TESTING

1) All the alarm signal services, releasing device and extinguisher system

should be disengaged during the test period and must be re-engaged

immediately at the conclusion of testing.

2) After energizing the detector head for approximately one minute, check

to see the indicator green LED flashing once every 3~5 seconds. If

green LED fails to flash, it indicates the non-functioning of the detector

or faulty wiring. Re-check the wiring or replace the detector if necessary.

3) Allow smoke from a cotton wick or a test smoke aerosol to enter the de-

tector-sensing chamber for at least 10 seconds. When sufficient smoke

has entered the chamber, the detector will signal an alarm, this being

visible by a continuous illumination of the LED. Reset each detector

and/or control unit before attempting to test any additional detectors in

the same zone. If the alarm fails in this step, it indicates a defective unit,

which requires service.

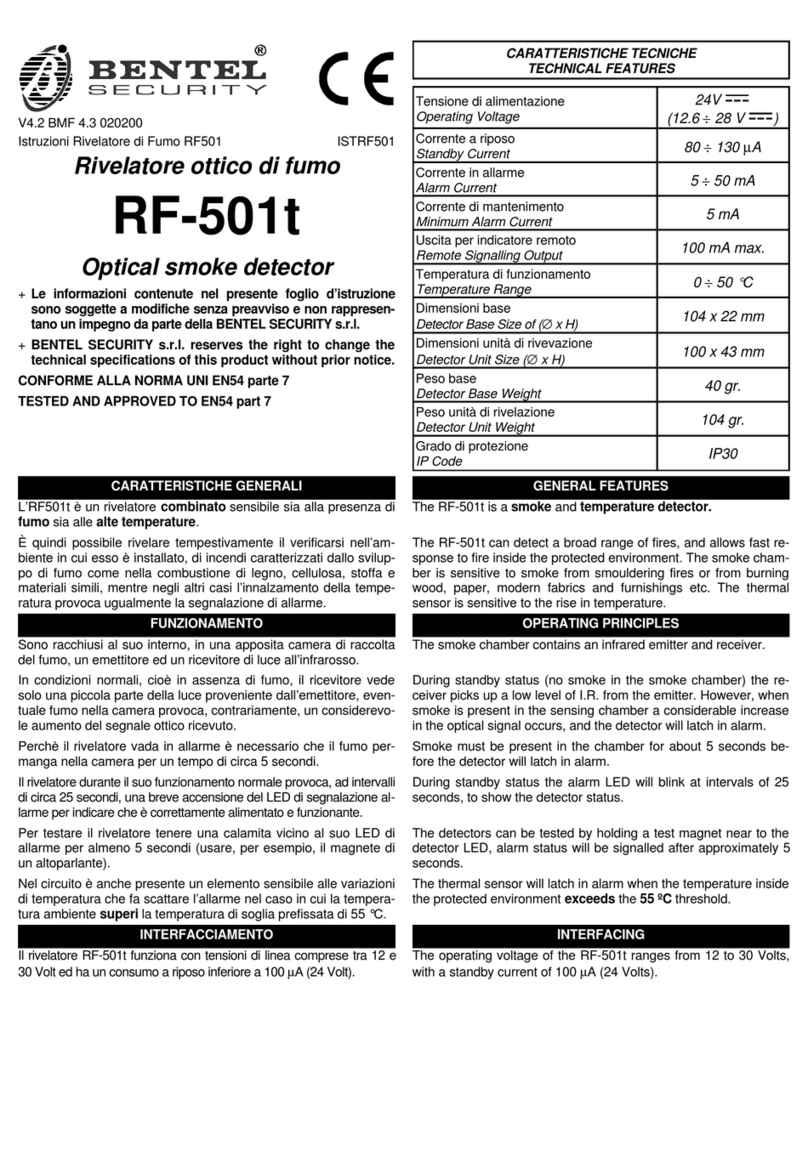

SPECIFICATION

http:www.bentelsecurity.com

MAINTENANCE

The recommended minimum requirement for detector maintenance con-

sists of an annual cleaning of dust from the detector head by using a vacuum

cleaner cleaning program should be agreed to the individual environment.

+CAUTION: DO NOT ATTEMPT TO DISASSEMBLY OF THE

FACTORY SEALED SMOKE DETECTOR. THIS ASSEMBLY IS

SEALED FOR YOUR PROTECTION AND IS NOT INTENDED TO BE

OPENED FOR SERVICING BY USERS. OPENING THE DETECTOR

HEAD WILL VOID THE WARRANTY.

RECYCLING INFORMATION

BENTEL SECURITY recommends that customers dispose of their used

equipments (panels, detectors, sirens, and other devices) in an environ-

mentally sound manner. Potential methods include reuse of parts or whole

products and recycling of products, components, and/or materials.

For specific information see

www.bentelsecurity.com/en/environment.htm

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE)

DIRECTIVE

In the European Union, this label indicates that this product

should NOT be disposed of with household waste. It should be

deposited at an appropriate facility to enable recovery and re-

cycling.

For specific information see

www.bentelsecurity.com/en/environment.htm

BENTEL SECURITY s.r.l. reserves the right to change the technical specifi-

cations of this product without prior notice.

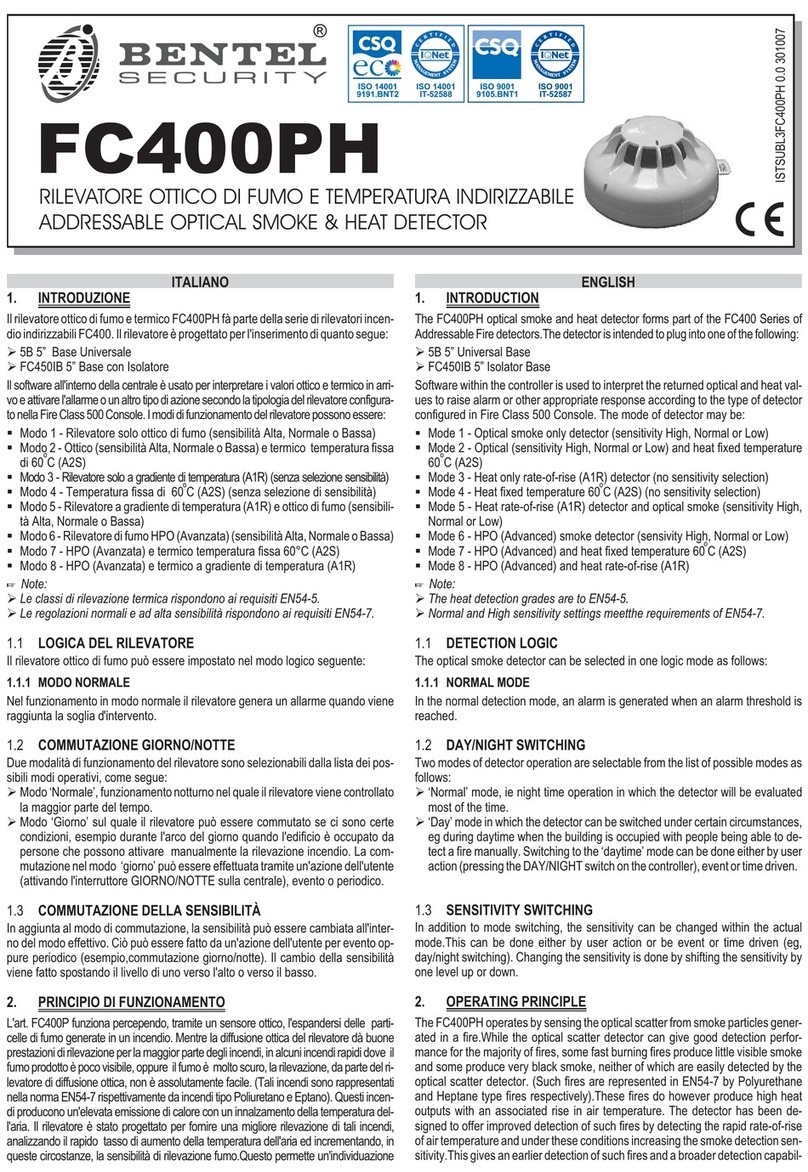

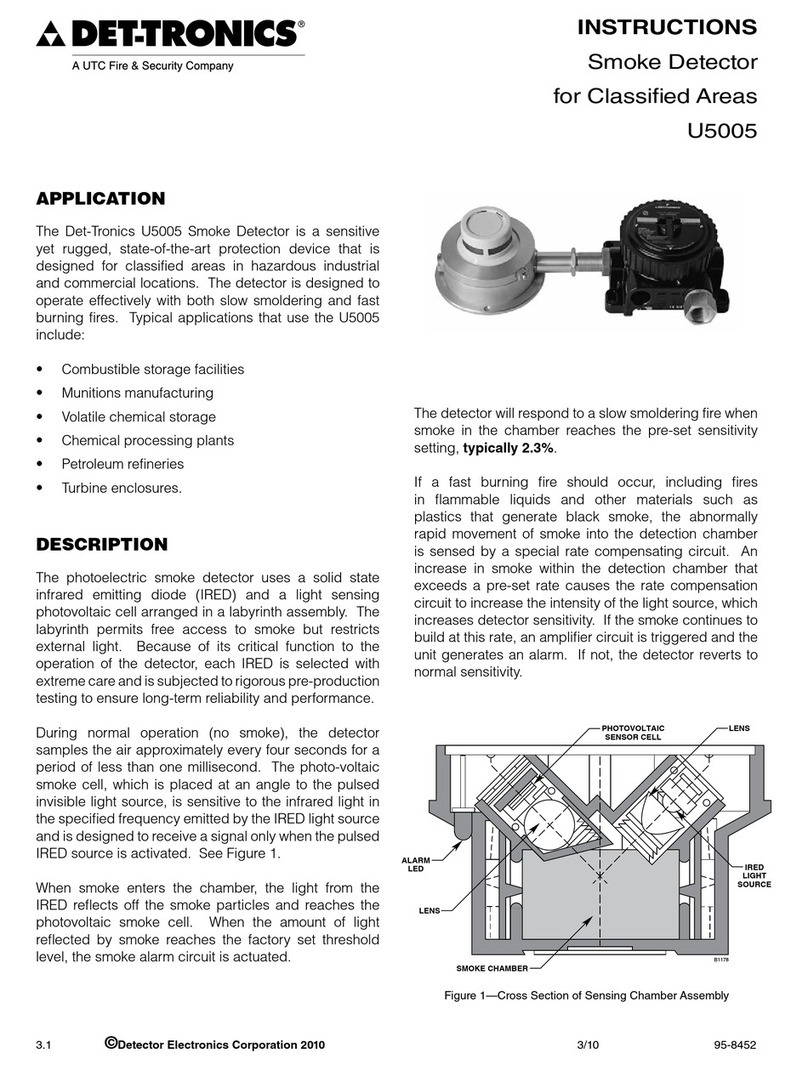

LED

RELAY

JUMPER SETTING

SMOKE CHAMBER

FIG. 3 Schematic of detector structure

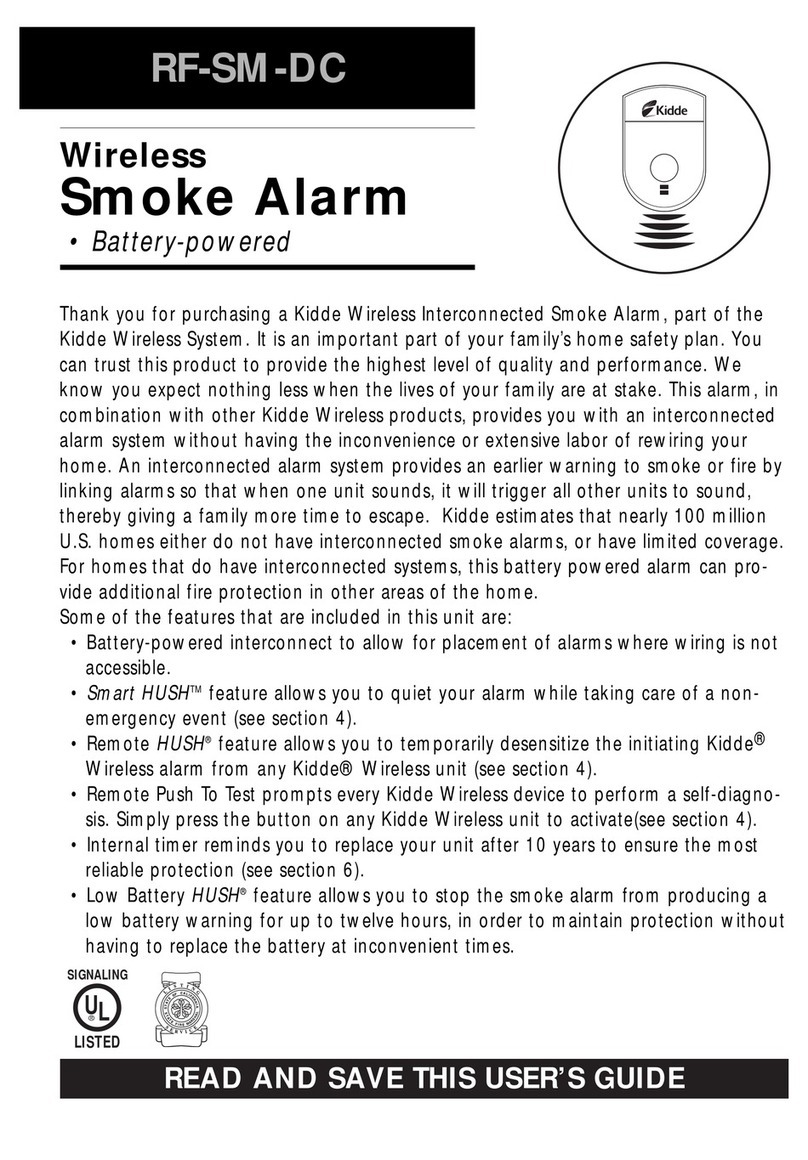

Model 2/4 wire Voltage DC

Standby

Current

(Max.)

Alarm

Current

(Max.)

Surge

Current

(Max.)

Start-Up

Time

(Max.)

Permissible

Current

(Max.)

Frequency Alarm

contact

ZT100P 228/12 V 90 µA50 mA 120 µA60 s 80 mA 3-5 s

ZT100PL 228/12 V 90 µA50 mA 120 µA60 s 80 mA 3-5 s

ZT100PR1 412 V 320 µA35 mA 120 µA60 s 80 mA 3-5 s Form A

ZT100PR2 424 V 320 µA35 mA 120 µA60 s 80 mA 3-5 s Form A