2

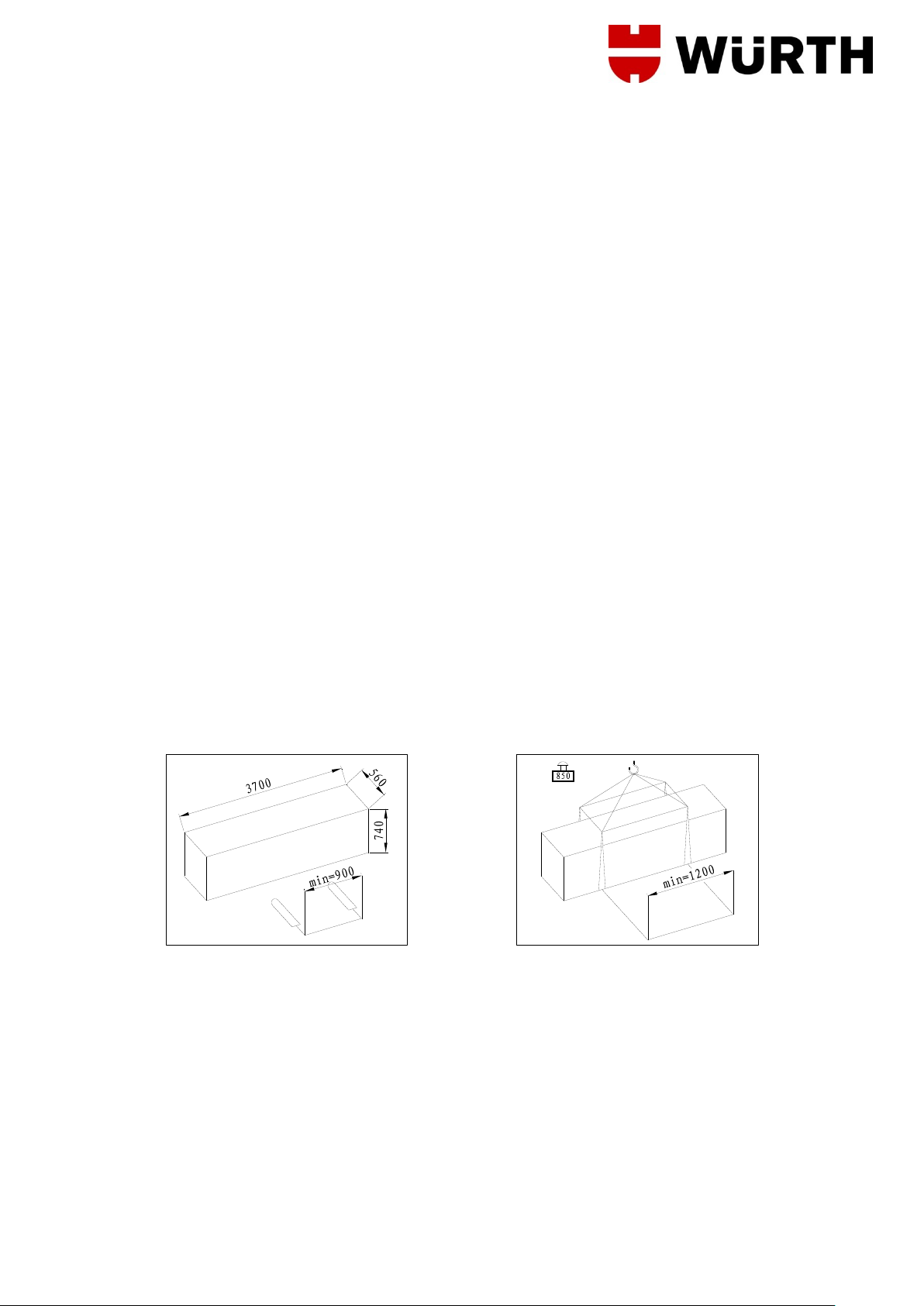

PACKING, TRANSPORT AND STORAGE................................................................................................... 4

PACKING ........................................................................................................................................................ 4

LIFTING AND HANDLING............................................................................................................................ 4

STORAGE ...................................................................................................................................................... 4

CRATE STACKING ....................................................................................................................................... 5

OPENING THE CRATES ............................................................................................................................. 5

DISPOSAL OF CRATES .............................................................................................................................. 5

INTRODUCTION WARNING ....................................................................................................................... 5

LIFT SATETY ................................................................................................................................................. 5

THE SAFETY OF LIFTED VEHICLES ....................................................................................................... 5

CONSERVING THE MANUAL .................................................................................................................... 5

LAW S............................................................................................................................................................... 6

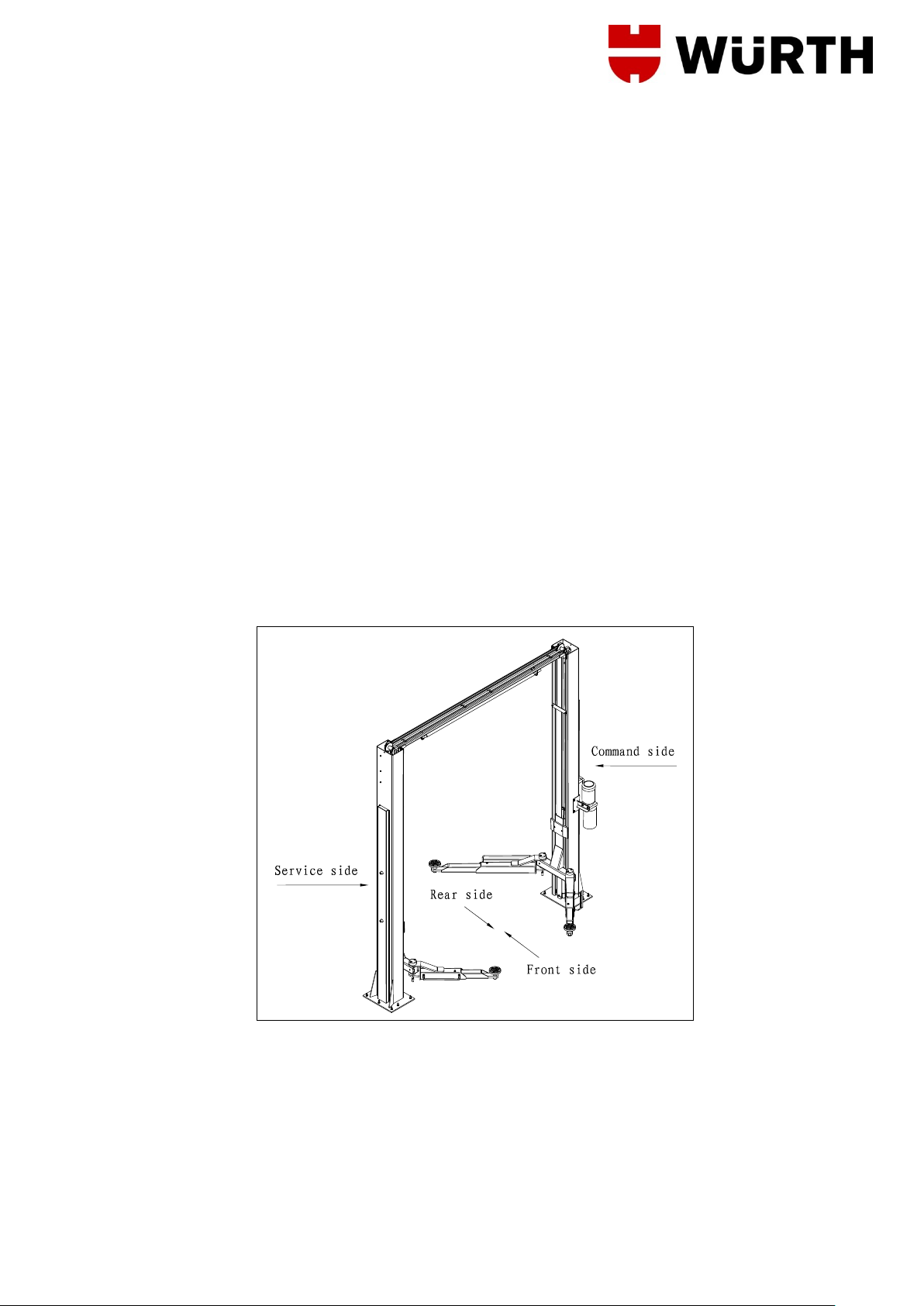

CHAPTER 1 DESCRIPTION OF THE MACHINE........................................................................................ 7

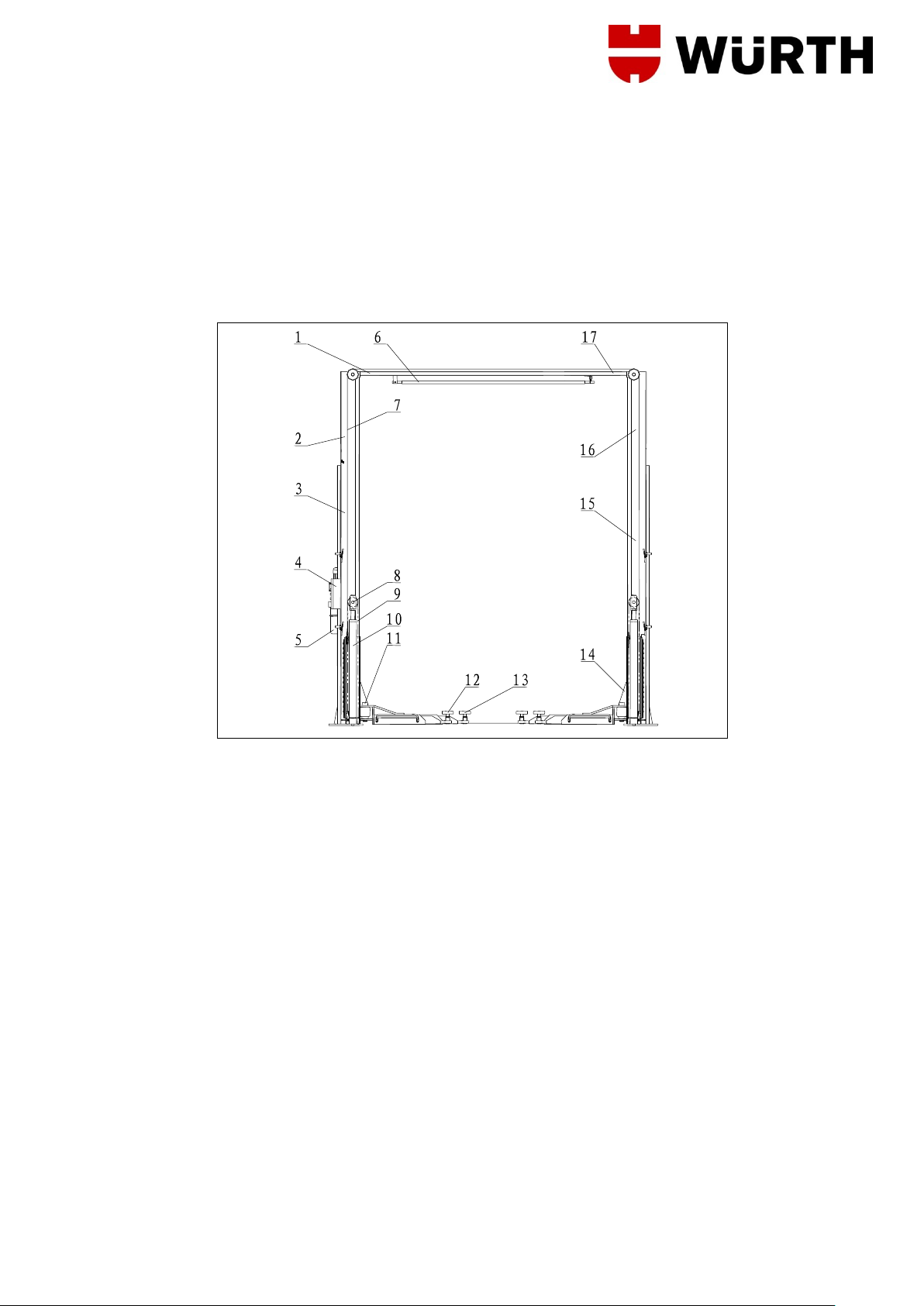

1.1 FIXED STRUCTURE (FIG.4) ................................................................................................................ 8

1.2 MOVING UNITS (SEE FIG.4)................................................................................................................ 8

1.3 LIFT UNIT (SEE FIG.4) .......................................................................................................................... 8

1.4 HYDRAULIC POWER UNIT (FIG.5) .................................................................................................... 9

1.5 CONTROL BOX (FIG.6) ......................................................................................................................... 9

1.6 SAFETY DEVICE.................................................................................................................................... 9

CHAPTER 2 TECHNICAL SPECIFICATIONS........................................................................................... 10

2.1 ELECTRIC MOTOR.............................................................................................................................. 12

2.2 HYDRAULIC UNIT PUMP ................................................................................................................... 12

2.3 OIL........................................................................................................................................................... 12

2.4 HYDRAULIC OIL DIAGRAM ............................................................................................................... 12

2.5 VEHICLE WEIGHT AND SIZE............................................................................................................ 14

2.6 MAXIMUM DIMENSIONS OF VEHICLES TO BE LIFTED ............................................................ 15

CHAPTER 3 SAFETY .................................................................................................................................... 16

3.1 GENERAL PRECAUTIONS ................................................................................................................ 17

3.2 RISKS OF ELECTRIC SHOCK: ......................................................................................................... 17

3.3 RISKS AND PROTECTION DEVICES .............................................................................................. 17

3.4 LONGITUDINAL AND LATERAL MOVEMENT ................................................................................ 17

3.5 RISKS WHILE THE VEHICLE IS BEING RAISED .......................................................................... 18

3.6 RISKS OF PERSONS .......................................................................................................................... 20

3.6.1 RISK OF CRUSHING (OPEARATOR)....................................................................................... 20

3.6.2 RISK OF CRUSHING (PERSONNEL)....................................................................................... 20

3.6.3 RISK OF IMPACT.......................................................................................................................... 20

3.6.4 RISK DUE TO VEHICLE MOVEMENT...................................................................................... 20

3.6.5 RISK OF VEHICLE FALLING FROM LIFT............................................................................... 21

3.6.6 SLIPPING ....................................................................................................................................... 21

3.6.7 RISK OF ELECTRIC SHOCK………………………………………………………………… 22

3.6.8 RISK OF COMPONENT FAILURE DURING OPERATION. .................................................. 22

3.6.9 RISK RELATED TO IMPROPER USE....................................................................................... 22

3.7 SAFETY INSTRUCTINS FOR SERVICING ......................................................................................... 22