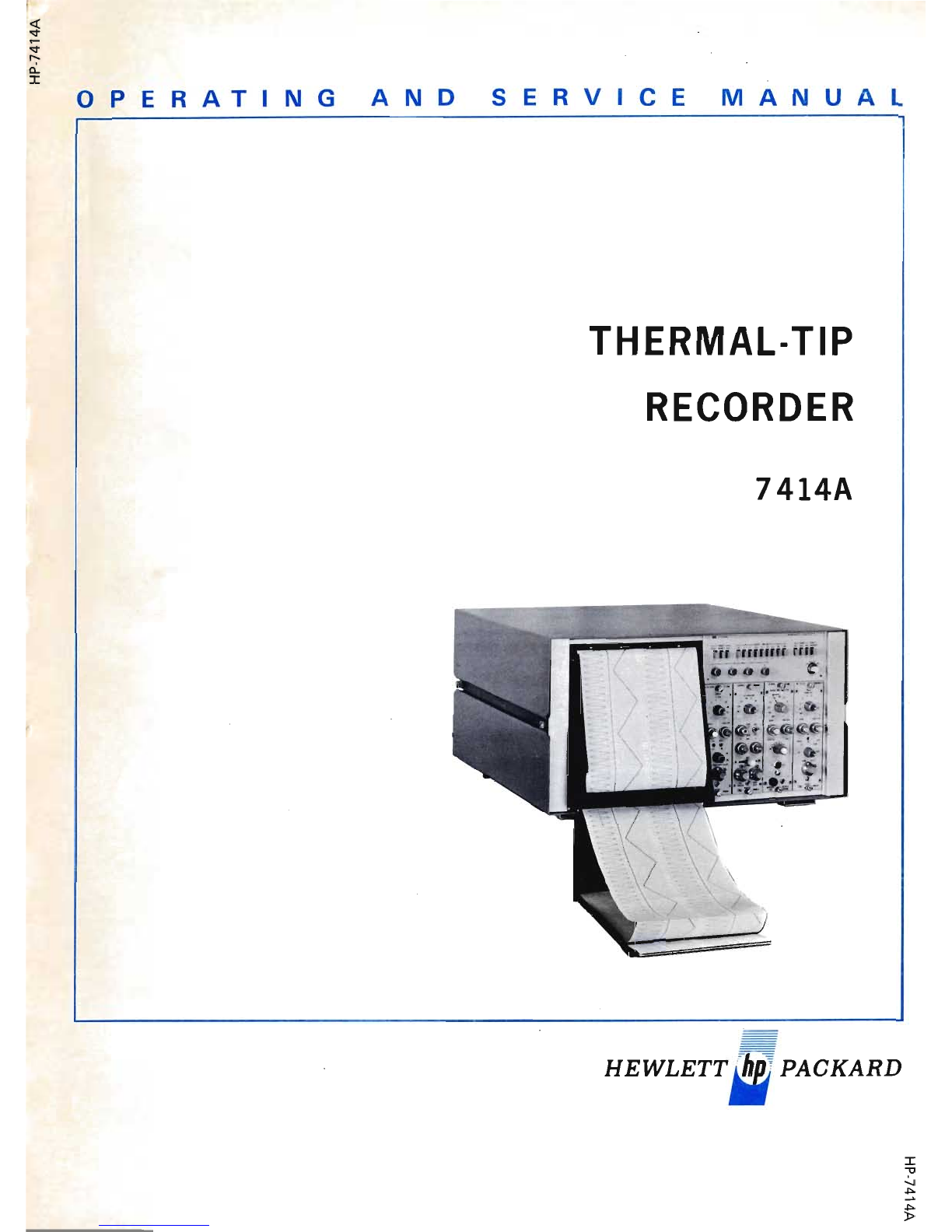

Model

7414A

SECTION I

GENERAL

INFORMATION

Section I

General Information

1-1.

INTRODUCTION.

1-2. This manual contains installation, operating, and main-

tenance instructions for

your

Hewlett-Packard Model

7414A Recording System, which has four channels, and

produces four recorded traces with heated styli on heat-

sensitive chart paper Permapaper.® Other manuals, for use

with the 8800-Series Preamplifiers, and for

other

equip-

ment ordered with the 7414A System are provided sepa-

rately since avariety

of

preamplifiers, scopes, tape

re-

corders,

computer

terminals and control units

may

be used

with the recording system.

1-3.

FOUR-CHANNEL

RECORDER.

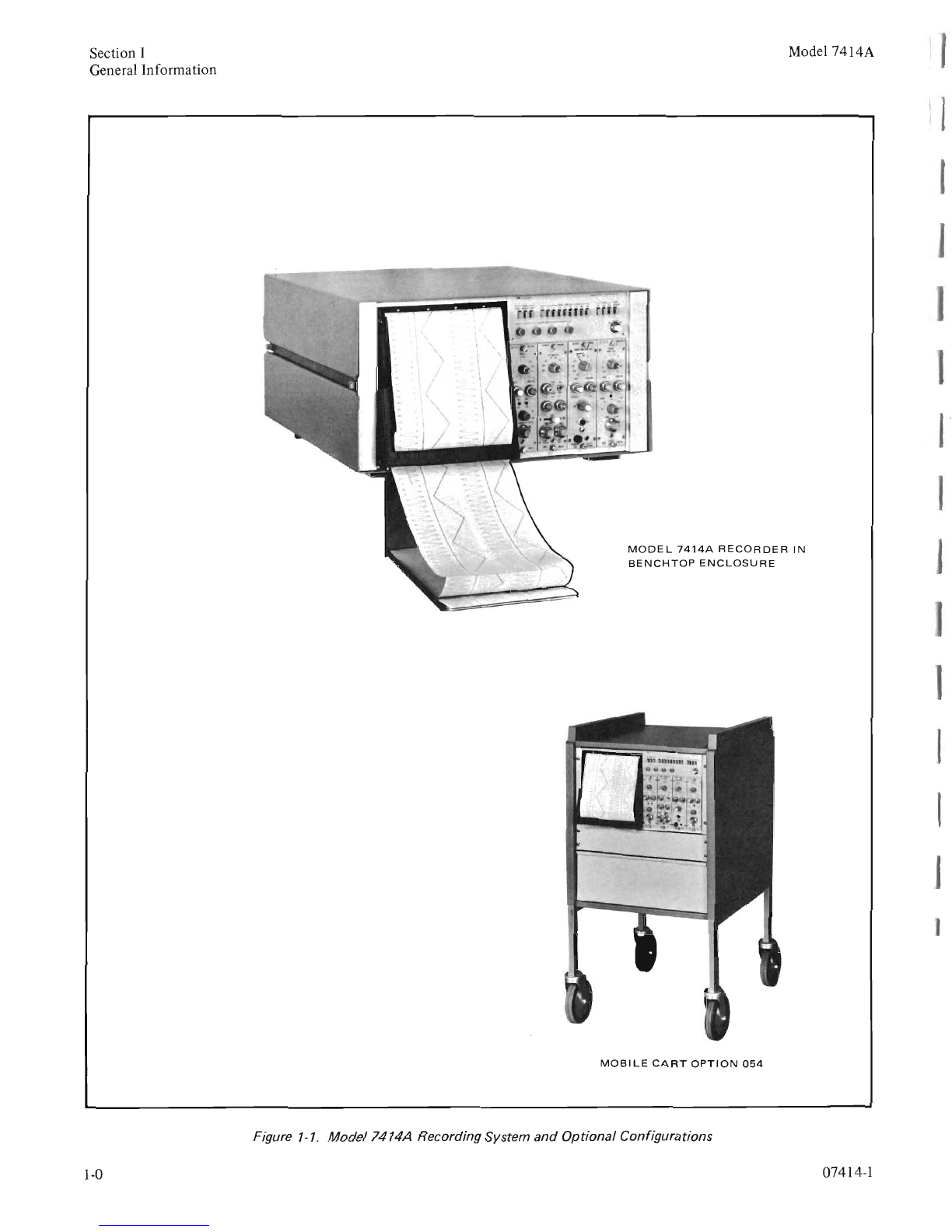

1-4. The Model 7414A Recorder (Figure 1-1)

at

the core

of

the system,

is

supplied

mounted

in a

benchtop

enclosure.

It

is

optionally available

mounted

in

amobile cart, or

unenclosed, for mounting in an existing

equipment

rack.

1-5. The Recorder houses

up

to

four Hewlett-Packard

8800

Series Preamplifiers and supplies

them

with operating

power and signal connections. The preamplifiers, selected

for each channel and ordered separately, are installed and

tested with the recorder

at

the factory.

It

is

easy

to

change

the function

of

any channel

by

loosening two front panel

thumbscrews and replacing the preamplifier with adifferent

model.

1-6. The Model

7414A

Recording System records signals

monitored from devices, processes, or transducers. To

monitor

asignal, connect the signal cable to the

input

connector for the assigned channel

on

the recorder rear

panel. The rear panel inputs are connected

to

signal condi-

tioning preamplifiers

mounted

in

the recorder. Each pre-

amplifier

output

is

applied to apower amplifier

that

drives

one recording stylus.

From

the preamplifier

output

on,

all

four channels are identical.

For

ease

of

maintenance, all

electrical adjustments are accessible from the front or top

of

the recorder, and most assemblies can be removed with

the recorder

mounted

in the enclosure, mobile cart, or

equipment

rack.

1-7. The recorder uses Z-fold chart paper for convenient

access to any

part

of

the recording. The folded paper

permits rapid scanning

of

the record

to

assess response

trends. All pages are numbered to allow insertion in a

notebook,

or

the complete record may be filed in the

original flat

box

(pages are 8 x 12 inches,

20

x

30

cm,

approximately). Anew pack

of

chart paper can be loaded

quickly, in less

than

ten

seconds,

to

minimize loss

of

recording continuity.

07414-1

1-8. The recorder may be remotely controlled to mark

events, start, or go on standby. Two event markers are

provided; one permits the user to indicate the start and

finish

of

an event, the second provides time interval

marking in minutes

or

seconds.

1-9. Applications

and

Specifications.

1-10. Awide selection

of

transducers and Hewlett-Packard

preamplifiers are available for research, laboratory, and

industrial applications. The following list gives some typical

applications where data can be measured, monitored, and

recorded using the recorder and Hewlett-Packard preampli-

fiers:

Engine Testing

Aircraft, Missile, and Space Flight Analysis

Seismographic Studies

Environmental Pollution Monitoring

Telemetry Systems

Production Control

Relative Displacement and Velocity Monitoring

1-11. Hewlett-Packard will be glad

to

cooperate in the

selection

of

transducers and preamplifiers for any particular

measurement, and to send you information

as

additional

instruments are developed

to

provide

your

recording system

with

other

capabilities.

For

help in expanding

your

system,

contact the field engineer

at

any Hewlett-Packard Sales/

Service Office listed in the

back

of

this manual.

1-12. Table

1-1

gives the specifications for the Model

7754A Recorder, a

part

of

the Model

7414A

Thermal Tip

Recording System, and Table

1-2

lists the recorder options

available. Preamplifier specifications will be found in the

separate preamplifier manuals. Preamplifier frequency

response and rise time

must

be modified by the frequency

response and rise time specifications given for the recorder.

Recording quality

is

improved by the recorder's low level

of

hysteresis distortion. Minor waveform details are

not

obscured by recorder-contributed distortion.

1-13. 8800 Series Preamplifiers

(7414A

System).

1-14. The

7414A

Recording System

is

factory assembled

for use with the solid-state

8800

Series Preamplifiers

(Figure 1-2). They plug in interchangeably from the front

of

the recorder. Signal connections are made

at

the rear,

but

signals can be monitored from the

front

of

the

preamplifiers. The general characteristics

of

each preampli-

fier are given in the following paragraphs.

For

complete

information see the preamplifier instruction manual.

1-1