3

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix®replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

REMOVING

1. Secure the vehicle on a level surface by means other

than the brakes.

2. Drain all reservoirs to 0 p.s.i. (0 kPa) air pressure.

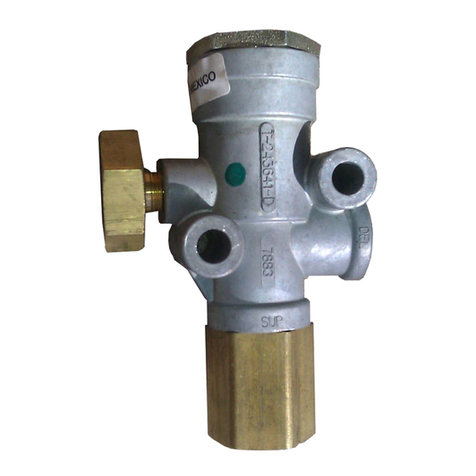

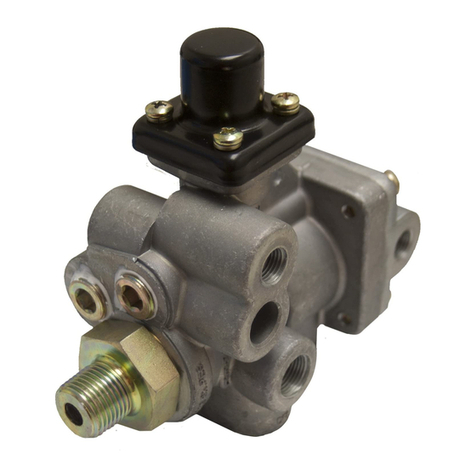

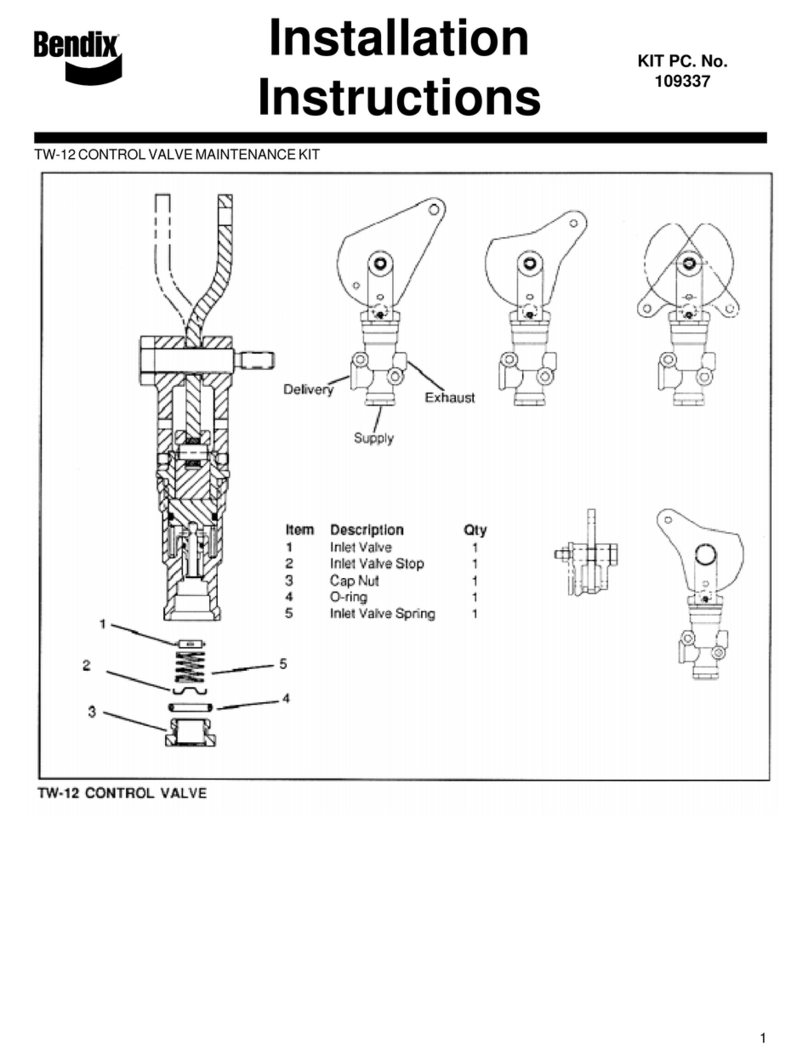

3. Identify, mark and remove the air lines from the TW-N™

valve.

4. Remove the TW-N™valve from the vehicle.

DISASSEMBLY

1. Before disassembly, move the TW-N™valve lever to the

air delivery position and note or mark the position of the

lever relative to the valve body. NOTE: The TW-N™valve

is in the air delivery position when the plunger is closest

to the mounting surface of the body. Confirm that the

TW-N™valve is in the air delivery position by applying air

to the supply port and noting that it exits the delivery

port.

2. Using a drift punch, drive the lever pin out and remove

the lever.

3. Remove the plunger and plunger return spring.

4. Remove both the large and small diameter o-rings from

the plunger.

CLEANING AND INSPECTION

1. Clean the valve body, plunger return spring and plunger

in a mild solvent such as mineral spirits and dry

thoroughly.

2. Inspect the valve body bore and piston for scratches,

nicks, cracks and distortion. If noted, the entire TW-N™

valve must be replaced.

3. Inspect the return spring for distortion and corrosion. If

noted, the entire TW-N™valve must be replaced.

ASSEMBLY

Prior to assembly lubricate the valve body bore, plunger and

o-rings with Bendix silicone lubricant Pc. Nos. 291126.

1. Install large and small diameter o-rings on plunger.

2. Install plunger return spring in body and install plunger.

3. Note the lever position marked during disassembly. Care

should be exercised as lever can be installed in either

position. (Lever position is dictated by function marked

on dial or dash.) Place lever in body and gently depress

the lever and plunger until the lever pin holes in the

body and the lever are aligned.

4. Install the lever pin and press into position. It may be

necessary to hold the lever to guide the pin into the

body hole opposite the press. The lever pin should be

flush with the body on one side.

INSTALLING

1. Install the TW-N™valve on the vehicle.

2. Connect the air lines to the TW-N™valve according to

the markings made during “Removal”. IMPORTANT:

Fittings installed in the supply and delivery ports of the

TW-N™valve should not be torqued to greater than 8 ft.

lbs. (10.85 N.M).

3. Before placing the vehicle in service, perform the

“Operation and Leakage Tests”.

BW1444 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.