2

RELEASING

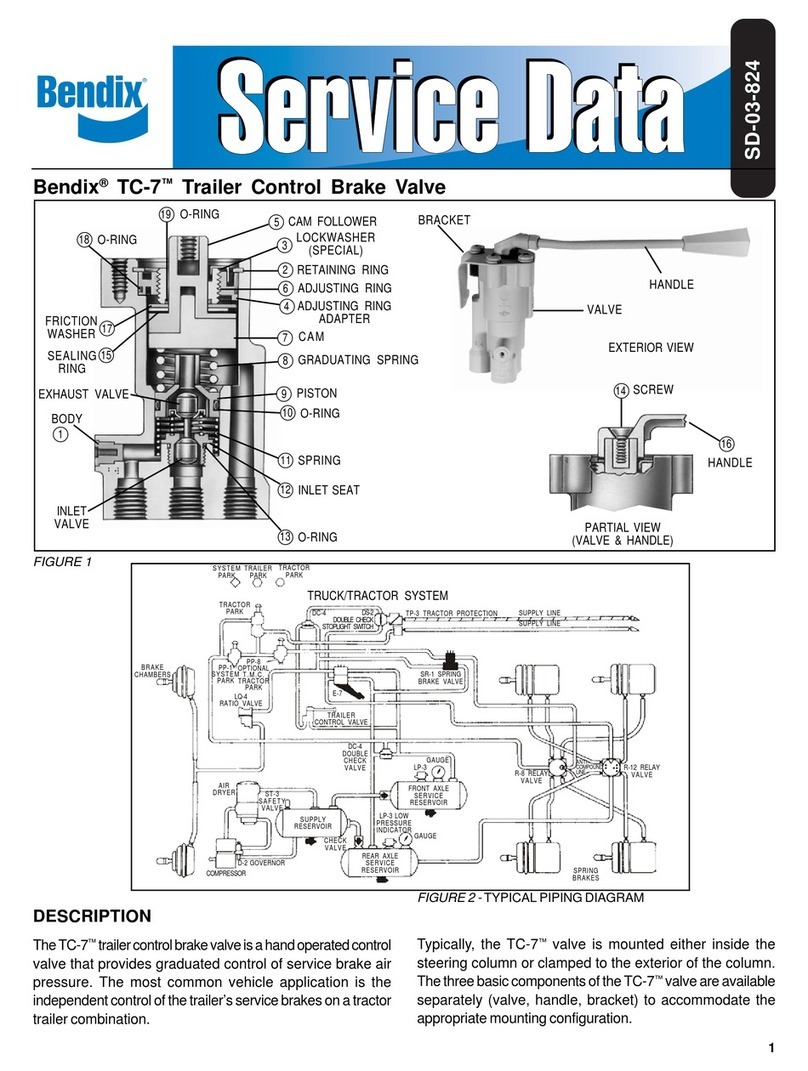

When the handle or operating lever is moved in a

counterclockwise direction the force above the piston is

decreased.Theair pressure beneathwillthenlift the piston,

moving it away from the exhaust valve. With the exhaust

passage open, air pressure in the service line will exhaust

out the exhaust port of the valve.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is

performed during this period.

Because no two vehicles operate under identical

conditions, maintenance and maintenance intervals will

vary.Experienceisa valuable guide indeterminingthebest

maintenance interval for any one particular operation.

Visuallycheck forphysicaldamagetothebrakevalvesuch

as broken air lines and broken or missing parts.

Every 3 months, 25,000 miles or 900 operating hours

perform Operating and Leakage Tests.

SERVICE CHECKS

OPERATING TEST

Connect an accurate test gauge to a delivery port. When

thehandleismovedto the fully applied position, the gauge

shouldregister full reservoir pressure. NOTE: Somevalves

may be preset to deliver lower than reservoir pressure;

however,the standardvalvesgenerally usedontractors are

settodeliverfullreservoirpressure.Intermediatepositions

should deliver proportional intermediate pressures. Upon

release, the gauge should immediately register zero.

LEAKAGE TEST

Locate the exhaust port or exhaust line and apply a soap

solution. (It is common practice to connect a line from

the valve exhaust port to a location remote from the

immediate driver’s area.) With the valve in the released

position, exhaust leakage should not exceed a 1" bubble

in 5 seconds (100 sccm).

With the valve fully applied, leakage at the exhaust

should not exceed a 1" bubble in 3 seconds (175 sccm).

If the valve does not function as described or leakage is

excessive, it is recommended that it be replaced with a

neworremanufacturedunit,orrepairedwithgenuineparts

available at Bendix outlets.

REMOVING AND INSTALLING

REMOVING

1. Block and hold vehicle by means other than air

brakes.

2. Drain air brake system.

3. Ifremote-operatedtypevalve, disconnect the operating

mechanism.

4. Disconnect air lines from valve.

5. Remove mounting clamp bolts, clamp, and then valve.

INSTALLING

1. Check and clean air lines to valve.

2. Operating mechanism for remote type should be

checked functionally and for proper adjustment.

3. Mount valve with clamp and mounting bolts.

4. Tighten mounting bolts evenly to approximately 200

inch pounds torque (3/8-16 bolt torque 180-220 inch

pounds.)

5. If remote type valve, connect operating mechanism.

DISASSEMBLY

HANDLE OPERATED VALVE

1. Drive out the spirol pin and remove the handle, head,

and head seal o-ring.

2. Remove handle o-ring.

3. RemoteOperatedTypeValve:Removesetscrew, head

and head seal o-ring.

4. Remove adjusting ring lock washer.

5. Removecapscrewsthatholdbody and cover together;

separate cover from body.

6. Remove gasket and graduating spring.

7. Remove cam and cam follower from cover.

8. Unscrew and remove adjusting ring.

9. Remove piston and piston return spring from body.

10.Remove piston o-ring.

11. Remove inlet and exhaust insert screws and lock

washers, then insert and o-ring seal.

12.Theinletandexhaustvalve insert can bedisassembled

if desired or necessary.

13.Insert some object such as a cap screw in the supply

port to hold the inlet valve on its seat.

14.Depress the exhaust valve guide and spring; remove

the exhaust valve.

15.Remove stem with inlet valve from inlet seat and

remove inlet valve from stem.

CLEANING AND INSPECTION OF PARTS

1. Clean all metal parts in mineral spirits.

2. Wipe rubber parts clean.

3. Inspect valve seats for nicks or burrs.

4. Check all springs for distortion, cracks, and

corrosion.

5. All rubber parts should be inspected for wear or

deterioration.

6. Replace all parts not considered serviceable during

their inspection with genuine Bendix replacement

parts.