Bender IR5002 User manual

Insulation monitoring device for

IT DC systems 350 ... 800 V

IR5002

Operating Manual

TGH 1360E

Edition 04/2008

Quality System

Certified

ISO 9001

MiniMax

IR5002

ALARM L- ALARM L+

ENTER

kΩ

MONITOR

****** BENDER ******

A - ISOMETER IR5002

Version 1.2 / 5.96

ENTER

Dipl.-Ing. W. Bender

GmbH+CoKG

Londorfer Str. 65

D-35305 Gr nberg

Postfach 1161

D-35301 Gr nberg

Tel. 06401/807-0

Fax 06401/807-259

E-Mail [email protected]

IR5002

Operating manual

TGH 1360EEdition 04/2005

Edited by

Dipl.-Ing. W. BENDER GmbH+CoKG

This manual may not be copied, in whole

or part, without written consent of BENDER.

All rights reserved.

Right to modifications reserved._Mac_PM6.5

3

TGH 1360E

1 General .................................................................................. 4

About the IR5002 ........................................................................... 4

IT System....................................................................................... 4

Underlying standards ..................................................................... 4

The concept of IR5002................................................................... 5

Coupling device AG5002 ............................................................... 5

2 Safety information .................................................................. 6

Intended use .................................................................................. 6

Personnel....................................................................................... 6

Copyright........................................................................................ 6

Warranty and liability...................................................................... 7

Explanation of symbols and warnings............................................ 7

Hazards when handling the system ............................................... 7

Inspection, transport and storage .................................................. 8

Warranty statement........................................................................ 8

3 Principle of operation ............................................................. 9

Symmetrical and asymmetrical insulation faults .......................... 10

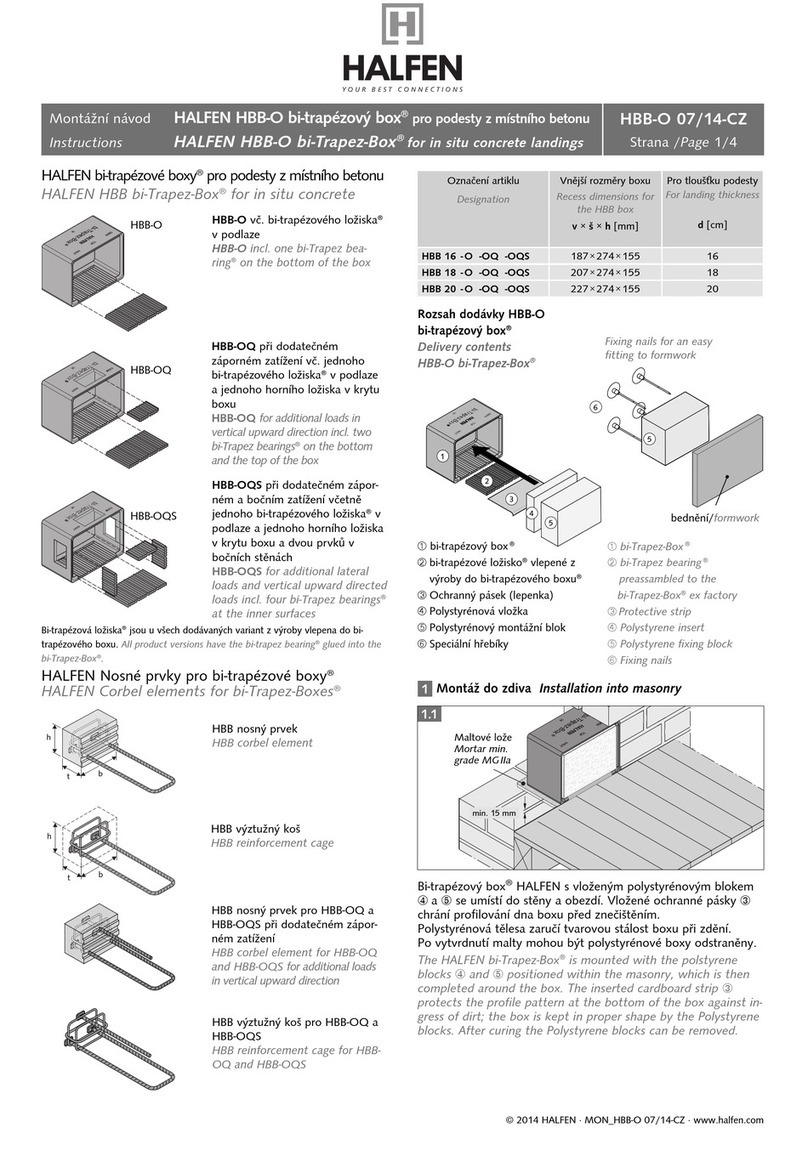

4 Product description .............................................................. 11

Mechanical design ........................................................................11

Dimension diagrams .................................................................... 12

Wiring diagram............................................................................. 14

Legend to wiring diagram............................................................. 15

Terminal strips.............................................................................. 16

5 Setting and operation .......................................................... 17

Function keys............................................................................... 17

Welcome screen .......................................................................... 17

Main screen ................................................................................. 17

Menus .......................................................................................... 18

The individual menus ................................................................... 19

Setting the response values......................................................... 19

Time response ............................................................................. 19

Indication of the time response .................................................... 21

Operating principle of the alarm relays ........................................ 21

N/O or N/C operation ................................................................... 22

Setting the threshold of the voltage ............................................. 22

Setting the serial interface ........................................................... 23

Adjusting digital input 1 ................................................................ 23

Temperature display..................................................................... 24

Setting date and time ................................................................... 24

Software version .......................................................................... 25

Factory settings............................................................................ 25

6 Wiring and commissioning ................................................... 26

Error messages............................................................................ 29

System errors, CRITICAL ERRORS ............................................ 30

Indication of asymmetrical faults.................................................. 31

Data output .................................................................................. 32

7 Technical Data...................................................................... 33

Analog output IR5002 .................................................................. 35

Contents

4

TGH 1360E

About the IR5002

1 General

With the insulation monitoring device IR5002, BENDER offers a special

equipment for continuous monitoring of the insulation resistance of IT DC

systems to earth. The device is intended to indicate when the value falls below a

preset response value.

The IR5002 is suitable for IT DC systems involving:

• systems with low insulation resistance and high nominal voltages

• systems with water-cooled components

• heating systems with ionizing air

• smelting plants

• extended systems

Special features of the IR5002 are:

• voltage range of the system to be monitored:

DC 350 ... 800 V

• 3-voltmeter method for fast detection of symmetrical and asymmetrical

insulation faults

• wide response range: 5Ω ... 100 kΩ

• integrated voltage monitoring

• two serial interfaces: RS232 and RS485

• linear analog output 0...20 mA

• three different alarm relays for earth fault at L+, earth fault at L- and

system faults

• large LC display

• control via microcontroller

• real-time clock

• menu-driven operating and setting

• robust enclosure for surface mounting

If increased availability of power supply is concerned, the IT system, i.e. the

unearthed system, is the right choice. In contrast to the earthed system, the first

insulation fault does not lead to a disconnection. Combined with a well-chosen

insulation monitoring device, insulation faults and deteriorations are recognized

early, possibly when developing. Hence, increased availability of power supply

in an IT system stands and falls with the well-chosen insulation monitoring

device.

Maintaining a good insulation condition is decisive for reliable power supply.

Therefore the relevant standards demand that the first fault is to be cleared as

soon as possible.

IEC 60364-4-41 Punkt 413.1.5.4 (Note):

It is recommended that the first fault should be eliminated with the shortest

practical delay.

The A-ISOMETER ® IR5002 complies with the requirements of IEC 61557-8.

The internal resistance has been adapted to the special applications for systems

with low insulation resistance values.

The standard deals with constructional and measuring parameters as well as the

test procedures, and the safety aspects of the insulation monitoring devices in

IT systems, including the use in IT AC systems, IT DC systems and IT DC

systems with galvanically connected DC circuits.

Underlying

standards

IT System

5

TGH 1360E

General

IR5002 works according to a passive 3-voltmeter method. Different voltages are

measured within the system to be monitored. Comparative measurements of the

internal resistor network are carried out in order to determine the correct

insulation resistance of the system.

For calculation of the insulation resistance, the measured analog voltages are

digitilized by a 22-bit AD converter which is connected to the microcontroller

via a serial bus.

The detection, processing, analysis and output of the measured values are

controlled by a microcontroller which allows the setting of different parameters.

The measured values can be transmitted to peripheral devices, e.g. computers or

PLC via serial interfaces.

The device parameter settings are stored in a non-volatile EEPROM. The values

of the insulation resistance and the time when the measurements are carried out

are indicated by the internal real-time clock.

The measuring circuit is isolated from the output circuits (relays, interfaces).

That provides adequate safety of the IR5002 and the connected peripheral

devices.

IR5002 can be used as an independent device or in combination with the

coupling device AG5002. If response values below 1000 Ω are to be set, the use

of a coupling device AG5002 will be necessary. IR5002 recognizes automatically

if a coupling device has been connected.

Coupling device

AG5002

The concept of

IR5002

6

TGH 1360E

2 Safety information

IR5002 is intended exclusively for measuring and evaluating the

insulation resistance in IT DC systems of 350 V to 800 V.

Any other use, or any use which goes beyond the foregoing, is deemed to be use

other than for the intended purpose. The BENDER companies shall not be

liable for any losses or damage arising therefrom.

The basic requisite for handling the IR5002 in accordance with safety

requirements, and for it to operate without faults, is a knowledge of the funda-

mental safety information and the safety regulations.

This manual contains important information needed in order to operate the

IR5002 in accordance with safety requirements. This manual, and

in particular the safety information, must be noted by all persons who work

with the IR5002.

In addition, it is essential to comply with the rules and regulations on accident

prevention which are valid for the place of use.

Only appropriately qualified personnel may work on the IR5002. "Qualified" means

that such personnel are familiar with the installation, commissioning and operation

of the product and that they have undergone training or instruction which is

appropriate to the activity.

The personnel must have read and understood the safety chapter and the warning

information in this operating manual.

The copyright to this operating manual shall remain with the BENDER

Companies. The operating manual is solely intended for the operator and his

personnel. It contains regulations and information which must not be

reproduced, disseminated or otherwise divulged, either in whole or in part.

Contraventions may entail criminal prosecution.

Intended use

Copyright

Warranty and

liability

• use of the IR5002 other than for the intended purpose

• incorrect assembly or installation, commissioning, operation and

maintenance of the IR5002

• failure to comply with the information in the operating instructions

regarding transport, storage, assembly or installation, commissioning,

operation and maintenance of the IR5002

• unauthorized structural modifications to the IR5002

• failure to comply with the technical data

• improperly executed repairs, and the use of spare parts or accessories

which are not recommended by the manufacturer

• cases of disaster and force majeure

normal control, e.g. acts of God

Personnel

As a basic principle, our "General Conditions of Sale and Delivery" shall apply. At

the latest, these shall be available to the operator when the contract is concluded.

Warranty and liability claims in cases of damage to persons and property shall be

excluded if they are attributable to one or more of the following causes:

7

TGH 1360E

Safety information

The following designations and signs are used for hazards and warnings in

Bender documentation.

This symbol means an immediate threat of danger to the life and health of

human beings.

Failure to comply with these warnings means that death, serious physical injury

or substantial damage to property will ensue if the relevant precautions are not

taken.

This symbol means a possible threat of danger to the life and health of human

beings.

Failure to comply with these warnings means that death, serious physical injury

or substantial damage to property may ensue if the relevant precautions are not

taken.

This symbol means a possible dangerous situation.

Failure to comply with these warnings means that slight physical injury or

damage to property may ensue if the relevant precautions are not taken.

This symbol gives important information about the correct handling of the

IR5002.

Failure to comply with this information can result in faults on the IR5002 or in

its environment.

Where you see this symbol, you will find application tips and other particularly

useful information.

This information will help you to make optimal use of the IR5002.

Explanations of

symbols and

warnings

The IR5002 is constructed according to the state-of-the-art and the recognized safety

engineering rules. Nevertheless, when it is being used, hazards may occur to the life

and limb of the user or of third parties, or there may be adverse effects on the IR5002

or on other valuable property. The IR5002 must only be used:

• for the purpose for which it is intended

• when it is in perfect technical condition as far as safety is concerned

Impermissible modifications and the use of spare parts and additional devices which

are not sold or recommended by the manufacturer of the devices may cause fire,

electric shocks and injury.

Hazards when

handling the

system

Danger !

Warning

Attention

Make sure that the operating voltage is correct!

Unauthorized persons must not have access to or contact with the IR5002.

Warning signs must always be easily legible. Damaged or illegible signs must be

replaced immediately.

Check the dispatch packaging and the equipment packaging for damage, and

compare the contents of the package with the delivery documents. In the event

of damage during transport, please notify BENDER immediately.

The IR5002 must only be stored in rooms where it is protected against dust and

moisture, and spraying or dripping water, and where the indicated storage

temperatures are maintained.

Inspection,

transport and

storage

8

TGH 1360E

Safety information

In respect of the IR5002, BENDER provides a warranty of fault-free execution

and perfect material quality under normal operation and maintenance

conditions, for a period of 24 months from the date of delivery. This warranty

does not extend to all accessories and consumable components.

For warranty the device must be returned, prepaid, to the nearest authorized

Bender service representative.

The warranty shall only be valid for the first purchaser, and shall not extend to

products or individual parts thereof which have not been correctly used, or

which have undergone modifications. Any warranty shall lapse if the IR5002 is

used other than for the intended purpose.

The warranty obligation is limited to the repair or the exchange of a product

which has been sent to BENDER within the warranty period. The qualifying

conditions are that BENDER shall recognize the product as being faulty, and

that the fault cannot be attributed to improper handling or modification of the

device, nor to abnormal operating conditions.

Any warranty obligation shall lapse if repairs are undertaken on the IR5002 by

persons who are not authorized by BENDER.

The foregoing warranty provisions are valid exclusively, and instead of all other

contractual or legal warranty obligations, including (but not restricted to) the

legal warranty of marketability, suitability for use and expediency for a specified

use.

BENDER shall not assume any liability for direct or indirect concomitant or

subsequent damage, regardless of whether these are attributable to legal, illegal

or other actions.

This statement of warranty shall only be valid in conjunction with the delivery

note from BENDER company.

Warranty

statement

9

TGH 1360E

3 Principle of operation

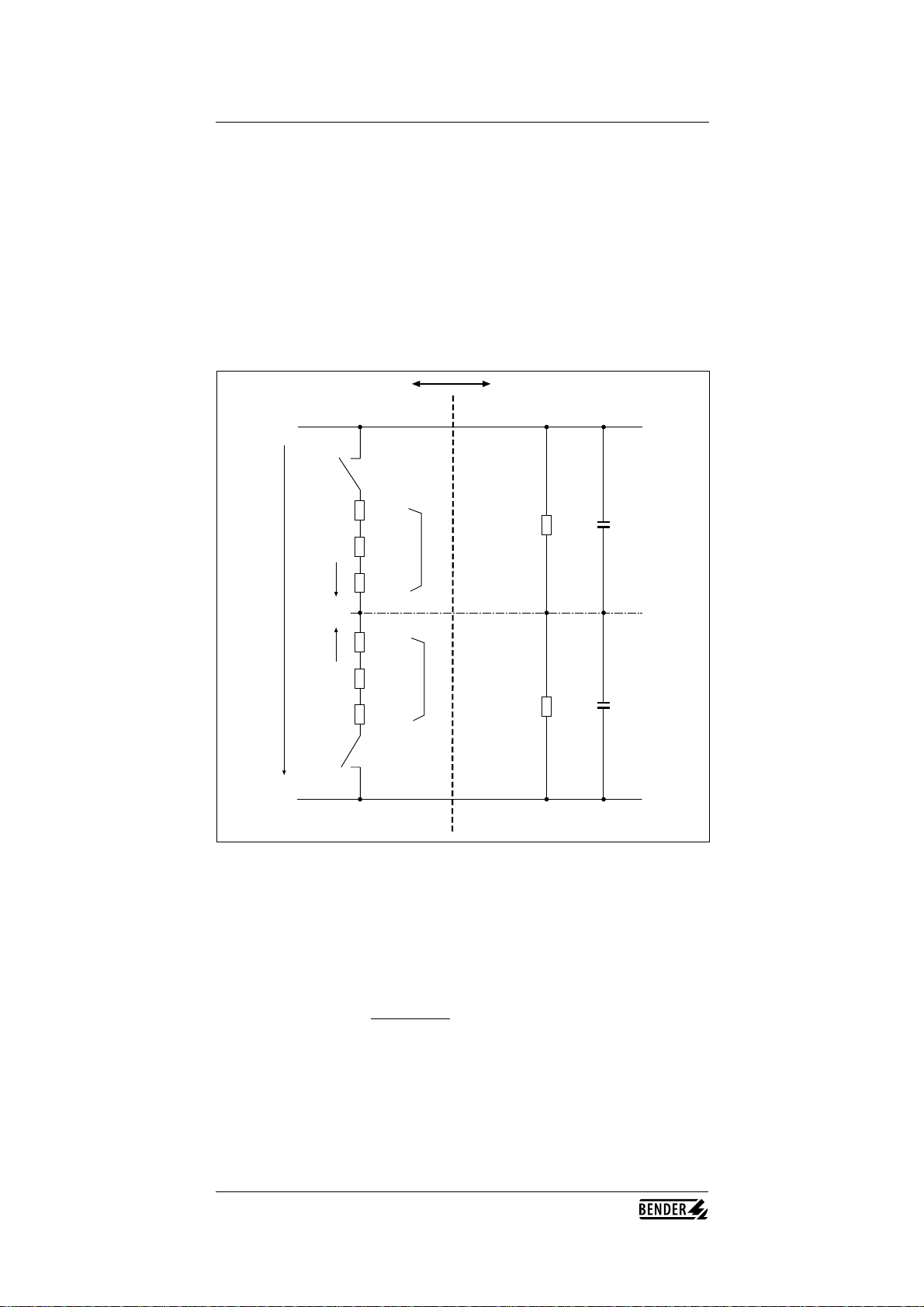

IR5002 uses the measuring principle "3-Voltmeter-Method". Asymmetrical as well

as symmetrical insulation faults in IT DC systems can be detected according to

this measuring principle. In combination with the microcontroller a fast, safe

and exact measurement and evaluation can be realized.

In some respect, the measuring time is dependent on the system leakage

capacitances CE+ and CE- (illustrated below). The capacitances are always

recharged when the coupling switches are closed resp. opened.

internal coupling monitored system

L+

PE

L-

S1

R1.1

Rm1

S2

R2.1

Rm2

RF-

RF+ CE+

CE-

R1

R2

UN

U1

U2

The time delay prevents false trippings during recharging:

• S1 closed, S2 opened measuring of the voltage U1 at Rm1

• S1 opened, S2 closed measuring of the voltage U2 at Rm2

• S1 and S2 closed measuring of the voltage UN

UN= (U1+U2) x R1+R2

Rm1+Rm2

10

TGH 1360E

The insulation resistances RF+ and RF- can be calculated according to the

following equations:

• for symmetrical coupling, i.e R1=R2 and Rm1=Rm2

Principle of operation

(UN x Rm1 - (U1+U2) x R2)

RE+ = U2

• for asymmetrical coupling, i.e. relation AK+ / AK- = 2:1

(UN x Rm2 - (U1+U2) x R1)

RE- = U1

RE+ = (UN x Rm1 x (UN x Rm2 - R2 x (U1 + U2)))

(U2 x (UN x Rm1 - U1 x R2))

RE- = (UN x Rm1 x (UN x Rm2 - R2 x (U1 + U2)))

(U1 x (UN x Rm2 - U2 x R2))

Condition: R1 = 2 x R2

Rm1 = 2 x Rm2

These calculations of the insulation resistances are done by the integrated

microcontroller. The results are indicated on the display.

Symmetrical and

asymmetrical

insulation faults

The measuring values are determined by the device with a passive measuring

principle. This entails some specialities regarding the measured insulation values.

If the relation between the single insulation values RF+ and RF- is high

(asymmetrical faults) the accuracy of the higher value is less than the accuracy of

the lower value, because the measuring voltage drop for an insulation fault is

gathered at the opposite side of the coupling network. That means that the

main measuring voltage for the higher value decreases with the dropping of the

lower insulation value. In the reverse case the measuring voltage of the lower

value increases with the dropping of this value. Because of this, the lower value

is measured with the highest accuracy.

In practice, this effect may entail a little change of the higher value in display

when the lower value increases or decreases.

The accuracy of both values is identical if the insulation values are symmetrical.

11

TGH 1360E

4 Product description

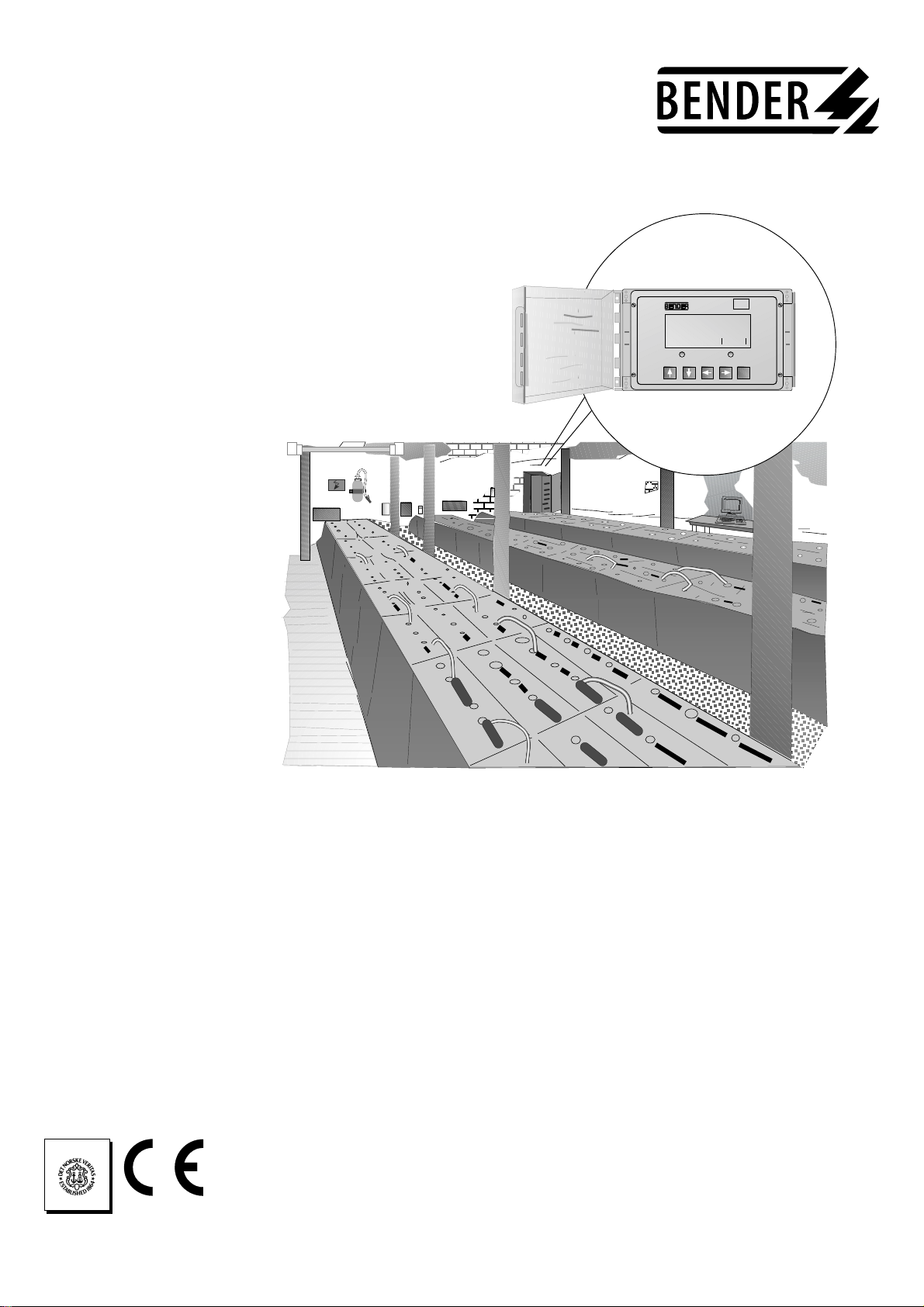

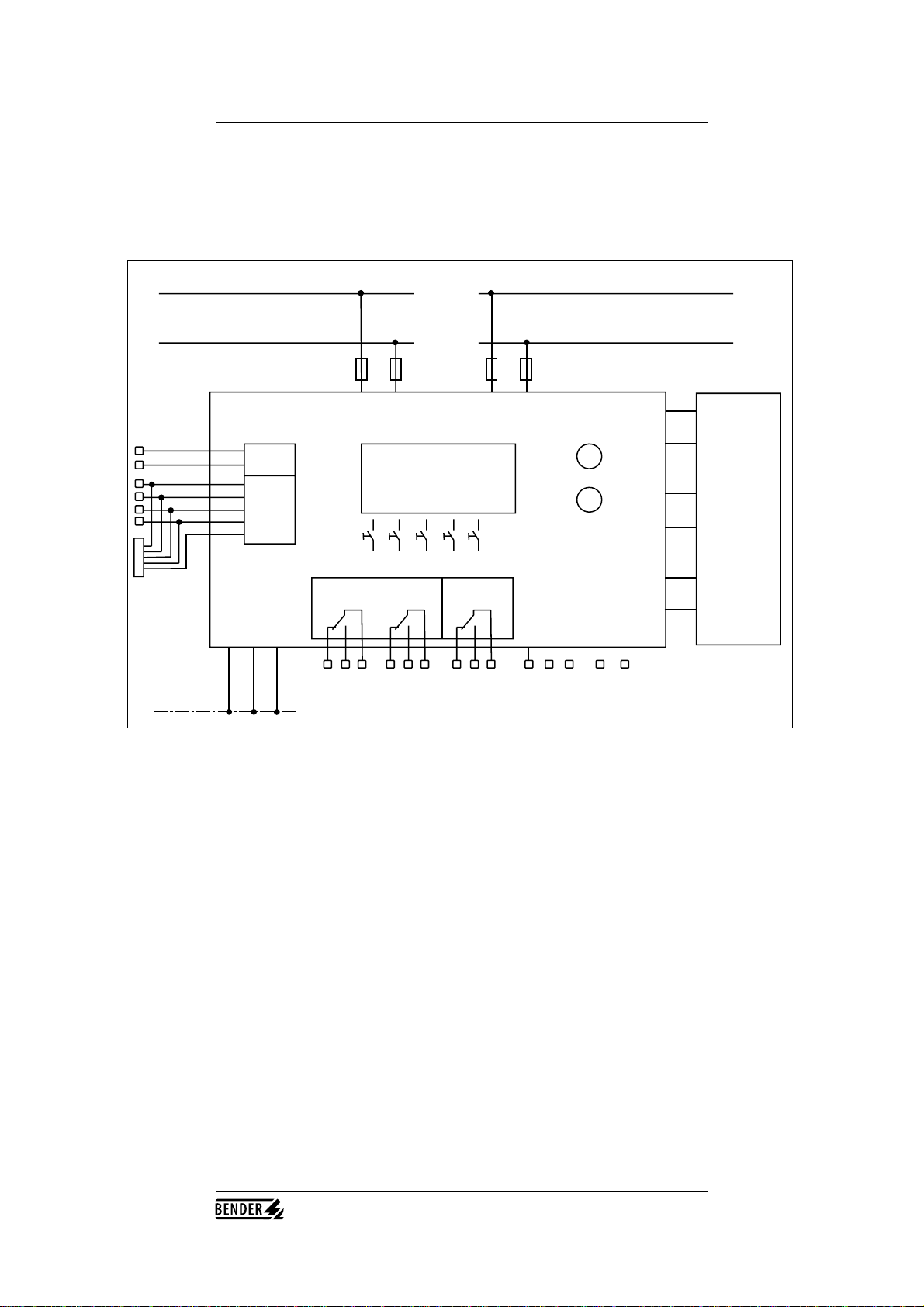

Mechanical designIR5002 is mounted in a 19"-inch plastic casing with a lockable transparent cover.

The casing is equipped with two separate terminal boxes. The upper terminal

box contains terminals for the coupling to the system to be monitored as well as

to the optional coupling device AG5002. The lower terminal box contains

terminals for PE coupling, supply voltage, contacts of the alarm relay, serial

interfaces, temperature sensor input, digital inputs, and analog output.

IR5002

ALARM L- ALARM L+

ENTER

kΩ

MONITOR

****** BENDER ******

A - ISOMETER IR5002

Version 1.2 / 5.96

ENTER

RS232

Isolate elsewhere

before opening

Vorsicht Spannung

Attention

Danger

Isolate elsewhere

before opening

Vorsicht Spannung

Attention

Danger

12

TGH 1360E

side view (right)

Product description

top view

General dimensions according to DIN 7168, dimensions in mm

147

327

71

277

203,5

4,2

100

100 80

227

237

277

front view

Dimension

diagrams

13

TGH 1360E

Product description

Dimensions coupling device AG5002

130

143

Ø 6,5

260

302

22

80

103

14

TGH 1360E

Product description

Wiring diagram

monitored system supply voltage

UN = DC 350 - 800 V US = DC 110 V /AC 100 - 240 V

P1

H1

H2

RS485

RS232

S1 S2 S3 S4 S5

Coupling

device

AG5002

AK1/L+

AK1/L-

AK1/U+

AK1/U-

T1

T2

A

B

RxD

TxD

SGND

RTS

CTS

Sub-D

K1 K2 K3

PE PE2 S

PE

E1 E2 EG M+ M-

external

digital

input

optional:

analog

output

0 ... 20 mA

L+ L- L1/L+ N/L-

IR5002

15

TGH 1360E

Product description

Designation Terminal Explanation

designation

P1 LC display, 4 lines á 20 characters

H1 alarm LED red, alarm L+

H2 alarm LED yellow, alarm L-

K1 11,12,11,14 alarm relay alarm L+, 1 change-over contact

K2 21,22,21,24 alarm relay alarm L-, 1change-over contact

K3 31,32,31,34 alarm relay system fault, 1 change-over contact

S1 UP-Taste

S2 DOWN-key

S3 RIGHT-key

S4 LEFT-key

S5 ENTER-key

E1 E1 digital input 1, measurement suppression

E2 E2 digital input 2, (without function at the

moment)

EG EG earth terminal of the digital inputs 1 and 2

L+ L+ system coupling L+

L- L- system coupling L-

AK1/L+ AK1/L+ output L+ of coupling device AG5002

AK1/L- AK1/L- outputg L- of coupling device AG5002

AK1/U+ AK1/U+ input U+ of coupling device AG5002

AK1/U- AK1/U- input U- of coupling device AG5002

T1 T1 positive input temperature measuring of

coupling device AG5002

T2 T2 negative input temperature measuring of

coupling device AG5002

PE PE coupling PE (earth)

PE2 PE2 control earth (connection monitoring)

S PE connection for cable shielding

A A output A RS485 interface

B B output B RS485 interface

M+ M+ analog output + (0...20 mA, linear)

M- M- analog output - (0...20 mA, linear)

RxD, TxD RxD, TxD output RS232 interface on the terminal strip

SGND SGND and on 9-pole Sub-D connector (f)

RTS, CTS RTS, CTS

Legend to wiring

diagram

16

TGH 1360E

Product description

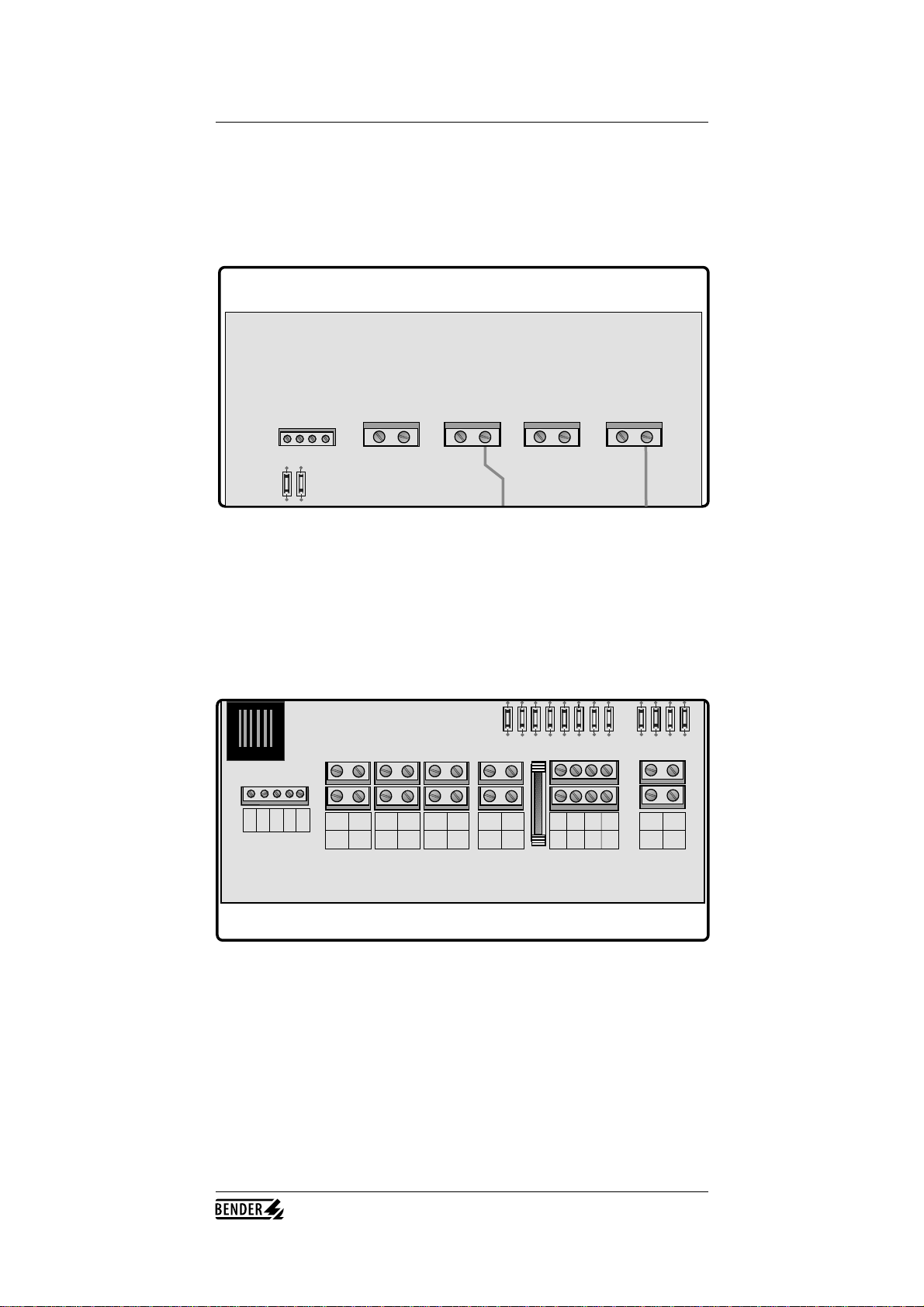

Terminal strips IR5002 is equipped with two separate terminal boxes. The cables are led into the

terminal boxes using screwed cable glands (PG9 and PG11).

Upper terminal box

X1 X2 X3 X4 X5

AK/U+

AK/U-

PE

L+

L-

AK/L+

AK/L-

To external

Coupling

The upper terminal box is exclusively used for the coupling of the measuring

circuit to the system to be monitored and the connection to the optional

coupling device AG5002.

Lower terminal box

X12 X13 X14 X16X15 X17 X18

X19

X10

X11

L1/l+

N/L-

PE

PE

PE2

12

11

14

11

22

21

24

21

32

31

34

31

E1

EG

E2

EG

RTS

T1

M+

T2

M-

RxD TxD

PEBA

GND

PE

SUPPLY

ALARM L+

ALARM L-

AL SYSTEM-

External

Inputs

RS232

RS485

Tem p.

Input

Analogue

Output

The lower terminal box is equipped with the strip terminals X10...X19. These

terminals are used to connect the supply voltage, PE connections as well as all

inputs and outputs.

17

TGH 1360E

5 Setting and operation

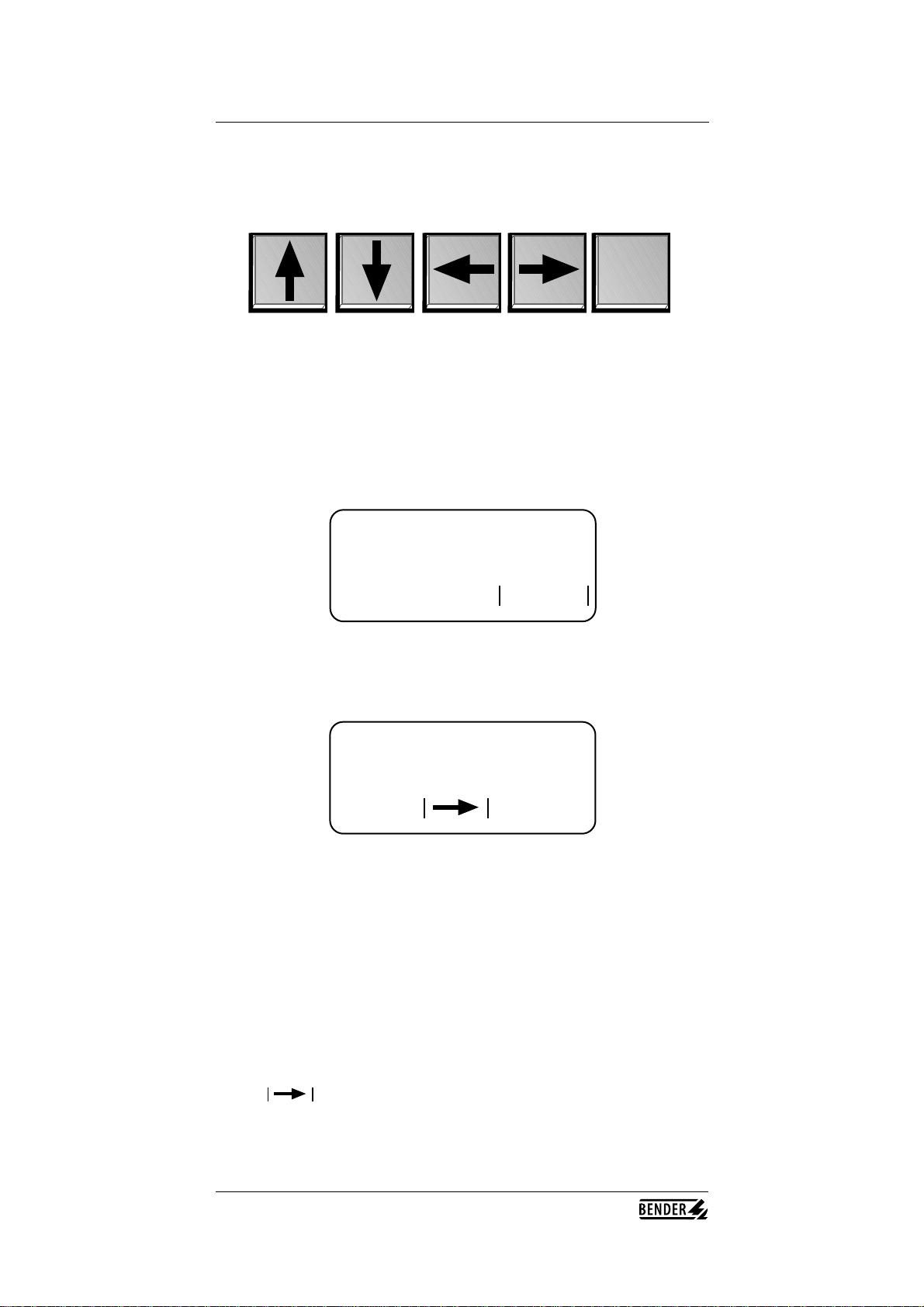

Operation as well as all the settings are carried out by means of the software

using 5 function keys.

UP-key DOWN-key LEFT-key RIGHT-key ENTER-key

When operating under normal conditions, the main screen displays the currently

applicable measuring values. For changing parameters or settings, the main

menue has to be selected.

Once the power supply is switched on, the welcome screen appears displaying

the manufacturer's name (BENDER), the device type, and the firmware version.

ENTER

The welcome screen is displayed for about 5 seconds and then automatically

changes to the main screen. If the ENTER-key is activated within this time, the

main screen will be displayed immediately.

The picture above shows a main screen typical for IR5002 during operation.

U- = 564 V The currently applicable measuring value of the negative pole-

to-earth voltage is 564 V

UN = 620 V The current measured value of the nominal system voltage

is 620 V

RF- = 100kΩThe negative pole-to-earth insulation resistance is 100 kΩ

(calculated value)

RF+ = 10 kΩThe positive pole-to-earth insulation resistance is 10 kΩ

(calculated value)

AL- = 100 kΩThe pre-set response value for the negative fault is 100 kΩ

AL+ = 10 kΩThe pre-set response value for the positive fault is 10 kΩ

Menue: Press the RIGHT-key to change to the respective menu

08:37 System time of the IR5002 (real time clock)

Function keys

Welcome screen

Main screen

*******BENDER*******

*A-ISOMETER IR5002*

*VERSION L2.0/05.96*

ENTER

U- = 564 V UN = 620 V

RF- = 100kΩRF+ = 10kΩ

AL- = 100kΩAL+ = 10kΩ

Menue: 08:37

18

TGH 1360E

Setting and operation

The following picture shows a main menu indicating that the measurement

suppression has been activated. Measurement suppression can be activated or

deactivated by digital input 1. IR5002 is isolated from the system to be

monitored during measurement suppression.

**** MEASURING ****

*** SUPPRESSION ***

****** ACTIVE ******

Menue: 08:37

IR5002 offers 10 different menus for setting and operation. Pushing the RIGHT-

key from the main screen opens the screen with the menu selection.

Of course, not all the menus can be presented within one four-line LC display.

You can choose between 3 menus by scrolling the display via the UP and

DOWN keys. The other menus can be selected by scrolling the DOWN key.

In order to activate the desired menu, scroll the UP and DOWN keys and

position the cursor on the respective digit. Then activate the menu by pushing

the ENTER-key.

All menus are displayed in the following picture:

1. MAIN SCREEN

2. RESPONSE VALUES

3. ALARM TIMING

ENTER

Menus

1. MAIN SCREEN

2. RESPONSE VALUES

3. ALARM TIMING

4. RELAY MODE

5. ALARM SYST. VOLT.

6. SERIAL INTERFACE

7. ENABLE MEASUREM.

8. TEMPERATURE

9. SET CLOCK

10.ABOUT

ENTER

19

TGH 1360E

Setting and operation

The individual

menus

After positioning the cursor on menu 1 MAIN SCREEN by means of the UP

and DOWN keys and activating the ENTER-key, the already familiar screen

appears.

In menu 2 RESPONSE VALUES it is possible to set the response values for

positive and negative faults separately.

By positioning the cursor on 1 MAIN SCREEN, the IR5002 links to the MAIN

SCREEN for setting the response values. Selecting 2 (AL+) allows for setting the

response value for positive faults.

After selecting 2 AL+ by activating the ENTER-key, use the LEFT and RIGHT-

key to select the respective digit you are going to change. Select the appropriate

value by scrolling the UP and DOWN key. The digit can be changed in 1-unit

steps. If you position the cursor on k of the dimension kΩ, for example, you

can change the dimension from Ω into kΩ or vice versa by scrolling the UP and

DOWN key.

Confirming with ENTER after finishing the modifications returns you to the

previous screen. In the same way, the response value for the negative fault AL-

can be changed.

Positioning the cursor onto 1 MAIN SCREEN and confirming with ENTER

opens the MAIN MENU.

From the main menu select the submenu 3 ALARM TIMING for setting the

delay time.

In the submenu 2 DELAY TIME, it is possible to set a delay time between 0 and

100 seconds for the alarm relays. To open this sub menu position the cursor

onto 2 and confirm with ENTER.

Time response

Setting the

response values

1. MAIN MENU

2. DELAY-TIME: 10s

3. WINDOW-TIME: 50s

ENTER

1. MAIN MENU

2. AL+ = 100kΩ

3. AL- = 100kΩENTER

1. MAIN MENU

2. AL+ = 100kΩ

3. AL- = 100kΩENTER

20

TGH 1360E

Setting and operation

As shown in the picture above, the cursor is now positioned before the time

display (10s). Now choose the new value by scrolling the UP and DOWN keys.

This is possible in five-second steps. Confirming with ENTER accepts the

selected value and returns you to the sub menus 1, 2 or 3. Proceed in the same

way if you are going to set the value for WINDOW TIME. Here you can

choose the value in 10-seconds steps between 10 and 300 seconds.

DELAY TIME and WINDOW TIME are dependent on each other. Accordingly

some explanations:

If an insulation fault occurs the DELAY TIME starts running and stops when

the pre-set delay time is reached unless the insulation fault has been cleared. The

counter stops running as soon as the insulation fault is cleared within the

running DELAY TIME.

The WINDOW TIME also starts running when an insulation fault is detected.

Yet, unlike the DELAY TIME, the WINDOW TIME will not be interrupted if

the insulation fault is cleared within this period.

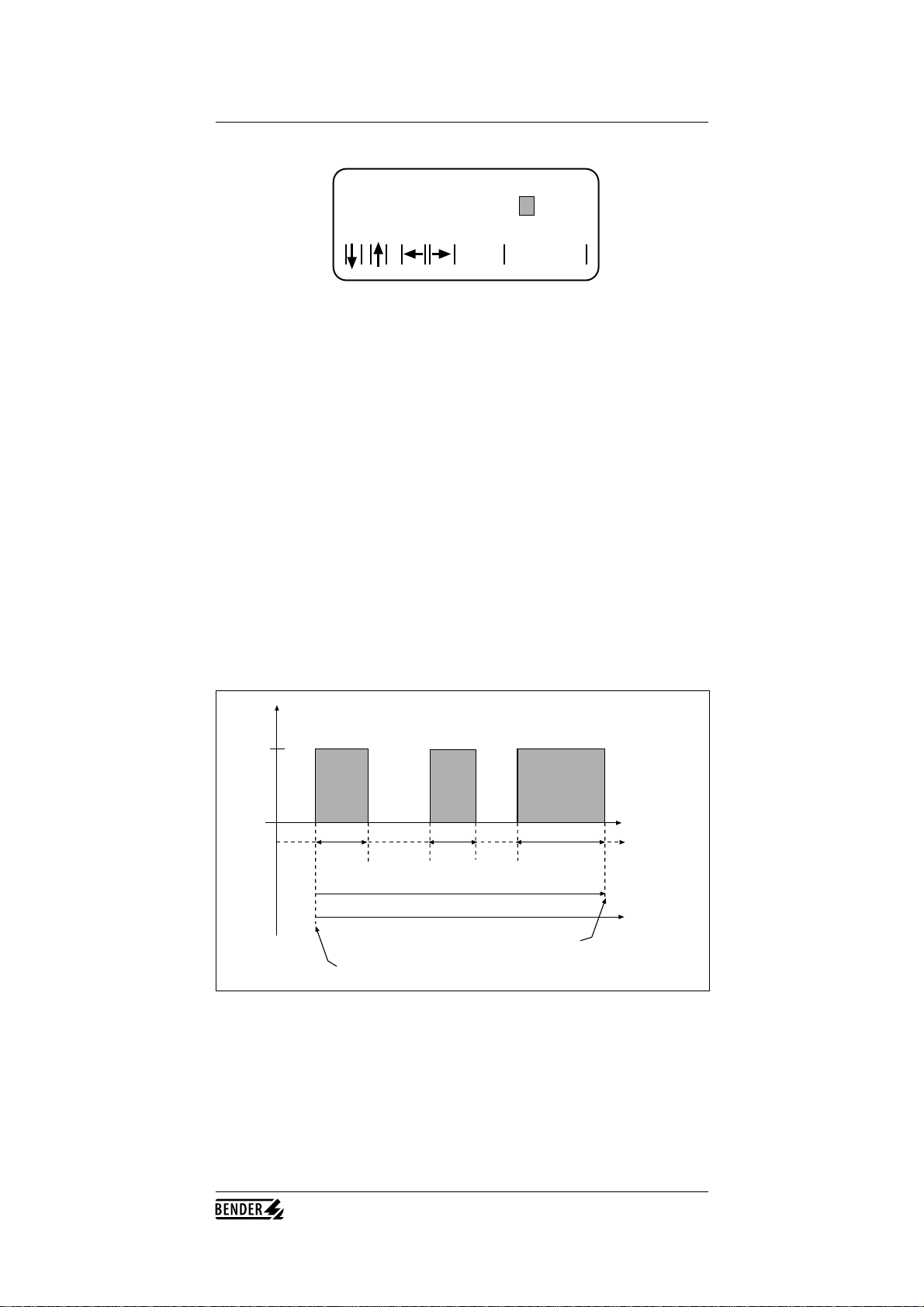

The following diagram shows the correlation between fault detection and the

different times.

Insulation

fault

Insulation

OK t

delay-time

t1 t2 t3

t4

window-time

Alarm is activated

Beginning of delay-time and window-time

After detecting the insulation fault the DELAY TIME and WINDOW TIME

start running. The pre-condition for the activation of the alarm relay is:

Activation if:

(t1 + t2 + t3) > delay-time .AND. (t4 < window-time)

Important:

The pre-set value for the WINDOW TIME has always to be greater than the pre-

set DELAY TIME.

1. MAIN MENU

2. DELAY-TIME: 10s

3. WINDOW-TIME: 50s

ENTER

Table of contents

Other Bender Industrial Equipment manuals