Enduraplas IceMaster Systems Liquid Master W Series User manual

LIQUID MASTER W-SERIES

®

OWNER’S MANUAL

Version 1.1 Copyright © Enduraplas. All Rights Reserved.

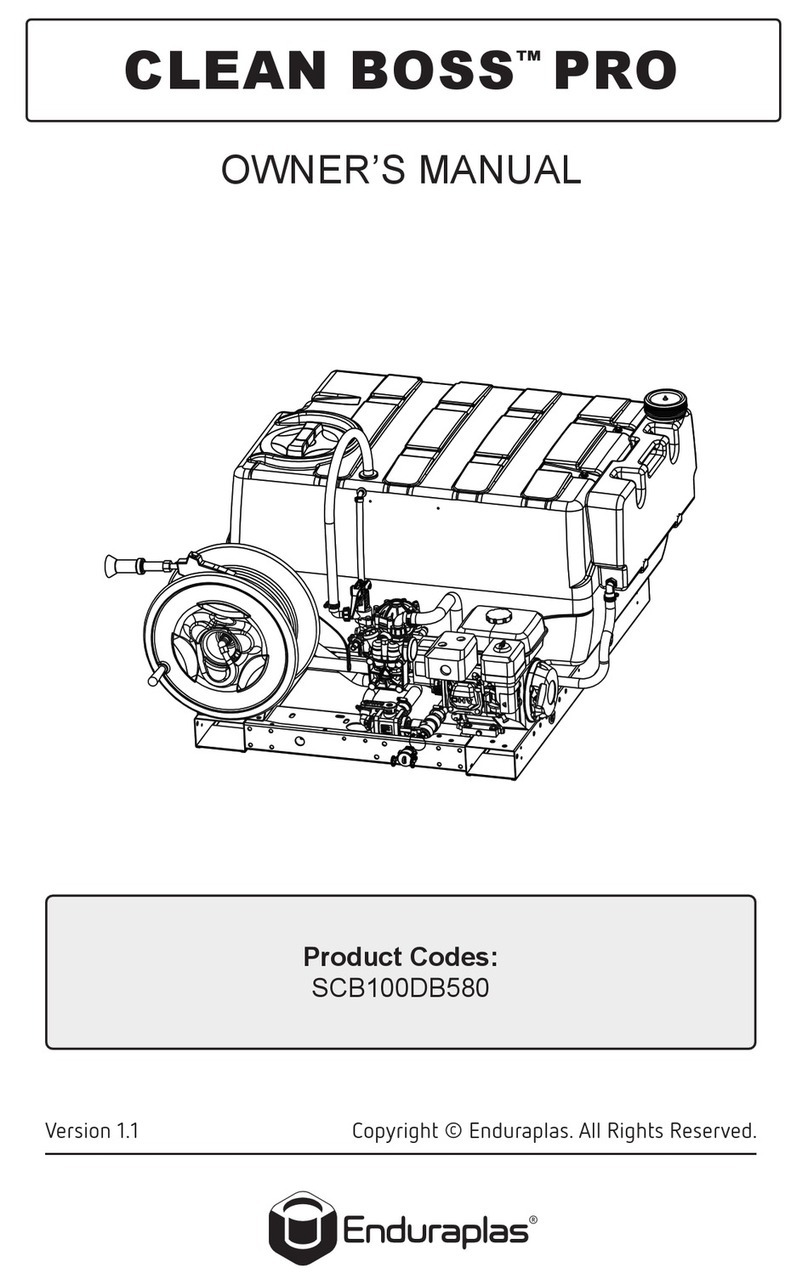

Product Codes:

IMS12W24V

2Liquid Master® W-Series

English

CONTENTS

INTRODUCTION 3

WARNINGS 4 - 7

SETUP & DRAWINGS 8 - 17

MAINTAINING 18 - 19

TROUBLESHOOTING 20 - 21

!

3Version 1.1

English

INTRODUCTION

Congratulations! You now own an ICE MASTER SYSTEMS

sprayer. Durable design and construction assure you a

lifetime of extreme performance. No sprayer is tougher. No

sprayer will last longer.

Take a look through this owner’s manual to learn how the

pros use their ICE MASTER SYSTEMS sprayer.

Discover More Helpful Tips:

blog.enduraplas.com/ice-control

Watch Instruction Videos:

www.youtube.com

Search ‘ICE MASTER SYSTEMS’

4Liquid Master® W-Series

English

WARNINGS

1. Do not exceed vehicle manufacturers loading, towing or

lifting specications and regulations.

2. Ensure tank is rmly secured in an appropriate manner.

3. Use caution at all times, particularly when driving on

rough terrain.

4. Comply with chemical manufacturers safety requirements

and all relevant legislations.

5. ALWAYS keep tank tightly covered, to prevent children or

animals from entering tank.

6. Tank is not re resistant. NEVER expose it to open ame

or heat.

7. Keep sharp objects from tank. Tank could be punctured

and contents could escape and cause injury to persons

or property.

8. This tank can be used only with polyethylene compatible

liquids. If you are uncertain, ask chemical supplier if

material can safely be stored in a polyethylene tank.

USE OF TANK WITH ANY OTHER MATERIAL COULD

CAUSE TANK TO FAIL, RESULTING IN INJURY OR

PROPERTY DAMAGE.

9. DO NOT MIX CHEMICALS. THIS CAN RESULT IN

DAMAGE TO THE TANK OR NEARBY PERSONS OR

PROPERTY.

10.Clean out tank before changing chemicals OTHERWISE

A DANGEROUS MIXTURE OF CHEMICALS

COULD CAUSE DAMAGE TO PERSONS, TANK OR

PROPERTY.

11. Regular service and maintenance is the Owner’s

responsibility and is a condition of your warranty.

12.FAILURE TO COMPLY WITH ALL WARNINGS

AND INSTALLATION INSTRUCTIONS WILL VOID

WARRANTY.

!

5Version 1.1

English

Discover More Helpful Tips:

blog.enduraplas.com/ice-control

Calcium Chloride Brine, Salt Brine and Premium Branded

Liquids.

Caution: Brine that contain tacky substances or solid

particles may clog pumps and nozzles. These are not

recommended.

Warning: DO NOT USE any products that contain

petroleum or petroleum by-products of any kind. These

destroy seals and will void warranty.

COMPATIBLE LIQUIDS

!

!

13.No modications and/or alterations may be made to this

sprayer. Any such modications not only void the sprayer

warranty but can make the unit dangerous to anyone

operating the pump.

14.Always inspect hoses and piping to avoid burst injuries.

15.DO NOT turn suction valve o while pump is running.

NEVER RUN PUMP DRY.

6Liquid Master® W-Series

English

WARNING

WARNING: Improper use or failure to follow instructions can result in explosive failure causing serious

eye or other injury. For safe use of this product you must read and follow all instructions. Do not leave a

pressurized sprayer in the hot sun. Heat

can cause pressure build-

up resulting in possible explosion. Do not

store or leave solution in tank after use. Always wear goggles,

gloves,

long sleeve shirt, long pants and full foot

protection when spraying. Do not attempt to modify this sprayer. Replace parts only with manufacturer’s original

parts. Never spray flammable, caustic, acidic, chlorine, bleach or other corrosive solutions or heat,

pressure, or gas producing chemicals. Always read and follow chemical manufacturer’s instructions

before use with

this sprayer as some chemicals may be hazardous when used with this sprayer.

CAUTION

•

PRE-USE CHECK: Before each use check tightness of hose nut to be sure hose is securely attached to

the shut-off assembly. Ensure that all nozzle and wand connections are tight.

•

Do Not exceed a tank solution temperature of 120º F/ 49º C.

NOTE: The tank and hose may have residual water in it due to quality testing performed on the sprayer.

WARNING

This sprayer is designed to operate with a Chapin 24V Lithium Ion battery ONLY. Any other batteries could

cause serious harm or injury to the operator and serious damage to the sprayer.

WARNING: For safe operation, read this manual before using the charger

. The battery pack is not fully charged

out of the carton. Before using the battery pack and charger, read the safety instructions below. Then follow

charging procedures outlined.

NOTE: Remove battery and place in charger when not in use.

IMPORTANT SAFETY INSTRUCTION FOR BATTERY PACKS READ ALL

INSTRUCTIONS

•DO NOT incinerate the battery pack even if it is severely damaged or is completely worn out. The

battery pack can explode in a fire. Toxic fumes and materials are created when battery packs are burned.

•

DO NOT charge or use battery in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust.

Inserting or removing the battery from the charger may ignite the dust or fumes.

•If battery contents come into contact with the skin, immediately wash area with mild soap and water.

If battery liquid gets into the eye, rinse water over the open eye for 15 minutes or until irritation ceases. If

medical attention is needed, the battery electrolyte for Lithium-Ion batteries is composed of a mixture of

liquid organic carbonates and lithium salts.

•

Contents of opened battery cells may cause respiratory irritation. Provide fresh air. If symptoms persist,

seek medical attention.

WARNING: Burn hazard. Battery liquid may be flammable if exposed to spark or flame.

•

Charge the battery packs only in Chapin chargers.

•

DO NOT splash or immerse in water or other liquids. This may cause premature cell failure.

•DO NOT store or use the tool and battery pack in locations where the temperature may reach or

exceed 105ºF (40ºC) (such as outside sheds or metal buildings in summer).

WARNING:

Never attempt to open the battery pack for any reason. If battery pack case is

cracked or damaged,

do not insert into charger.

Do not crush, drop or damage battery pack. Do not use a battery pack or charger

that

has

received a sharp blow, been

dropped, run over or damaged in any way (i.e., pierced with a nail, hit with a

hammer,

stepped on). Damaged battery packs should be returned to service center for recycling.

WARNING:

Fire hazard. Do not store or carry battery so that metal objects can contact exposed

battery

terminals.

For example, do not place battery in aprons, pockets, tool boxes, product kit boxes, drawers,

etc.,

with

loose nails, screws, keys, etc.

Transporting

batteries can possibly cause fires if the battery terminals inadvertently come in contact

with

conductive

materials such as keys, coins, hand tools and the like.

The US Department of transportation

Hazardous Material Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes (i.e.,

packed in suitcases and carry-on luggage) UNLESS they are properly protected from short circuits. So when

transporting individual batteries, make sure that the battery terminals are protected and well insulated from

materials that could contact them and cause a short circuit.NOTE: Lithium-Ion batteries should not be put in

checked baggage.

7Version 1.1

English

STORAGE RECOMMENDATIONS

1.The best storage place is one that is cool and dry away from direct sunlight and

excess heat or cold.

2.Long storage will not harm the battery pack or charger.

CHARGING PROCEDURE

Chapin chargers are designed to charge Chapin battery packs in 3.5-4 hours

depending on the pack being charged.

1.Plug the charger (C-13) into an appropriate outlet before inserting the battery pack.

2.Insert the battery pack (C-12) into the charger as shown in figure A.

3.The red light on the charger is continuously on when the battery is charging.

C-13

Figure

A

4.The green light on the charger is continuously on when the battery is charged. The pack is fully charged and

may be used at this time

or left on the charger.

5.Blinking red and green lights on the charger indicates a defective battery and should properly be disposed of.

Battery Charge Indicator

When battery is disconnected from the charger,

depress green button to see the charge level.

To charge see “Charging Pocedures” in this

manual.

Recharge discharged batteries as soon as

possible

after use or battery life may be

greatly diminished. For longest b

attery life, do

not discharge batteries fully. It

is

recommended that the batteries be recharged

after each use.

LEAVING THE BATTERY IN THE CHARGER

Red Needs

Charge

1/4 Charge

1/2 Charge

3/4 Charge

Green Check Button

The charger and battery pack can be left connected with the green LED

glowing indefinitely.

The charger will keep the battery pack fresh and fully charged.

IMPORTANT CHARGING NOTES

1. Longest life and best performance can be obtained if the battery pack is charged when the air temperature is

between 65°F and 75°F (18°- 24°C). DO NOT charge the battery pack in an air temperature below +40°F

(+4.5°C), or above +105°F (+40.5°C). This is important and will prevent serious damage to the battery pack.

2.The charger and battery pack may become warm to touch while charging. This is a normal condition, and does

not indicate a problem. To facilitate the cooling of the battery pack after use, avoid placing the charger or battery

pack in a warm environment such as in a metal shed, or an uninsulated trailer.

3.If the battery pack does not charge properly:

a.Check current at receptacle by plugging in alamp or other appliance.

b.Check to see if receptacle is connected to alight switch which turns power off when you turn out the lights.

c.Move charger and battery pack to a location where the surrounding air temperature is approximately 65°F and

75°F (18°- 24°C).

4.

The battery pack should be recharged when it fails to produce sufficient power on jobs which were easily

done previously. DO NOT CONTINUE to use under these conditions. Follow the charging procedure. You may

also charge a partially used pack whenever you desire with no adverse affect on the battery pack.

5.Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup of

metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply

when there is no battery pack in the cavity. Unplug charger before attempting to clean.

6.Do not freeze or immerse charger in water or any other liquid.

WARNING: Shock hazard. Do not allow any liquid to get inside charger. Never attempt to open the battery pack for

any reason. If the plastic housing of the battery pack breaks or cracks, call 1-800-822-8837 for recycling

information.

C-12

8Liquid Master® W-Series

English

INSTALLING AND REMOVING THE BATTERY PACK

FROM THE SPRAYER

WARNING: Make sure switch is in the off position.

TO INSTALL BATTERY PACK:

Insert battery pack into tool until an

audible click is heard (Figure B). Make sure battery pack is fully

seated and latched into position.

TO REMOVE THE BATTERY PACK: Depress the battery release

button as shown in Figure C and pull battery pack out of tool.

Figure

C

IMPORTANT SAFETY INSTRUCTIONS FOR BATTERY CHARGERS

Figure

B

SAVE THESE INSTRUCTIONS:

This manual contains important safety instructions for battery chargers.

•

Before using charger, readall instructions and cautionary markings on charger,battery pack, and product usingbattery pack.

WARNING: Shock hazard.

Do not allow any liquid to get inside charger.

CAUTION: Burn hazard.

To reduce the risk of injury, charge only designated Chapin batteries. Other types of batteries my burst

causing

personal injury and damage.

CAUTION:

Under certain conditions,with the charger plugged into the power supply,the charger canbe shorted by foreign material.

Foreign

materials of aconductive nature such as, but not limited to, steel wool, aluminum foil, or any build up of metalic partices should be

kept

away from charger cavities.Always unplug the charger from the power supply when there is no battery pack in the cavity. Unlplug

charger

before attempting to clean.

WARNING:

DO NOT attempt to charge the battery pack with any chargers other than the ones in this manual.

The charger and

battery

pack are specifically designed to work together.

•

ThesechargersarenotintendedforanyusesotherthanchargingdesignatedChapin rechargeablebatteries.

Anyotherusesmay

result in risk of fire, electric shock or electrocution.

•

DO NOT expose charger to rain or snow.

•

Pullby plugratherthan cord whendisconnectingcharger.

This will reducerisk ofdamageto electricplugandcord.

•

Makesurethat cord islocatedso that itwillnotbesteppedon,trippedover,orotherwise subjected todamageorstress.

•

DO NOT use an extension cord unless it is absolutely necessary.

Use of improper extension cord could result in risk of fire,

electric

shock, or electrocution.

•

An extension cord must have adequate wire size (AWG or American Wire Gauge) for safety.

The smaller the gauge number of the

wire, the greater the capacity of the cable, that is 16 gauge has more capacity than 18 gauge. When using more than one extension to

make up the total length, be sure each idividual extension contains at least the minimum wire size.

•

DO NOT operate charger with damaged cord or plug

-have them replaced immediately.

•

DO NOT operate charger if it has received asharp blow, been dropped, or otherwise damaged in any way.

Take it to an

authorized

service center.

•

DO NOT dissassemble charger;

take it to an authorized service center when service or repair is required. Incorrect reassembly may

result in a risk of electric shock electrocution or fire.

•

Disconnect the charger from the outlet before attempting any cleaning.

This will reduce the risk of electric shock. Removing the

battery pack will not reduce the risk.

•

NEVER attempt to connect 2chargers together.

•

The charger is designed to operate on standard household electrical power (120Volts). Do not attempt to use it on any other

voltage.

Symbols The label on your tool may include the following symbols.

Vvolts Hz

hertz

min minutes

direct current

Class I Construction

(grounded)

Class II Construction

( double insulated)

Read instruction

manual before use

Use proper eye

protection

Aamperes

W watts

alternating current

no load speed

earthing terminal

safety alert

symbol

/min or

rpm

revolutions

or

reciprocation per minute

Use proper

respiratory protection

Use proper hearing

protection

9Version 1.1

English

Sprayer Hardware

(Actual size)

H-3

H-1

H-2

H-5

H-4

H-6

H-7(X2)

H-8

H-9 (X2)

H-10

H-12,(X2)

H-11 (X2)

Contents:

10 Liquid Master® W-Series

English

TOOLS NEEDED:

10 mm

10 mm

Sprayer Components

(Not Actual size)

C-1

Wheels

C-3

Axel Rod

C-6

Nozzle Bar

C-5

Handle Bar Tubing

C-2

Tank

C-4

On/off Switch Wiring Harness

(Attached to C-2)

C-7

Nozzle Bracket

C-11

Handle

C-12

Battery

C-10

Handle

C-8

Frame Leg

C-9

Frame Leg

C-13

Battery

Charger

C-16

Tank Filter Basket

C-17

Tank Cap

C-14

Extension Wand

C-15

Discharge w/hose

Note: Not all components shown may be needed on your model

11Version 1.1

English

FRAME LEG INSTALLATION

Attach frame leg (C-8 and C-9) with nuts and bolts (H-1) to tank assembly (C-2). Install end caps (H-12) into

frame legs (C-8 and C-9).

C-8

H-1

H-1

H-1

C-9

H-1

H-12

H-12

H-1

H-1

H-1

H-1

C-4

HANDLEBAR INSTALLATION

Run on/off switch wiring harness (C-4) through handlebar

tubing (C-5).

Bolt handle bar to assembled frame legs using H-1 nuts

and bolts.

H-1

H-1

H-1

H-1

C-5

C-4

12 Liquid Master® W-Series

English

H-1

H-9

H-1

H-1

C-5

H-9

H-1

C-4

C-17

C-16

ASSEMBLE FILTER AND CAP

Insert Filter (C-16) and twist on cap (C-17).

Bolt wand clips (H-9) to handlebar tube (C-5).

13Version 1.1

English

Connect the on/off wiring harness ( C-4) to switch and insert switch bracket (H-10) into square handle bar tubing

(C-5). Bolt the right (C-10)

and left handles (C-11) to the handle bar tubing using (H-1) bolts. Lastly, insert handle grips (H-11) onto

handlebars (C-10 and C-11).

H-11

C-11

H-10

H-10

C-10

H-1

H-1

H-11

H-1

H-1

C-5

C-4

Flip unit upside down for easy access.

Insert axel rod (C-3) into axel bracket

until centered; then fasten each wheel

with washer (H-7) and cotter pin (H-3)

using the outermost hole in axel. Bend

each cotter pin to ensure asecure

installation.

H-7

H-3

Ben

d

Cotter Pin

attaches on

outside of each

wheel

C-1

C-1

H-7

H-7

C-3

C-3

H-3

H-3

AXEL AND WHEEL INSTALLATION

ASSEMBLE HANDLES AND ON/OFF SWITCH

14 Liquid Master® W-Series

English

ASSEMBLE ADJUSTABLE NOZZLE BRACKET

Assemble cam lock bracket (H-4) with supplied nuts and bolts from (H-4) to nozzle bracket (C-7). Then

fasten nozzle assy (H-2) to

nozzle bar (C-6) as shown.

C-6

H-4

C-6

H-4

C-7

H-4

H-4

C-7

H-2

H-2

Assembl

ed

Using supplied machine screws (H-6) fasten adjustable nozzle bracket assembly to tank.Assemble hose from tank

(C-2) to nozzle assembly

(H-2) with worm gear clamp (H-5).

H-5

H-2

H-6

H-6

Assembl

ed

ATTACH NOZZLE BRACKET AND ADJUSTABLE NOZZLE TO TANK

15Version 1.1

English

ASSEMBLE DISCHARGE TO DIVERTING

VALVE

Connect discharge with hose (C-15) to diverting valve as shown. Thread hose through loop clamp (H-8)( Figure A).

Assemble worm gear clamp

(H-5) to hose (Figure B). Assemble hose to diverting valve (Figure C). Tighten worm gear clamp and loop

clamp.

H-8

Figure A

H-5

H-8

C-15

BB

Figure B

Image shown without

frame legs and handle

bar for clarity

Figure C

ASSEMBLE WAND TO SHUT-OFF

Make sure the O-ring is installed on the end of the extension wand (C-14). Insert the wand into discharge with

hose (C-15). Turn and

tighten the retaining nut clockwise onto the shut-off valve.

O-ring

Retaining Nut

Discharge with Hose (C-15)

Wand (C-14)

16 Liquid Master® W-Series

English

FILLING THE SPRAYER

Make sure the filter basket is in place to keep debris from entering the tank.

Determine the amount of mixture needed for your application. Add the proper amount of water to the tank. Add the proper

amount of chemical to the tank (check the chemical label for proper ratio of chemical). Stir mixture in tank with a clean

utensil (like a paint stirrer). The tank will hold

the 12-gallon (45.4L) capacity plus the chemical.

It is not necessary to completely fill the sprayer tank with each use.

You can fill the tank with only the amount

needed for each application. Always follow the manufacturer’s instructions included on their product la

bel.

OPERATING THE SPRAYER

•

Plug in charged battery

•

Turn switch to on position

•Spray liquid back into tank to prime

pump

•

Close shut-off. Pump should stop

running.

•Replace cap & begin spraying.

When finished spraying turn switch to off position. Remove and re-charge battery.

Note: Unit is equipped with a battery protection circuit. If sprayer abruptly stops after spraying for an extended period

of time, the battery may require charging.

POWDER-BASED CHEMICALS

Powder

-based chemicals (powder mixed with liquids to make the spraying agent) are usually abrasive and can cause

wear.

When you use a powder-based chemical in your sprayer, make sure it is thoroughly dissolved in the liquid

solution.

Thoroughly clean and flush the sprayer with water to extend the life of the sprayers parts.

CLEANING

•Always empty the sprayer and clean the tank thoroughly after each use.

Other Cleaning Tips:

•Improper spray distribution usually means the nozzle is clogged, remove the nozzle and clean it.

•Soap can be added to the water to clean the tank.

•Do not use strong cleaning agents or abrasives.

•If you use a chemical agent to clean the tank follow the manufacturer’s recommendations for the

disposal of the waste water.

•Follow the chemical manufacturers instructions for clean-up.

STORING / MAINTAINING YOUR SPRAYER

The Battery Should be removed prior to storage.

•The sprayer should be stored out of direct sunlight in a cool dry space.

•Before freezing weather make sure to drain all liquid in the tank, pump, hose, shut-off valve, wand and nozzle,to

avoid liquid expansion and cracking in the sprayer components (See “Cleaning” section). Lock the shut-off valve in

the “open” position.

•When service is required call your nearest dealer and always insist on original manufactured replacement parts.

•Inspect the hose, wand, tank and shut-off valve for wear, damage or leaks on a regular basis and repair defects

promptly.

Recycling Spent Battery

In some areas, it is illegal to place spent lithium-ion batteries in the trash or municipal solid waste stream. You may

also contact your local recycling center for information on where to drop off the spent battery, or call 1-800-8-

BATTERY.

17Version 1.1

English

SWITCH FROM BOOM SPRAY TO SPOT

SPRAY

Turn switch to the desired spray

option.

SPRAY PATTERN ADJUSTMENT FOR PUSH

SPRAYING

Easily spray to left or right with positionable wand holder built right

into the cap.

Spray Right

Spray left

ADJUST NOZZLE HEIGHT

Loosen the cam lock handle to adjust the

height

of the nozzle bar.

18 Liquid Master® W-Series

English

MAINTAINING

Keeping your sprayer in good condition will help you

lengthen the life of the sprayer. Everyone knows a well

maintained piece of equipment ensures a longer life span.

Sprayer maintenance can seem a huge task if you don’t

have the right tools.

Discover More Helpful Tips:

blog.enduraplas.com/ice-control

Watch Instruction Videos:

www.youtube.com

Search ‘ICE MASTER SYSTEMS’

FILLING THE SPRAYER

Make sure the filter basket is in place to keep debris from entering the tank.

Determine the amount of mixture needed for your application. Add the proper amount of water to the tank. Add the proper

amount of chemical to the tank (check the chemical label for proper ratio of chemical). Stir mixture in tank with a clean

utensil (like a paint stirrer). The tank will hold the 12-gallon (45.4L) capacity plus the chemical.

It is not necessary to completely fill the sprayer tank with each use. You can fill the tank with only the amount

needed for each application. Always follow the manufacturer’s instructions included on their product label.

OPERATING THE SPRAYER

•Plug in charged battery

•Turn switch to on position

•Spray liquid back into tank to prime

pump

•Close shut-off. Pump should stop

running.

•Replace cap & begin spraying.

When finished spraying turn switch to off position. Remove and re-charge battery.

Note: Unit is equipped with a battery protection circuit. If sprayer abruptly stops after spraying for an extended period

of time, the battery may require charging.

POWDER-BASED CHEMICALS

Powder-based chemicals (powder mixed with liquids to make the spraying agent) are usually abrasive and can cause

wear. When you use a powder-based chemical in your sprayer, make sure it is thoroughly dissolved in the liquid

solution. Thoroughly clean and flush the sprayer with water to extend the life of the sprayers parts.

CLEANING

•

Always empty the sprayer and clean the tank thoroughly after each use.

Other Cleaning Tips

:

•

Improper spray distribution usually means the nozzle is clogged, remove the nozzle and clean it.

•

Soap can be added to the water to clean the tank.

•

Do not use strong cleaning agents or abrasives.

•

If you use a chemical agent to clean the tank follow the manufacturer’s recommendations for the

disposal of the waste water.

•

Follow the chemical manufacturers instructions for clean-up.

STORING / MAINTAINING YOUR SPRAYER

The Battery Should be removed prior to storage.

•

The sprayer should be stored out of direct sunlight in a cool dry space.

•

Before freezing weather make sure to drain all liquid in the tank, pump, hose, shut-off valve, wand and nozzle,to

avoid liquid expansion and cracking in the sprayer components (See “Cleaning” section). Lock the shut-off valve in

the “open” position.

•

When service is required call your nearest dealer and always insist on original manufactured replacement parts.

•Inspect the hose, wand, tank and shut-off valve for wear, damage or leaks on a regular basis and repair defects

promptly.

Recycling Spent Battery

In some areas, it is illegal to place spent lithium

-ion batteries in the trash or municipal solid waste stream. You may

also contact your

local recycling center for information on where to drop off the spent battery, or call 1-800-8-

BATTERY.

19Version 1.1

English

The information applies in normal operating conditions. The specic intervals must be short-

ened accordingly for longer daily working hours. If the machine is only used occasionally, the

intervals can be extended accordingly.

Before starting work

At the end of work

and/or daily

Weekly or every 40

operating hours

After the rst 5

operating hours

Every 250 operating

hours o once a year

If damaged

If required

Complete machine

Visual inspection (condition, leaks) X

Clean

Tank, hoses and ttings

Clean X

Drain X

In-line lter Clean X X

Spray lance nozzle

Clean X

Replace X

All accessible screws and nuts Retighten X

Safety labels Replace X

Pump Maintain Read and follow all maintenance and care instructions in the

Pump manual.

20 Liquid Master® W-Series

English

TROUBLESHOOTING

CONDITION CAUSE REMEDY

Pump will not

prime

1) Insucient motor

RPM

2) Air leak on suction

plumbing

3) Blocked/Restricted

intake hose

4) Filter cap

disengaged

5) Filter gasket

damaged/missing

1) Increase motor

RPM until pump

primes

2) Tighten/replace

ttings & hose

clamps. Verify suction

hoses are in good

condition

3) Remove blockage

from suction line,

ensure line is not

kinked

4) Lock lter cap into

position

5) Replace lter

gasket

Pressure drops/

uctuates during

standard

operation

1) Restriction on

suction line

2) Pump sucking air

3) Plugged lter

4) Damaged regulator

1) Inspect tank and

suction lines and

remove restriction

2) Tighten ttings

3) Remove and

clean lter mesh and

housing

4) Remove regulator

stem and inspect for

broken parts/pieces

This manual suits for next models

1

Table of contents

Other Enduraplas Paint Sprayer manuals

Enduraplas

Enduraplas STEEL BOOM User manual

Enduraplas

Enduraplas FIELD BOSS 365 SFB060FG225GH User manual

Enduraplas

Enduraplas SPOT CHIEF SSC025212V User manual

Enduraplas

Enduraplas FIELD BOSS ECOLITE SFB060FG712V User manual

Enduraplas

Enduraplas ICEMASTER LIQUID MASTER T Series User manual

Enduraplas

Enduraplas XSTREAM User manual

Enduraplas

Enduraplas CLEAN BOSS PRO User manual

Enduraplas

Enduraplas Gold Series User manual