Barrier Systems X-TENSION Manual

INSTALLATION AND MAINTENANCE MANUAL

X-TENSION®/ X-MAS®

NCHRP 350 TL-3 Tangent / Flared End Terminal and Median Attenuator

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

2

INSTALLATION AND MAINTENANCE MANUAL

Table of Contents

Introduction 3

System Overview 3

Before Installation 3

Warranty 4

Limitations and Warnings 5

Safety Statements 5

Parts Identication 6

Preparation 8

Soil Conditions 8

Tools Required 8

Before Starting 8

X-Tension Tangent Installation 9

X-Tension Flared Installation 17

X-MAS Median Installation 19

Optional Nose Cover 24

Installation Checklist 25

Trafc Face Impacts 26

Head on Impacts 27

APPENDIX - Drawings

XTGTSS1 Roadside / Imperial Wood Blockout - Wood Post 28

XTGTSS2 Roadside / Imperial Wood Blockout - Steel Post 29

XTGTSS3 Roadside / Imperial Composite Blockout - Steel Post 30

XTMTSS2 Median / Imperial Wood Blockout - Steel Post 32

XTMTSS3 Median / Imperial Composite Blockout - Steel Post 31

MAINTENANCE

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 3

X-TENSION®SYSTEM

X-Tension Introduction

Introduction

The X-Tension Guardrail End Terminal has been designed and tested to meet the evaluation

criteria of NCHRP 350 Test Level 3.

The system has been tested to the guidelines in NCHRP 350 for a non-gating, re-directive guard-

rail end treatment. When correctly installed and maintained, the system is capable of stopping,

containing, or re-directing an errant vehicle in a safe manner under NCHRP 350 impact condi-

tions.

The X-Tension Guardrail End Terminal is the world’s rst fully re-directive, non-gating guardrail

terminal end. The unique X-Tension technology is a tension based solution rather than compres-

sion based. It offers exceptional vehicle control and energy absorbing capabilities in head on

impacts, where the energy is absorbed with resistance at the impact head rather than being trans-

ferred down the rail as occurs with other systems. Even head on, high angle (15o during testing)

impacts on the nose resulted in the vehicle being redirected and controlled.

System Overview

The X-Tension Guardrail End Terminal is designed and constructed to provide acceptable struc-

tural adequacy, minimal occupant risk and safe trajectory as set forth in NCHRP 350 for guard-

rail terminal ends.

When impacted head on with an 820 – 2000kg (1800 – 4400lb) vehicle at speeds of up to 100kph

(62 mph), the impacting vehicle is brought to a controlled stop or allowed to penetrate to the back

side, depending on the impact conditions.

Before Installation

Placement and use of the X-Tension Guardrail End Terminal should be done in accordance with

the guidelines and recommendations set forth in the “AASHTO Roadside Design Guide”, FHWA

memoranda and other state and local standards.

Depending on the application and circumstances at the site, installation and assembly of a Test

Level 3 system should take a two person crew less than two hours.

The X-Tension Guardrail End Terminal is a highly engineered safety device made up of a rela-

tively small number of parts. Before starting installation ensure that one is familiar with the make

up of the system.

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

4

STANDARD LIMITED WARRANTY

Lindsay Transportation Solutions, Inc. “LTS” ( formerly Barrier Systems ) has tested the impact

performance of its barriers and crash cushion systems, and other highway safety hardware under

controlled conditions, however, LTS does not represent nor warrant that the results of those controlled

conditions would necessarily avoid injury to persons or property. LTS EXPRESSLY DISCLAIMS ANY

WARRANTY OR LIABILITY FOR CLAIMS ARISING BY REASONS OF DEATH OR PERSONAL

INJURY OR DAMAGE TO PROPERTY RESULTING FROM ANY IMPACT, COLLISION OR

HARMFUL CONTACT WITH THE PRODUCTS OR NEARBY HAZARDS OR OBJECTS BY ANY

VEHICLE, OBJECTS OR PERSONS.

LTS warrants that any product or component part manufactured by LTS will be free from defects in

material or workmanship. LTS will replace free of cost any Product or component part manufactured by

LTS that contains such a defect.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES

NOT EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESS OR IMPLIED BY OPERATION

OF LAW OR OTHERWISE, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LTS’ LIABILITY UNDER THIS WARRANTY IS EXPRESSLY LIMITED TO REPLACEMENT

FREE OF COST (IN THE FORM AND UNDER THE TERMS ORIGINALLY SHIPPED), OR TO

REPAIR OR TO MANUFACTURE BY LTS, PRODUCTS OR PARTS NOT COMPLYING WITH

LTS SPECIFICATIONS, OR, AT LTS’ ELECTION, TO THE REPAYMENT OF AN AMOUNT

EQUAL TO THE PURCHASE PRICE OF SUCH PRODUCTS OR PARTS, WHETHER SUCH

CLAIMS ARE FOR BREACH OF WARRANTY OR NEGLIGENCE. LTS SHALL NOT BE LIABLE

FOR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL LOSSES, DAMAGES OR EXPENSES

OF ANY KIND, INCLUDING, WITHOUT LIMITATION, ANY SUCH LOSSES, DAMAGES OR

EXPENSES ARISING DIRECTLY OR INDIRECTLY FROM THE SALE, HANDLING OR USE OF

THE PRODUCTS FROM ANY OTHER CAUSE RELATING THERETO, OR FROM PERSONAL

INJURY OR LOSS OF PROFIT.

Any claim by the Buyer with reference to Products sold hereunder for any cause shall be deemed waived

by the Buyer unless LTS is notified in writing, in the case of defects apparent on visual inspection,

within ninety (90) days from the delivery date, or, in the case of defects not apparent on visual

inspection, within twelve (12) months from the said delivery date. Products claimed to be defective may

be returned prepaid to LTS’ plant for inspection in accordance with return shipping instructions that

LTS shall furnish to the Buyer forthwith upon receipt of the Buyer’s notice of claim. If the claim is

established, LTS will reimburse that Buyer for all carriage costs incurred hereunder.

The forgoing warranty benefits shall not apply to (i) any Products that have been subject to improper

storage, accident, misuse or unauthorized alterations, or that have not been installed, operated and

maintained in accordance with approved procedures and (ii) any components manufactured by the

Buyer.

W030587 Rev. 8 revised February 4, 2013

180 River Road •Rio Vista, CA 94571 •Tel. +1 (707) 374-6800 •Fax. +1 (707) 374-6801

INSTALLATION AND MAINTENANCE MANUAL

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 5

X-Tension Introduction (continued)

Limitations and Warnings

The X-Tension Guardrail End Terminal has been rigorously tested and evaluated per the

recommendations in the NCHRP 350 guidelines for terminals and crash cushions. The impact

conditions recommended in NCHRP 350 are intended to address typical in–service collisions.

When properly installed and maintained, the system is capable of containing and re-directing

impacting vehicles in a predictable and safe manner under the NCHRP 350 impact conditions.

Vehicle impacts that vary from the NCHRP 350 impact conditions described for guardrail end

terminals may result in signicantly different results than those experienced in testing. Vehicle

impact characteristics different than or in excess of those encountered in NCHRP 350 testing may

result in system performance that may not meet the NCHRP 350 evaluation criteria.

Safety Statements

General Safety

All required trafc safety precautions should be complied with. All workers should wear required

safety clothing (high visibility vests, steel capped footwear, gloves, hard hats, safety glasses etc.)

All underground services must be located before installation of any posts.

Only Authorized trained personnel should operate any machinery. Where overhead machinery is

used, care must be taken to avoid any overhead hazards.

Gloves should be worn at all times. Particular care should be taken to avoid galvanizing spikes.

X-Tension Safety Statements

All installers must be well clear of post driving machinery when in use.

Avoid placing hands or ngers in and around moving parts when components are being lifted and

manoeuvred into place. (i.e. around splice holes, etc.) permeable

The cables should be tted by one person only. Other workers should stand clear to avoid being

caught in moving cables.

Securely fasten the impact head and rail before turning the friction plate.

The friction plate should be turned manually with a crow bar and extension handle. Do not attempt

to turn it with the assistance of machinery. Ensure crow bar is securely held while the 4 locking

bolts are tightened.

X-TENSION®SYSTEM

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

6

X-Tension Parts Identication

INSTALLATION AND MAINTENANCE MANUAL

Impact Head

(1 Required)

B061072

Friction Plate

(1 Required)

B061058

Soil Anchor

(1 Required)

B061104

Slider Bracket + Angle Bar

(1 Required Roadside – 2 Median)

B061079

Cable Bracket

(1 Required)

B061083

Cable Assembly

(2 Required)

B061109

Slider Panel

(1 Required Roadside – 2 Median)

B061088

Post 1 - Top

(1 Required)

B061099

Ground Strut

(1 Required)

B061094

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 7

X-TENSION®SYSTEM

Post # 2 (1 Req.)

Roadside can be CRT Timber

B061100

Galv. Line Post (3-6)

(CRT Timber Posts allowed roadside)

BSI-1012078-00

Post #1 Bottom

(1 Required)

B061098

W-Beam Guardrail RWM02a

(3 Required Roadside – 5 Median)

4000443

Median Radius Rail 1 (12’-6”)

(1 Required – Shop Curved)

B070233

Median Secondary Head

(1 Required)

B070219

Shear Bolts

8 Required Roadside - 16 Median)

K080123

Blockout (Plastic or Timber)

(5 Required Roadside – 10 Median)

B090534

Hardware Set

(Roadside)

K070202 & K070204

X-Tension Parts Identication

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

8

X-Tension – Preparation for all Applications

Preparation

Before installing an X -Tension, ensure that all materials required for an 11.4 m (38 ft) system

are on site and have been identied. See bill of materials for the particular application and parts

identication sheet.

Ensure that the area where the X-Tension is to be installed is at enough so that the soil anchor

will not protrude more than 100mm (4 in) from ground level, when measured with a straight line

over a 1.5m (5 ft) cord. Minor site grading may be required.

Soil Conditions

The X-Tension has been designed to be installed in median or edge of road locations and in soil

that meets or exceeds the AASHTO “standard soil” specication. If rock or saturated soil is en-

countered during post installation, refer to appropriate State specications. Guidelines will vary

from State to State.

Tools Required

The same tools required to install standard highway guardrail will also install an X-Tension. Spe-

cically: Sockets (commonly used in Guardrail), Drill, Wrenches, Large Crow Bar, String line,

Level, Augers, Tampers and Post Pounders commonly used in driving posts.

Before Starting

For all applications, begin the installation from the downstream end of the terminal at the point

where it joins the standard guardrail (post 7).

For the tangent and ared applications, the X-Tension connects directly to standard steel post or

timber post strong post W – beam highway guardrail, SGR04a-b.

The median application X-Tension connects directly to standard steel post or timber post

strong post W-beam median barrier SGM04a-b

Follow step by step instructions for the appropriate application.

Important Note about posts and blockouts:

Tangent & Flared Systems:

Post 1 steel – Post 2 either CRT timber or crimped steel

Post 3-6 either CRT timber or standard steel I beam posts

Median system:

Posts 1 & 2 are always crimped steel.

Posts 3 – 6 are standard steel I beam posts

Blockouts may be either composite or timber.

INSTALLATION AND MAINTENANCE MANUAL

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 9

X-Tension - Tangent Installation Instructions

At

Post 7

At

Post 5

At

Post 3

At

Post 1

Step 1 - Set Out

The tangent terminal is essentially an 11.4m (38 ft) continuation of the standard guardrail run.

Pull a string line out with the desired offset (0 -450mm : 0-1.5 ft) over the length of the system, in

a straight are (Figure 1). The system should not be installed on parabolic curve. The string

line should be set to follow the roadside edge of the posts.

All the posts except post #1 have a blockout so take care to place the roadside face of

post #1 200mm (8 in) towards the roadway to compensate for the lack of blockout.

X-TENSION®SYSTEM

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

10

Step 2 – Installing Posts 6- 2

Begin installing posts 2 – 6 at standard highway

post spacing, 75” (1905mm) and post height, 28

1/4” (720mm) or 31 3/4” (805mm) depending on the

height of the system being installed.

Please note: Post 1 consists of two parts, Post 1

Top and Post 1 Bottom. Post 1 Top is different for

27 ¾” systems vs 31” systems . Ensure that the

correct Post 1 Top is installed for the appropriate

height system. Post 1 Top is not interchangeable

between 27 ¾” and 31” height systems.

All posts should be the same height from

ground level throughout the entire system.

Posts #6 to #3 are either standard “I” beam

posts OR timber CRT posts. Post 2 is either the

Special “I” beam post or a timber CRT (see parts

identication photo).

Posts may be directly driven, or in stiff soils a

150mm (6 in) diameter hole drilled, and the post

then driven into the hole. The post may also be

placed in an oversized augured hole but care

must be taken to ensure the backll is properly

compacted.

Hint: Offset Post 3 back from the string line 40-

50mm (up to 2 in) to make it easier to push rail 1

and Slider Panel over rail 2.

When driving steel posts, ensure that a driving

cap with timber or plastic insert is used to prevent

damage to the galvanizing on the top of the posts.

Ensure that Post 2 has the post bolt holes on the

side nearest the rail

Notches go to the backside as shown and are

only used on the median application.

(Figure 2)

Bolt the blockout to the post at post 3, prior to

attaching to the rail (Figure 3).

Figure 1. Pull a string line with the desired offset.

Figure 2. Holes on straight rail side, notches on

the backside.

Figure 3. Bolt the blockout to post 3 prior to

attaching the rail.

X-Tension - Tangent Installation Instructions

INSTALLATION AND MAINTENANCE MANUAL

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 11

Step 3 – Post 1, Ground Strut and Soil Anchor

Place the roadside face of post 1 bottom anchor, 200mm (8 in) towards the roadway to

compensate for the lack of blockout (Figure 4). Post 1 bottom, the Ground Strut and the Soil

Anchor are then placed parallel to the string line at this roadside offset position.

Drive or place the bottom of post 1 in the augured hole so that no more than 75mm (3 in) [100mm

(4 in max)] protrudes above ground level (Figure 5). Use the Ground Strut as a template to place

the Soil Anchor in the correct place. The Soil Anchor can then be driven into place or placed in an

augured hole and backlled. The Ground Strut should be level or lower at the anchor end than at

the post 1 bottom end.

Place post 1 top in the post 1 bottom anchor ensuring that the post bolt notches are at the top

and facing the Soil Anchor (Figure 6). Use M16 x 200mm (5/8 in x 8 in) hex head bolt with nut and

washers. Do not over tighten bolt.

Figure 4. Measure 8 in. towards roadway. Figure 5. Drive post 1 into augured hole. Figure 6. Post 1 top in post bottom.

Step 4 – Hang Rail 3 and Cable Anchor Bracket

Rail 3 is installed like standard

guardrail with post 6 at the center

of the rail and blockouts between

the rail and post. Place the Cable

Anchor Bracket on the back of the

rail at the joint between rail 3 and

rail 4 (post 7).

The two “boxes” on the cable

bracket should be on the impact

head side of the splice joint. At-

tach rails to post with post bolt and

splice rail 3 to rail 4 with 8 standard

splice bolts (Figure 7).

Figure 7. Splice rail 3 to rail 4 with 8 standard splice bolts.

X-Tension - Tangent Installation Instructions

X-TENSION®SYSTEM

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

12

Figure 10. Bolt Slider Bracket to end of rail 2 at post 3. Figure 11. Remove angle bar bolts.

Step 5 – Hang Rail 2 and Shear Bolts

Before installing rail 2, double check that the blockout is already bolted to post 3.

Bolt rail 2 to the post and blockouts at posts 4 and 5 with the appropriate post bolt (Figure 8).

DO NOT BOLT THE RAIL TO POST 3.

Splice rail 2 to rail 3 with the 8 special shear bolts (yellow) supplied (Figure 9). Put the

washer and nut on inside of rail.

IMPORTANT NOTE: DO NOT USE STANDARD SPLICE BOLTS AT POST 5 SPLICE. DO

NOT USE AN AIR-IMPACT WRENCH TO TIGHTEN SHEAR BOLTS. SHEAR BOLTS WILL

BREAK IF OVER-TIGHTEND.

Figure 8. Bolt rail 2 to post and blockouts. Figure 9. Splice rail 2 to rail 3 with 8 special shear bolts.

Step 6 – Attach Slider Bracket to Rail 2

Bolt the Slider Bracket to the end of rail 2 at post 3 (Figure 10). Use 4 standard splice bolts. The

angle bar end should be closest to the Impact Head end.

Remove the angle bar and 2 x M20 x 25mm (3/4 in x 1 in) bolts (Figure 11).

X-Tension - Tangent Installation Instructions

INSTALLATION AND MAINTENANCE MANUAL

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 13

Step 7 – Assemble Slider Panel onto Rail 1

Start by sitting rail 1 on a blockout or post so that it is raised off the ground as shown (Figure 12).

Slide the Slider Panel onto the downstream end of rail at post 3 location (Figure 13) and bolt into

place using 4 standard splice bolts, pushing the bolt through from the inside of the slider to the

outside so that the nut is on the trafc face.

The curved and reinforced (post breaker) end of Slider Panel sits at the rail end.

Use guardrail pin bar or crow bar to assist with lining up splice holes.

Figure 12. Sit rail 1 so it is raised off the ground.

Step 8 – Hang Rail 1

Figure 13. Slide the Slider Panel onto downstream end.

Lift rail 1 with Slider Panel attached and push the slider end over rail 2 (Figure 14). Overlap the

rails as per a standard splice joint overlap.

Bolt rail 1 and blockout to post 2 using a standard post bolt that is supplied (Figure 15).

Re-attach the angle bar to the slider bracket on the backside of the rail (Figure 16).

Figure 14. Push Slider Panel over rail 2. Figure 15. Bolt rail 1 and blockout to post 2. Figure 16. Reattach the angle bar.

X-Tension - Tangent Installation Instructions

X-TENSION®SYSTEM

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

14

Figure 17. Attach Impact Head to rail 1.

Step 9 – Attach Impact Head

Place Impact Head on upstream end of rail 1 and attach using 8 standard splice bolts with nuts on

trafc face (Figure 17). Hint: Place bottom two bolts rst then use guardrail pin bar to lever head

up snug onto rail.

Bolt head and rail 1 to post 1 using the supplied M16 x 50mm (5/8 in x 2 in) guardrail post bolt.

Ensure to use a 5/8” hex nut at post 1. Use a 50mm x 50mm (2 in x 2 in) washer under the nut

on the inside of post 1 (Figure 18).

Step 10 – Place the Cables

Push the cables under the steel strap on the Ground Strut (Figure 19) and forward through the

holes at the top of the anchor. Lay the cables out parallel to the guardrail, downstream from the

anchor.

Ensure that bottom cable (Cable B in Diagram 1) has half the thread protruding through the an-

chor, as shown. Ensure the top cable has the nut wound on a least two turns past the end of the

thread (Figure 20). Cable A should always pass through the top hole on the impact head. Cable

B should always pass through the bottom hole on the impact head as shown in Diagram 1.

In addition, ensure that the bottom cable passes through the ground strut hole nearest the straight

(non-radius) side of the system.

Figure 20. Thread the nuts as shown.Figure 19. Push cables under steel strap on

Ground Strut.

Diagram 1.

Figure 18. Bolt head and rail 1 to post 1 with

washer & 5/8” hex nut.

INSTALLATION AND MAINTENANCE MANUAL

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 15

Figure 23. Use crow bar to turn Friction Plate. Figure 24. Use socket to lock bar in the turned position.

Step 11 – Installing the Cables

Install the Friction Plate in the top of the Impact Head, adjustment hole up. Take the cable closest

to the road, pick up the downstream cable tting and walk to the head, passing the cable through

the bottom hole, through the Friction Plate (Figure 21) and out the backside of the Impact Head.

Now thread the cable down the backside of the rail following the bottom trough of the W-beam

and attach to the bottom “box” on the Cable Bracket at post 7. Repeat this process with the other

cable but push it through the top hole and thread it along the top trough of the W-beam.

Place the nuts and washer on the cables at the Cable Bracket end but only run them a few turns

(Figure 22).

Do not tighten cables at this stage (or the Friction Plate will not turn)

Figure 21. Pass the cable through the bottom hole. Figure 22. Do not tighten nuts at this time.

Step 12 – Turning the Friction Plate

Put a crow bar through the hole at the top of the friction plate (Figure 23) and turn it to the nal

position. Using a socket, tighten the 4 - M20 x 75mm (3/4 in x 3 in) bolts on the side of the impact

head to lock the bar in the turned position (Figure 24).

Diagram 1.

X-TENSION®SYSTEM

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

16

Step 13 – Tightening the Cables

Only tighten the cables using the nuts at the Cable Bracket end (post 7) (Figure 25).

Do not tighten the cable nuts at front of the Ground Anchor.

Tighten the cables until they are taut, i.e. they rest in the backside of the W-beam and do not

visibly sag between posts (Figure 26). There is no torque requirement for the cables.

Figure 25. Tighten cables at Cable Bracket end (post 7). Figure 26. Tighten cables until they are taut.

Step 14 – Attach Nosing

Push nosing into place on the front of the impact head. Attach using the supplied nylon push

rivets (Figure 27).

Delineation to be attached to nosing, as per the Local Authorities requirements.

Figure 27. Attach nose using nylon push rivets.

INSTALLATION AND MAINTENANCE MANUAL

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 17

0 - 1.2 m (0 - 4 ft)

This section deals with installation of a Flared X-Tension system in a roadside guardrail terminal

end application.

Apart from the initial set out, the ared X-Tension and installation procedure is identical to the

Tangent system, the only difference being the amount of offset used.

Site preparation

The Flared terminal may be installed either parallel to the edge of the roadway (tangent) or with

the impact head end of the rail offset by up to 1.2m (4 ft) away from the road (Figure 28) in a

straight are, over the length of the system. The system should not be installed on parabolic

curve.

Ensure that the area where the X-Tension is to be installed is at enough so that the anchor will

not protrude more than 75 mm (3 in) [100 mm (4 in) max] above ground level, when measured

with a straight line over a 1.5m (5 ft) cord. Minor site grading may be required.

Figure 28. Maximum offset is 1.2 m (4 ft).

X-Tension - Flared Installation Instructions

X-TENSION®SYSTEM

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

18

Figure 30. Place roadside face of post 1 towards roadway.

0 - 1.2 m (0 - 4 ft)

Figure 29. Pull string line to follow roadside edge of posts.

Figure 31. Place Ground Strut parallel to string line.

Now follow steps 2 – 14 in the Tangent installation instructions.

Note: The “kink” in the line of rail between rail 3 and rail 4 (at post #7) is

formed by simply pushing the rails around to follow the ared line of posts.

This is not factory bent.

Step 1 - Set Out

Pull a string line out with the desired offset (0 -1.2m; 0-4 ft)

Note that the are is a straight are, over the length of the system (11.4m; 38 ft)

The string line should be set to follow the roadside edge of the posts (Figure 29).

All the posts except post 1 have a blockout so take care to place the roadside face of post 1

200mm (8 in) towards the roadway (Figure 30).

Post 1 bottom, the Ground Strut and the Soil Anchor are then placed parallel to the string line on

the roadside of it (Figure 31).

X-Tension - Flared Installation Instructions

INSTALLATION AND MAINTENANCE MANUAL

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 19

Slider Brackets

Figure 32. X-Tension median installation.

Post 5 Shear Bolts

Median Radius Rail

Impact Head

Median Impact Head

This section deals with installation of a X-Tension Median Attenuator System (X-MAS) as a median

guardrail terminal end application.

Site preparation

The X-Tension Median Attenuator System is installed parallel to the standard median barrier,

therefore no offset is used (Figure 32).

Ensure that the area where the X-Tension is to be installed is at enough so that the soil anchor

will not protrude more than 100mm (4 in) [preferred 75 mm 3 in)] from ground level when

measured with a straight line over a 1.5m (5 ft) cord. Minor site grading may be required.

X-MAS - Median Installation Instructions

X-TENSION®SYSTEM

Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800 Lindsay Transportation Solutions Sales and Services, Inc (888) 800-3691 [U.S. toll free] or +1 (707) 374-6800

20

Step 1 - Set Out

The X -Tension Median Attenuator is essentially one Tangent X-Tension installed parallel to one

side of the median barrier (Figure 33), with a small number of additional components and rail

attached parallel with the other side of the barrier (Figure 34).

Pull a string line out the length of the system, parallel with the median barrier posts.

The string line should be set to follow the side of the posts, on the side that it is desired to install

the tangent X-Tension.

The X-Tension portion (straight side) of the X-Tension Median Attenuator should always be

installed on the side with approach trafc. See Diagram 2.

Figure 33. Essentially a tangent system

installed parallel to median barrier.

Figure 34. Small number of additional

components.

Step 2 – Installing Tangent X-Tension Portion

Follow steps 2 – 13 in the Tangent installation instructions, with the following exceptions.

(1) DO NOT set post 3 back 30-50mm (1 -2 in) as per the instructions in Step 2 of the Tan-

gent installation instructions. For the Median application, Post 3 remains parallel with the

other line posts.

(2) As noted on page #7, Post 2 must be steel crimped and Post 3-6 are

always standard steel I-beam posts.

Now follow the remaining steps 3 to 8 to complete the backside of the median terminal.

X-MAS - Median Installation Instructions

Diagram 2.

INSTALLATION AND MAINTENANCE MANUAL

This manual suits for next models

1

Table of contents

Popular Control System manuals by other brands

Autotrol

Autotrol Performa 440i Control Installation, operation and maintenance

BST

BST ekrPro Com60 Quick reference guide

Bosch

Bosch Rexroth IndraDrive Mi KCU01 operating instructions

Ascon tecnologic

Ascon tecnologic vP4 installation manual

Siemens

Siemens IR-64K Brief description and installation instructions

Altronics

Altronics PowerQuest manual

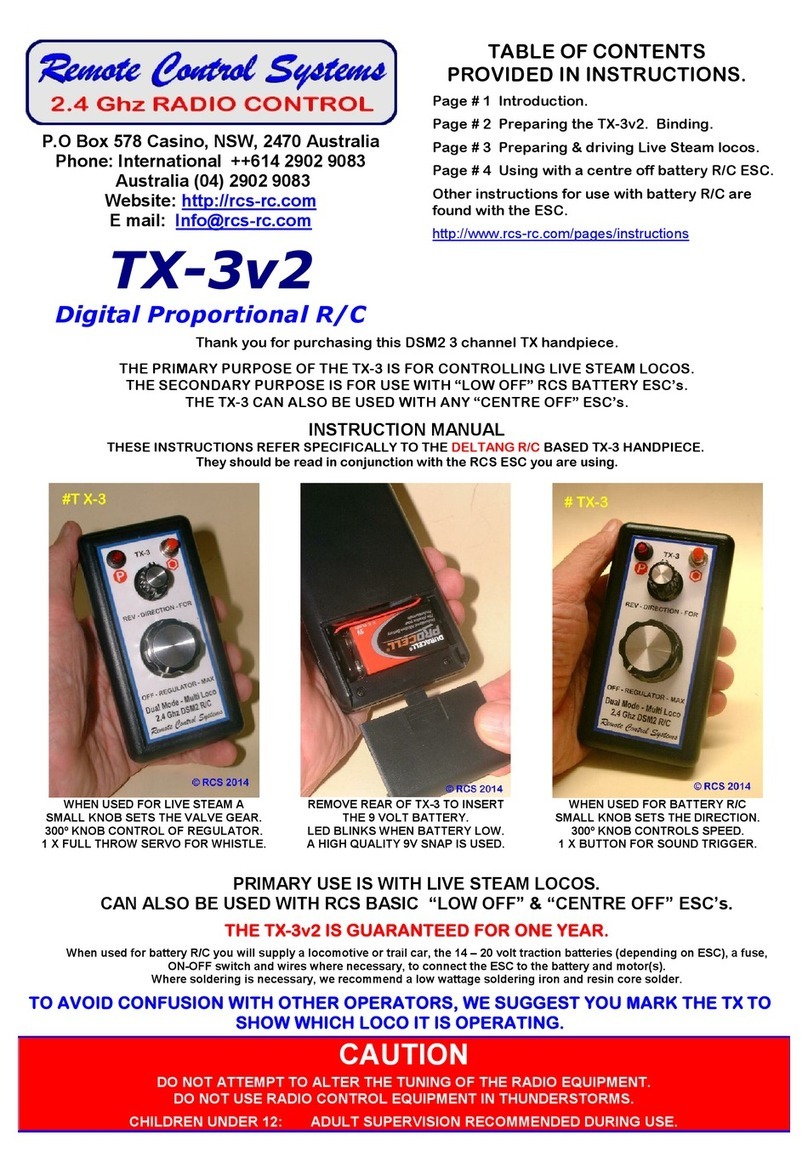

Remote Control Systems

Remote Control Systems TX-3v2 manual

Shure

Shure GLXD+FM user manual

International

International Easikey 1000 Installation and user guide

PAW

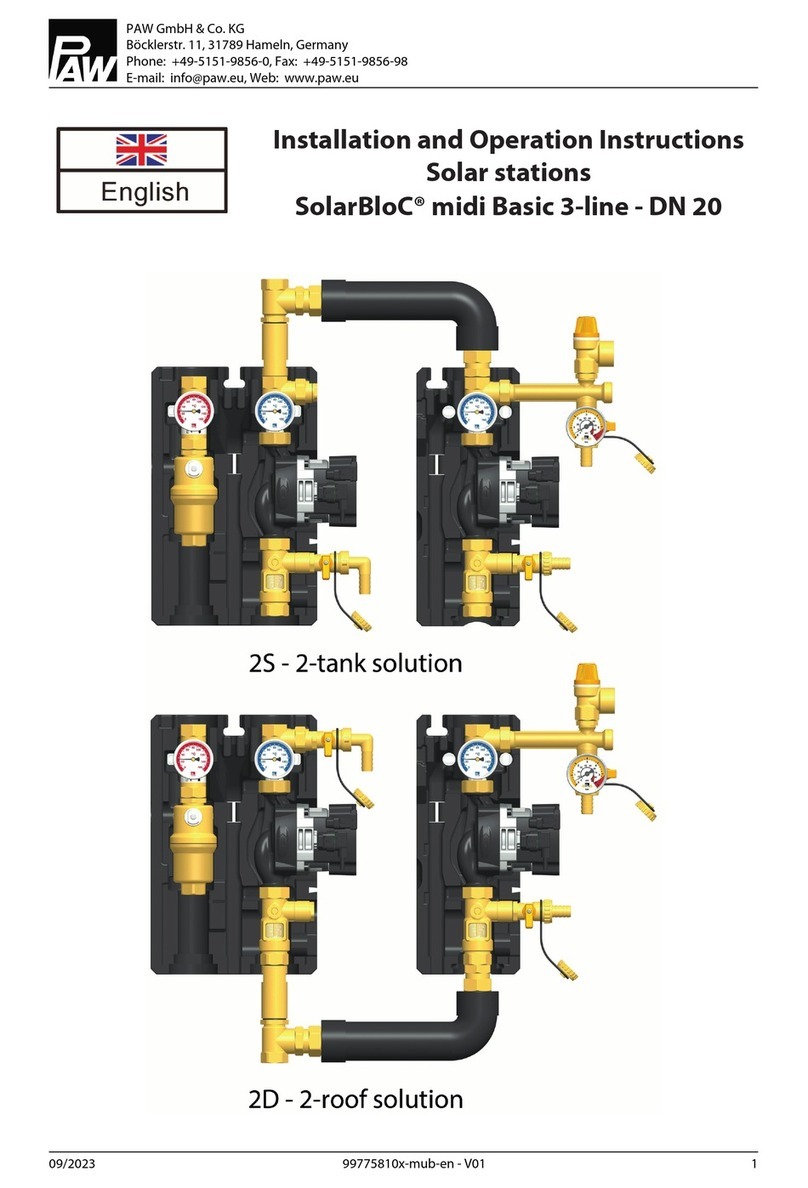

PAW SolarBloC midi 2S Installation and operation instruction

Pearpoint

Pearpoint P350 Operation manual

Lutron Electronics

Lutron Electronics RadioRA Setup guide