Bender GmbH & Co. KG

Londorfer Straße 65

35305 Grünberg

Germany

Tel.: +49 6401 807-0

info@bender.de

www.bender.de

© Bender GmbH & Co. KG, Germany

Subject to change! The specified

standards take into account the edition

valid until 01/2024 unless otherwise

indicated.

Alle Rechte vorbehalten.

Nachdruck und Vervielfältigung nur mit

Genehmigung des Herausgebers.

All rights reserved.

Reprinting and duplicating only with

permission of the publisher.

EU Declaration of Conformity

The full text of the EU Declaration of

Conformity is available via the QR Code:

CTBC120 when IΔn ≥ 100 mA.....................................................330 A

CTBC120P when IΔn ≥ 100 mA...................................................630 A

CTBC210 when IΔn ≥ 300 mA.....................................................630 A

CTBC210P when IΔn ≥ 100 mA...................................................630 A

CTBC210P when IΔn ≥ 300 mA.................................................1000 A

Measurement accuracy........................................±1 % of full scale value

Test winding........................................................................................ yes

Rated continuous thermal current Icth.................................................30 A

Rated short-time thermal current 1) Ith.......................................2.4 kA/1 s

Rated dynamic current 1) Idyn....................................................6 kA/40 ms

1) refers to the residual current

Operating uncertainty ................................................................ ±17.5 %

Relative uncertainty .................................................................0…-35 %

Outputs

Outputs.................................................................. 2 changeover contacts

Operating principle............................................configurable, see manual

Switching outputs (K1, K2) .......................................................250 V, 5 A

Switching capacity............................................................1500 VA/144 W

Contact data acc. to IEC 60947-5-1

Rated operational voltage AC........................................ 250 V/250 V

Utilisation category .......................................................AC-13/AC-14

Rated operational current AC .................................................5 A/3 A

Rated operational voltage DC...................................... 220/110/24 V

Utilisation category ................................................................... DC12

Rated operational current DC...........................................0.1/0.2/1 A

Minimum current ..................................................... 10 mA at DC 5 V

Ordering details

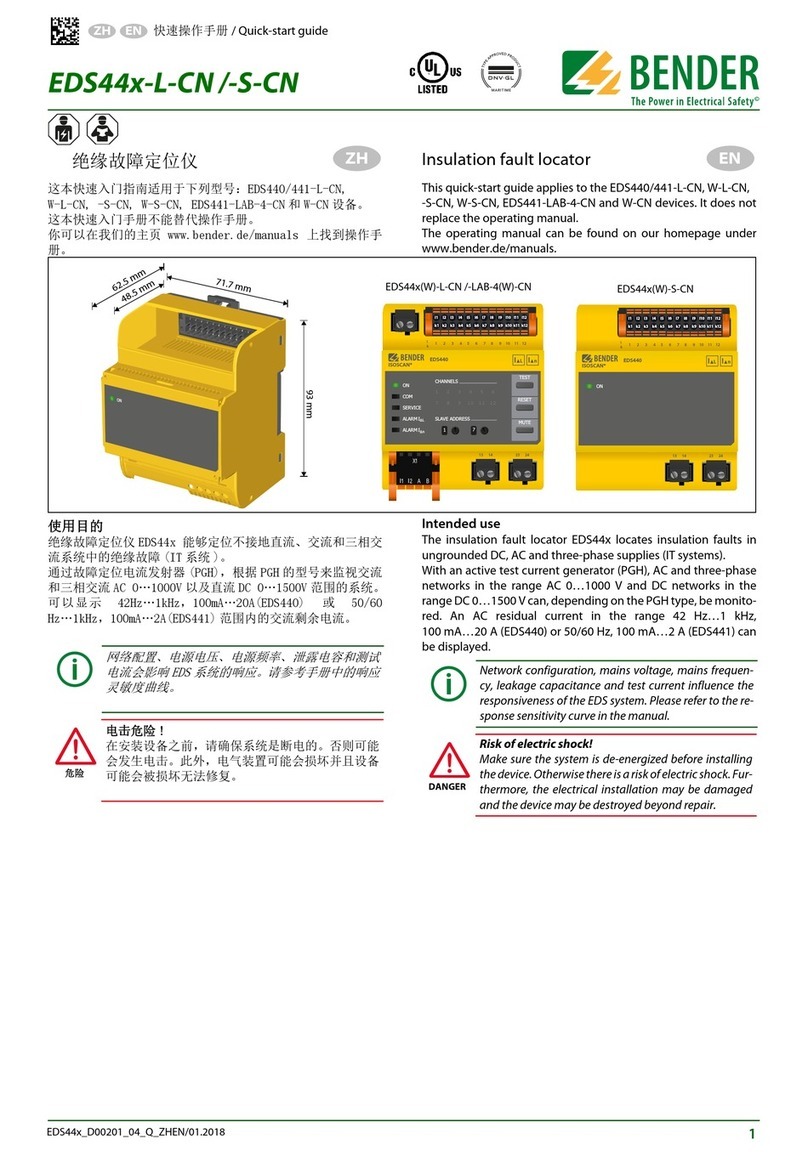

Suitable measuring current transformer cores

ø current

transformers Type Art. No.

20 mm CTBC20 B98120001

CTBC20P B98120002

35 mm CTBC35 B98120003

CTBC35P B98120004

60 mm CTBC60 B98120005

CTBC60P B98120006

120 mm CTBC120 B98120007

CTBC120P B98120020

210 mm CTBC210 B98120008

CTBC210P B98120021

System components

max. connected

current transformers Type Art. No.

14 STEP-PS/1 AC/24 DC/1.75 B94053111

34 STEP-PS/1 AC/24 DC/4.2 B94053112

Accessories

Type Art. No.

USB to RS-485 interface converter B95012045

Terminal set for RCMB module (spare part) B74043124