2

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuableguidein determiningthebestmaintenance interval

forair brakesystem components.At aminimum, theTC-6™

valveshouldbeinspectedevery6 months or1500operating

hours,whichever comes first, for proper operation. Should

the TC-6™valve not meet the elements of the operational

testsnotedinthisdocument,furtherinvestigationandservice

ofthevalve maybe required.

Every900 hours,25,000milesorevery3months,dropsome

lubricant such as BW-650M silicone lubricant (Bendix part

number 291126) (Dow Corning 55-M) through the handle

operating slot, to re-lubricate the cam roller and hinge pin.

Performoperating andleakage tests.

REMOVING AND INSTALLING

Secure vehicle with spring brakes or blocks. Drain the

reservoir which supplies the TC-6™valve. Remove the

fasteners which secure the mounting bracket to the panel.

Disconnectthe connectingair lines.Removevalve.

INSTALLING

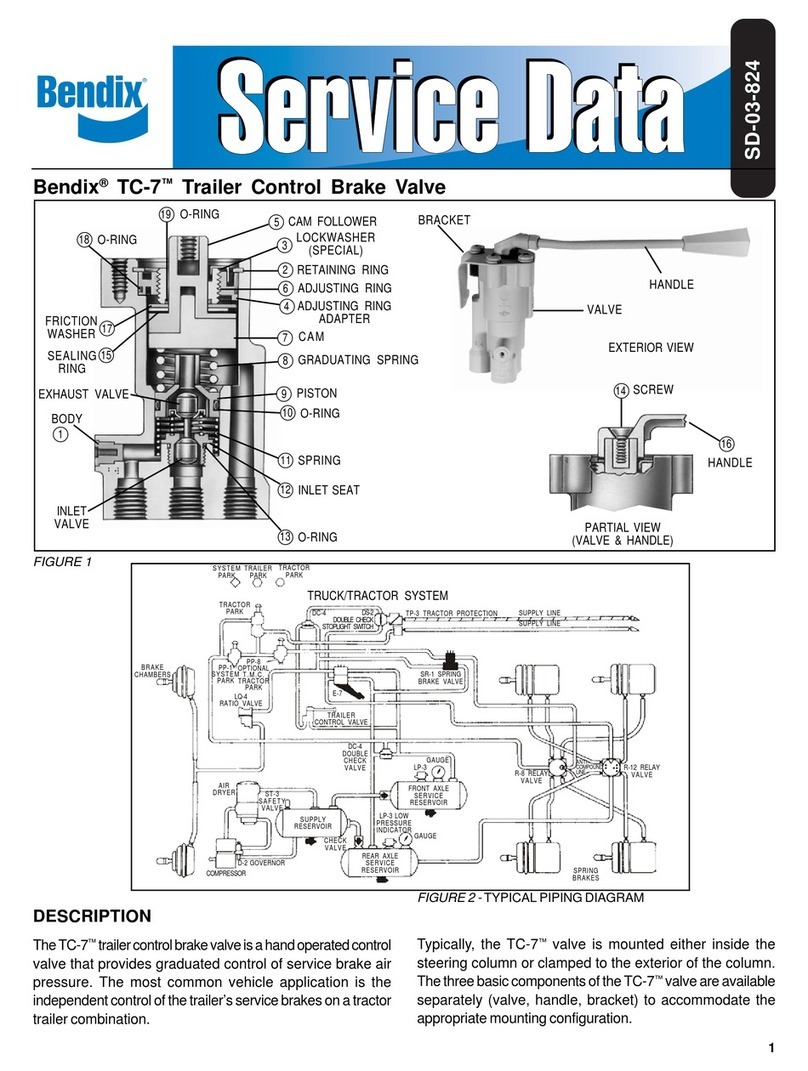

Atypicalpipingarrangement fortheTC-6™valveisshown in

Fig. 3. Check connecting air lines for integrity and foreign

material. Replace lines if necessary. Re-connect air lines.

Replace fasteners securing bracket to panel. Check

operation of valve by charging system and performing the

service check as described in this manual.

SERVICE CHECKS

OPERATING

Connect an accurate test gauge to the trailer service line

hose and leave the trailer emergency or supply hose

connectedtothe trailerorif a trailerisnot available,connect

the trailer supply hose to an unvented dummy coupling or

toa pluggedhose fitting. Thetrailer supplyvalve shouldbe

in the normal position.

When the operating lever is moved to the fully applied

position, the gauge should register full reservoir pressure.

Intermediate positions should deliver proportional

intermediate pressures. Upon release, the gauge should

immediatelyregister zero.

The location of the atmospheric end of the exhaust line

from the valve should be found, probably in the engine

compartment.

With the TC-6™valve in the release position, no pressure

shouldregister onthe test gaugeand leakageat the end of

the exhaust line should not be greater than 100 SCCM

(1" bubble in 5 seconds).

With the valve fully applied, leakage at the exhaust line

should not be greater than 175 SCCM (1" bubble in 3

seconds).

Ifthe valvedoes notfunctionas described,or ifthe leakage

is excessive, it is recommended that it be returned to the

nearest Bendix authorized distributor for a factory

remanufacturedvalveunder theexchangeplan.If thisisnot

possible,thevalvecanberepairedwithgenuineBendixparts,

in which case the following should be helpful. The

maintenancekitfor theTC-6™valveis partnumber289890.

DISASSEMBLY

Remove the valve from the panel. Place the lever in a vise

and with a firm pull the rubber handle may be removed.

Remove the two slotted head cap screws (14) which hold

themountingbracketinplaceasshownin Fig. 2andremove

themounting bracket.

Drive the pivot pin (13) out of the body with a drift punch.

Thehandle (10), roller cam(11)andtorsion spring (8) may

nowbe removed. Removethe roller camfrom the handle.

The cam follower (9), graduating spring (6), plunger (12),

andplunger returnspring (4) maynow beremoved through

thetopofthevalve. Careshouldbetakennot tolosewasher

(15).

Placethebodyina soft-jawedviseandremovecapnut (16).

Removeo-ring(1) fromcap nut.

Inletvalvespring(3)andinletvalve(2)maynowberemoved.

CLEANINGAND INSPECTION OF PARTS

Clean all metal and plastic parts with mineral spirits or

equivalent. Wipe all o-rings and rubber parts dry. Replace

any which show signs of wear or deterioration. Inspect

valve seats for nicks or burrs and remove any deposits.

Check all springs for distortion, cracks and corrosion.

Replaceallpartsnotconsideredserviceableafterinspection.

ASSEMBLY

Before assembling the valve all bores, cam, pivot pin,

plungers, and o-rings should be lubricated with silicone

lubricantDow Corning55-M (Bendix partnumber 291126).

Placebodyin asoft-jawedvise withportspointing up.Place

inletvalve (2)in inletcavity andinstall inlet valve spring (3).

Place o-ring (1) on cap nut (16) and assemble cap nut in

body. Torque cap nut to 50-150 inch pounds.

Install o-rings (5) and (7) on plunger (12) and cam follower

(9).Caution:o-ring (7)is slightlylargerthan (5)and goes on

thecam follower(9).

Reverse position of body in vise and install plunger return

spring (4), plunger (12), washer (15), graduating spring

(6), and cam follower (9). Note: The cam follower must be

positioned so that the projection on the side of the body

matches the corresponding groove in the body.