10 to 15 mv

hum output. With the head connected, hum is from

the power transformer and should be under 50 mv.

This can be reduced by shimming the transformer

mounting spacers to tilt the transformer (only neces-

sary in extreme cases).

2. PIug inthe take-up motor (45) inthe direction

giving lowest hum. Check hum balance control (R3).

3. Plug in capstan motor (62) in the direction

givinglowest hum - donot change take-up motorcon-

nections. Check hum balance control (R3). Brown

wire on common should be minimum.

4. Plug in rewind motor (a1) in the direction

giving lowest hum. This motor will introduce l2O

cycle hum which willnot be helped by the humbalance

control, however it sometimes affects hum balance

stightly and the hum control should be adjusted after

this last motor is connected.

Measure hum

"Volume " control

minimum.

output voltage across 6O load,

maximum and "Tone" control

PAGE 5

A PHOTOFACT'EXPLODED" VIE\Y

@ Howard \7. Sams & Co., lnc. 1957

PAGE 6

FIGURE 4A. EXPLODED VIEW OF PARTS ABOVE BASEPLATE.

@@

\_L

A PHOTOFACT "EXPLODED" VIEW

@ Howard W. Sams & Co., lnc. 1957

I

Rt*-

tJ

--4--@

tH

e=

I||r

I

'ln

FO

{F

irz

oe

A

PAGE 7

FIGURE 48. EXPLODED VIEW OF PARTS BELOW BASEPLATE.

The capstan shaft (portion extending above top

deck plate), pressure roller (1?), tape guides (29), and

play-record-erase head (13) are subjectto an accumu-

lation of tape coating oxide which is worn off the tape

as it passes these parts. These parts should be

cleaned approximately every ten hours of runningtime .

All of these parts except the pressure roller (1?)may

be cleaned vrith head cleaning solvent, alcohol, or

Lubricants applied at time of manufacture are

sufficient to last for a long period of time,but in case

parts arereplaced,or after each 1000hours of opera-

tion - more or less, Iubricate as follows:

1. Apply one drop of #10 motor oil to the top

and bottom bearings of the take-up motor (45) and the

rewind motor (41). An oiling hole is provided in each

bearing holder casting.

2. Apply one drop of #10 motor oil to the top

andbottombearings of the capstan motor (62). Caution:

After oiling this motor, be certain that no oil seeps

onto the motor pulleys.

TROUBLES

Poor Tape Drive In Play and Record -

Poor tape drive can be caused by:

1. Oil or grease on the driving surfaces of cap-

stan drive wheel ( 57) and the upper pulley on the capstan

motor (62). This will cause poor tape drive when

operating in the ? t/2 inch per second speed position.

2. OiI or grease on the driving surfaces of the

capstan drive wheel (72) and the lower pulley on the

capstan motor (62). This will cause poor tape drive

when operating in the 3 3/4 inch per second speed

position.

3. Oil, grease or tape coating oxide on the pres-

sure roller (17) and the upper portion of the capstan

shaft rvill cause poor tape drive in both the 3 3/4 and

7 L/2 inch per second speed position.

CAUTION: Use alcohol or water when cleaning rub-

ber driving surfaces. Never use carbon

tetrachloride when cleaning rubber parts.

4. Spring (67) disconnected or missing. If this

springis disconnectedthere willbe notape drivewhen

operating the recorder in the ? L/2 inch per second

speed position. Replace spring (6?),

5. Spring (61) disconnected or missing. If this

springis disconnectedthere will beno tape drive when

PAGE 8

CLEANING

carbon tetrachloride. Use alcohol or water when

cleaning the pressure roller; never use carbon tetra-

chloride rvhen cleaning any rubber driving surface.

CAUTION: Topreventscratchingthe headpolepieces,

never use a metal tool when cleaning the

play-record-erase head (13).

LUBRICATION

3. Apply one drop of #10 motor oil to the top

and bottom capstan bearings. Caution: Afteroiling

these bearings be certain that no oil seeps onto the

rubber idlers (5? and 72) or onto the portion of the

capstan shaft which extends above the top deck plate.

4. Apply one drop of#10 motor oil tothe pres-

sure roller bearing (17).

NOTE: Only a very small amount of oil is needed on

each bearing. It is desirable to use too little

rather than too much for Iess trbuble is likely

to result. OiI onthe rururing surfacesbetween

the motor pulleys and the rubber idlers is

often a cause for poor or no drive as well as

excessive wow and flutter.

AND REMED IES

operating the recorder in the 3 3/4 inch per second

speed position. Replace spring (61).

Take-Up ReelWill Not Take Up Tape

In Play Or Record Position -

1. Set screw (4) in take-up reel platform (3)

loose, causing the reel platform to slip on the motor

shaft. Tighten the set screw.

2. Resistor (R26) open. Replace.

Recorder Will Not Rewind Tape -

1. Set screw (4) in supply reel platform (2)

loose, causing the reel platform to slip on the rewind

motor shaJt. Tighten the set screw.

Dynamic Brakes Do Not F\rnction Properly --

1. Check selenium rectifier (M1).

2. Check resistors (R25 and R2?). If either of

these resistors is open, there wiII be no hold-back

tension on the re'urind reel when in the "PIay" or

'Record" mode.

3. If, when going from "Rewind" to 'Stop", tape

spills from the take-up reel(3), check resistor (R25).

4. If, when goingfrom "Fast Forward"to "Stop",

tape spills from the rewind reel (2), check resistor

(R2?).

Normal DC voltages for selenium reqtifier (M1)

and motors (41) and (45) are as follows:

Selenium rectifier (M1), 'lPlay" position - 30

volts DC.

Rewindmotor (41),'Flay or Record'- 8 volts DC.

Rewind motor (41) in 'Stop" after 'Flay or

Record" - 28 volts DC.

Take-up motor (45)in "Stop" after "Play or Re-

cord" - 1? volts DC.

1. Check aII tubes, inspect wiring and function

switch (Mb) for poor or open connections.

2. Test all four jacks for open or shorted cir-

cuits. These jacks mustnot groundagainstcover plate

(e).

3. Refer to schematic for all voltage and re-

sistaJrce readings.

4. Test bias oscillator as follows: Connect a

AC vacuum tube voltmeter across the erase head wind-

ing atthe play-record-erase head socket. Due to high

frequency, use unshieilded wiring. Place recorder in

"Record" position. Voltage should be 50 to 68 volts.

Check bias and erase frequency with a signal

generator and scope. This should be 58 to 65 kc.

AMPLIFIER TESTS AND REPAIRS

EI.TCTRICAL PARTS LIST

Check bias voltage across play-record head

winding at the play-record-erase head socket.

A. 30 to 50 volts atl L/2 inches per second.

B. 10 to 1? volts at 3 3/4 inches per second.

5. The play-record-erase head may be tested

for continuity ii suspected of being open. The erase

winding should be approximately 10 ohms and the play-

record winding about 160 ohms.

CAUTION: Whenever the headis tested for continuity

it willbecome magnetized to some extent.

Therefore, always demagnetize head aJter

testing.

En

(,tr

mr

'l^

-o

:{C

pz

o9

5

Ref.

No. Part No. Description Ref.

No. Part No. De6cription

V1

v2

V3

v4

C1A

c1B

c1c

c2A

c28

czc

c3

cq

c5

c9

c10

c11

cl2

c13

c14

cl5

c16

c17

c18

cl9

R1

R2

c6

c7

C8

R3

R4

R5

R6

R?

R8

R9

B-20048P28

B-20048P28

B-2004?P98

B-20047P14

B-20t4tPt

B-20047P81

B-20049P87

B-2004?P86

B-20047P81

B-2004?P86

B-20047P1?

B-2004?P96

B-20049P98

B-20047P81

B-20049P87

B-20047P81

B-20047P1?

B-20049P?

B-20049P64

B-20066P106

B-20066P108

B-20066P72

12AX?, Pre-Amp.

6SN?GT, Bias Osc,-AF Amp.

6V6GT, Audio Output

6X5GT, Rectifier

Cap., Elect., 20 mfd. @ 450 V.

Cap., Elect., 20 mfd. @ 450 V.

Cap., Elect., 50 mfd. @ 50 V.

Cap., Elect., 20 mfd, @ 450 V.

Cap., Elect., 20 mfd.@ 450 V.

Cap., Elect., 50 mfd.@ 50 V.

Cap., Molded Tub., .1 mfd.@ 200V

Cap., MoldedTub., .0013 mfd.@

400 v.

Cap., Ceramic Disc, 101000 mmi

@ 500 v.

Cap., Molded Tub., .05 mfd.@400 V.

Cap., Mica, 4?0 mmf.@ 500 V.

Cap., MoldedTub.,.005 mfd. @

400 v.

Cap., MoldedTub., .05 mfd. @400 V

Cap.,Molded Tub,, .005 mfd.@400 V

Cap.,Molded Tub., .002 mfd,@400 V.

Cap.,Molded Tub., .1 mfd. @400 V.

Cap.,Mica, 150 mmf. @ 500 V.

Cap.,Molded T\rb., .05 mfd. @400 V

Cap., Mica, 470 mmf. @ 500 V.

Cap., Molded T!b., .05 mfd. @400 V.

Cap., Molded T\rb., .002 mfd. @

400 v.

Cap., Mica, 100 mmf. @500 V.

Cap., Mica, 2?0 mmf. @ 500 V.

Volume Control, 1 meg.

Tone Cont. and On-Off Switch,

500 KC}.

Ilum Adj. Cont., 100O

Resistor, 470K O, l/2 walt

Resistor, 1500 f,,, 1/2 watt

Resistor, 10 K o, 1/2 Watt

Resistor, 4.7 meg.,L /2 Watt

Resistor, 68 K r}, 1/2 Watt

Resistor, 4.7 meg., l/2 Watt

R10

R11

R12

R13

R14

Rl5

Rl6

R17

R18

R19

R20

R21

F.22

R23

R24

R25

R26

P"21

R28

R29

R30

R31

R32

R33

T1

T2

sP1

L1

M1

M2

M3

M4

M5

M6

M7

M8

M9

Ml0

Ml1

Ml2

B-20256P18

B-20256P16

B-20256p1?

B-20256P15

B-20366

B-20352

B-201 11P29

B-23704

B-2010?-P10

B-20043P31

B-25251

A-25342

B-20209P30

B-20209P20

B-20209P32

B-20209P32

Resistor, 4.7 meg.,l/2 Watt

Resistor, 4?0 K O, l/2 watti+s%

Resistor, 4?0 K f,l, l/2 Watt

Resistor, 33 K A, 1/2 Watt

Resistor, 820 A, l/2 Watt

Resistor, ?500 O, 1/2 Watt

Resistor, 1 meg., 1/2 Watt

Resistor, 1500 A, l/2 Watt; +5$

Resistor, 470 K f,, l/2 Watt

Resistor, 100 K f,,, L/2Waft

Resistor, 390 A, 1 Watt

Resistor, 2.2 meg.,l/2 Watt

Resistor, 2?0 K O, 1/2 W^tt

Resistor, 100 K O, l/2 Watt

Resistor,6 f,,, 4 Watt

Resistor, 150 A, 5 Watt

Resistor, 200 O, 10 Watt

Resistor, 50 O, 5 Watt

Resistor, 21 K A, l/ 2 Watt

Resistor, 10 K C}, 1/2 Watt

Resistor, 4?0 Q, 1 Watt

Resistor, 470 Q, 1 vratt

Resistor, 27 O, l/2 Watt

Resistor, 47 K A, l/2 Watt

Power Transformer

O:tput Translormer

Spealcer, P.M.; 5 l/4 inch Round

Bias Osc. Coil

Selenium Rectifier

Fuse, Pig-Tail - 3 Amp.GJV

Pilot Lamp, #4?

Neon Lamp, #NE-51

!\nction Switch

Leaf Switch, 'Memory"

Br4king Switch

Motor Socket, I Pin

Head Socket,4 Pin

Mic. Input Jack

Radio Input Jack

Ext..AmpI. Ortput Jack

Ext. Spkr. Ortput Jack

PAGE 9

AMPLIFIER - FRONT VIEW

65N7GT

I2AX7 6X5GT 6V

AMPLIFIER - REAR VIEW

PAGE IO

;H

Etr

tnt

I

'Ul

nO

{e

$2

oe

I

tr)

*

(o

cO

-_

o

gd;

; €3e E

E F€E aE

E= s =EEEi

: EE:5 EEE

=ef.--*EFi

s€ !e =E; F

fra 5 H= H E g

€! iE; scs

E g E gEE i:E

E :E€ =E5;

BFE€P:;E

;;frEEEE:

-; ^iri.cri <;

T UEET U

ci

U

F

2

(9

Itt

I4J

6

lai

r/,

=

c,

u

!

F

o

t/l

tt

u

J

z

J

z.

o

=

tn

o

o-

5

l

=

z.

u

!z

F

tt't

F

=z

=o

uF

9<;€

J o>

#18

=a=

^u o=

I <-)a-

3E==

- >&,o

6-rF

HenH*

EEEEE

O (-)a

7 <+ Z'F

all

(,

2

a

u

u

t!

(J

z.

F

rt,

6

U

e.

nt

--J-e-E--

u?

ooooo

dNco-fLo

--^ -;-;--- -;

b,6666

2

:

E

ts

UI

CL

-.

{@

J''l

z.

o

F

(-)

U

VI

F

=

o

e.

L

5

o-

!<

o

6

)tcil

=

o

F

a(-)

96

tt l-

z.

o

e.

r

Ir, z

o

o=

d ir

<ii

=(/r

oaF

oz.

Lcle,

5

Ir' 2

o

=E

=Yr

UF

Ezo

d

L

-r11,'

-l I

I

(o F

x$l(')

lr)Ct qt

e.

o

F

d)O =

-o F

(\l

J

-o

c)9a

LF

,-z

=o

l'/)o

rU

LZ.

oo

IF

=2.

vo

E@

2

o

6F

e<)

3./,

UF

e. z.

o

E,

L

=

I

z.

o

F

\H

FF z,

o

E.

L

F

u

!z

(J

o

a/,

6

U

-

EA

.: E E/

a

@

F

=

CL

z.

{

=

@

@

@

@

>zl

ol I

/a\

tNt

\e=,/

E

E

o

N

ifit'

6q{

G)E

-,lF I

{o

:@

=

o

ts

-f

=

o

ts

-t

o

r')

x

€

e

o

&,

=

E,

o

14

6

z.

=

u

E,

IA

a) z.

Fct

==

(F/E:

F<

9p

=-

q

or

o

c'

o

=

\

-l c

o

Y

o

o

rn

+

+F

o- +

c

c

N

o- F

<

q

z.

v

I

+

F

F

(.9

ts

z

NI

4e.

=o

EE

-

ro

a.t

t^

I-rr,,

l@

-l

1

\,,

F

r!

I

vI

o;

-C

l--

6.,

z8

6-

EE

N;

i;

F!

gAs

F}

LJo

<I

$o

o

I

c

el

v\l

!zlrl I

R6'

F

g

OF

<=

da_

6=

z

o

-

a-

l@

ol

ll

-z.

O

AF

e(J

gfr

UF

e. z.

c

-

o

to

(\t

o

ro

6t

IE

IE

lo

IN

L$l',

@=

ts

sl

@

*AF

xE

sE

* --+a-{r'

E /6\

g-E

=--------Jv\4.

@

)/

.o

3r

J

-\

!z

o

N

/i,

\

o

o

z.

o

F

c)

l4I

v,

F

=

o

e.

r

PAGE II

MECHANICAL PARTS LIST

Ref.

No- Part No. Dese.ription Ref.

No. Part No. Description

1

2

3

4

5

6

7

8

I

10

11

12

13

t4

15

16

t1

18

19

20

2l

22

23

26

21

28

29

30

31

32

33

34

35

36

24

25

A-25328

A-25328

B-25292

B-20148P51

B-20148P51

D-25291

A-25264

A-2531 I

9-23721P2

A-25402

A-23822

A-23?63P2

A-23518P1

B-20089P48

A-25315

A-25270

B-2540?

A-25334P1

A-25331

B-25332

A-25265

A-25391

A-25269

A-25268P1

#14 Crutch 'Iip, l/4 r.D,

Reel Platform, Supply

Reel Platform, Ta.keup

#8-32X 3h6 Set Screw, Bristol

Cup Point

Head Cover

#6X1/4 Sheet Metal Screw

Tone Control On-Off Knob

Volume Control Knob

Cover Plate

#8l{L/4 Sheet Metal Screw

Head Retaining Spring

Head Cover Bracket

Play-Record-Erase Head

Head Plate

Retaining Ring

Nylon Washer

Pressure Roller Assembly

#6 - 32){l/ 4 Screw, Phillips

Binder Head

Flat Washer

SIide Bearing

Pressure Roller Spring

Erase Pressure Pad Ass'y

Record Pressure Pad Ass'y

Felt Pad

Lock$rasher

nE42Xl/4 Phillips Rd, IId. Mach.

Screw

Presaure RoUer Actuator Ass'y

Hex. Hd. SeIf Tapping Screw

Cover Plate Retaining Clip

Tape Guides

Record Latch Ass'y

#6-32X1/4 Philtips Flat Hd. Mach.

Screw

Tinnerman Push Nut

Shaft

Key (6 used)

Stop-Rewind- Forward Key

Actuator

Play-Record Key Actuator

3?

38

39

40

4t

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

6l

62

63

64

65

66

67

68

69

?0

7t

72

?3

74

75

76

77

A-25268P2

B-20089P58

D-25340

B-25400P1

B-25400P2

A-25399

A-25394

A-25389

B-20089-P26

B-25386P1

A-25397P1

'B-25388

A-25395

B-20025P23

B-20029P41

A-25397P2

A-25382

A-25406

B-25386P2

B-25381

A-25257

Record Key (red)

Fibre Washer (13 used)

Deck Plate Assembly

#6-32 X 1 Hex. Hd, Mach. Screw

Rewind Motor

I-ockwasher

#6 Hex. Nut

#6-32X1 Hex. Hd. Mach. Screw

Take-up Motor

Lockwasher

.#6 Hex. Nut

Gasket

Motor and Capstan Mtg. Housing

#S-32XL/4 IIex. Screw

Capstan Lever WeId Ass'y

Spring Washer

Shoulder Washer

#6 Hex. Nut.

Capstan Shaft

FeIt Washer

Capstan Drive Wheel, 1 l/2 l.P.S.

RoII Pin

#6-32X1 f/4 Rd. Hd. Mach. Scres

Lockwasher

Motor Spring

Capstan Motor Assembly

Capstan Motor Support Assembly

6-32X3/8 FiI. Hd. Mach. Screw

Spacer

Grommet

Motor Spring

Capstan Motor Support

Eyelet

Motor Spacer

#6 Hex. Nut

Capgtan Drive Wheel, 3 3/4 I.P.S.

Capstan Yoke

#8-32 Hex. Nut

Lockwasher

#8-32X3/8 Phillips Hd. Mach.

Screw

FlywheeI Assembly

Page 12

Table of contents