2

PP-1 20,30,40

or 60 psi

PP-2 40 psi

PP-5 40 psi 18 psi

RD-3 Must be held

manually

PP-8 Will remain in

either position

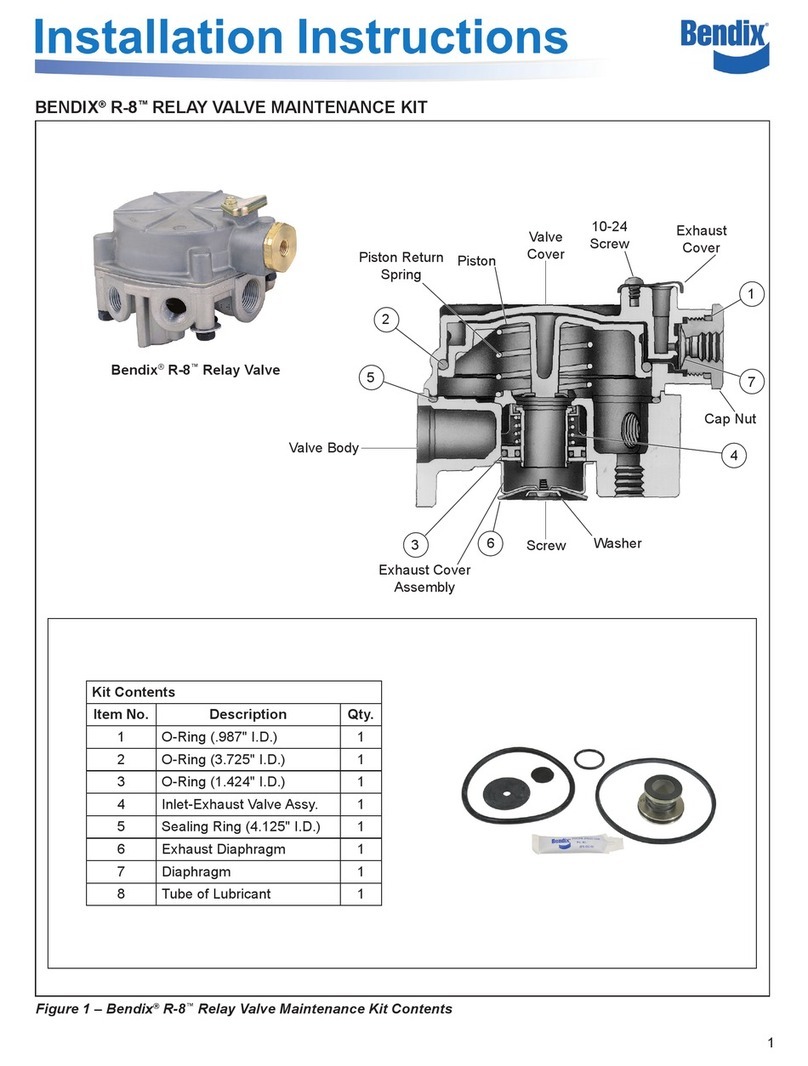

4. Removetheinlet-exhaust valve (4),andpiston (5).

5. Removeo-rings (6 & 7) from piston.

OPERATING AND LEAKAGE TESTS

PP-1™, PP-8™, RD-3™VALVE

1. An accurate test gauge should be tee’d into the supply

lineanda means ofcontrollingthe supply pressurepro-

vided. Apply a 120 psi air source to the supply port. A

small volume reservoir (e.g. 90 cu. in.) with a gauge

should be connected to the delivery port.

2. With 120 psi supply pressure, and the button pulled out

(exhaust position), leakage at the exhaust port should

not exceed a 1" bubble in 5 seconds; at the plunger

stema1"bubblein5 seconds. There should benoleak-

agebetweenupper and lower body.

3. Push the button in (applied position). Leakage at the ex-

haustport should not exceed a 1" bubble in 3seconds;at

the plunger a 1" bubble in 3 seconds. (The RD-3™valve

will have to be manually held in this position.)

4. Reduce the supply pressure. At a pressure from 60 to

20psidependingonthespringinstalledthebuttonshould

pop out automatically, exhausting the delivery volume.

(This does not apply to the RD-3™, PP-8™or some

PP-1™valve’s).

PP-5™VALVE

1. Proceedas for PP-1™valvethrough Step3.

2. Connect a modulated source of air pressure to the pilot

air inlet. With the button pushed in (applied position)

with125psi supply pressureanda gradually increasing

pressure applied at the pilot air port the valve should

move to the release position with a pilot pressure of not

more than 18 psi. Leakage in this mode should not

exceed a 1" bubble in 3 seconds at the exhaust port

and a 1" bubble in 5 seconds at the plunger stem.

PP-2™VALVE

1. Proceedas for PP-1™valvethrough Step1.

2. With the button pulled out (exhaust position), leakage

atthebrake valve portorat the plungerstemshould not

exceed a 1" bubble in 5 seconds.

3. Push the button in. Supply pressure should be present

in the delivery volume. Leakage at the exhaust port or

aroundtheplunger stem shouldnot exceed a1" bubble

in 5 seconds.

4. Pull the button out and apply supply pressure at the

brake valve port. Supply pressure should be present in

the delivery volume and leakage at the exhaust port

should not exceed a 1" bubble in 5 seconds.

Note: Ifanyoftheabovepush-pullvalvesdo not function as

described or if leakage is excessive, it is recommended

they be returned to our nearest authorized distributor for a

factoryrebuiltornew valve.

REMOVAL

Block and/or hold the vehicle by a means other than air

brakesanddrain all reservoirs.

1. Drivethebuttonroll-pinoutwithapunchandremovethe

button.

2. Markeachair supply lineandits port foreasyreinstalla-

tion,then disconnectthem. Remove the valve from the

panelby removing the panel mountingnut.

INSTALLING

1. Install valve in panel, securing with the panel mounting

nut.

2. Reconnecttheairlinesusingmarksmadeduringremoval

as a guide.

3. Installtheoperatingbutton.Secure the operating button

by installing the button roll pin.

DISASSEMBLY: PP-1™, PP-8™AND RD-3™

VALVES

1. Remove the two cap screws (3) which retain the lower

coverandremovecover. Remove the sealingring(4).

2. Insertasmall punch through therollpin hole inthestem

and remove the lock nut (5).

3. Removeinlet-exhaustvalve(6)andplunger(7)andspring

(8)(if any).

4. Removeo-ring(9)fromplunger.

DISASSEMBLY: PP-5™VALVE

1. Performsameoperations as forPP-1™valve.

2. Remove inlet seal (10) in Figure 4 from lower cover.

Removethe ringdiaphragm (4)from theinlet seat.

3. Removepiston(11)Figure 4 ando-ring (2).

DISASSEMBLY: PP-2™VALVE

1. Insertasmallpunchthroughtherollpinholeintheplunger

and remove the lock nut (1) from the plunger.

2. Withdraw the plunger and remove the spring (9) and

o-ring(8).

3. Remove the two machine screws (2) and remove the

lowercover(3).

AUTOMATIC MOMENTARY PILOT TRIP NON-

EXHAUST APPLY FEATURE AUTOMATIC