Bentone BFG 1-2 H3 Technical specifications

Providing sustainable energy solutions worldwide

Installation- and maintenance instruction

BFG 1-2 H3

LME22.233C2

MB-ZRDLE 407

178 088 35-7 P93783 2023-01-11

Translation of the original instructions.

2Bentone

example Beispielexempel

352011030141

Designation

Type

Model

Serial no.

Motor supply

Main supply

MADE IN SWEDEN BY

LIGHT OIL 35-90kW 1,25-6,0 cSt 7-14bar

BF 1 KS 76-24

BF 1

BF 1 KS 76-24

1234567

1~230V 1,0A 50Hz IP 20

Man.Year 2019

Cap. Min-Max

3

?

1

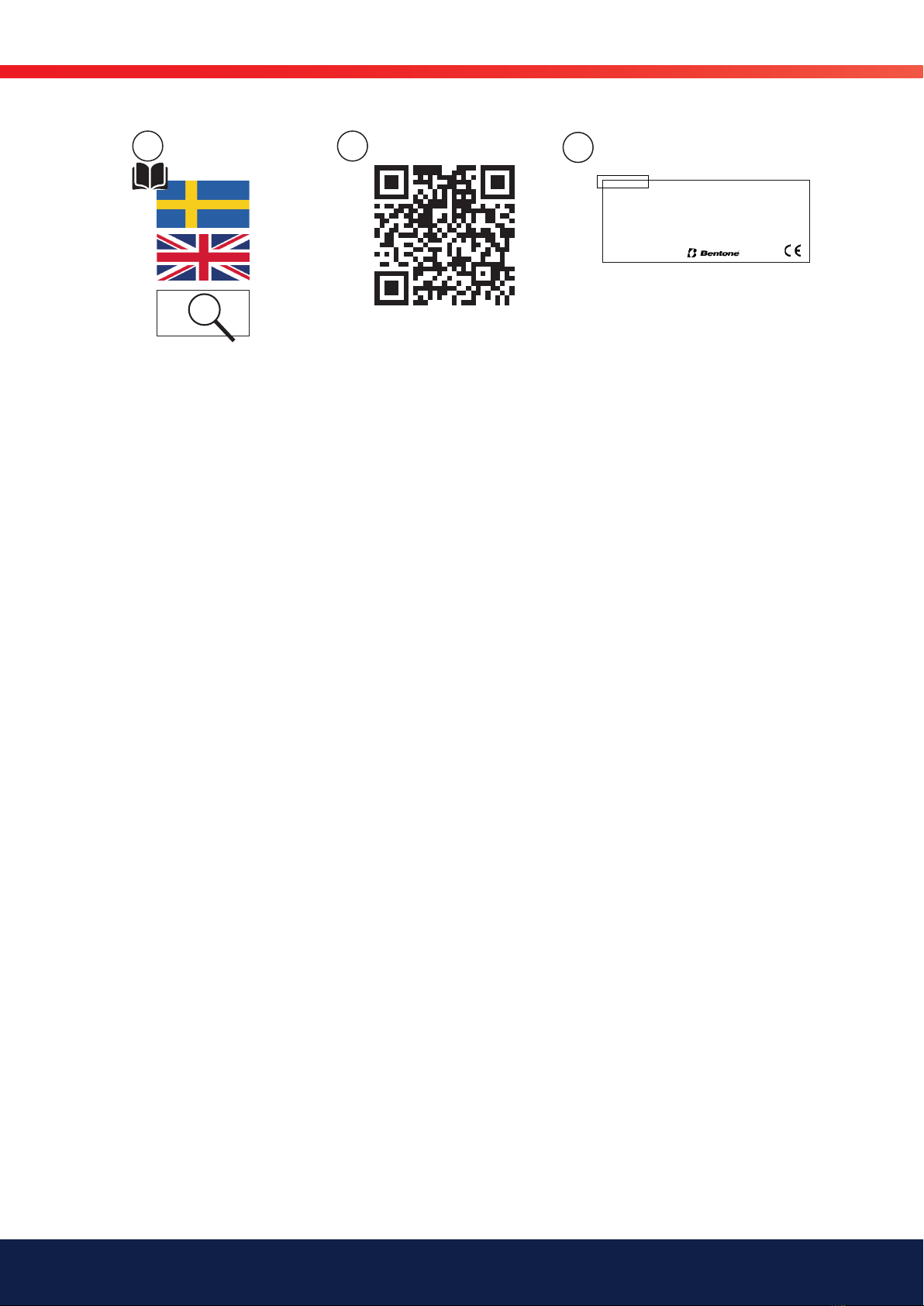

-sv

1. Manualer på övriga språk

2. www.bentone.com\

nedladdning eller scanna

QR-koden.

3. Skriv in brännarens

artikelnummer som nns på

din typskylt (se bild) och välj

ditt språk.

Detaljerad ecodesign

information kan laddas ner

på: www.bentone.com/

ecodesign.

-en

1. Manuals in other languages

2. www.bentone.com\

download or scan QR-code.

3. Enter the burner`s article

number on your data plate

(see picture) and select

language.

Detailed ecodesign

information can be

downloaded at:

www.bentone.com/

ecodesign.

-da

1. Manualer på andre sprog

2. www.bentone.com\

download eller scan

QR-koden.

3. Indtast brænderens

artikelnummer, der ndes

på typeskiltet (se billede), og

vælg dit sprog.

Detaljerede oplysninger om

ecodesign kan downloades

på: www.bentone.com/

ecodesign.

-fr

1. Manuels dans d’autres

langues

2. www.bentone.com\

download ou scannez le

code QR.

3. Saisir le numéro d’article

du brûleur sur votre plaque

signalétique (consultez

l’illustration) et sélectionnez

la langue.

Des informations détaillées

sur l’écodesign peuvent être

téléchargées à l’adresse:

www.bentone.com/

ecodesign.

-de

1. Gebrauchsanweisungen in

anderen Sprachen

2. www.bentone.com\

download oder scannen Sie

den QR-Code.

3. Geben Sie die

Artikelnummer des Brenners

auf Ihrem Typenschild ein,

(siehe Bild) und wählen Sie

die Sprache aus.

Detaillierte Informationen

zum Ecodesign können unter

www.bentone.com/ecodesign

heruntergeladen werden.

2

3Bentone

Table of contents

1. General Information............................................................4

1.1 Delivery inspection........................................................................ 4

1.2 Safety ............................................................................................... 4

1.3 What to do if you smell gas......................................................... 5

2. Technical data.......................................................................6

2.1 Dimensions BFG 1-2 H3............................................................... 6

2.2 Capacity range............................................................................... 7

2.3 Gas categories, approved gases................................................ 7

2.4 Technicalspecication ................................................................. 7

2.5 Model BFG 1 H3 ............................................................................ 8

2.6 Components................................................................................... 9

2.7 Skeleton diagram........................................................................ 11

3. Installation..........................................................................12

3.1 General instructions................................................................... 12

3.2 Instructions .................................................................................. 12

3.3 Inspection and maintenance.................................................... 12

3.4 Preparation for assembly ......................................................... 12

3.5 Gas supply .................................................................................... 12

3.6 Electric connection ..................................................................... 12

4. Electric equipment.............................................................13

4.1 Safety system .............................................................................. 13

4.2 Wiring diagram............................................................................ 13

4.3 Function LME... ............................................................................ 14

4.4 Control program at faults; fault mode indicator LME .... .... 15

5. Mounting ............................................................................17

5.1 Hole pattern................................................................................. 17

5.2 Burner installation ...................................................................... 17

5.3 Gas connections.......................................................................... 17

5.4 Electric connection ..................................................................... 17

5.5 Gas quality.................................................................................... 18

5.6 De-aerating................................................................................... 18

5.7 Tightness control ........................................................................ 18

5.8 Calculationofgasow.............................................................. 19

6. Settings ...............................................................................20

6.1 Brake plate adjustment ............................................................. 20

6.2 Air adjustment ............................................................................. 20

6.3 Startup........................................................................................... 21

6.4 Control of combustion .............................................................. 21

6.5 Settingtheairpressureswitch ................................................ 22

6.6 Settingthegaspressureswitch,min...................................... 23

7. Gas valve, MultiBloc ZRDLE 405-420................................24

8. Service .................................................................................27

8.1 Burner Service Schedule, Gas .................................................. 27

8.2 Component replacement intervals.......................................... 27

8.3 Combustion device ..................................................................... 28

8.4 Fan motor replacement............................................................. 29

8.5 Air intake and suction cone ...................................................... 30

8.6 Fanwheel...................................................................................... 32

8.7 Electrical package ....................................................................... 33

8.8 Controlofamemonitoringandionizationcurrent ........... 35

9. Handing over of the installation ......................................37

10. Troubleshooting.................................................................38

11. Service- and inspection protocol .....................................40

4Bentone

172 515 01-2 2021-10-05

1. General Information

The burner may only be used for its intended purpose in accordance with the

product’s technical data.

We reserve the right to make design changes and cannot be held liable for any

misprints or typographical errors.

Modifying the design or using accessories or components that have not been

approved by Enertech in writing is strictly prohibited.

This Installation and Maintenance manual:

• is to be regarded as part of the burner and must always be kept near

the installation site.

• must be read prior to installation.

• is intended for use by authorised personnel.

1.1 Delivery inspection

• Make sure everything is delivered and the goods have not been

damaged during transit. Transport damage should be reported to the

shipping company.

• If something is wrong with a delivery, report it to the supplier.

1.2 Safety

- before installation:

• Installation and work on the burner and associated system

components may only be carried out by persons who have undergone

relevant training.

• The product is packaged to prevent damage from occurring when

handled – Handle the product with care! Lifting equipment must be

used to lift larger packages.

• The products must be transported/stored on a level surface in a dry

environment, max. 80% relative humidity, no condensation.

Temperature -20 to +60 °C.

- installation:

• The burner must be installed in accordance with local regulations for

re safety, electrical safety, and fuel distribution.

• The premises must comply with local regulations pertaining to use of

the burner and must have adequate air supply.

• The installation site must be free of chemicals.

• Fire extinguisher with Class BE recommended.

• Make sure when installing the burner that there is enough space to

service the burner.

• The electrical installation must be professionally carried out in

accordance with current mains electricity regulations and in a

professional manner.

• Make sure that the burner is suitable for the application (see Technical

Data).

• All components must be installed without being bent, twisted or

subjected to mechanical or thermal forces that affect components.

5Bentone

• Care must be taken by the installer to ensure that no electrical cables

or fuel lines are pinched or otherwise damaged during installation or

service.

• Sharp edges can occur on, for example: ame tube, fan wheel and air

damper.

• The gas outlet from the pressure regulator must be con gured in

accordance with applicable regulations and lead to a safe area.

- before rst start:

• The burner must not be put into operation without proper safety and

protection devices.

• Permitted ambient temperature during operation -10 to +60 °C. Max.

80% relative humidity, no condensation.

• The surface temperature of the burner’s components may exceed

60 °C.

• Handle with caution – the burner has moving parts, and there is risk

of crushing injuries.

• Seal inspections must be performed during installation and servicing

to prevent leakage.

• Fitting and installation work has been completed and approved.

• Electrical installation has been correctly performed.

• Flue gas ducts and combustion air ducts are not blocked.

• All actuators and control and safety devices are in working order and

correctly set.

• If the boiler is equipped with an access hatch, this must be equipped

with a hatch opening switch connected to the burner’s safety system.

• When in operation, the burner’s noise level can exceed 85 dBA – use

hearing protection!

- Operation:

• Carry out all stipulated settings, service and inspection work within

the set time.

1.3 What to do if you smell gas

• Turn off the fuel supply.

• Turn off the device and remove the boiler from operation.

• Open windows and doors.

• Prevent open ames or sparking, e.g. do not turn lights on or off, do

not use any electrical appliances or mobile phones.

• Evacuate the building.

• Notify the installer or gas supplier of the problem so that it can be

recti ed.

Table of contents

Other Bentone Industrial Equipment manuals