791-6440 8 04/02/20

INFORMACIÓN DE ADVERTENCIA

Este símbolo indica una alerta de seguridad y se usa para

advertir sobre peligro de accidentes personales. Observe toda

la información de seguridad que sigue a este símbolo para

evitar la posibilidad de que ocurran lesiones o muerte.

IMPORTANTE: LEA ESTAS INSTRUCCIONES ANTES DE USAR EL DISPOSITIVO

ANTES DE USAR ESTE DISPOSITIVO, LEA ESTE MANUAL DETENIDAMENTE. PROCURE ENTENDER SUS PROCEDIMIENTOS OPERATIVOS,

ADVERTENCIAS DE SEGURIDAD Y FORMA DE MANTENIMIENTO.

El propietario es responsable de asegurarse de que todo el personal lea este manual antes de usar el dispositivo. Asimismo, es responsabilidad

del propietario mantener este manual en buenas condiciones en una ubicación conveniente para su consulta. Si las etiquetas del manual o

producto son ilegibles o no están en su lugar, deberá ponerse en contacto con NAPA para obtenerlas gratis. El comprador/propietario o una

persona designada deberá leer y comentar el producto y las advertencias de seguridad en la lengua materna del operario que no hable inglés

uido, a n de asegurarse de que comprende el contenido.

NATURALEZA DE LAS SITUACIONES DE RIESGO

El uso de dispositivos de elevación de automotores se halla sujeto a ciertos riesgos que no se pueden prever por medios mecánicos, sino por la

información, la diligencia y el sentido común. Por lo tanto, es esencial que el uso del dispositivo quede en manos de los propietarios y de personal

que sea cuidadoso, competente, capacitado y habilitado para realizar una operación segura. Algunos ejemplos de peligros son dejar caer, inclinar

o resbalar las cargas, principalmente como consecuencia de una sujeción incorrecta, sobrecarga, posición no centrada, uso en supercies no

niveladas o rmes, así como usar el dispositivo con un n para el que no está diseñado.

FORMAS DE EVITAR LAS SITUACIONES DE RIESGO

• Lea, estudie, comprenda y observe todas las instrucciones antes de operar este dispositivo.

• Veriqueelgatoantesdeusarlo.Nolousesitieneroturas,alteraciones,fugasdelíquidohidráulicooestáenmalascondiciones,

comotampocosipresentainestabilidaddebidoapiezasmetálicasopartesdesajustadasofaltantes.Tomelasmedidasde

corrección apropiadas antes de usarlo.

• Usesolosobresuperciesdurasniveladascapacesdesoportarlacargaylibresdeobstruccionesconelndequeelgatoestélibrede

reposicionarse durante las operaciones de elevación y descenso.

• Utiliceeldispositivodeelevaciónúnicamenteenlasáreasdelvehículoespecicadasporsufabricante.

• UseprotecciónparalosojosquecumplaconlasnormasANSIZ87.1yOSHA(usuariosyespectadores).

• No use el gato para elevar pesos superiores a su capacidad. No ocasione ninguna descarga a la carga.

• Este dispositivo se debe utilizar únicamente para levantar cargas. No bien haya elevado la carga, sujete el vehículo con

torres que tengan la capacidad para sostenerlo antes de comenzar a trabajar.

• Useelgatoúnicamenteensuperciesniveladasrmesenlasquenohayaobstáculos,demodoqueeldispositivo

pueda posicionarse durante las operaciones de elevación y descenso.

• Centrelacargaenelasiento.Asegúresedequeelarmadodeldispositivoseaestableantesdecomenzaratrabajar.

• Nomuevaniempujeelvehículosobreelgato.

• Nouseningúnmaterialquepuedafungircomoplataforma,espaciadoroexpansorentrelasilladeelevaciónestándarylacarga.

• Nouseningúnadaptadorelquerepongalasilladeelevaciónestándaralmenosqueseaaprobadooprovistoporelfabricante

del gato.

• Nouse(nimodique)laherramientaparaningúnotrousoexceptoélparaelcualfuediseñado,sinprimeroconsultaral

representante autorizado del fabricante.

• Baje el gato siempre despacio y con cuidado.

• Nocumplirconestasindicacionespuedeprovocarlesionesgravesopeligrodemuerte,asícomodañosmateriales.

ADVERTENCIA:Esteproductolepodráexponeraciertosquímicos,paraincluirelníquel,conocidosenelEstadodeCaliforniapor

ocasionarcáncerydefectoscongénitosuotrosdañosalareproducción.Paramayoresinformes,visitewww.P65Warnings.ca.gov.

CONSECUENCIAS DE NO PREVENIR LAS SITUACIONES DE RIESGO

No leer, comprender u observar todo el contenido de este manual en relación con sus INSTRUCCIONES DE USO, ADVERTENCIAS DE

SEGURIDAD y FORMA DE MANTENIMIENTO, así como desatender las FORMAS DE EVITAR LAS SITUACIONES DE RIESGO, puede provocar

accidentes que tengan como consecuencia lesiones graves, peligro de muerte o daños materiales.

ADVERTENCIA: Indica una situación

peligrosa que si no se evita, puede

provocar la muerte o lesiones graves.

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

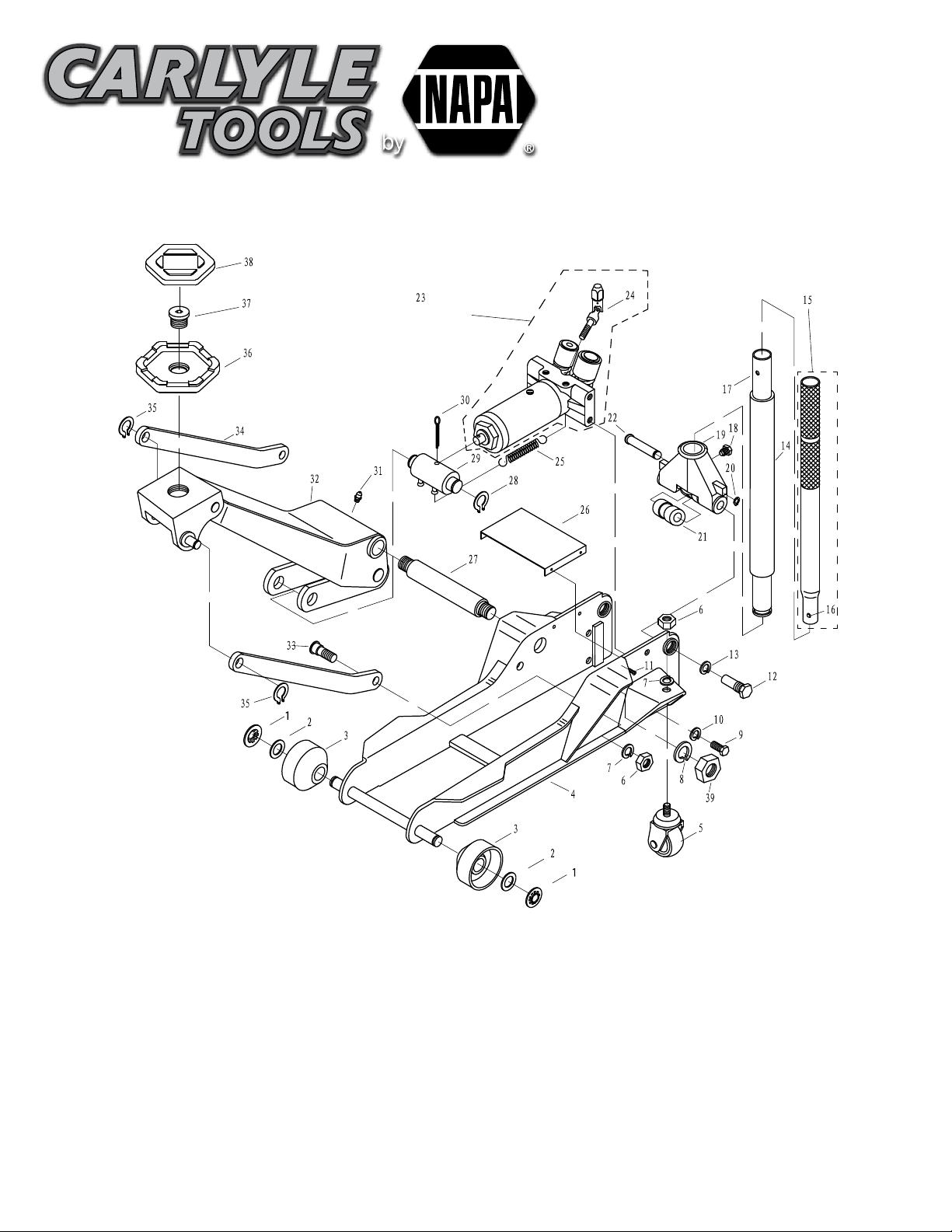

MANUAL DEL FUNCIONAMIENTO PARA 791-6440

ADVERTENCIA