EU RoHS Directive

China RoHS Directive

*Standards for "RoHS Directive-Compliant Products"

Name and Amount of Toxic and Hazardous Substances or Elements

Lead

1000 ppm max.

Mercury

1000 ppm max.

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd) (Cr (VI))

PBB PBDE

Cadmium

100 ppm max.

Hexavalent chromium

1000 ppm max.

PBB

1000 ppm max.

PBDE

1000 ppm max.

(Items that are exempted in the RoHS Directive are excluded from these standards.)

Usage deadline

for environmental

protection Product name

Control Unit

for LED Lights

Toxic or hazardous substances and elements

Usage Deadline for Environmental Protection

产品中有毒有害物质或元素的名称及含量

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr (VI))

环保

使用期限 产品

LED 照明

专用电源

有毒有害物质或元素

*Lead and cadmium are excluded in EU RoHS.

:表示该有毒有害物质在该部件所有均质材料中的含量均在 SJ/T11363-2006 标准规定的限量要求以下。

:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 SJ/T11363-2006 标准规定的限量要求。

此标志的数字是根据中华人民共和国电子信息产品污染控制管理办法以及有关标准等,表示该产品的环保使用期限的年数。

遵守产品的安全和使用上的注意,在产品使用后采取适当的方法根据各地法律,规定,回收再利用或进行废弃处理。

环保使用期限

(注) 铅和镉中的“×”,因欧洲 RoHS 没限定,故用“○”表示。

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

Environmental Regulation

The RoHS Directive is short for the "restriction of use of certain hazardous substances in electrical and

electronic equipment." As a directive, it restricts the use of specific hazardous substances for new electrical and

electronic equipment marketed in the EU on or after July 1, 2006, and restricts the use of six substances,

which are (1) lead, (2) mercury, (3) cadmium, (4) hexavalent chromium, (5) polybrominated biphenyl (PBB),

and (6) polybrominated diphenyl ether (PBDE).

China RoHS Directive is formally known as "Management Methods for Controlling Pollution by Electronic

Information Products", which was implemented on March 1, 2007 in China. Same as EU RoHS Directive,

this regulation restricts the usage of six substances such as lead, mercury, cadmium, hexavalent chromium,

polybrominated biphenyl (PBB), and polybrominated diphenyl ether (PBDE). This regulation requires

electronic information products which are manufactured or imported, and sold in China, to clearly disclose

contents of the 6 restricted substances listed below.

Hexavalent

chromium

: Indicates that this toxic or hazardous substances contained in all the homogeneous materials for this part, according to

SJ/T11363-2006 is within the limit requirement.

: Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to

SJ/T11363-2006, is over the limit requirement.

The number used in this logo is based on “Management Methods for Controlling Pollution by Electronic Information

Products” and related regulations from People’s Republic of China. It shows the product usage duration in years for

environmental protection. After finishing a product usage, the product needs to be re-used or discarded appropriately following

local law and regulations, complying with safety and usage caution.

Warranty Information

Copyright© 2011 CCS Inc. All Rights Reserved.

Descriptions in this instruction guide are based on information available as of October 2011. KZ03993-T001-000

Ask any product queries to the following address or to your nearest CCS representative.

Shimodachiuri-agaru, Karasuma-dori, Kamigyo-ku, Kyoto 602-8011 Japan

Phone : +81-75-415-8284 Fax : +81-75-415-8278 E-mail : intlsales@ccs-inc.co.jp

Headquarters

http://www.ccs-grp.com/mvad/

Do not use the product in the following situations.

medical equipment, amusement machines, or safety equipment.

Under conditions or in an environment not described in this instruction guide.

In nuclear energy control systems, railroad systems, aviation systems, vehicles, combustion equipment,

In applications involving serious risk to life or property, particularly applications demanding a high level of safety.

Contents of this Instruction Guide may be changed without prior notice.

Illustrations used in this Instruction Guide may differ from actual products.

CCS maintains the copyright on this Instruction Guide. Unauthorized transfer or reproduction is strictly prohibited.

Instruction Guide and Dimensional Diagrams in PDF or CAD can be downloaded from the CCS website.

http://www.ccs-grp.com/

EXCEPT FOR THE EXPRESS WARRANTIES STATED IN THIS DOCUMENT, CCS MAKES NO ADDITIONAL WARRANTIES,

EXPRESS, IMPLIED, OR STATUTORY, AS TO ANY MATTER WHATSOEVER. IN PARTICULAR, ANY AND ALL WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

EXCEPT AS EXPRESSLY SET FORTH HEREIN, CCS MAKES NO WARRANTIES WITH RESPECT TO THE PRODUCTS.

WARRANTY PERIOD: TWO YEARS, STARTING FROM CCS Inc. SHIPPING DATE.

CCS Inc. WILL REPAIR OR REPLACE THE PRODUCT FREE OF CHARGE IF IT SHOULD FAIL TO FUNCTION WITHIN THE

SPECIFIED WARRANTY PERIOD. IF EITHER OF THESE CONDITIONS OCCURS, PLEASE TAKE THE PRODUCT TO YOUR

CCS SALES REPRESENTATIVE.

WARRANTY TERMS

1 CCS Inc. WILL REPAIR OR REPLACE THE PRODUCT FREE OF CHARGE IF IT SHOULD FAIL TO FUNCTION UNDER USE

ON OUR SPECIFIED CONDITION IN ACCORDANCE WITH THE INSTRUCTION GUIDE AND OTHER WRITTEN CAUTIONS

DURING THE INDICATED WARRANTY PERIOD OF TWO YEARS.

2 CCS Inc. WILL CHARGE A REPAIR FEE UNDER THE FOLLOWING CONDITIONS:

1) IF THE PRODUCT HAS BEEN SUBJECTED TO MISUSE, UNAUTHORIZED REPAIRS, OR MODIFICATION FROM ITS

ORIGINAL DESIGN.

2) IF THE PRODUCT HAS BEEN DAMAGED FROM IMPACTS DUE TO INAPPROPRIATE HANDLING.

3) IF DAMAGE TO THE PRODUCT RESULTS FROM EXTERNAL CAUSES INCLUDING ACCIDENTS, FIRE, POLLUTION,

RIOTS, COMMUNICATION FAILURES, EARTHQUAKES, THUNDERSTORMS, WIND AND FLOOD DAMAGE, OR ANY

OTHER ACT OF PROVIDENCE, OR FROM ANY EXTRAORDINARY CONDITIONS SUCH AS ELECTRICAL SURGES,

WATER LEAKAGE, CONDENSATION, OR THE USE OF CHEMICALS.

4) IF THE DAMAGE RESULTS FROM CONNECTION TO ANY LED LIGHT UNIT OR TO ANY EQUIPMENT WHICH CCS Inc.

DOES NOT MANUFACTURE OR DOES NOT SPECIFY FOR USE.

3 CCS ASSUMES NO LIABILITY FOR ANY PURCHASER’S SECONDARY DAMAGE (DAMAGE OF EQUIPMENT, LOSS OF

OPPORTUNITIES, LOSS OF PROFITS, ETC.) OR ANY OTHER DAMAGE RESULTING FROM A FAILURE OF OUR

PRODUCT.

THIS WARRANTY INFORMATION PROVIDES THE SCOPE OF CCS'S PRODUCT WARRANTY WITHIN THE SPECIFIED

PERIOD, AND DOES NOT INDICATE OR IMPLY ANY FURTHER GUARANTEE BEYOND THE WARRANTY TERMS.

CONTACT CCS FOR INQUIRIES OR INFORMATION ON REPAIRS TO THE PRODUCT AFTER THE EXPIRATION OF THE WARRANTY.

Use our website to find your nearest CCS representative.

1010

14

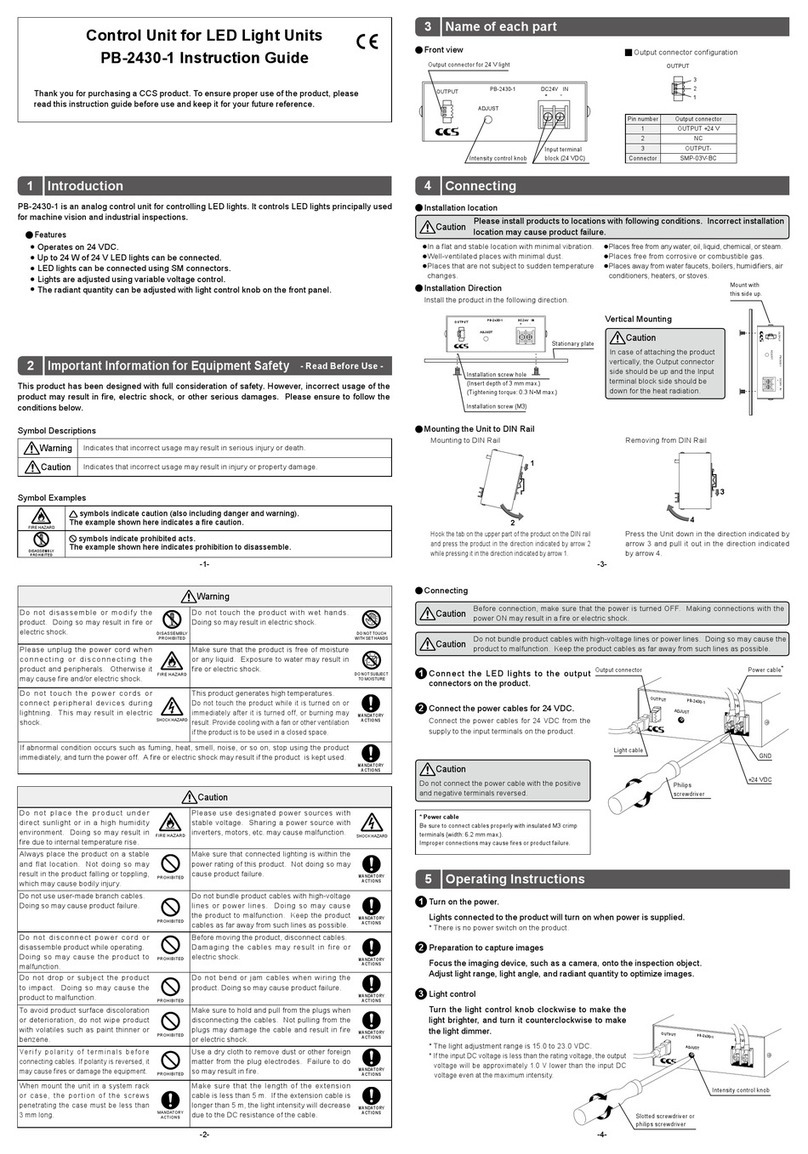

Dimensions

124

197

120

(6)

(1.8)

82.6(13)(8)

14 169

1059.3

(6)(6)

13

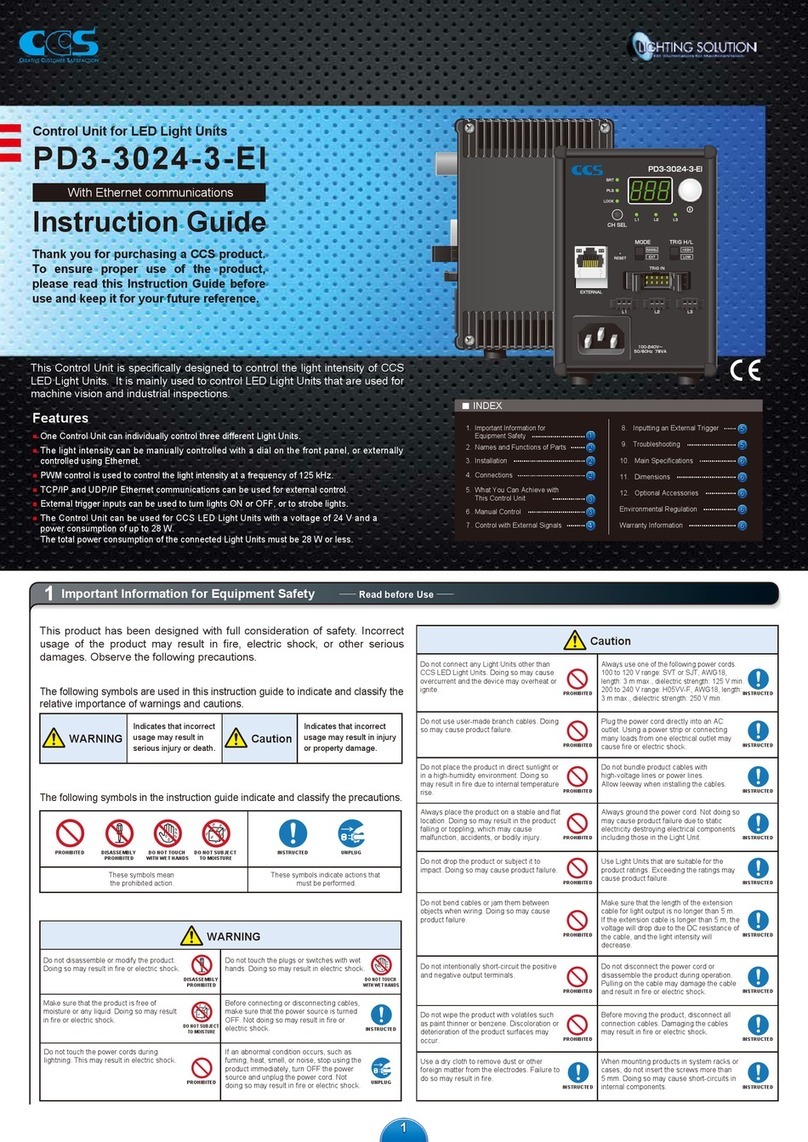

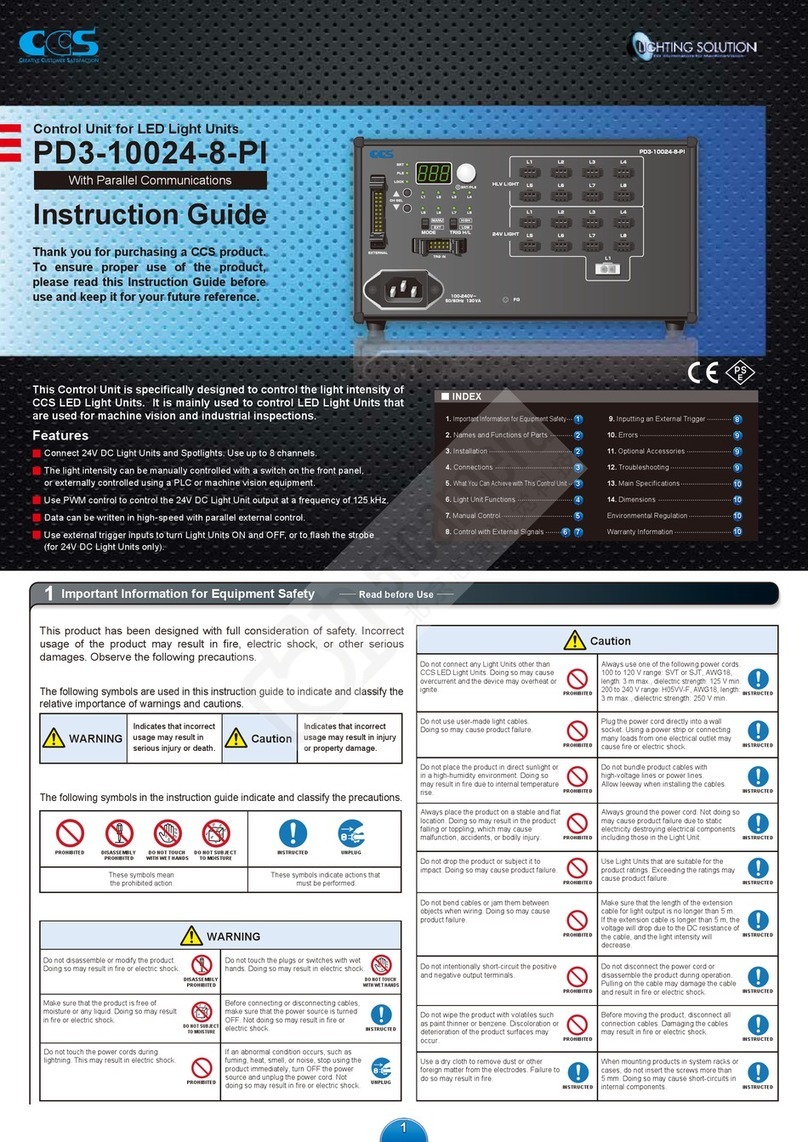

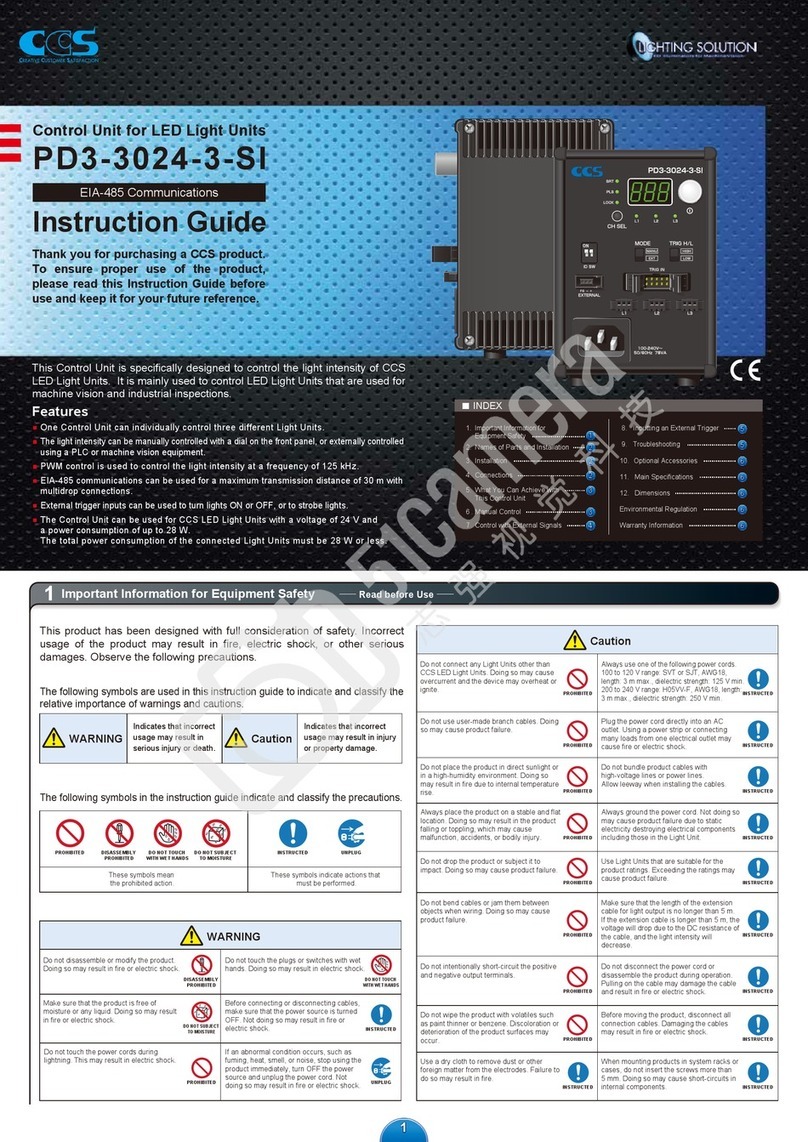

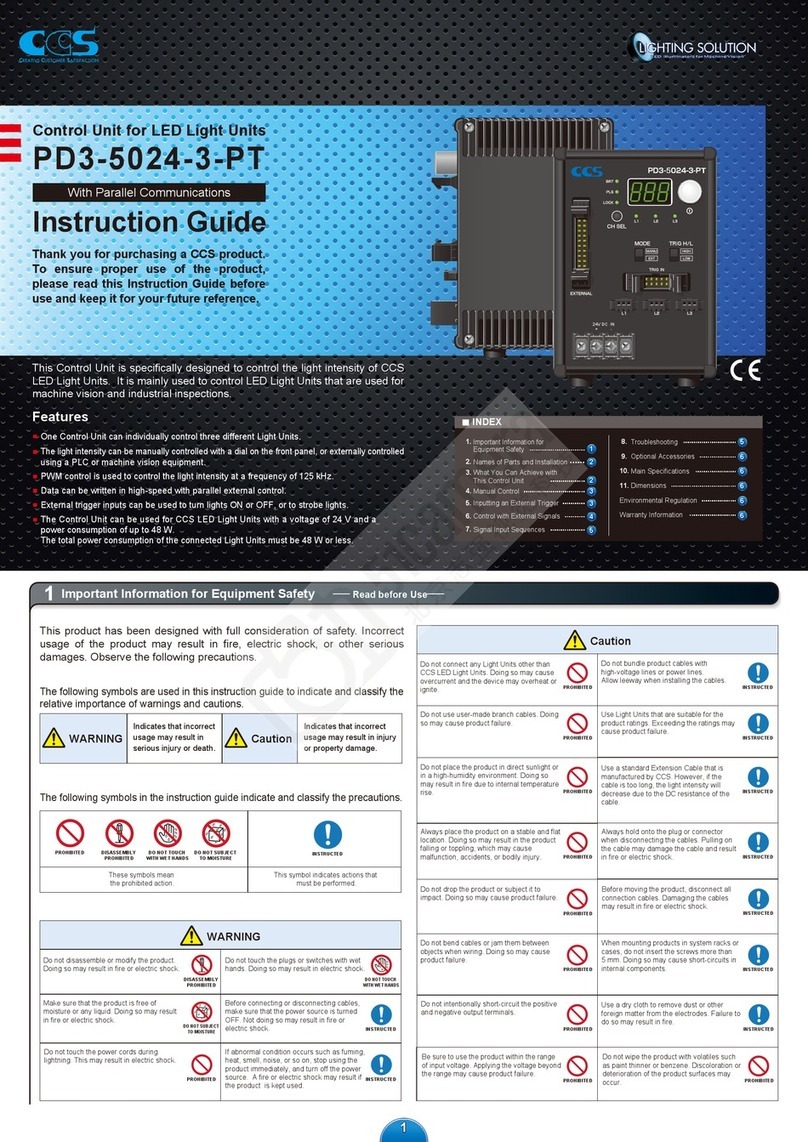

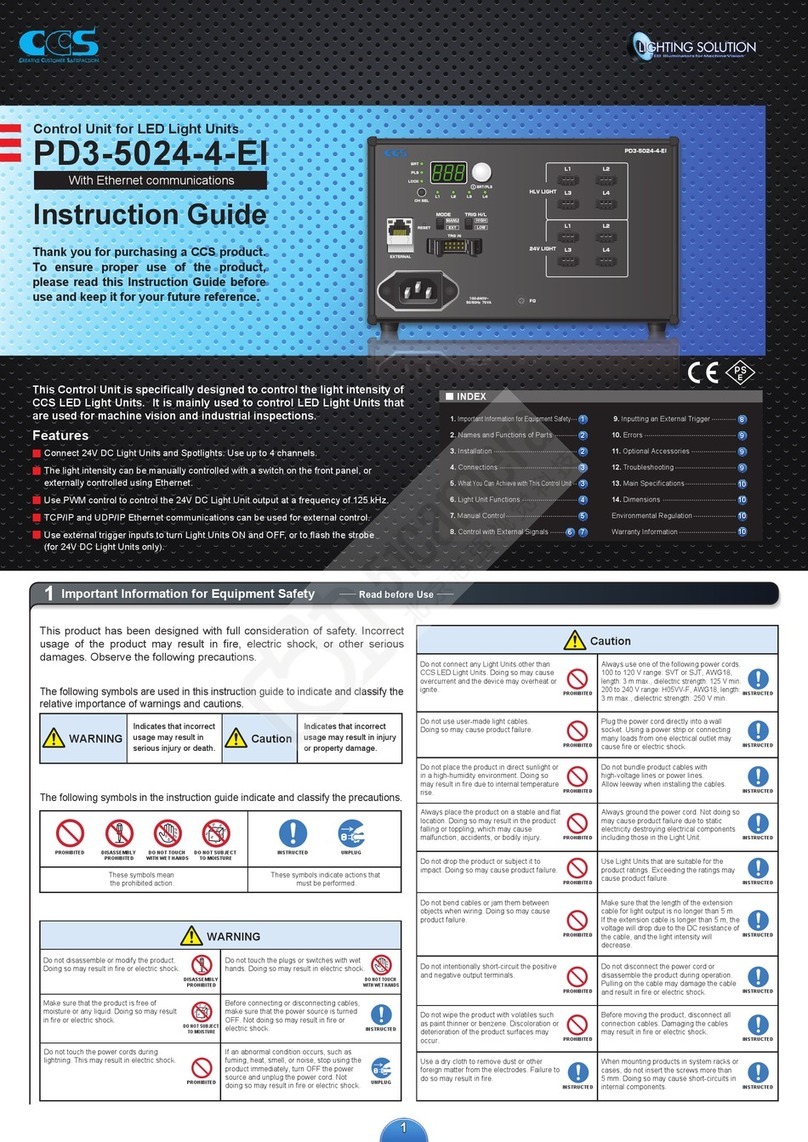

Main Specifications

Product name

Model

Rated capacity

Input power supply

Inrush current (typ.)

Ground leakage current

Rated output voltage

Insulation withstand voltage

(input-output, input-FG)

Operating temperature and humidity

Storage temperature and humidity

Vibration resistance

Cooling method

CE Marking

PSE

Environmental regulations

Input connector

External control connector

Material and surface processing

Weight

Accessories

Digital Control Unit for LED Light Units (with EIA-485 communications)

PD3-5024-4-SI

46 W max. for 8 connectors total

100 to 240V AC (+10%, −15%), 70 VA, 50/60 Hz

15 A (at 100V AC), 30 A (at 200V AC) from a cold start

3.5 mA max. (264V AC, 60 Hz, with no load)

24V DC

1,500V AC for one minute, Cutoff current: 10 mA,

500V DC, 20 MΩ min.

Temperature: 0 to 40°C, Humidity: 20% to 85% (with no condensation)

Temperature: −20 to 60°C, Humidity: 20% to 85% (with no condensation)

Acceleration: 19.6 m/s2, Frequency: 10 to 55 Hz, Cycles: 3 minutes,

Sweep cycle: For 1 hour each in X, Y, and Z directions

Forced air cooling

Safety standard: Conforms to EN 61010-1, EMC standard: Conforms to EN 61326, Class A.

Specified Electrical Appliance and Material(DC power supply units)Conformity with METI Ordinance Article 1

RoHS compliant

AC input: 3-pin inlet EN 60320-1 certified C14 type × 1

Trigger input: MIL connector (MIL-C-83503 compliant), 10-pole

For setting the light intensity and lighting mode: e-CON 3-pole

Material: Aluminum and resin, Surface processing: Blue alumite

1200 g max.

2-m long 3-pin power cord with ground terminal x1, Base Brackets x1 set, Instruction Guide x1

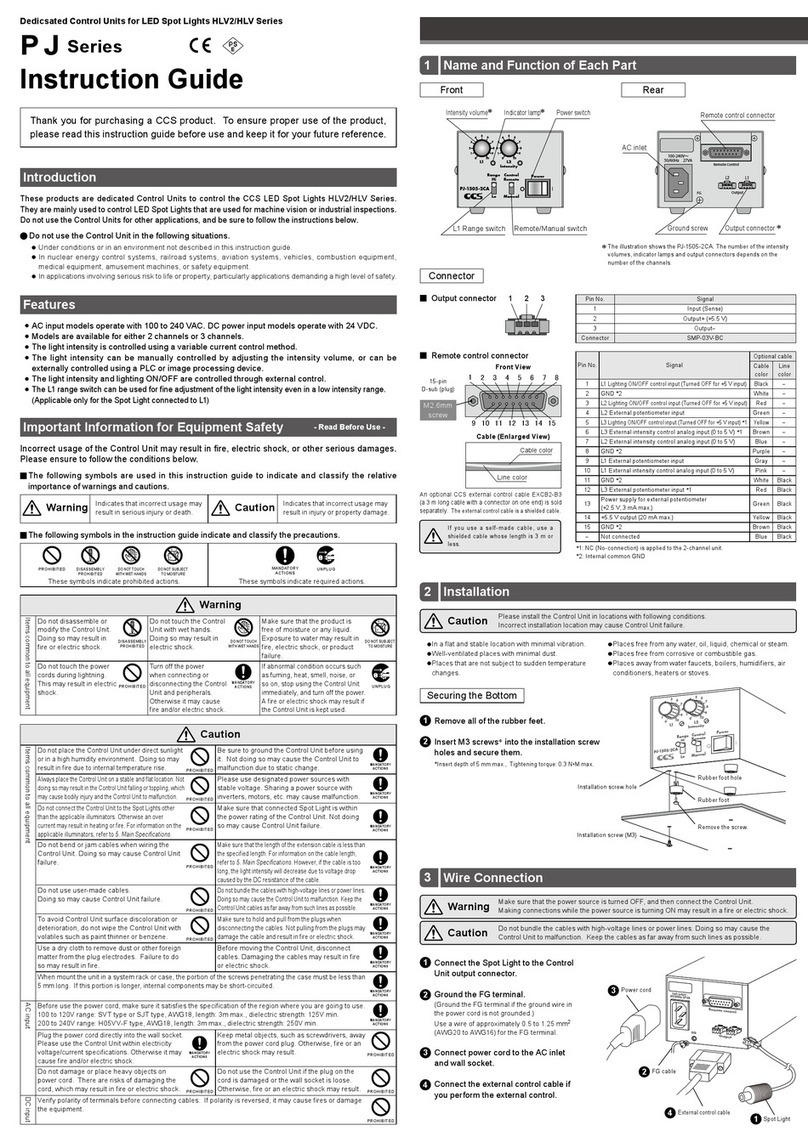

Specifications for Different Output Connectors

24V DC Light Units

46W max.

PWM control (125kHz) or

lighting time control

Detected when connected

for the first time.

0.5 s

SMP-03V-BC

(J.S.T. Mfg. Co., Ltd.) x 4

Input type

Applicable

illuminators

Rated capacity

Lighting method

Light Unit

connection detection

Power startup time

Output

connectors

Spotlights: HLV 2 series, HLV series*

*not including HLV-27 series/HLV-14-R/

HLV-14-GR/HLV-14-BL/HLV-14-SW

Per connector: 3.9 W (700mA) max.

Variable current control

Detected at any time.

3 s

SMP-03V-BC

(J.S.T. Mfg. Co., Ltd.) x 4

Front View

Side View

Bottom View

Four, M3 screws

(Insertion depth of 5 mm max.)

Four, M3 screws

(Insertion depth of 5 mm max.)