Bentone BG 300LN Technical specifications

1172 115 07 05-01

Installation- and maintenance instruction

BG300LN

178 026 72

1

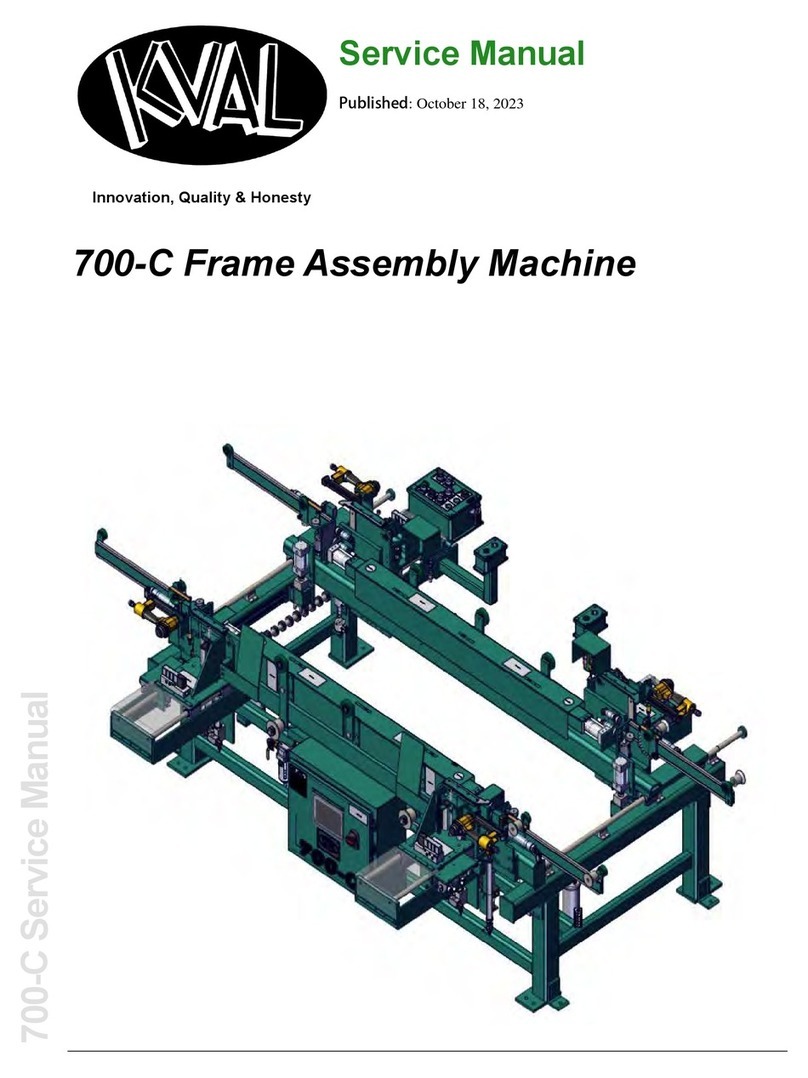

DESCRIPTION BG300/400LN

1. Switch man-aut

2. Switch 0-1

3. Change -over switch

increasedecrease

4. Indicating lamp Stage 1

5. Reset button

6. Air pressure switch

7. Damper motor

8. Connection flange

9. Blast tube

10. Gas nozzle

11. Connection gas fittings

12. Multibloc

13. Air intake

14. Shut-off cock

15. Cover, inspection glass

16. Transformer

17. Gas burner control

18. Electric panel

19. Electrical connection

20. Motor

172 205 99 03-01

14

15

16

17

18

19

20

45 6

3

178910

2

13

11

12

1172 215 53 03-01

TECHNICAL DATA

Type designation BG 300LN

The above dimensions are max. measurements. Depending on the com

ponents used, the measurements may vary.

Lengthof Measure A

Standard 230 217

ø110

M10

ø175-240

1/2

245185

ø100

ø108

330

220

485 A345

2172 215 53 03-01

TECHNICAL DATA

Type designation BG 300LN

Connection 3) Motor Ignitiontransformer

Naturalgas

1-fas, 0,18 kW Primary 230 V, 1 A

1" 2 800 r/m, 230 V Secondary 8 000 V

1,3 A

1) G20 = Natural gas Calorific value 10 kWh/Nm3

G25 = Natural gas Calorific value 8,2 kWh/Nm3

2) Dimension and capacity depending on gas quality and

available pressure

Output range

Capacity Gas volume at a min.Gas volume at a max Max. inlet Rated inlet pressure

kW output Nm3/h 1) output Nm3/h 1) pressurembar mbar

G20 51-120 kW1) G20 5,1 G20 12 360 20

G25 45-120 kW G25 5,5 G25 14,6

Capacity chart according to EN 676

2/2

6172 415 05 03-01

SKELETON DIAGRAM

2-stage or modulating burners

1. Ball valve

2. Filter

3. Governor

4. Pressure gauge with shut-off cock

5a. Gas pressure switch, mini

5b. Gas pressure switch, maxi

6a. Main valve, 2 -stage. When modulating operation is required,

this valve is equipped with controls for variable opening.

6b. Safety valve

1)7. Valve proving system

8. Air damper motor

9. Air pressure switch

10. Gas burner control

Pos. 5b, 7: Components not required according to EN 676.

1) Required over 1200 kW according to EN 676.

When biogas is used, Bentone shall always be contacted.

7

6b 6a

5a

4

2

1

5b

10

9

8

3

Incorporated in the MultiBloc

7

MOUNTING ON THE BOILER

Fit the burner to the boiler by means of 4 bolts M10 (do not forget the

flange gasket). For flange and bolt dimensions see Technical Data or use

the fixing flange as a pattern. If for some reason you want to separate the

combustion part from the fan housing part to mount the burner on the

boiler, see General Instructions.

Mounting of the multi-bloc on the burner

Connect the multi-bloc to the burner head. Connect PLto the fan housing.

Connect the two cables by means of the plug-in contact to the multi-bloc.

Do not mix up the cables to the valves and to the gas switch.

IMPORTANT! The burner cannot start, if these cables have been mixed

up. Do not forget to connect the plug-in contact to the leakage control,

if any.

Installation example

Connect the gas to the burner by means of the ball valve. Ensure that the

union nut, ball valve and tubing make it easy to remove the burner for

inspection and service.

172 155 01 03-01

a

PL

8172 425 51 08-01

*

ELECTRIC EQUIPMENT

Gas burner control: LMG22/LME22

Wiring diagram

1(2)

* If there is no Plug-in contact (X4,X16) on the boiler,

connect to the contact enclosed.

9172 425 51 08-01

ELECTRIC EQUIPMENT

List of components

A1 Gas burner control S12 Change-over switch, Increase-

A2 Power control Reduce

B1 Ionization electrode S15 Control thermostat, 3-pole

F1 Operating fuse (only for 2-stage sliding)

H1 Operating lamp T1 Ignition transformer

H3 Alarm signal 230 V X1 Connection terminal board

M1 Burner motor X2 Earth terminal

M2 Damper motor, X3 Plug-in contact, burner

L&S SQN75.624A21B X4 Plug-in contact, boiler

P1 Time meter, X15 Plug-in contact, power

total operating time controller, burner

S1 Operating switch X16 Plug-in contact, power

S3 Control thermostat controller

S4 Temperature limiter S9 Gas pressure switch

S5 Micro switch for hinged door Y1 Gas solenoid valve 1

S7 Main switch Y3 Safety solenoid valve

S8 Air pressure switch

S11 Change-over switch,Aut.-Man.

Mains connection in fuse in accordance with local regulations.

2(2)

Gas burner control: LMG22/LME22

Function

1.Operating switch ON-Thermostat ON-Gas pressure switch ON-Air

damper closed.

A control is made that the air pressure switch does not indicate fan

pressure. Then the burner motor starts.

2.Air damper motor opens.

The air damper motor opens the damper to max. position. A control is

made that the air pressure switch indicates sufficient fan pressure.

3.Air damper motor closes.

The air damper motor closes to min. load position. Then the ignition spark

is formed.

4.Main and safety valves open.

The gas is ignited. The ionization electrode indicates a flame.

5.The safety time expires.

The ignition spark goes out. The safety time expires. If there is no flame or

if for some reason the flame disappears after this time limit, the burner

control locks out.

6.Operating position.

The burner is in operating position and can now change over to the capa-

city controlled by the regulator.

7.Stop. The operation of the burner can now be interrupted by means of

the operating switch or the thermostat.

The control locks out. The red lamp in the control is lit. Restart the burner by pressing the reset

button.

21

Error code table

Blink code Possible cause

2 x • No establishment of flame at the end of «TSA»

•• - Faulty or soiled detector electrode

- Faulty or soiled fuel valves

- Poor adjustment of burner

3 x • Air pressure monitor does not close

••• - «LP» faulty

- «LP» incorrectly adjusted

- Fan motor does not run

4 x • Air pressure monitor does not open or extraneous

light on burner startup

•••• - «LP» faulty

- «LP» incorrectly adjusted

5 x • Extraneous light during pre-purging

••••• - Or internal device fault

7 x • Loss of flame during operation

••••••• - Poor adjustment of burner

- Faulty or soiled fuel valves

- Short-circuit between detector electrode and ground

8...17 x • Free

••••••••

..................

••••••••••

•••••••

18 x • Air pressure monitor opens during pre-purging or

operation

•••••••••• - «LP» incorrectly adjusted

•••••••• - Four times loss of flame during operation (LMG25)

19 x • Faulty output contact

•••••••••• - Wiring error

••••••••• - External power supply on output terminal

20 x • Internal device fault

••••••••••

••••••••••

172 425 57 08-01

ELECTRIC EQUIPMENT

Control diagnosis under fault conditions and lockout indication

Gas burner control: LMG ...

Diagnosis of cause of fault After lockout, the red fault LED is steady on. For reading the cause of fault,

refer to the blink code given in the following table:

During the time the cause of the fault

is diagnosed, the control outputs are

deactivated.

- The burner remains shut down

- Exception: fault status signal «AL»

at terminal 10

The burner is switched on only after

a reset is made.

- Press lockout reset button for

0.5...3 seconds

AL

FS

Red LED on

Blink code

LED on (waiting time 10 s)

Fault

Press lockout reset button

for > 3 s Blink code Off

Approx.

3 s

Connecting signal amplifier A1 = LMG

GP

R/W

LN

br bl rt sw

sw rtQ1 = AGQ 2...

QRA

11112 2

22 172 445 02 08-01

ELECTRICAL EQUIPMENT

Control program when disruption; disruption display

Gas burner control: LME....

Diagnosticsalarm trigger

Colourcodes

Limit on start attempts

LME 11 … limits the number of start attempts if the flame does not ignite on start-up

or goes out during operation. LME 11 … permits a maximum of three start attempts

if the start cycle is uninterrupted.

The red alarm signal lamp lights continuously after the alarm is disconnected.

Diagnostics for alarm triggers can be read as specified by the following sequence:

Colour code table for multi-coloured signal lamps (Light diodes)

Status Colour codes Colours

Waiting time «tw», other waiting times Off

Ignition phase, ignition checked Flashingyellow

Normaloperation Green

Operation, poor flame signal Flashinggreen

Prohibited flame signal during start up Green-Red

Undervoltage Yellow-Red

Disruption,alarm Red

Flashing code for fault codes Flashingred

Interfacediagnostics Redflickering

Continuous

Off

Red

Yellow

Green

1(2)

Light period (waiting time 10 s)

AL

FS

Flash code Pause Flash code

Approx. 3 s

lights red Press the reset

button > 3 s

23 172 445 02 08-01

Alarm control table

ELECTRICAL EQUIPMENT

Control program when disruption; disruption display

Gas burner control: LME....

During alarm trigger diagnostics, control outputs are to be disconnected from all power.

- The burner is disconnected

- Exception, the «AL» alarm signal at connection block 10

The burner is only to be reconnected after it is reset

- Press the reset button 0.5...3 s.

To switch to interface mode, hold the reset button depressed for more than 3 s. To return

to normal mode, hold the reset button depressed for more than 3 s. If the firing unit is in

the alarm mode, it is reset by pressing the reset button 0.5...3 s.

Interfacediagnostics

Connecting signal amplifier

2(2)

Red flashing code on Possible causes

signal lamp (LED)

Flashing 2 x No flame at End of «TSA»

•• - Defectiveor obscured flame monitor

- Defectiveorobscuredfuelvalves

- Poorburner installation

- Defectiveignitionunit

Flashing 3 x «LP»defective

••• - No air monitor signal after «t10»

- «LP» is welded in the open position

Flashing 4 x Prohibited flame signal during start up

••••

Flashing 5 x Time out «LP»

••••• - «LP» is welded in the closed position

Flashing 6 x Free

••••••

Flashing 7 x Too many loss of flame during operation

••••••• - Poorburner installation

- Defectiveorobscuredfuelvalves

- Defectiveor obscured flame monitor

Flashing 8 x Free

••••••••

Flashing 9 x Free

•••••••••

Flashing 10 x Connection fault or internal fault,

•••••••••• outgoing contacts or other fault

Flashing 14 x CPI contact not closed

••••••••••

••••

A1 = LME

GP

R/W

LN

br bl rt sw

sw rtQ1 = AGQ 3...

QRA

11112 2

33 172 205 34 07-01

MEASURES AND CHECKS BEFORE START-UP

2-Stage or modulating burners

General rules Care should be taken by the installer to ensure that no electrical cables or

fuel/gas pipes are trapped or damaged during installation or service/

maintenance.

Inner assembly Ensure that the ignition and ionisation electrodes are correctly adjusted.

The sketch (see separate page) shows the correct measurements.

Gas quality Ensure that the burner head is meant for the gas quality to be used

(see fig.).

Venting The gas line is vented by loosening the screw on the test nipple for the inlet

pressure. Connect a plastic hose and conduct the gas into the open air.

After having vented the gas line tighten the screw again.

Electric function test: Ensure that phase and neutral are not reversed. The gas shut-off cock

should be closed.To prevent the gas pressure switch from locking out,

it should be linked temporarily.

After the main switch has been switched on and the thermostats have

been adjusted, the pre-purging period begins (30-35sec.). At the end of

this period the pre-ignition period starts (0,5-2,5 sec. depending on the

design of the gas control). The gas valve is energized and opens and flame

is established. At the end of the safety time (2-3 sec.) the gas control

locks out. The solenoid valve and the motor will be "dead". Remove the link

from the gas pressure switch after the test is finished.

Note on 2-stage and modulating burners that during the pre-purging period

the damper opens to the set value for air on stage 2 and just before the end

of the pre-purging period it goes down to the air setting for stage 1. On

some burners under 350kW the pre-purging mainly takes place with the air

damper set for stage 1.

NOTE! Applies only to gas burner control LFL1.

When using LPG (Propane) the burner should be connected for post-purging.

Move the connection on terminal 6 to terminal 7 in the base of LFL1.

Leakage control When making a leakage control of the gas supply system, the solenoid

valve should be closed. Connect a pressure gauge to the test nipple Pa,

see fig. The test pressure in the system should be 1,5x max. inlet pressure

or min. 150 mbar. If any leakage, locate the source by means of soapy

water or a leak location spray. After tightening repeat the test.

Gas train Multibloc

14 172 155 05 01- 01

EASURES AND CHECKS BEFORE START-UP

BG300 / 400LN

Gas nozzle assembly

Natural gas

4-5

12-14

2

36

DETERMINATION OF GAS VOLUME FOR THE INSTALLATION

Specifications on natural gas, town gas and biogas vary. For more exact

information please contact the gas distributor.

Example how to calculate the gas volume (natural gas)

V = Gas volume Nm3/h

Q = Boiler output 120 kW

Hu= Calorific value of the gas A. 37 144 kJ/Nm3, B. 10.3 kWh/ Nm3

η= Expected efficiency 90%

Ex. A

Ex. B

If the barometer height, pressure and temperature of the gas deviate con-

siderably from the normal values this must be taken into account as follows:

f=

t = Temperature of the gas at the gas meter (15°C)

B = Barometer height (945 mbar)

Pu= Pressure of the gas at the gas meter (15,0 mbar)

f=

f≈1.11

The gas volume read on the gas meter actually reads 1,11 .12,9 = 14,4 m3/h.

172 205 16 03-01

Net calorific value

Gas quality kWh/Nm3kJ/Nm3kcal/Nm3

Natural gas 10.3 37 144 8 865

Propane 26.0 93 647 22 350

Butane 34.3 123 571 29 492

Town gas 4.9 17 653 4 213

Biogas 7.0 25 219 6 019

273+15

273 .1013,25

945+15

V=120

10,3 · 0,90 ≈12,9 Nm3/h

B+Pu

273+t

273 .1013,25

120 .3 600

37 144 .0,90

V=Q .3 600

Hu · η =≈12,9 Nm3/h

16 172 205 43 03-01

DUNGS COMBI BLOC WITH RATIO ADJUSTMENT

MB-VEF BO1, 407

View

1. Electrical connection gas pressure switch mini

2. Electrical connection gas valve

3. Pressure switch mini

4. Flange connection inlet

5. Test point connection 1/8" before V1

6. Filter

7. Data plate

8. Connection 1/8" PL

9. Adjustment screw V for ratio PBr: PL(max. load)

10. Test point connection 1/8" before V1(before governor)

11. Connection M4 for measurement of burner presssure after V2

12. Adjustment screw for zero point adjustment N (min. load)

13. Test point connection 1/8" PF

14. Test point connection 1/8" PBr

15. Flange connection, outlet

16. Test point connection 1/8" Pabefore V2(after governor)

17. Indication of V1and V2in operation (not standard)

1)18. Impulse line PBr (gas pressure)

19. Impulse line PL(air pressure)

20. Impulse line (fire room)

It is possible to connect a leakage control VPS 504 and a gas pressure

switch maxi.

1)NOTE!

The impulse line PBr can be replaced by an impulse flange on

the multiblock.If so, the impulse line PBr is placed included in the flange.

46

MULTI-BLOC, MB-VEF 412 - 425 B01

Technical data

- Max inlet pressure 360 mbar

- Valves V1+V2class A group 2 in accordance with EN 161

- Governor class A group 2 in accordance with EN88

- Ratio V PBr:PL 0,75:1-3:1

- Filter according to DIN 3386

- Ambient temperature -15°C- +70°C

- Protection standard type IP54 (according to IEC 529, DIN 40050)

- Gas family 1 +2 +3

- Outlet pressure 0,5 - 100 mbar

- Zero point adjustment N ±2 mbar

- Pressure switch DIN3398 TI

- Fan pressure PL0,4-100 mbar

- Fire room pressure PF -2 -+5mbar

- Burner pressure PBr 0,5 - 100 mbar

Mounting instruction - impulse lines PL, PFand PBr

- Impulse lines should preferably be made of steel. Inside diametre

>ø 4 mm (steel tube ø 6/4)

- For PLother material can be used.

- Impulse lines PLand PBR are ready from factory

- Impulse lines shall be mounted in such a way that no conden sate

can flow back into the multibloc.This is especially important

when PFis concerned.

- Impulse lines shall be mounted in such a way that they are

protected against rupture and damage.

- Impulse lines shall be as short as possible

Adjustment possibilities

Adjustment range

PBr = PBr - PF

PL= PL-PF

Effectiveburnerpressure

Effectivefanpressure

!

!

172 215 16 03-01

pBr,min =0,5mbar

PL, max. = 100 mbar

PBr , max. = 100

pL,min =0,4mbar

V = 3:1

V = 1:1

V = 0,75:1

V = 3:1

V = 1:1

V = 0,75:1

V

+ N

- N

1172 305 68 03-01

ADJUSTMENT OF GAS FLOW

- Before the burner starts vent the lines to make sure that there is gas

available at the multibloc

- Use an allen key size 2,5 mm for adjusting N and V.

- Connect a pressure gauge for measur-ing PBr, (advisable to find out if

the valves are open)

- Set the switch in position MAN.

- Set the gas pressure switch min. and air pressure switch on min.

adjustment. Set the gas pressure switch max, if any, on max.

adjustment.

- Start the burner, observe the pressure gauge, if no flame is established

and the pressure gauge needle does not flicker, increase N. When the

flame is established adjust the gas flow by means of the screw N. Use

a flue gas instrument.

- Change over to max. load, press the switch “increase”

- Adjust the gas flow with V and check at the same time the

combustion values.

- Go back to min. load and check the combustion value. Adjust if

necessary.

- If necessary repeat the controls of the adjustment made on min. (N)

and max .load(V)

- The desired gas flow on min. and max. has now been adjusted by

changing the orange and the red cams. Check the gas flow on the gas

meter available on the installation.

Note! Do not forget to set the air and gas pressure switches after the

adjustment, see special instructions.

Damper motor, air volume

Adjust the orange cam for min. load (about 5-10 on scale)

Adjust the red cam for max. load (90° )

The blue cam is factory set for closed position during standstill

The black cam has no function at modulating operation

Releasing button

By pressing the button and snapping it down, the motor will be released

and the damper can easily be turned. This function facilitates an

exchange of damper motor..

Max. load (red)

Min.load (orange)

Closeddamper(blue)

Gasvalve(black)

Releasing button N.B.

The upper position is

o

18 172 305 61 03-01

GENERAL INSTRUCTIONS

General instructions

The installation of the gas burner must be carried out in accordance with

current regulations and standards. The installers of gas burners should

therefore be acquainted with all regulations and ensure that the installation

complies with the requirements. The installation, mounting and

adjustment should be made with the greatest care and only the correct

gas should be used

Operating instructions

The operating instructions accompanying the burner should be left in a

prominent position in the boiler room.

Instructions

The user should be thoroughly instructed in the function of the gas burner

and the whole installation. The supplier must instruct the user.

Inspection and maintenance

Daily inspection is advisable.

Start up

After the burner has been fitted to the boiler and the electric connection,

the leakage control, the venting and the electric function test have been

carried out, the burner will be ready for start-up.

Howerer, study the sections dealing with adjustments of multi-bloc,

combustion air and combustion head.

Open the ball valve and switch on the main switch. If the burner starts the

actual adjustment can be made.

Commissioning of installation

Control of the combustion. The combustion quality is checked by means

of a flue gas analysis device. Adjust the burner to appr. 20% excess air in

accordance with the table. Check the flue gas temperature. Calculate the

efficiency. Check also the actual gas volume on the gas meter so that the

correct input is achieved.

Service

Service should be carried out by qualified personnel.

Replacement parts should be of the same make and approved by the same

authorities as the original. If the burner is converted to fire, another gas

quality it must be re-commissioned. If town gas is to be fired, the combustion

head must be converted and the gas train adjusted to suit (i.e. larger

gas armature or a different spring in the governor may be required).

Important

To get as low emissions as possible, the burner, the boiler and the

chimney must be adapted to each other.

Gas quality CO2%0

2% max CO2%

lambda1,2

Naturalgas 10,0 3,5 11,9

20 172 305 62 03-01

GENERAL INSTRUCTIONS

Adjustment of shrouded disc and burner head

The burner head is firm adjusted and there are no possibilities of

settings besides the adjustment and the inspection of the ignition

electrode and the ionisation electrode.

Inspection of burner head when multi-bloc MB...407

The burner head, the shrouded disc and the electrodes can be inspected

by following the instructions below:

Loosen the nut a, the nut bto the impulse line PL, the plug-in contacts c

and the screws d. Pull out the fan housing part. Loosen carefully the

ionisation and ignition cables. When the fan housing part is separated

from the fixing flange, the combustion unit can be checked as follows:

Loosen the screws eand pull out the combustion unit.

Note! Greatest caution at this working moment.

When making service to the burner,

switch off the electric current and the gas supply. Do not forget the gaskets

and O-rings and to check the density after the service.

This screw should be loosen when pulling out the blast tube. When re-

mounting the blast tube, push the blast tube so far into the flange that the

ring in the blast tube fits tight to the combustion head.

abce

d

Other manuals for BG 300LN

1

This manual suits for next models

1

Table of contents

Other Bentone Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

nord

nord MAXXDRIVE Customer's operating and assembly instructions

MATO

MATO CMiNDTEK EP 200-DS operating instructions

Thiele

Thiele TWN 0850/1 operating instructions

U-Line

U-Line H-1843 instructions

Endress+Hauser

Endress+Hauser Stamoclean CAT430 operating instructions

AGI BATCO

AGI BATCO 1500 Series Operator's manual