Bend-Tech Dragon A400 Operating instructions

A400

Part 1 of 2

Maintenance & Troubleshooting

Part 1: Dragon A400

Version 2 | English ©2020 Bend-Tech LLC

ii Bend-Tech Dragon A400

Maintenance & Troubleshooting

©2020 Bend-Tech LLC

All rights reserved. The information in this manual is subject to change without notice.

Bend-Tech LLC strives to produce the most complete and accurate information regarding

its products. We are constantly working to improve and advance our products to increase

performance, user satisfaction and experience. Bend-Tech LLC assumes no responsibility for

errors or omissions regarding this manual. Bend-Tech LLC assumes no liability for damages

resulting from the use of the information contained in this publication.

iiiBend-Tech Dragon A400 Maintenance & Troubleshooting

Dragon A400

Maintenance & Troubleshooting

Version 2

English

Original Instructions

March 2020

Bend-Tech, LLC

729 Prospect Ave.

Osceola, WI 54020 USA

(651) 257-8715

www.bend-tech.com

iv Bend-Tech Dragon A400

Maintenance & Troubleshooting

Covering Bend-Tech Dragon

Bend-Tech, LLC provides a limited warranty on all new Dragon machines that are

manufactured directly or under license by Bend-Tech, LLC, and sold by Bend-Tech, LLC or its

approved distributors.

Warranty Coverage

Each Bend-Tech Dragon machine is warrantied by the manufacturer against defects in material

workmanship for 12-months. The warranty period commences the date the Dragon machine is

installed at the customer’s facility.

Repair or Replacement Only

The Manufacturer’s sole liability, and the Customer’s exclusive remedy under this warranty

shall be limited to repairing or replacing the defective part. Repair or replacement of parts

is at the sole discretion of the manufacturer. The Customer is responsible for warranty parts

installation. Bend-Tech does not provide warranty service labor.

Limits

This warranty does not cover components subject to wear due to normal use of the machine

such as belts, lights, tooling etc. This warranty is void if Bend-Tech, LLC has determined any

failure is the result of mishandling, abuse, misuse, improper installation, improper storage,

Software

Dragon software is covered by a 2-year maintenance plan from the purchase date of the

Dragon A400 machine. After the 2-year maintenance plan is expired, the Customer can

purchase a maintenance plan. A maintenance plan will ensure the customer always has

the newest version of Dragon software. The maintenance plan is critical to keeping Dragon

software updated with the newest capabilities possible, and is critical to the servicing of the

machine. Bend-Tech, LLC will contact the Customer regarding updates to the maintenance

plan within 1-month of expiration. Contact Bend-Tech Support to ensure software is up to date:

Limited Warranty

vBend-Tech Dragon A400 Maintenance & Troubleshooting

Any questions or concerns regarding this manual can be directed to Bend-Tech, LLC

representatives via the Dragon website, www.bend-tech.com. Click Contact in the menu bar for

communication options and send your comments to the Dragon Customer Service department.

Online Resources

• https://www.youtube.com/user/bendtech2020

• http://www.bend-tech.com/wiki7

• http://www.bend-tech.com

• https://www.facebook.com/2020ssi

• https://www.instagram.com/bend_tech

Customer Service

Congratulations on your purchase of the world’s best CNC plasma tube and pipe cutting

machine, the Dragon A400. Bend-Tech, LLC places great pride in customer satisfaction and it

our support is a key factor in your success.

Contact Us

You can contact Bend-Tech, LLC customer service at 651-257-8715. Our support hours are

mailing address is: Bend-Tech LLC, 729 Prospect Ave., Osceola, WI 54020, U.S.A..

Customer Satisfaction Commitment

vi Bend-Tech Dragon A400

Maintenance & Troubleshooting

This manual contains important statements that are called out from the regular text with an

associated signal word: “Danger,” “Warning,” “Caution,” or “Note.” Each of these signal words

is accompanied by its own icon. These signal words and icons indicate the severity of the

condition and the warning. The machine operator should familiarize themselves with these

warnings and read the statements before operating the machine.

Denitions & Examples

Danger

Danger indicates a serious condition that could cause severe injury or death to the operator or

bystanders if the instructions are not followed.

Warning

A Warning indicates there is a possibility for minor injury if the instructions are not followed

correctly.

! Danger !

Exceeding the material weight limit of the Dragon A400 can result in serious injury

to the operator and/or bystanders.

! Warning !

Due to the extreme temperatures that result from the plasma cutting process, parts

cooled in water in the parts catcher can still be extremely hot. Always use caution

when handling newly-cut parts.

Warnings

Example

Example

viiBend-Tech Dragon A400 Maintenance & Troubleshooting

Caution

Caution warns the operator that minor injury or machine damage could occur if instructions are

being performed.

Note

! Caution !

the Dragon A400.

Water Cooling system greatly reduces smoke and vapor emitted by the machine.

Bend-Tech recommends use of the Water Cooling system whenever possible.

Example

Example

viii Bend-Tech Dragon A400

Maintenance & Troubleshooting

Glossary

Glossary

A400

Indicates machine with 400-lb weight limit.

Axis

Bend-Tech 7X

Machine design software - CAD.

BOB

Breakout Board.

Material Support Lifter

The Material Support Lifter supports

material to reduce sag.

Chuck

Located on the Trolley, the Chuck holds the material

so it can be moved forward, backward and rotated.

Control Box

Connects Dragon Software Suite to the Dragon A400.

Coolant Tray

Cools cut parts as they are produced.

Drive Belt

The X Motor uses the Drive Belt to power the

Trolley along the Rail. The Drive Belt is mounted

stationary along the length of the machine.

Drive Belt Pulley

Located on the X Motor, it works in conjunction with

the Drive Belt to power the Trolley along the Rail.

E-Stop

Emergency stop.

ESS

Ethernet Smooth Stepper (Control Board).

Ethernet

System for connecting multiple computers

via a Local Area Network.

Front Gate

The Gate supports the material at the

front of the machine. It consists of two

sets of self-centering roller jaws.

Gate Lead Screw

Controls operation and adjustment of the Gate.

Interface

Any particular screen display generated

by Bend-Tech software.

Mach3

Machine driver software.

Parts Catcher

The parts catcher is placed at the front of the

machine to catch parts as they are cut.

Rail

The Rail is the main structure of the Dragon

A400. The Trolley rides on the Rail.

Tail

The Tail is located at the opposite end of the Head

of the machine. The Tail arrives pre-assembled. The

X Axis homing sensor, Drive Belt Adjustment Block

and E-Stop are located at the Tail of the machine.

Toolhead

Operates the Marker, Engraver and Torch.

Trolley

The Trolley rides on the Rail, and carries

the Chuck forward and backward along

the length of the Rail Support Beam.

ixBend-Tech Dragon A400 Maintenance & Troubleshooting

Contents

Limited Warranty .....................iv

Customer Service.................... v

Customer Satisfaction

Commitment............................. v

Warnings ..................................vi

Glossary ..................................viii

Contents...................................ix

01

Introduction............................. 13

Introduction ...................... 13

How To Send A Support Session ...... 13

02

Gate ......................................... 15

Gate Troubleshooting............... 15

Eccentric bearing on Gate sticking .. 15

Front Gate binding .............. 15

.... 15

Loose front Gate................ 15

Gate Not Operating Smoothly. . . . . . 16

Play in Gate ................... 16

Gate Jaws not operating smoothly .. 16

Contents

03

Laser........................................ 17

Laser Troubleshooting .............. 17

Laser not lining up with end of tube . 17

Laser failure ................... 18

04

Torch & Cutting....................... 19

Diagnosing Cutting and Torch Issues... 19

Cope at both ends of the tube are

not the same rotation ............ 19

Cut quality issues ............... 20

Round holes are coming out oval ... 20

Machine cutting and then returning to

previous engraving .............. 20

material....................... 20

Jagged Cuts ................... 20

Grounding The Torch ............... 21

Torch Not Firing ................ 21

Torch Colliding With Material ...... 21

05

Engraver.................................. 23

Engraver Guide ................... 23

Setting Engraver Air Pressure ..... 23

Engraver digging into material or

marking too light ................ 23

xBend-Tech Dragon A400

Maintenance & Troubleshooting

Contents

Engraver not turning on .......... 23

Engraver Bleeder Valve .......... 24

06

Material Support Lift............... 25

Material Support Lift Guide .......... 25

Material Support Lift Settings In

Bend-Tech 7x .................. 25

Change the Support Lifter Gap..... 25

Lifter colliding with Rail ........... 26

Lifter Not Homing ............... 26

Lifter pausing at wrong time ....... 26

Lifter too high, Trolley hitting Lifter

as it travels down the Rail......... 26

Lifter bottoming out on top of housing 26

Adjusting Lifter Trigger Pause. . . . . . 26

Material Support Lift Support Retraction

Settings....................... 26

Setting Material Support Lift Actuation

and Retraction Adjustment ........ 26

Disabling the Material Support Lift .. 27

07

X Axis Motor............................ 29

X Axis Motor Troubleshooting ........ 29

X Axis Won’t Jog................ 29

X Axis Motor or Trolley Binding While

Jogging At Full Speed............ 29

X Axis Motor Skipping Steps. . . . . . . 30

Setting Rail Distance ............... 30

Adjusting Trolley Eccentric Bearings ... 30

08

Drive Belt................................. 33

Drive Belt Troubleshooting........... 33

Belt running up on lip of Drive Belt

Pulley ........................ 33

Bonding the Drive Belt Pulley ........ 34

Replacing the Drive Belt. . . . . . . . . . . . . 35

Drive Belt Replacement Procedure . 35

Checking Drive Belt Tension ......... 36

Drive Belt Tensioning Procedure ...... 37

Adjusting Belt Tension ........... 38

09

Chuck ...................................... 39

Chuck Troubleshooting ............. 39

Chuck skipping steps ............ 39

Chuck not level in load position .... 39

Removing and Cleaning Chuck Jaws .. 40

Removing The Chuck............... 40

Cleaning The Chuck................ 40

10

Control Box............................. 41

Control Box ...................... 41

Replacing a Motor Driver ......... 41

Replacing the Control Box Power

Switch ........................ 42

Replacing the Smoothstepper ..... 42

Replacing Control Box Fuses ...... 43

xiBend-Tech Dragon A400 Maintenance & Troubleshooting

Contents

Reseating the Breakout Board ..... 43

Replacing the Control Box ........ 43

11

ESS Connections ................... 47

Troubleshooting the ESS Connections . 47

ESS Failure To Connect .......... 47

Connection Lost While Machine Is

Running ...................... 48

12

Sensors ................................... 49

Sensor Overview .................. 49

Diagnosing Sensor Issues ........ 49

Setting a Sensor. . . . . . . . . . . . . . . . . . . 49

Inspecting Sensor Cables ........... 50

Checking a Sensor................. 50

A and Z sensors ................... 50

13

Miscellaneous......................... 51

Ethernet Connections. . . . . . . . . . . . . . . 51

Rail Alignment .................... 53

Poor cutting accuracy and/or quality 53

Drive Belt riding up on edges of Drive

Belt Pulley..................... 53

Checking Rail Beam For Straightness/

Level ......................... 53

Trueing the Dragon A400 Rail Beam 53

Rail Splices.................... 54

xii Bend-Tech Dragon A400

Maintenance & Troubleshooting

Contents

13Bend-Tech Dragon A400 Maintenance & Troubleshooting

Introduction

01

01

Introduction

Introduction

The Dragon A400 Maintenance & Troubleshooting guide contains information intended

to assist the Operator in maintaining proper operation of the machine as well as solving

operational issues that may arise during regular use. This guide addresses typical operations

and procedures to resolve them. Should the User encounter an issue or situation that cannot

be resolved using this guide, or that goes beyond the scope of this guide, please contact

How To Send A Support Session

Properly setting up a Support Session with a Bend-Tech Service Technician can be key

to keeping the Dragon A400 up and running. Bend-Tech knows keeping the Dragon A400

performing optimally is critical to our customers’ bottom line. We are more than happy to help,

possible. Many times, if the right information is given, a Service Tech can have a solution ready

before we even pick up the phone.

1.

sending a Support Session, then keep the project open after submitting.

2. In the Bend-Tech Dragon Home interface, click the Help tab, then click Support Session.

3. Fill in Name, E-mail, Phone, and if you know a Service Tech or have had help with this

14 Bend-Tech Dragon A400

Maintenance & Troubleshooting

Introduction

01

4. Give a detailed description of the issue in the Description of Problem text box. The more

information given the better our Service Techs can help.

5.

Click Submit.

15Bend-Tech Dragon A400 Maintenance & Troubleshooting

Gate

02

02

Gate

Gate Troubleshooting

The majority of Gate issues are the result of a dirty Gate. It is important to clean the Gate on a

regular basis to keep it working smoothly and properly.

with older machines who are having this issue should contact Bend-Tech regarding updating

the Gate Lead Screws. Original design Gate Lead Screws have right-hand threads that place

too much pressure on the lead screw clip. Updated Gate Lead Screws are designed with left-

hand threads that hold pressure via the the block and threads rather than the retaining clip.

Symptom Cause Corrective Action

Eccentric bearing on

Gate sticking Bearings dirty. Clean the bearings with compressed

air and/or brake cleaner.

Front Gate binding

Dirty bearings or dirty bearing

rotation plate.

Clean Gate using brake cleaner and/

or compressed air.

Eccentric bearing out of

adjustment.

Remove Gate and adjust eccentric

bearing on Bearing Rotation Plate/

Gate Ring Gear.

C drive motor backlash out of

adjustment.

Perform visual check of C Motor and

drive gear. If play is observed loosen

C Motor mount bracket and adjust so

gear meshes smoothly around the

circumference of the Gate Ring Gear.

screw

Obsolete Gate lead screw

design.

Contact Bend-Tech Service for an

updated Lead Screw design.

Loose front Gate Eccentric bearing has come out

of adjustment.

Remove Gate and adjust eccentric

bearing to eliminate play in Gate jaws.

16 Bend-Tech Dragon A400

Maintenance & Troubleshooting

Gate

02

Symptom Cause Corrective Action

Gate Not Operating

Smoothly

Gate dirty

Clean Gate with compressed air

and/or brake cleaner. If the Gate is

extremely dirty use a rag or toothbrush

to help clean it.

Eccentric bearing out of

adjustment

Remove Gate from machine and

adjust eccentric bearing so there is no

play and the Gate spins smoothly.

Play in Gate Eccentric bearing out of

adjustment

Remove Gate from machine and

adjust eccentric bearing so there is no

play and the Gate spins smoothly.

Gate Jaws not

operating smoothly

Dirty Lead Screws

Clean Gate Lead Screws, with brake

cleaner and/or compressed air. Re-

lubricate.

Dirty Gate Jaw rack Clean Gate Jaw Rack with brake

cleaner and/or compressed air.

Rack out of adjustment Remove the Gate and adjust Gate

jaws using the eccentric bearing.

Rack eccentric bearings dirty Clean the bearings with brake cleaner

and/or compressed air.

The Gate is exposed to Torch slag, cutting fumes and, if equipped with a Cooling

System, moisture. It is important to keep the Gate clean.

17Bend-Tech Dragon A400 Maintenance & Troubleshooting

Laser

03

03

Laser

Laser Troubleshooting

Symptom Cause Corrective Action

Laser not lining up with

end of tube

Material length set wrong

in software.

Check material length on machine,

verify length is correct in software

project settings.

Chuck grip set wrong in

software.

Verify the Chuck grip setting is correct

in Dragon CAM > Tube Library >

Machine > Chuck Grip. Click the

question mark to see examples of

Chuck grip settings.

Machine not homed/

calibrated correctly.

From the Bend-Tech Dragon home

interface click Machine Control, then

click Home All Axis to home the

Dragon A400. If it is determined the

machine needs to be calibrated, the

Operator can perform a full calibration

by clicking into Machine Library, and

in the Main interface click the Wizard

icon.

18 Bend-Tech Dragon A400

Maintenance & Troubleshooting

Laser

03

Symptom Cause Corrective Action

Laser failure

Laser burned out. Replace laser.

Cable or plug issue. Inspect cables, inspect plugs, replace

if damaged.

The Laser is a consumable. If the Laser quits working it may have reached the end of

its service life. Contact Bend-Tech to order a new Laser.

19Bend-Tech Dragon A400 Maintenance & Troubleshooting

Torch

04

04

Torch & Cutting

Diagnosing Cutting and Torch Issues

Symptom Cause Corrective Action

Cope at both ends of the

tube are not the same

rotation

Material not properly

secured in the Chuck.

Ensure material is tight in Chuck. If

using spacers for the material ensure

the measurements are correct.

Settings in Nesting Project

not correct. Check the part in Edit Flat.

Y Motor Backlash

incorrect.

Remove Trolley Cover and observe

backlash on Y Motor. If incorrect adjust

on machine. Perform a Backlash

Test in Machine Library > Mechanical

Settings.

Y Motor loose/Drive Gear

loose.

Remove Trolley Cover and perform

visual and physical check of Y Motor

and Y Motor Drive Gear.

Y Motor skipping steps.

Check Ethernet connectivity. Check

to ensure Breakout Board is seated

in Motor Drivers properly. Ensure

consistent power to machine.

20 Bend-Tech Dragon A400

Maintenance & Troubleshooting

Torch

04

Symptom Cause Corrective Action

Cut quality issues

Torch consumables worn

out.

Inspect Torch consumables, measure

pit depth of electrode.

Incorrect Torch height

settings.

Check settings in software and Torch

height on machine.

Incorrect cutting speed.

Ensure cutting speed is correct in

regard to amperage and material

thickness.

Incorrect cutting

amperage.

Ensure consumables match the

amperage settings on the machine.

Set cut speed appropriately.

Round holes are coming

out oval

Cutting speed. Adjust material feed rate.

Material loose in Chuck. Ensure material is secure in Chuck.

Gate too tight or too loose. Ensure material moves freely in Gate

with no play.

Backlash.

Perform a Backlash Test in Machine

Library > Mechanical Settings.

Remove the Trolley cover and perform

a visual inspection of backlash.

Ensure all motors are tight.

Machine cutting and then

returning to previous

engraving

Order of actions incorrect

in software settings.

Change order of actions

Machine Library > Basic > Default

Process Order.

rectangular material

Gate out of position.

Check homing sensors, check X

backlash, re-home, load material with

Gate in home position and perform

X Axis backlash out of

spec.

Remove Trolley Cover and observe

backlash on X Motor. If incorrect

adjust on machine. Perform a

Backlash Test in Machine Library >

Mechanical Settings.

Machine not homed

properly.

In the Machine Control interface click

Home All Axis.

Jagged Cuts

Material feed rate too high.

Ensure consumables match the

amperage settings on the machine.

Set cut speed appropriately.

Loose set screws on X or

Y Axis.

Remove Trolley cover and perform

inspection of X and Y Axis.

Gate too tight on material. Ensure material moves freely in Gate

with no play.

Other manuals for Dragon A400

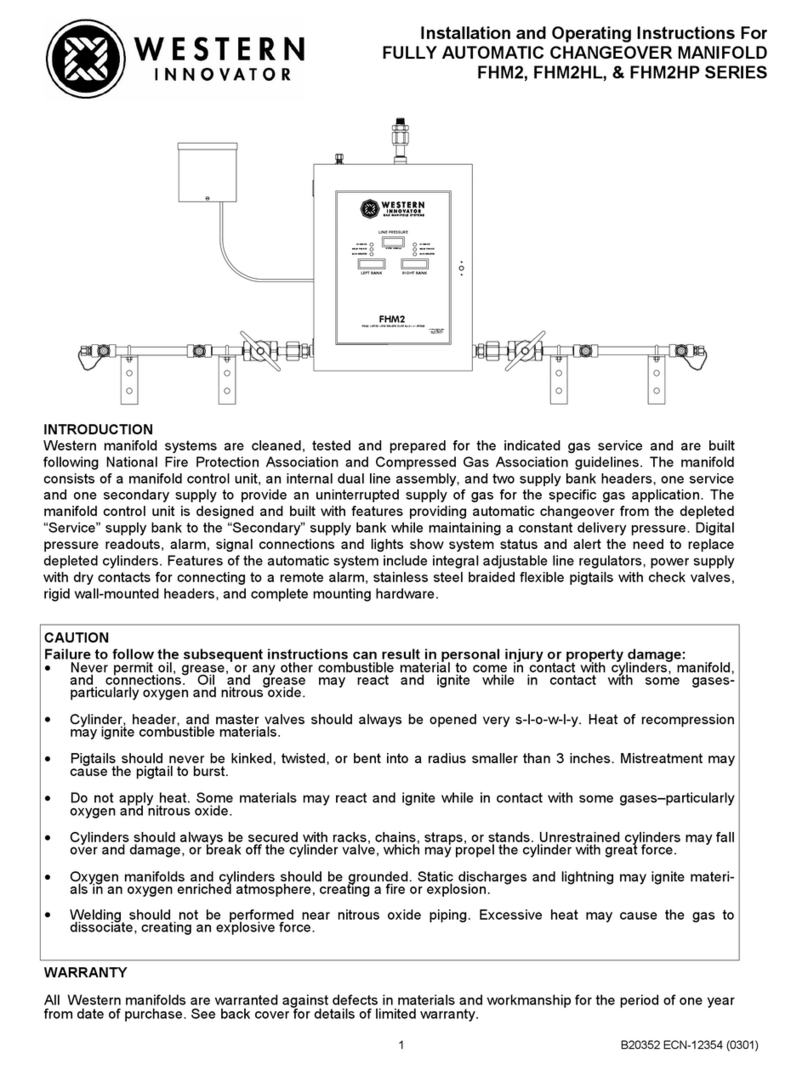

14

Table of contents

Other Bend-Tech Control System manuals

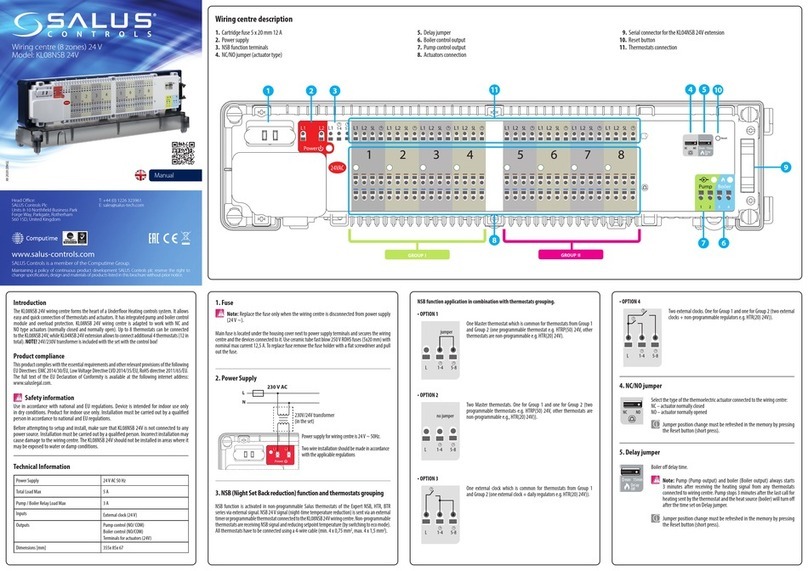

Popular Control System manuals by other brands

OBSIDIAN CONTROL SYSTEMS

OBSIDIAN CONTROL SYSTEMS NX DMX installation guide

Stagnoli

Stagnoli H230 manual

Norac

Norac UC4 Total Control installation manual

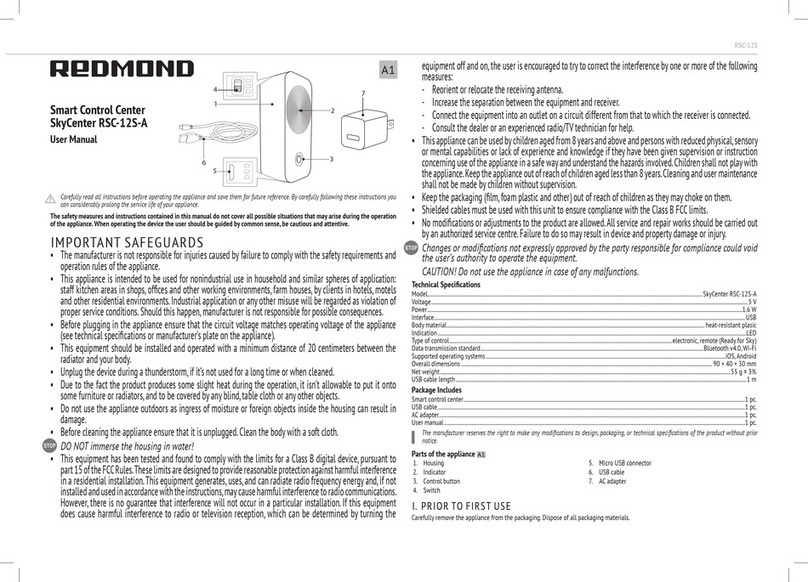

Redmond

Redmond SkyCenter RSC-12S-A user manual

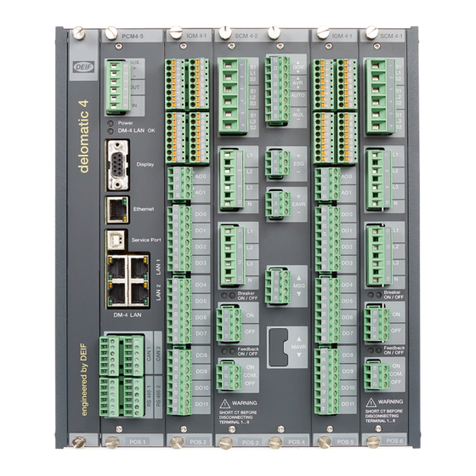

Deif

Deif DELOMATIC 4 Series Replacement instructions

Barrier Systems

Barrier Systems X-TENSION Installation and maintenance manual

Weishaupt

Weishaupt WCM-FS 2.0 Installation and operating instruction

Paso

Paso PM2021-V Instructions for use

Varifan

Varifan DIP-1/115 Installation & user guide

Union Instruments

Union Instruments CWD2005 SPC OPERATING INSTRUCTIONS AND SAFETY NOTES

Uponor

Uponor A3800165 instruction sheet

Centroid

Centroid Acorn CNC installation manual