Bender VG12 User manual

EN

Manual

VG12

Safety distributor for mobile power generators

ready for connection

VG12_D00032_03_M_XXEN/01.2019

Photos: Bender archive and bendersystembau archive.

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Grünberg • Germany

Londorfer Straße 65 • 35305 Grünberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

© Bender GmbH & Co.KG

All rights reserved.

Reprinting only with permission

of the publisher!

Subject to change!

3

Table of Contents

VG12_D00032_03_M_XXEN/01.2019

1. Making effective use of this document ............................................... 5

1.1 How to use this manual ......................................................................................... 5

1.2 Explanation of symbols and notes .................................................................... 5

2. Safety instructions .................................................................................. 6

2.1 Intended use ............................................................................................................. 6

2.2 Work activities on electrical installations ........................................................ 6

2.3 Device-specific safety instructions .................................................................... 7

2.4 General safety instructions .................................................................................. 7

3. System description ................................................................................. 8

3.1 Protective measures for mobile generators .................................................. 8

3.2 Prerequisites for use ............................................................................................... 8

3.3 Functional description ........................................................................................... 9

3.3.1 Display and operating elements ...................................................................... 10

4. Installation and connection ............................................................... 12

4.1 Installation ............................................................................................................... 12

4.1.1 Dimension diagrams ............................................................................................ 12

4.2 Connection .............................................................................................................. 14

5. Commissioning and continous operation ....................................... 16

5.1 Specific factory settings ...................................................................................... 16

5.2 Functional test before first use ......................................................................... 16

5.3 Test before daily use ............................................................................................. 17

5.4 Regular tests ............................................................................................................ 18

5.5 Troubleshooting .................................................................................................... 18

Table of Contents

4VG12_D00032_03_M_XXEN/01.2019

6. Technical data ........................................................................................ 19

6.1 Standards and certifications .............................................................................. 21

6.2 Ordering details ..................................................................................................... 22

6.3 Other safety distributors ..................................................................................... 22

INDEX ............................................................................................................ 23

5

VG12_D00032_03_M_XXEN/01.2019

1. Making effective use of this document

1.1 How to use this manual

This manual describes the operation of the safety distributor VG12. It informs about the

essential safety instructions to be considered and the underlying regulations of the

concept.

This manual is intended for qualified personnel working in electrical engineering and

electronics.

Please read this manual and the instructions of the power generator prior to using the

devices. Keep the two manuals within easy reach near the power generator.

If you have any questions, please do not hesitate to contact us. In this case, please refer

to our service:

www.bender.de/en/service-support/downloads

1.2 Explanation of symbols and notes

The following symbols to indicate hazards and to indicate optimum use of the product

are used in this manual

DANGER

This signal word indicates that there is a high risk of danger that will result

in death or serious injury if not avoided.

WARNING

This signal word indicates a medium risk of danger that can lead to

death or serious injury if not avoided.

CAUTION

This signal word indicates a low level risk that can result in minor or

moderate injury or damage to property if not avoided.

This symbol denotes information intended to assist the user in making

optimum use of the product.

6VG12_D00032_03_M_XXEN/01.2019

2. Safety instructions

2.1 Intended use

The VG12 safety distributor is intended for guaranteeing the protective measure "Pro-

tective separation with insulation monitoring and disconnection" according to

DIN VDE 0100-410, DIN VDE 0100-551 and GW 308 of the DVGW (German Association of

Gas and Water Line e.V.) and thus for the safe operation of mobile power generators.

The VG12 safety distributor is suitable for the direct connection to single-phase power

generators. The total load current must not exceed 16 A with respect to the plug of the

input cable.

The chapter "System description" lists the requirements to be fulfilled in order to be

able to apply the protective measure.

2.2 Work activities on electrical installations

Only electrically skilled persons are permitted to carry out the work necessary to

install, commission and run a device or system.

Compliance with applicable regulations governing work on electrical installations

and with the regulations derived from and associated with them, is mandatory.

EN 50110 is of particular importance in this regard.

If the device is being used in a location outside the Federal Republic of Germany,

the applicable local standards and regulations must be complied with. The Euro-

pean standard EN 50110 can be used as a guide.

WARNING

Danger as a result of unprofessional work!

Any work on electrical installations which is not carried out properly can

lead to death and injury! Therefore, observe the following safety

instructions!

Safety instructions

7

VG12_D00032_03_M_XXEN/01.2019

2.3 Device-specific safety instructions

2.4 General safety instructions

Bender devices are designed and built in accordance with the state of the art and ac-

cepted rules in respect of technical safety. However, the use of such devices may intro-

duce risks to the life and limb of the user or third parties and/or result in damage to

Bender devices or other property.

Use Bender devices only:

– as intended

– in perfect working order

– in compliance with the accident prevention regulations and guidelines appli-

cable at the location of use

Eliminate all faults immediately which may endanger safety.

Do not make any unauthorised changes and only use replacement parts and opti-

onal accessories purchased from or recommended by the manufacturer of the

devices. Failure to observe this requirement can result in fire, electric shock and

injury.

Reference signs must always be clearly legible.

CAUTION

Danger due to inappropriate power generators!

The VG12 safety distributor is only suitable for single-phase power

generators with AC 230 V. VG12 can conduct a maximum of 16 A.

CAUTION

Danger during insulation and voltage tests!

The VG12 safety distributor must be disconnected from the mains for the

duration of the test. Check the correct connection of the VG12 safety

distributor when recommissioning it. Perform a functional test according to

the instructions in the chapter

"Chapter 5. Commissioning and continous operation“.

8VG12_D00032_03_M_XXEN/01.2019

3. System description

3.1 Protective measures for mobile generators

The VG12 safety distributor is intended for the practical implementation of the protec-

tive measure "Protective separation with insulation monitoring and disconnection"

specified in section 551.4.4.2 of the standard DIN VDE 0100-551.

The voltage supply is designed in a way that protective separation is realised with more

than one load. The continuously measuring ISOMETER® switches off the mains voltage

if the value falls below the response value. This results in the following characteristics:

No earth spike

High-resistance insulation faults are detected immediately. When reaching the

response value, the socket-outlets of the VG12 are switched off.

(DIN VDE 0100-410, Annex C3)

Suitable only for operation and monitoring by electrically skilled or instructed

persons.

The exposed conductive parts of the whole generator circuit must be connected

by insulated, unearthed protective equipotential-bonding conductors PA (see

schematic wiring diagram on Page 15).

Such conductors must not be connected to the protective conductors or exposed

conductive parts of other circuits or to any other conductive parts.

An ISOMETER® measures the sum of all insulation faults in the system, i.e. the absolute

insulation value.

Page 21 provides a list of all relevant standards.

3.2 Prerequisites for use

The protective measure "Protective separation with insulation monitoring and discon-

nection" avoids hazards from indirect contact with parts carrying voltage due to faults

in the basic insulation of the circuit.

The power generator must supply a single-phase AC voltage of 230 V. Tolerances

according to IEC 38 are permissible. Higher voltages may destroy components of

the safety distributor. Hence, the protective function may be disabled.

The maximum load current must not exceed 16 A. Higher load currents may

destroy the contacts of the connection plug of the VG12 safety distributor and

thus disable the protective function.

System description

9

VG12_D00032_03_M_XXEN/01.2019

3.3 Functional description

The VG12 safety distributor provides a protective measure which

meets the legal provisions

is practice-oriented

does not hinder the work with the power generator

can be mounted quickly, simply and cost-effectively (plug connection)

can be connected to the interior of the power generator without any intervention

does not require maintenance.

The VG12 safety distributor has a compact plastic enclosure made of impact-resistant

material. The Schuko socket-outlets are integrated in this enclosure. The loads are sup-

plied exclusively via this socket-outlet after mounting and commissioning. A cable con-

nects the VG12 safety distributor to the power generator.

The VG12 safety distributor contains an insulation monitoring device in accordance

with EN 61557-8. It is an actively measuring ISOMETER® type IR423 which superimposes

a measuring voltage onto the system.

When the power generator is running, this device constantly monitors the insulation

condition of the power generator system against the equipotential bonding. If the in-

sulation resistance falls below 23 kΩ, the ISOMETER® triggers and disconnects the so-

cket-outlets from the main voltage via a relay within one second. At the same time, the

LEDs "AL1", "AL2" on the insulation monitoring device indicate the change in the insu-

lation resistance.

The disconnection and the indication via the LEDs "AL1", "AL2" can be reset via the com-

bined test/reset button "T/R" if the insulation fault is at least 25 % above the response

value of 23 kΩ.

System description

10 VG12_D00032_03_M_XXEN/01.2019

3.3.1 Display and operating elements

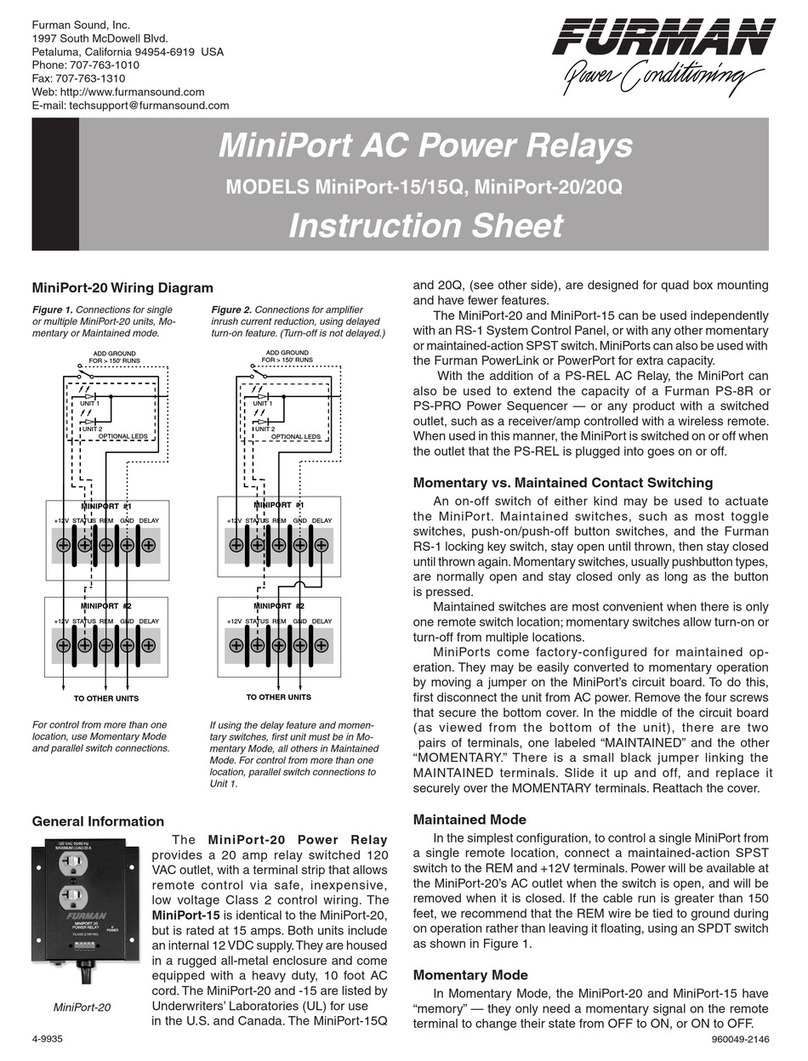

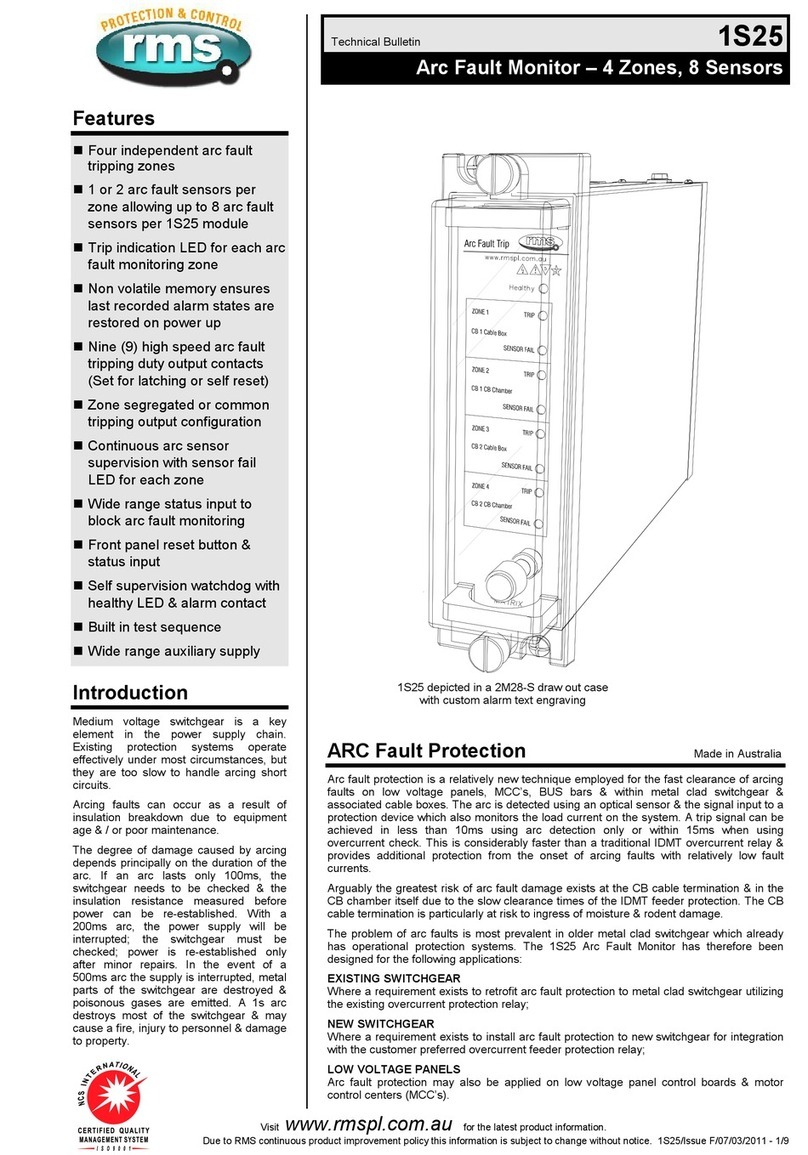

Fig. 3.1: Connecting cable and front view of the VG12

1Input: 0.7 m connecting cable H07RN-F3G 2.5 with Schuko plug for max. 16 A

2Output: 2 Schuko socket-outlets for max. 16 A output current

CAUTION

Danger due to excessive nominal current at the socket-outlets!

If both sockets are used, the total nominal current of both sockets

must not exceed 16 A.

3Insulation monitoring device IR423

4Instruction for daily test

5Combined test/reset button "T/R"

Achtung!

Tägliche Prüfung

Kombinierte Test/Reset-Taste:

- lang drücken (> 2 s) = TEST

"AL1" und "AL2" leuchten

- kurz drücken (< 1,5 s) = RESET

"AL1" und "AL2" erlöschen

Bedienungsanleitung beachten!

Attention!

Daily test

Combined test/reset button:

- long pressing (> 2 s) = TEST

"AL1" and "AL2" light

- short pressing (< 1.5 s) = RESET

"AL1" and "AL2" go out

Refer to operating manual!

123

4

"T/R"

5

System description

11

VG12_D00032_03_M_XXEN/01.2019

In general, an operation of the IR423 is not required. Thus, the description of the opera-

ting elements is only informative.

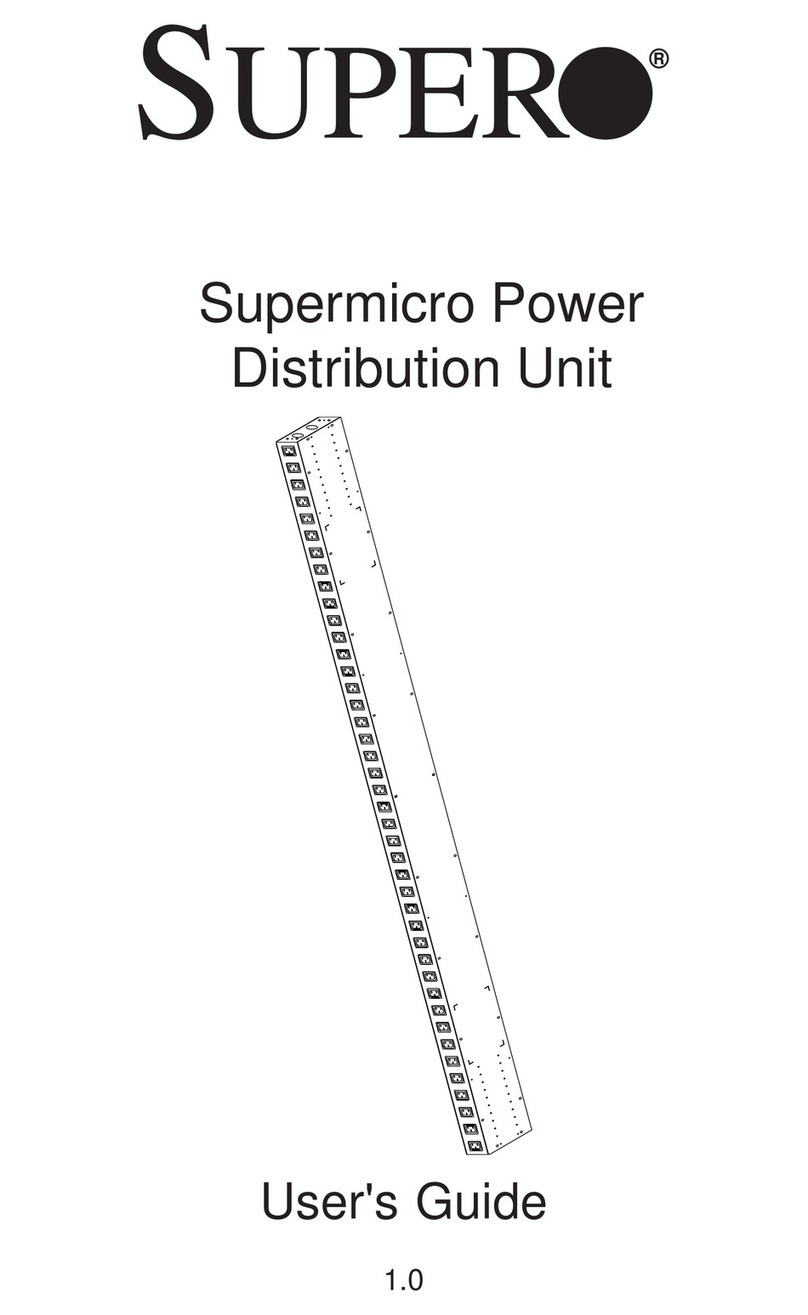

Fig. 3.2: Front view of the IR423

1POWER ON LED

2The alarm LED "AL1" lights up if the value falls below the response value

Ran1 (Alarm 1) (prewarning).

3The alarm LED "AL2" lights up if the value falls below the response value

Ran2 (Alarm 2) (prewarning).

4The test button "T" is intended for the daily test of the safety distributor.

After pressing it, "AL1" and "AL2" light up.

5The insulation monitoring device is reset by pressing the reset button "R".

The alarm LEDs "AL1" and "AL2" go out.

6The menu/enter button is intended for accessing the menu operation,

choosing functions and changing values. The button is not required for

normal operation!

7Display for indicating the insulation value and for navigating in the menu

123

456

MENU

7

12 VG12_D00032_03_M_XXEN/01.2019

4. Installation and connection

4.1 Installation

The cover of the VG12 must be unscrewed prior to installation. Mount the VG12 safety

distributor with four M4 screws to the power generator. Make sure that the mounting

parts have the required stability so that they are not destroyed by the typical vibrations

of the power generator. Avoid sharp edges and corners. Secure the mounting screws

via lock washers, spring washers or the like.

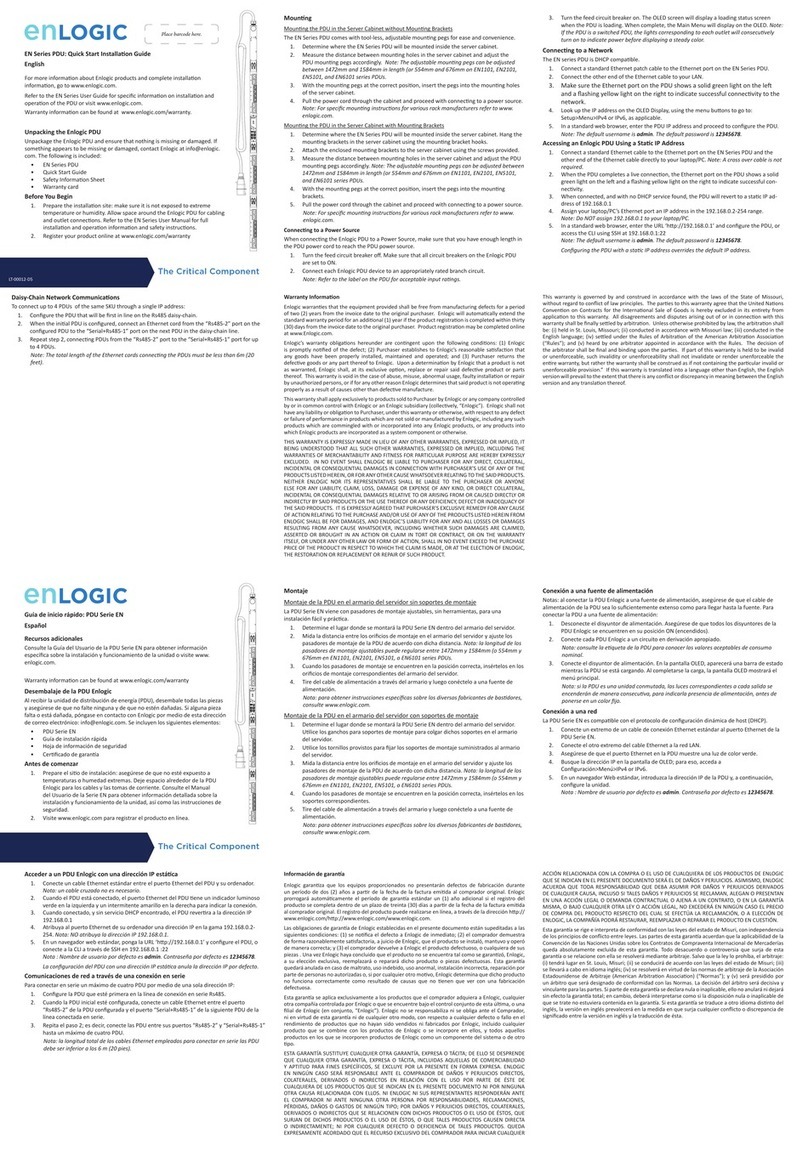

4.1.1 Dimension diagrams

Fig. 4.1: Drilling template

DANGER

Risk of an electric shock!

Do not carry out installation work while the power generator is

running. Make sure that the power generator is not activated during

installation work. Work activities on the running power generator

may cause severe injuries!

163 mm

113

Installation and connection

14 VG12_D00032_03_M_XXEN/01.2019

4.2 Connection

The VG12 is connected via a plug connection:

Connect the Schuko plug connecting cable of the VG12 safety distributor to a

Schuko socket-outlet of the power generator.

DANGER

Risk of an electric shock!

Work activities on electrical parts of the power generator and on the

electrical equipment must only be carried out by electrically skilled

persons.

WARNING

Danger due to freely accessible generator socket-outlets!

Use the socket-outlets of the VG12 safety distributor only.

Any other socket-outlets of the power generator must be shut down.

When the socket-outlets have been shut down and closed by means of

a protective cap, secure the socket-outlets with a locking wire against

unauthorised use.

CAUTION

Danger due to excessive nominal system voltage!

VG12 is only suitable for power generators with AC 230 V. Higher

voltages may destroy components of the safety distributor. Hence, the

protective function may be disabled.

Installation and connection

15

VG12_D00032_03_M_XXEN/01.2019

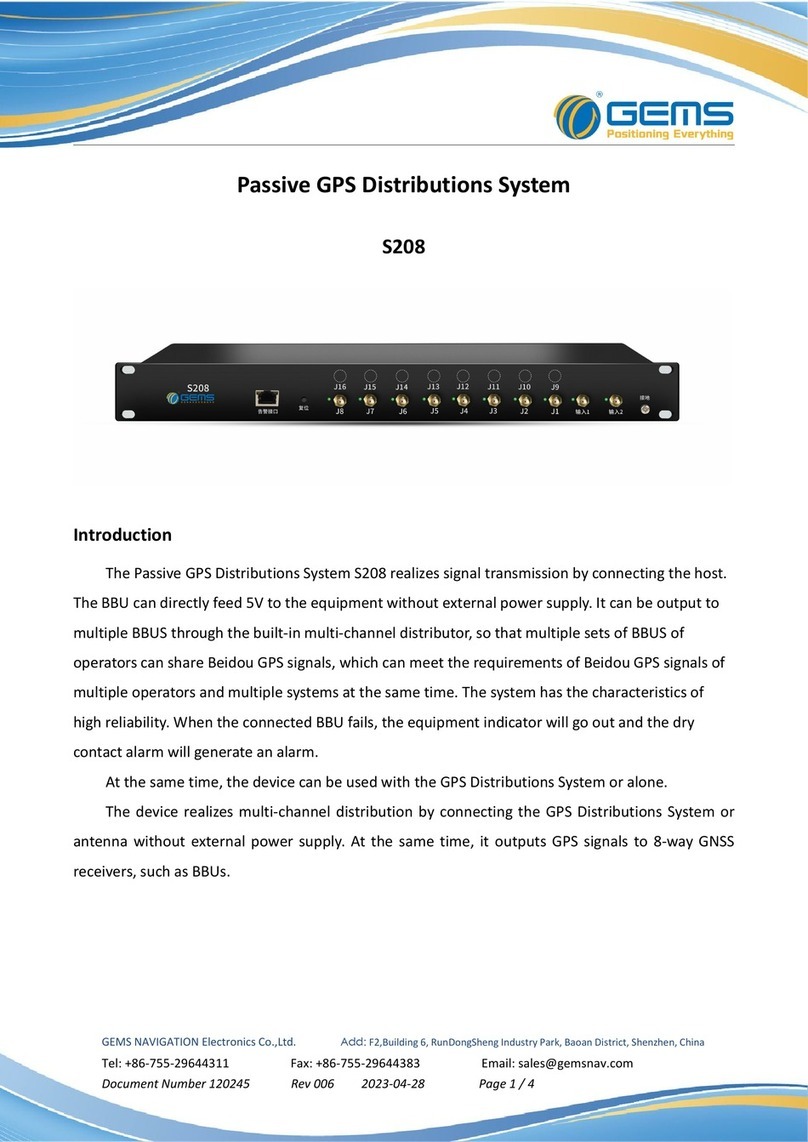

Schematic wiring diagram

The following wiring diagram informs you about the interaction of the components ge-

nerator, VG12 safety distributor and loads. The details are purely informative and not re-

quired for the connection of the VG12 to the power generator.

Fig. 4.3: Schematic wiring diagram

PA

Test/

Reset

„T/R“

IR423

< R

PA

VG12

Generator

AC 230 V Verbraucher/

Load

Verbraucher/

Load

16 VG12_D00032_03_M_XXEN/01.2019

5. Commissioning and continous operation

5.1 Specific factory settings

5.2 Functional test before first use

1. Check the correct mechanical mounting of the VG12 to the power generator.

2. Make sure that the connecting cable of the VG12 is connected to the generator secu-

rely.

3. Ensure that other socket-outlets of the generator are sealed.

4. Start the power generator.

5. Plug a load (e.g. an AC 230 V hand lamp) into a socket-outlet of the VG12 safety distri-

butor. The lamp should light up.

6. Press the combined test/reset button "T/R" of the VG12. A short time later, "tES"

appears on the display for a few seconds.

In the following, the alarm LEDs "AL1" and "AL2" light up and the VG12 disconnects all

poles of the safety socket-outlets (The hand lamp goes out).

The specific factory settings of the ISOMETER® IR123 in the VG12 differ

from the standard factory settings of an IR123!

Response value 1/2 (Alarm 1/2):

Operating mode K1/K2:

Fault memory:

Start-up delay:

Response delay:

Password:

46 kΩ/23 kΩ

N/C operation (n.c.)

activated (on)

t = 0 s

ton = 0 s

0, deactivated

CAUTION

Risk of malfunction!

If the power generator is not switched off after pressing the combined

test/reset button "T/R", a fault exists. Protect the power generator

against accidental switch-on. Please contact Bender.

Commissioning and continous operation

17

VG12_D00032_03_M_XXEN/01.2019

If the shutdown was carried out as intended:

1. Press the combined test/reset button "T/R“ for 1 s

– VG12 reconnects the socket-outlets (The hand lamp lights up).

– The alarm LEDs "AL1"and "AL2"go out.

2. Ensure that this manual as well as the instructions of the power generator are kept

within easy reach near the device.

5.3 Test before daily use

Check the safe function of the VG12 daily before each use of the power generator:

1. Start the power generator.

2. Plug a load (e.g. a hand lamp) into a socket-outlet of the VG12 safety distributor.

3. Press the combined test/reset button "T/R" of the VG12 for 3 s. A short time later, "tES"

appears on the display for a few seconds.

In the following, the alarm LEDs "AL1" and "AL2" light up and the VG12 disconnects all

poles of the safety socket-outlets. (The hand lamp goes out).

If the shutdown was carried out as intended:

1. Press the combined test/reset button "T/R“ for 1 s

– VG12 reconnects the socket-outlets (The hand lamp lights up).

– The alarm LEDs "AL1"and "AL2"go out.

2. After successful testing, the power generator can be used as normal.

CAUTION

Risk of malfunction!

If the power generator is not switched off after pressing the combined

test/reset button "T/R", a fault exists. Protect the power generator

against accidental switch-on. Please contact Bender.

Commissioning and continous operation

18 VG12_D00032_03_M_XXEN/01.2019

5.4 Regular tests

Observe the deadlines for regular testing of the power generator and the connected

electrical equipment according to the accident prevention regulation BGV A3.

5.5 Troubleshooting

Of course, an insulation fault can also occur during the daily use of the power generator.

Thus, all loads plugged into the VG12 are suddenly shut down and the LEDs AL1 and

AL2 light up. What is to be done in this case?

Fault description Presumed cause Actions

LEDs "AL1"/"AL2" light

up.

Combined

test/reset button

"T/R"was pressed

deliberately or acci-

dentally.

Press the combined test/reset button "T/R"

for 1 s.

LEDs "AL1"/"AL2" light

up

(no loads connected).

Insulation fault

power generator

Turn off power generator immediately.

Arrange checking by skilled person.

LEDs "AL1"/"AL2" light

up

(loads are connected).

Insulation fault load

or power generator

Unplug plugs of all loads. Then press com-

bined test/reset button "T/R".

a)

LEDs "AL1"/"AL2" do not go out:

Arrange checking of the power generator by

electrically skilled person.

b)

LEDs "AL1"/"AL2" go out:

A load has an insulation fault. Plug in plugs of

the loads one after the other until alarm and

shutdown occur again.

Remove damaged load again and press reset

button "R".

Arrange checking of damaged load by elec-

trically skilled person.

19

VG12_D00032_03_M_XXEN/01.2019

6. Technical data

Monitored IT system

Nominal system voltage Un............................................................................................ AC 192…276 V

Nominal frequency fn.............................................................................................................. 42…60 Hz

Response values

Response value Ran1 (ALARM 1) ............................................................................ 1…200 kΩ (46 kΩ)*

Response value Ran2 (ALARM 2) ............................................................................ 1…200 kΩ (23 kΩ)*

Relative uncertainty 1 kΩ…5 kΩ/5 kΩ…200 kΩ ....................................................... ±0.5 kΩ/±15 %

Hysteresis .......................................................................................................................................... 25 %

Time response

Response time tan at RF= 0.5 x Ran and Ce= 1 μF ......................................................................... < 1 s

Start-up delay (start time) t.............................................................................................. 0…10 s (2 s)*

Response delay ton ............................................................................................................ 0…99 s (0 s)*

Measuring circuit

Measuring voltage Um........................................................................................................................ 12 V

Measuring current Im(at RF= 0 Ω) .......................................................................................... < 200 μA

Internal resistance DC Ri ............................................................................................................... > 62 kΩ

Impedance Zi at 50 Hz .................................................................................................................. > 60 kΩ

Permissible extraneous DC voltage Ufg .................................................................................. < DC 300 V

Permissible system leakage capacitance Ce................................................................................... < 5 μF

Displays, memory

Display range measured value ............................................................................................ 1 kΩ…1 MΩ

Operating uncertainty 1 kΩ…5 kΩ/5 kΩ…1 MΩ....................................................... ±0.5 kΩ/±15 %

Password ..................................................................................................................... off/0…999 (off)*

Fault memory signalling relay................................................................................................ on/off (on)*

Switching element socket-outlets:

Nominal current.................................................................................................................................. 16 A

Nominal voltage .......................................................................................................................... AC 250 V

Max. switching capacity AC......................................................................................................... 7,500 VA

Recommended minimum load ...................................................................................... 500 mA/AC 12 V

Electrical endurance, number of cycles........................................................................................... 10,000

Technical data

20 VG12_D00032_03_M_XXEN/01.2019

Environment/EMC

EMC ............................................................................................................................................ IEC 61326

Operating temperature .................................................................................................. -25 °C…+55 °C

Classification of climatic conditions acc. to IEC 60721:

Stationary use (IEC 60721-3-3) .......................................... 3K5 (no condensation, no formation of ice)

Transport (IEC 60721-3-2) .................................................................................................................. 2K3

Long-term storage (IEC 60721-3-1) .................................................................................................. 1K4

Classification of mechanical conditions acc. to IEC 60721:

Stationary use (IEC 60721-3-3) ......................................................................................................... 3M4

Transport (IEC 60721-3-2) ................................................................................................................. 2M2

Long-term storage (IEC 60721-3-1) ................................................................................................. 1M3

Vibration resistance acc. to IEC 60068-2-6:

DIN rail ........................................................................................................................... 3 g/30…150 Hz

Screw mounting............................................................................................................. 6 g/30…150 Hz

Connection/Socket-outlets

Input:

Connecting cable with Schuko plug ....................................................................... H07RN-F3G2,5 black

Wire diameter......................................................................................................................... 3 x 2.5 mm2

Cable length....................................................................................................................................... 0.7 m

Output........................................................................ Schuko socket, protected against splashing water

Other

Operating mode......................................................................................................... continous operation

Mounting.............................................................................................. any position, but display oriented

Degree of protection, enclosure (DIN EN 60529) .............................................................................. IP54

Enclosure material .............................................................................................................. polycarbonate

Screw mounting ............................................................................................................................. 4 x M4

Weight ........................................................................................................................................... 1,300 g

( )*: factory setting

This manual suits for next models

1

Table of contents

Other Bender Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

LevelOne

LevelOne IPS-1201 Quick installation quide

Show Tec

Show Tec PSA-321 Service manual

rollease acmeda

rollease acmeda AUTOMATE Series manual

West Mountain Radio

West Mountain Radio RIGrunner 4004USB manual

Siemens

Siemens SIVACON S 8PQ Series operating instructions

RMS

RMS 1S25 Series Technical bulletin