Step 6

Install Hydraulic Power Unit (HPU) in a convenient location with

a dry environment. Important: The HPU must be mounted

in a dry enough location to avoid submersion and

drenching. Allow space above the HPU so that it may be slid

into its mounting bracket (about 3"). Lay out upper holes on

HPU mounting bracket 4 5/8" apart and start #10 x 1" screws

using 5/32" pilot holes.Then drill 5/32" pilot holes for lower

screws and mounting bracket. Slide HPU into bracket.

Step 7

Inside the transom, apply Teon tape on male threads of pipe

nipples and tighten 90 degree brass elbows to pipe nipples.

While tightening elbow, hold pipe nipple with vise grips

to prevent stripping.

Step 8

Run hydraulic tubing from actuators at transom to HPU

(See Figure 4) and cut to length. Note: Make port and

starboard lengths as equal as possible.

Step 9

Insert tubing through the nut with ferrule at 90 degree elbow. Push until it bottoms in

the tting. While continuing to bottom the tubing in the tting, tighten nut“nger

tight”, then one full turn with a 1/2" wrench . . . NO MORE.

Step 10

To connect tubing to Hydraulic Power Units, insert tubing through the nut with

ferrule tting and push into the pump-face tting until it bottoms.While continuing

to bottom the tubing in the tting, tighten nut“nger tight”, then one full turn with a

1/2" wrench … no more. Use tube bending clips at desired 90 degree bends in tubing to prevent kinking.

Step 11

Connect HPU ground wire to the the vessel’s negative ground system.

Step 12

Wire control and electrical system per separate instruction sheet.

Step 13

Remove plug from ller stack located at the front left corner of the reservoir. Fill reservoir to“Full Line”using any type

automatic transmission uid (ATF).

Step 14

Using the control, hold the“Bow Down”position for 15 seconds, then“Bow Up”for 15-20 seconds. Repeat 3 times.

This will purge air from the system.

Step 15

Place both tabs in the“full down”position and check all hydraulic connections for leaks. Bring the tabs to the full up position

and check uid level. Add ATF if necessary.

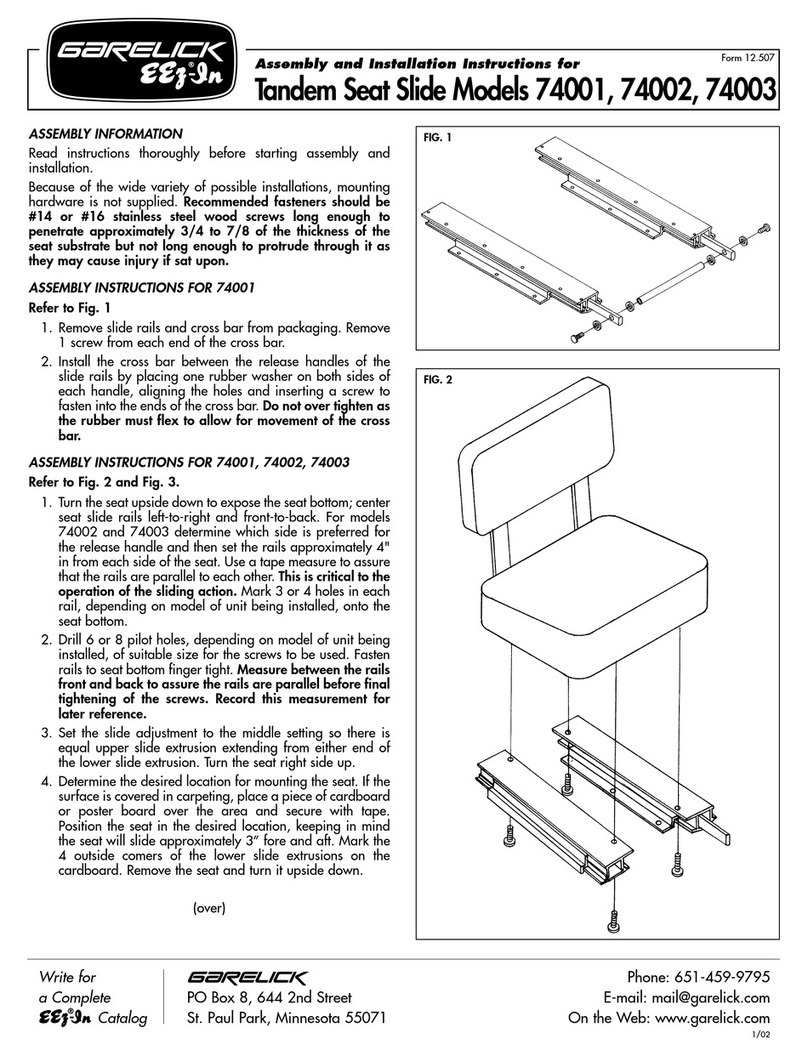

Figure 4

Tighten Nut with 1/2"Wrench One FullTurn Past Finger

Tight - NO MORE

PushTubing to Bottom of Fitting While Tightening