Benzlers J Series User manual

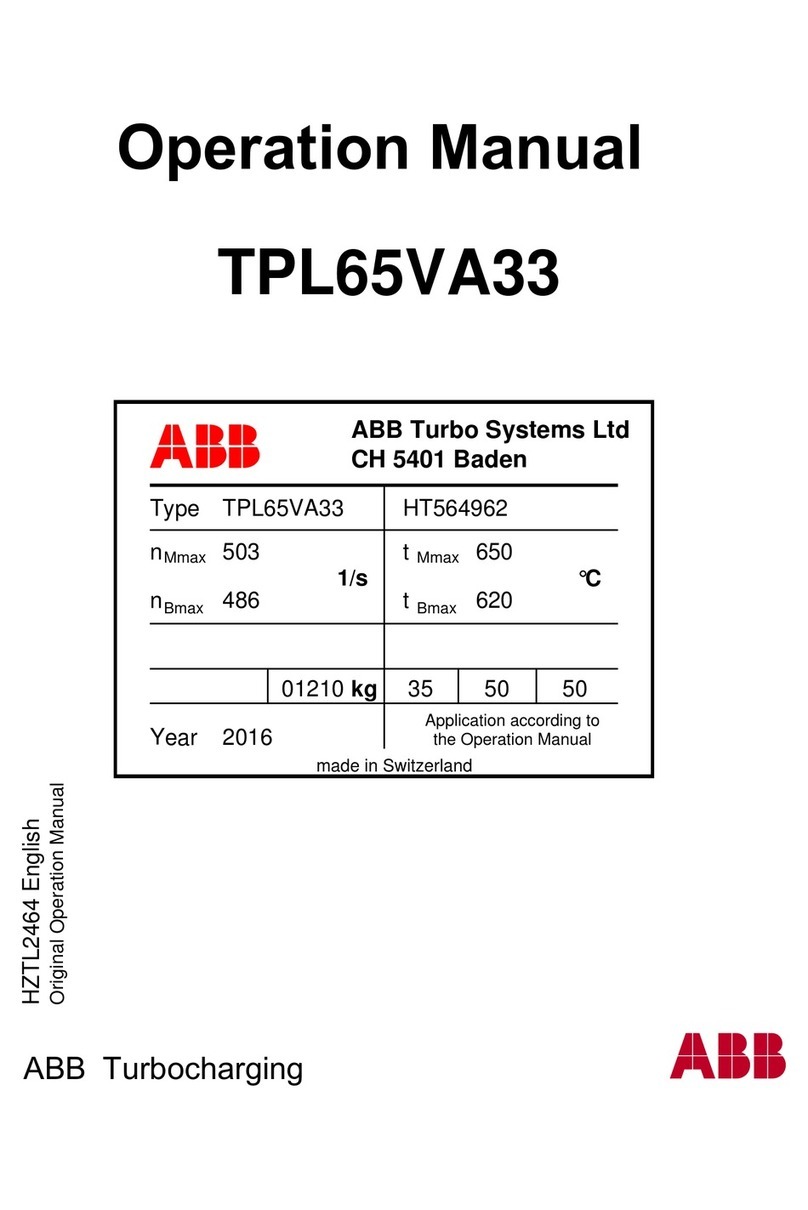

Series J Shaft Mounted Gearbox

Technical

Up to - 600kW / 57,000 Nm

Industrial Gearbox

CJ-2.00GB1211

We can create custom engineered transmission solutions of any size and configuration.

Serving an entire spectrum of mechanical drive applications from food, energy, mining and metal; to automotive,

aerospace and marine propulsion, we are here to make a positive difference to the supply of drive solutions.

We offer a wide range of repair services and many years experience of repairing

demanding and highly critical transmissions in numerous industries.

Series X

Cone Ring

Pin and bush

elastomer coupling

Series X

Torque Limiter

Overload protection

device

Series J

Shaft mounted

helical speed

reducers

Series C

Right angle drive

helical worm geared

motors & reducers

Series BD

Screwjack worm

gear unit

Series G

Helical parallel shaft

& bevel helical right

angle drive gear

units

Series X

Grid

Double flexing steel

grid coupling

Series M

In-line helical geared

motors & reducers

Series H

Large helical parallel

shaft & bevel helical

right angle drive units

Roloid Gear Pump

Lubrication and fluid

transportation pump

Series BS

Worm gear unit

Series X

Nylicon

Gear coupling with

nylon sleeve

Series A

Worm Gear units

and geared motors

in single & double

reduction types

Series X

Gear

Torsionally rigid,

high torque coupling

Series K

Right angle helical

bevel helical geared

motors & reducers

Series F

Parallel angle helical

bevel helical geared

motors & reducers

PRODUCTS IN THE RANGE

Total compliance with the ATEX Directive safeguarding the use of

industrial equipment in potentially explosive atmospheres is

assured for users of our geared products.

Certication is available for standard gearboxes and geared

motors with badging displaying the ATEX zone, name and location of

the manufacturer, designation of series or type, serial number, year of

manufacture, Ex symbol and equipment group/category.

ATEX directive 94/9/EC (also known as ATEX 95 or ATEX 100A)

enforced in all EC member states. Compliance is compulsory for

designers, manufacturers or suppliers of electrical and non-electrical

equipment for use in potentially explosive atmospheres created by the

presence of ammable gases, vapours, mists or dusts.

Ex compliant standard gearboxes can be supplied against Groups

2 or 3 for surface industries in designated hazardous location

Zones 1 and 2 for gases, vapours and mists; and in Zones 21 and

22 for dusts.

ATEX

Compliance Assured

SERIES J

SERIES J

2

Series J Shaftmounted Speed Reducers, General Description ________________________________ 4

Unit Designations ___________________________________________________________________ 5

Selection Procedure _________________________________________________________________ 6 - 7

Power ratings / Thermal power ratings

1-stage ______________________________________________________________________ 8

2-stage 15:1 __________________________________________________________________ 9 - 10

2-stage 20:1 __________________________________________________________________ 11

2-stage 25:1 __________________________________________________________________ 12 - 13

Dimensions

J 11 - 71 1-stage ______________________________________________________________ 14 - 15

J 100 - 125 1-stage ____________________________________________________________ 16 - 17

J 12 - 72 2-stage ______________________________________________________________ 18 - 19

J 100 - 190 2-stage ____________________________________________________________ 20 - 21

Selection of V-belt drives

Power ratings V-belt transmissions ________________________________________________ 22 - 52

Accessories

Threaded holes at gear house sides _______________________________________________ 53

Shaft bushings ________________________________________________________________ 54

Machine shaft dimensions _______________________________________________________ 55 - 57

KIBO Tapered bushing __________________________________________________________ 58 - 59

Motor mounts _________________________________________________________________ 60 - 61

Cooler fan/electric and oil cooler __________________________________________________ 62

Torque arm, Shock absorber and Overload protection _________________________________ 63

Shrink disc, Protection cover, V-belt protection cover __________________________________ 64

Hydraulic motors, Vertically mounted reducers _______________________________________ 65

Backstop

Backstop mounting ____________________________________________________________ 66 - 67

Installation and Maintenance

Mounting Positions ____________________________________________________________ 68

Installation ___________________________________________________________________ 68

Lubrication instructions _________________________________________________________ 69

CONTENTS PAGE

SERIES J

3

Series J

Series J Shaft Mounted Speed Reducers are high

quality products, submitted to intense quality control and

manufactured with the highest precision.

— Worldwide after sales service

— 19 types up to 600 kW, 57000 Nm

— Wide range of standard accessories

— High efciency

— Long gear and bearing lifetime

— All mounting positions possible

— Easy to mount

— Easy to change speed through change of V-belt

transmission

— Space saving

— Low noise level

— Easy to service, due to standard components

The shaft sleeve is supplied with tapped holes for dismounting

the reducer as well as locking the reducer to the shaft.*

The input shaft diameter corresponds to IEC standard for

motor shafts, thus simplifying standardization of V-belt pulleys

and couplings. Locating shoulder provided for pulleys and

couplings.

The input shaft is supplied with tapped hole for tting V-belt

pulley or locking washer for V-belt pulley.

All housing contact surfaces are ne milled thus eliminating

the necessity for gaskets and possible oil leaks.

KIBO® - One of the most cost efcient dismounting methods

that is available on the market, patented by us is available as

a standard accessory to every Series J shaft mounted speed

reducer.

Modern heat treatment of high quality gives gear wheel and

pinions the hard wearing surface and tough core necessary to

handle harsh duties.

Manufacturing tolerances comply to DIN and AGMA

specications. Helix angle and small modules give more teeth

in mesh for smooth and quiet running.

High quality bearings selected for long service life.

Backstop options are available for all double reduction units

(For single stage units on special request).

High quality close grained cast iron housing with maximum

rigidity and low weight saves space.

Torque arm bracket will stand up to tough reversible shock

load applications allowing for two torque arms to be mounted

in opposite directions.

GENERAL DESCRIPTION

* Not standard for the smallest sizes of single and double reducers.

SERIES J

4

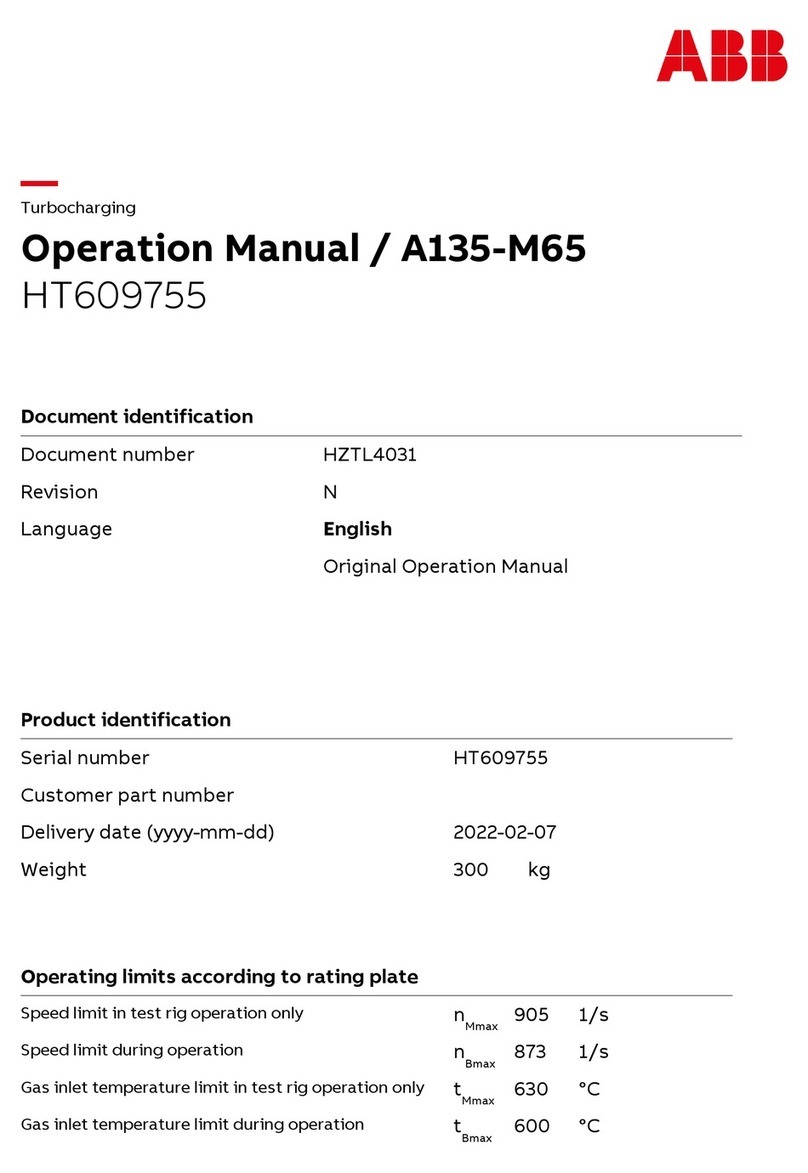

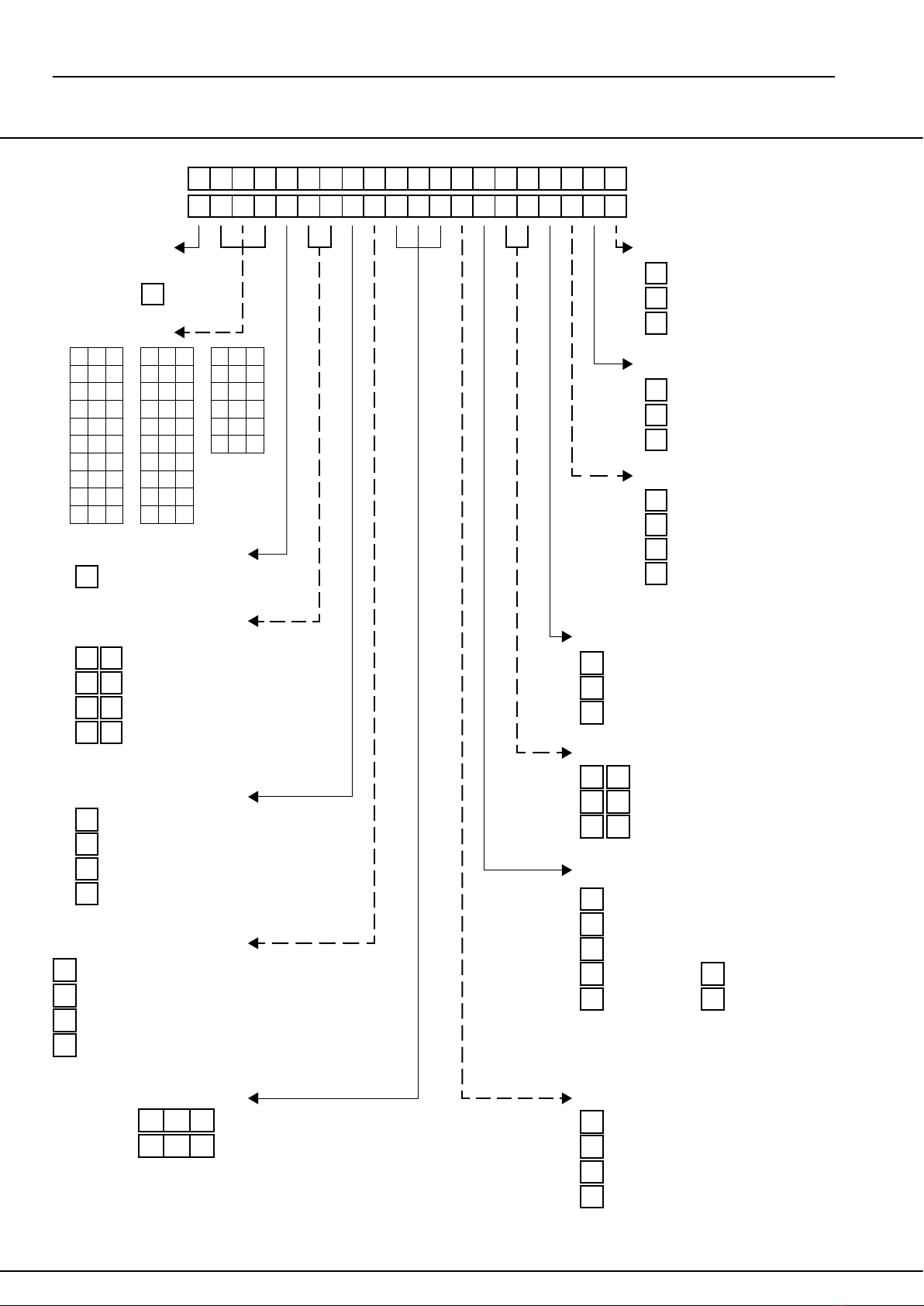

UNIT DESIGNATIONS

17 - COOLING OPTIONS (ONLY J100 - 190)

- - NO ADDITIONAL COOLING

E - ELECTRIC FAN

C - OIL COOLER

13 - INPUTSHAFT

- - STANDARD

M - MC - IEC FLANGE *

H - HD - HYDRAULIC MOTOR *

X - SPECIAL

* SPECIFY MOTOR SIZE

14 - MOUNTING POSITIONS

2 - H2 STANDARD

5 - H5 VERTICAL UP

6 - H6 VERTICAL DOWN

1 - H1 3 - H3

X - SPECIAL * 4 - H4

18 - PAINT OPTIONS

- - STANDARD

1 - SPECIAL COLOUR (ALKYD)*

2 - TWO PACK HIGH SOLID

3 - SPECIAL*

* SPECIFY TYPE AND COLOUR

19 - SEAL OPTIONS

- - STANDARD

L - LABYRINTH SEALS

T - VITON

20 - ADDITIONAL FEATURES

- - NONEREQUIRED

P - PULLEY OR/AND MOTOR

M - PRE-REDUCER TYPE M

15, 16 - BACKSTOP

- - NO BACKSTOP

B V LEFT ROTATION (Counter-Clockwise)

B H RIGHT ROTATION (Clockwise)

SEE PAGE 68

* SPECIFY INCLINATION ETC

8 - UNIT VERSION

eg - STANDARD R

1 STD RL (BALL JOINT)

2 STD RR (SHOCK ABSORBER)

3 STD RO (OVERLOAD PROTECTION)

9 - OUTPUTSHAFT

- - STANDARD HOLLOW SHAFT

K - KIBO See Hollow shaft bores page 54

S - SHRINK DISC ST

X - SHRINK DISC STX

1 - SERIES J

SHAFT MOUNTED GEARS

RANGE J

6, 7, - NOMINAL

OVERALL RATIO

eg - 5 Standard single stage

1 5 Standard double stage

2 0 Standard double stage

2 5 Standard double stage

See pages 8, 9, 10 , 11, 12 & 13

5 - REVISION VERSION

- Initial Version

2,3,4 - SIZE OF UNIT

*THIS PAGE MAY BE PHOTOCOPIED ALLOWING THE CUSTOMER TO ENTER THEIR ORDER

EXAMPLE

10, 11, 12 - BORE DIAMETER

eg 0 3 5

1 2 5

See page 54

J 1 1 A J 1 2 A J 1 0 0

2 1 A 2 2 A 1 1 0

3 1 A 3 2 A 1 2 5

5 1 A 5 2 A 1 4 0

7 1 A 7 2 A 1 6 0

1 1 B 1 2 B 1 9 0

2 1 B 2 2 B

3 1 B 3 2 B

5 1 B 5 2 B

7 1 B 7 2 B

*

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

J 1 1 0 - 2 0 - - 1 1 0 - 2 - - - - - -

SERIES J

5

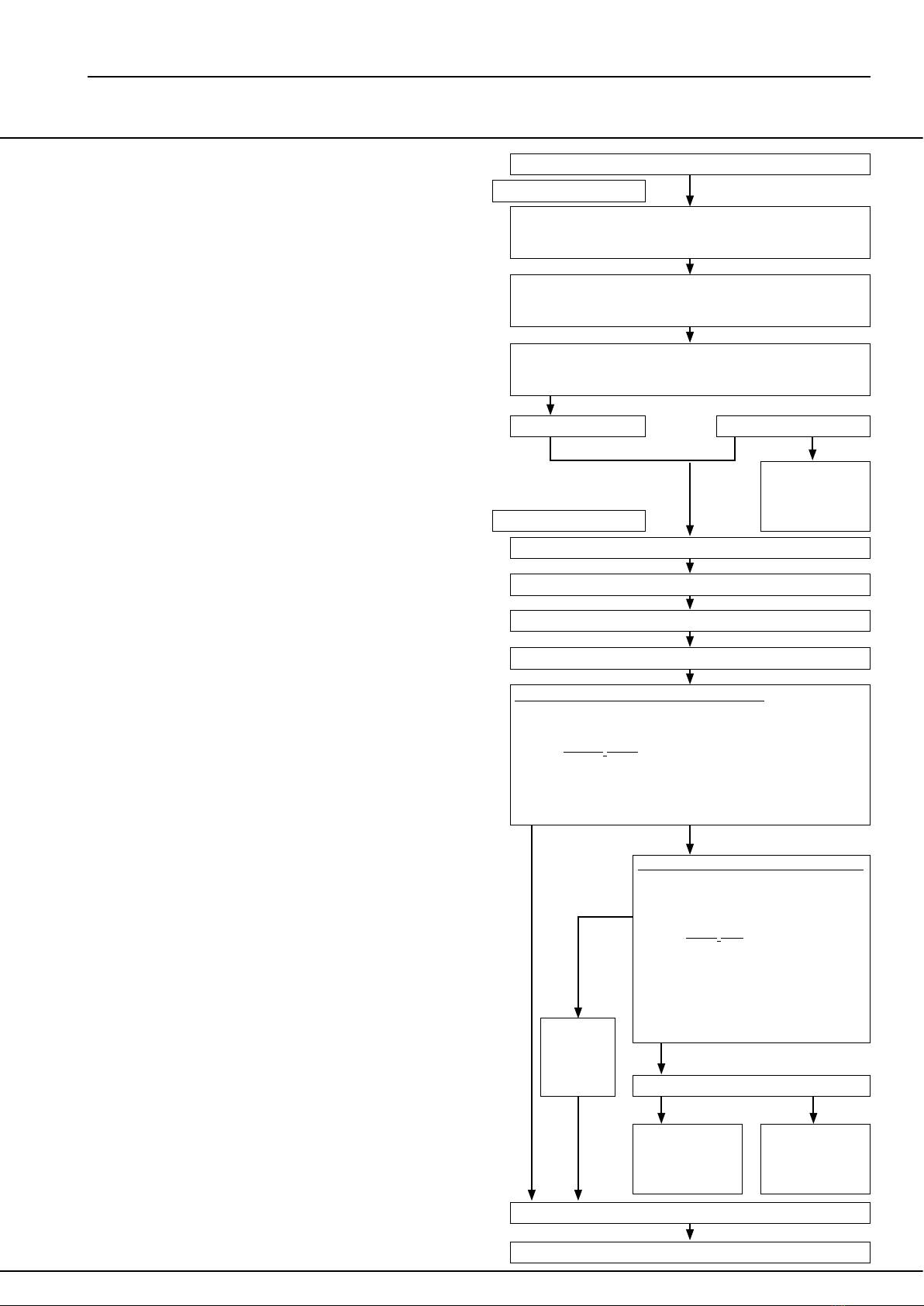

Denition of service factor

The torque ratings apply to service factor fb = 1,0.

The service factor fb = 1,0 gives continual operation 4

to 8 hours a day at a uniform load without shocks and

with 10 to 200 starts an hour. The moment of inertia of

the driven machines is less than 20 % of the electric

motor inertia and occasional peak torque may not

exceed 1,8 times the torque rating. For other running

conditions compensate with service factors according

to tables.

Denitions

Pe= Demand of power from driven machine (kW)

Te= Demand of torque from driven machine (Nm)

ne= Speed on driven machine (min -1)

Temax = Max peak torque from driven machine (Nm)

T2 = Max allowed torque at service factor fb =1,0

Thermal rating

Thermal rating is the power in kW (without service

factor) that the gear unit can transmit at continuous

operation in 1 hour or more without getting overheated.

Control of thermal rating is essential because if the

service generates more heat than it can emit, severe

damage may occur.

Thermal rating does not need to be controlled if the

duty time is less than 1 hour.

When the duty time is longer than 1 hour the gear unit

and cooling method must be selected so that the drive

transmission has enough thermal rating.

In the tables the thermal rating Pt is given in the

following conditions:

- 25 °C ambient temperature

- 0 to 750 m altitude above sea level

- Ambient air velocity between 1,4 and 3,7 m/s

(sheltered outdoor space)

- Continuous operation

For sizes J100 to J190 standardized solutions for

cooling of the gears are available. An electric fan

can be mounted on the gear. The gear may also be

provided with a water-based oil cooler (contact our

Application Engineers for selection of correct size).

1) At V-belt drive when the motor is placed

beside the gear, check the operation

according to the diagram.

SELECTION PROCEDURE

Yes

Start

Mechanical Rating

Determine the demand of power (Pe kW) or torque (TeNm)

and speed (nemin -1 ) to the driven machine by calculation or

measuring

Based on type of load / driven machine, operating hours a

day and number of starts an hour select service factor (fb)

according to table 1 and table 2

Select Series J gear from power rating tables on pages 22 - 52.

Select the mechanical rating:

T2 > fb x TeNm

Shock load ? Temax < 1,8 x T2Yes

No No

Use a larger gear

size or contact

our Application

Engineers

Thermal Rating

Select ambient temperature factor ft according to table 3

Select altitude factor fa according to table 4

Select ambient air velocity factor fv according to table 5

Select operation time factor fu according to table 6

Control of thermal rating without extra cooling

Check that the thermal rating of the selected gear Pt is bigger

than required thermal rating:

Pt ≥ Pe

ft x fa x fv x fu

Thermal rating Pt for mineral and synthetic oil are in the

tables on pages 8 - 13. The values are valid for horizontal

applications. For vertical applications 0,8 x Pt is used

No, extra cooling is neededYes

Control of thermal rating with electric fan

Check that the thermal rating of the

selected gear Pt is bigger than required

thermal rating:

Pt ≥ Pe

ft x fa x fu

Thermal rating Pt for mineral and

synthetic oil with fan cooling are in tables

on pages 8 -13. The values are valid

for horizontal applications. For vertical

application 0,8 x Pt is used.

Yes

No, cooling with fan is not enough

Can a water based oil cooler be used ?

Yes No

Use a larger gear

size or contact

our Application

Engineers

Order a water

based

oil cooler from us

Order an

electric fan

from us

Order gear with accessories according to 20-digit gure code page 5.

Select accessories (V-belt drive, motor mount, KIBO, backstop)

1)

SERIES J

6

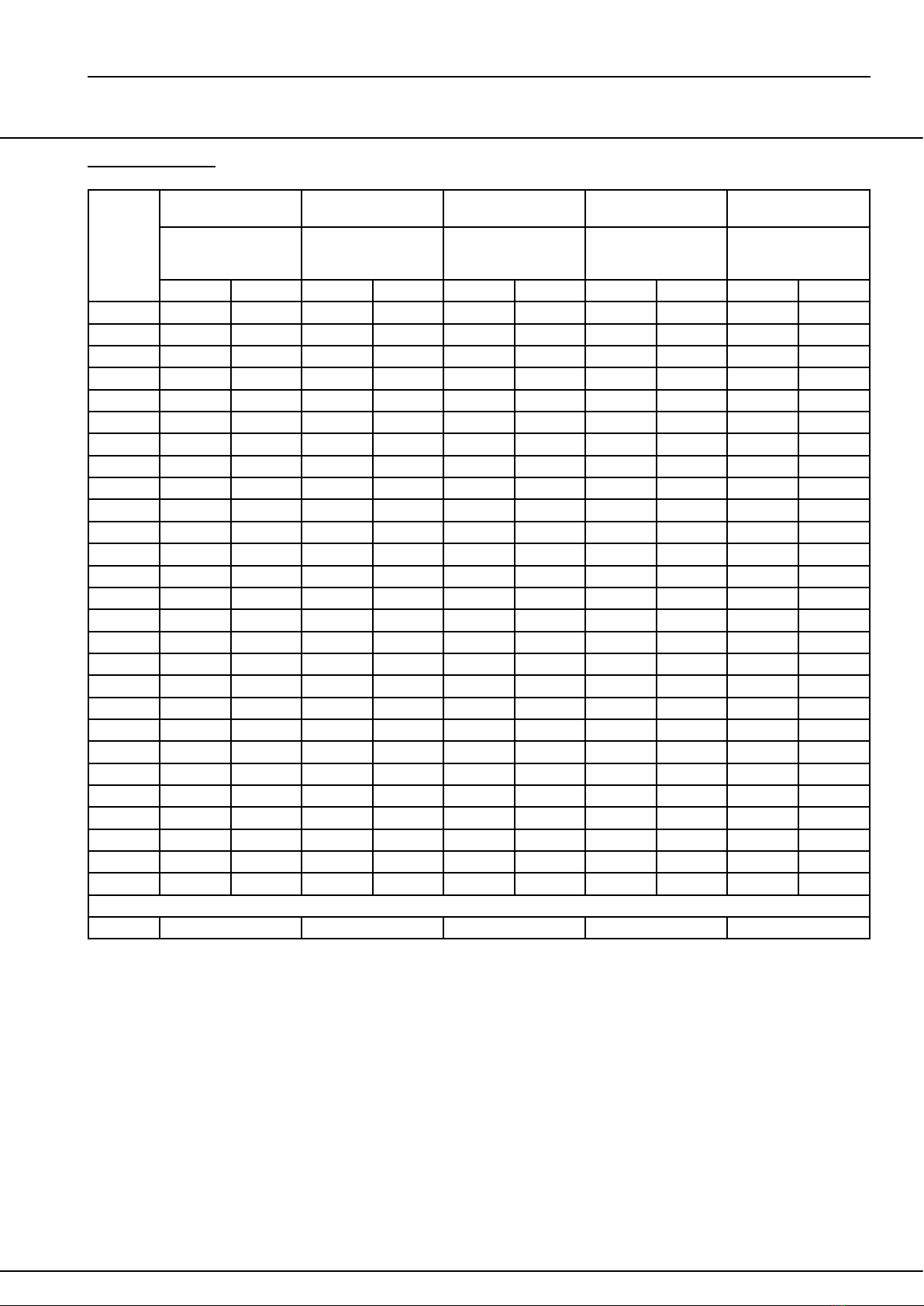

Service factors

Table 1. Service factor fb

SELECTION PROCEDURE

Daily operation 4 hours 8 hours 16 hours 24 hours

Starts per hour <10 10-200 >200 <10 10-200 >200 <10 10-200 >200 <10 10-200 >200

Load

classication

U 0.8 0.9 1.0 0.9 1.0 1.1 1.1 1.2 1.3 1.3 1.4 1.5

Ua 1.1 1.2 1.3 1.1 1.3 1.5 1.3 1.5 1.6 1.4 1.6 1.8

M 1.3 1.4 1.6 1.3 1.6 1.8 1.4 1.7 1.9 1.5 1.8 2.0

H 1.5 1.6 1.8 1.6 1.8 2.0 1.7 1.9 2.1 1.8 2.0 2.2

Load

classications

Description

Mass acceleration factor Example

Uniform

U

Machines with uniform load and no

shocks Mass acceleration factor < 0.2

Uniform loaded conveyors and elevators.

Centrifugal pumps and fans. Agitators and mixers

for liquids and semi-liquids without solid particles.

Uniform

Ua

Machines with small shocks and small

variations in load

Mass acceleration factor < 1

Larger conveyors. Reciprocating pumps with 3 or

more cylinders.

Agitators and mixers for media with high viscosity

and / or solid particles.

Moderate

M

Machines with moderate shocks and

variable load

Mass acceleration factor < 3

Larger conveyors. Reciprocating pumps with 3 or

more cylinders.

Agitators and mixers for media with high viscosity

and / or solid particles

Heavy

H

Machines with very heavy shocks and

large masses to be accelerated

Mass acceleration factor < 10

Heavy agitators and mixers. Reciprocating pumps

with 1 or 2 cylinders.

Crushers, mills and presses. Vibrators and shakers

Mass acceleration factor = all external moments of inertia *

moment of inertia of driving motor

* calculated with reference to the motor speed

Ambient temperature °C Factor ft

10°C 1.17

15°C 1.12

20°C 1.06

25°C 1.00

30°C 0.94

35°C 0.88

40°C 0.81

45°C 0.74

50°C 0.66

Table 2. Description of load classications

Table 3. Ambient temperature factor ft (All cooling methods) Table 4. Altitude factor fa (Only for air cooling)

Altiitude m Factor fa

0 - sea level 1.00

750 0.95

1500 0.90

2250 0.85

Operation Factor ft

100% 1.00

80% 1.05

60% 1.15

40% 1.35

20% 1.80

Air velocity V ref

m/s Environment Factor fv

Vref < 0.5 Small conned space 0.53

0.5 < Vref < 1.4 Large indoor space 0.71

1.4 < Vref < 3.7 Sheltered outdoor space 1.00

Vref > 3.7 Outdoor space 1.35

Table 5. Ambient air velocity factor fv (Without electric fan) Table 6. Operation time factor fu (All cooling methods)

SERIES J

7

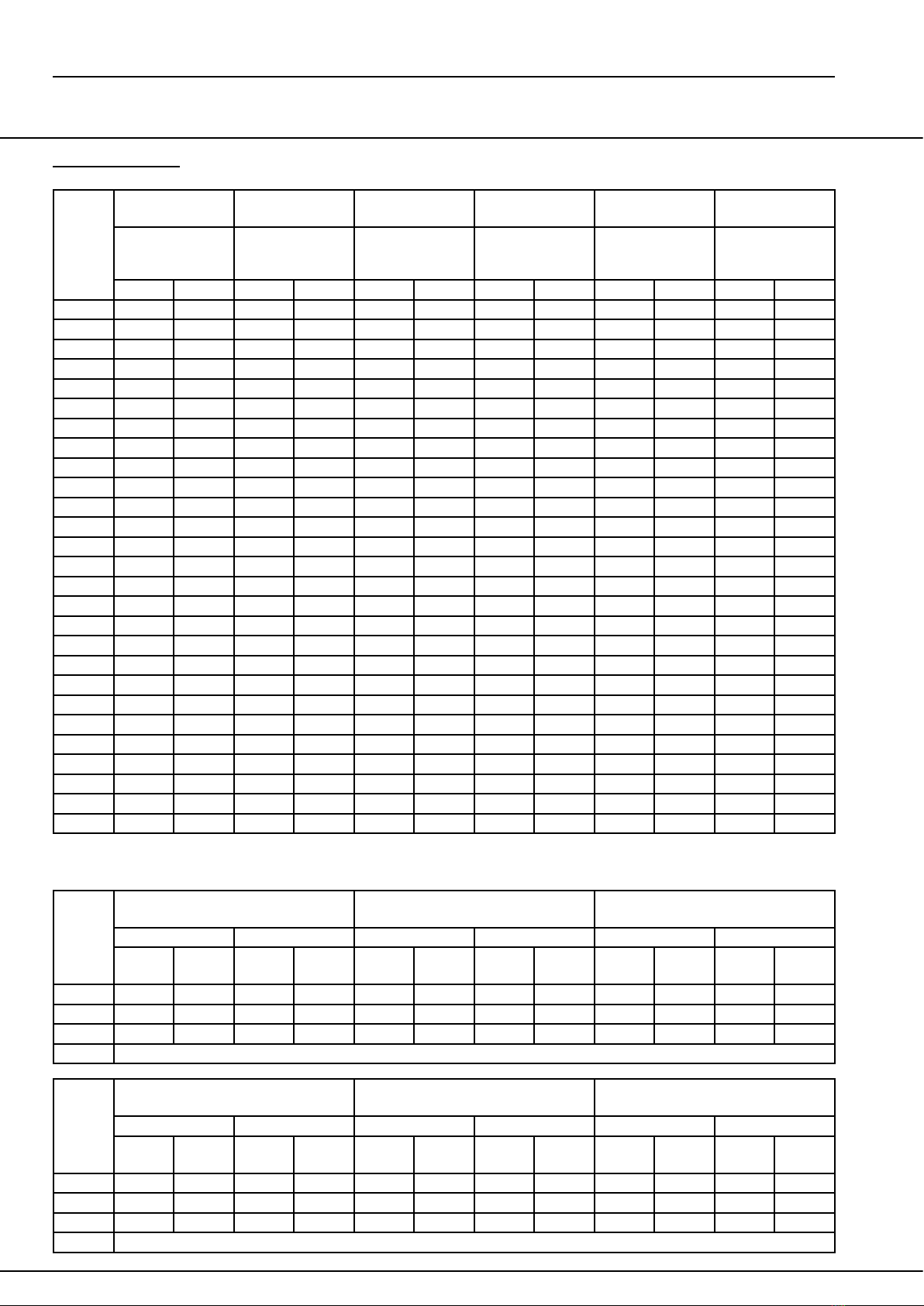

Rpm J100 J110 J125 J140 J160 J190

0 - 60 1 1 1 1 1 1

60 - 80 1 0,9 0,85 1 0,95 0,9

80 - 100 1 0,85 0,8 1 0,95 0,9

100 - 200 1 0,85 0,8 1 0,95 0,9

Single reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 lbf.ft)

POWER RATINGS -

SINGLE REDUCTION

Thermal rating Pt kW at 25 C ambient

temperature outdoor at continuous

operation

Output

rpm

J11

4.94:1

J21

5.00:1

J31

5.00:1

J51

5.08:1

J71

4.94:1

for driven

pulley

Pitch ø140

for driven

pulley

Pitch ø160

for driven

pulley

Pitch ø180

for driven

pulley

Pitch ø355

for driven

pulley

Pitch ø355

kW Nm kW Nm kW Nm kW Nm kW Nm

80 2.57 307 8.93 1066 8.44 1007 16.89 2016 22.84 2726

100 2.98 285 10.44 997 9.79 935 19.59 1871 26.5 2531

120 3.37 268 11.86 944 11.06 880 22.13 1761 29.92 2381

140 3.74 255 13.21 901 12.26 836 24.53 1673 33.16 2262

160 4.09 244 14.51 866 13.39 799 26.81 1600 36.26 2164

180 4.41 234 15.76 836 14.48 768 28.99 1538 39.2 2080

220 5.05 219 18.13 787 16.56 719 33.15 1439 44.83 1946

260 5.64 207 20.39 749 18.51 680 37.05 1361 50.09 1840

300 6.22 198 22.52 717 20.36 648 40.74 1297 55.13 1755

350 6.89 188 25.1 685 22.58 616 45.15 1232 61.09 1667

400 7.5 179 27.56 658 24.67 589 49.38 1179 66.76 1594

450 8.1 172 29.92 635 26.67 566 53.39 1133 72.24 1533

500 8.74 167 32.2 615 28.59 546 57.28 1094 77.49 1480

Thermal rating Pt in kW at 25º C ambient temperature, outdoor and 24 hours daily working.

13 17 23 25 31

Output

rpm

J100

5.07:1

J110

5.07:1

J125

4.88:1

for driven

pulley

Pitch ø250

for driven

pulley

Pitch ø280

for driven

pulley

Pitch ø315

kW Nm kW Nm kW Nm

80 44.88 5358 73.04 8719 110.32 13169

100 52.47 5011 85.38 8154 128.96 12316

120 59.61 4744 97.01 7720 146.51 11660

140 66.41 4530 108.06 7371 163.21 11133

160 72.91 4352 118.65 7082 179.2 10696

180 79.18 4201 128.85 6836 194.61 10325

220 91.11 3955 148.26 6436 223.96 9722

260 102.42 3762 166.67 6122 251.72 9246

300 113.21 3604 184.24 5865 278.26 8858

350 126.11 3441 205.24 5600 309.94 8457

400 138.47 3306 225.34 5380 340.31 8125

450 150.36 3191 244.7 5193 369.57 7843

500 161.88 3092 263.4 5031 397.85 7599

J100 J110 J125

<150

rpm

Mineral 72 118 178

Synthetic 131 214 323

Mineral with fan 144 234 354

Synthetic with fan 183 299 451

151 - 300

rpm

Mineral 77 125 187

Synthetic 125 202 304

Mineral with fan 162 263 397

Synthetic with fan 210 340 516

>300

rpm

Contact Benzlers

When the reducer is working with a low

output speed less than:

For single reduction 1 RPM

For double reduction 0,3 RPM

Please contact our Application Engineers

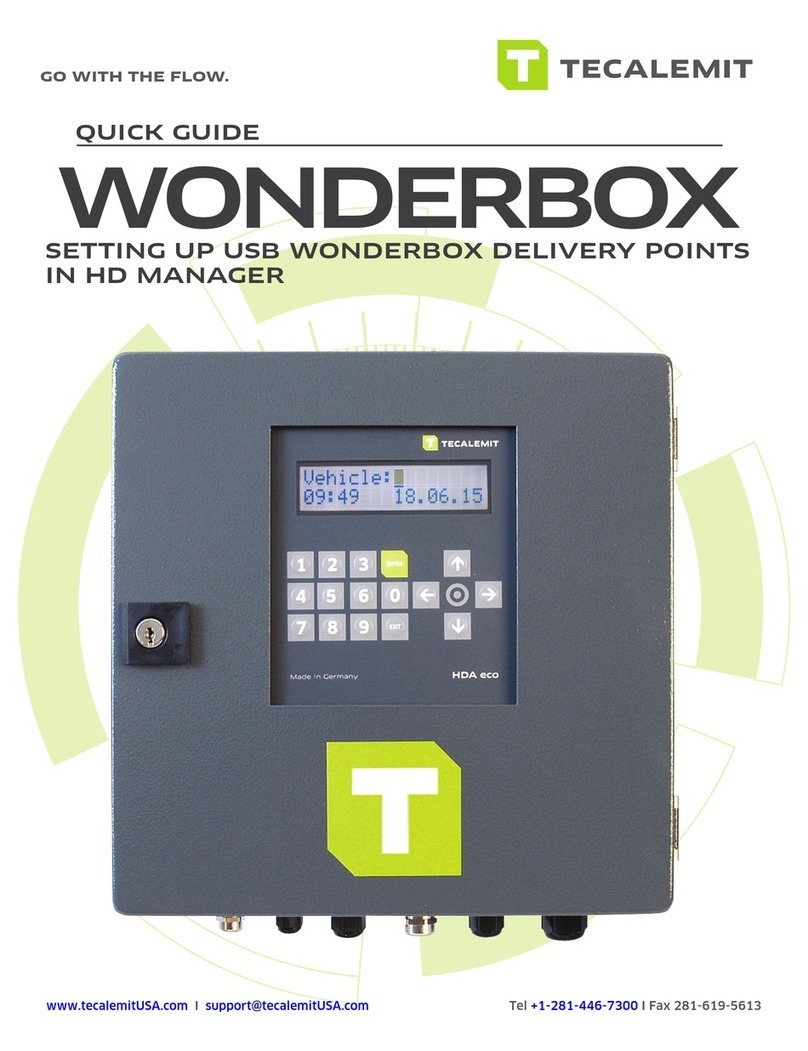

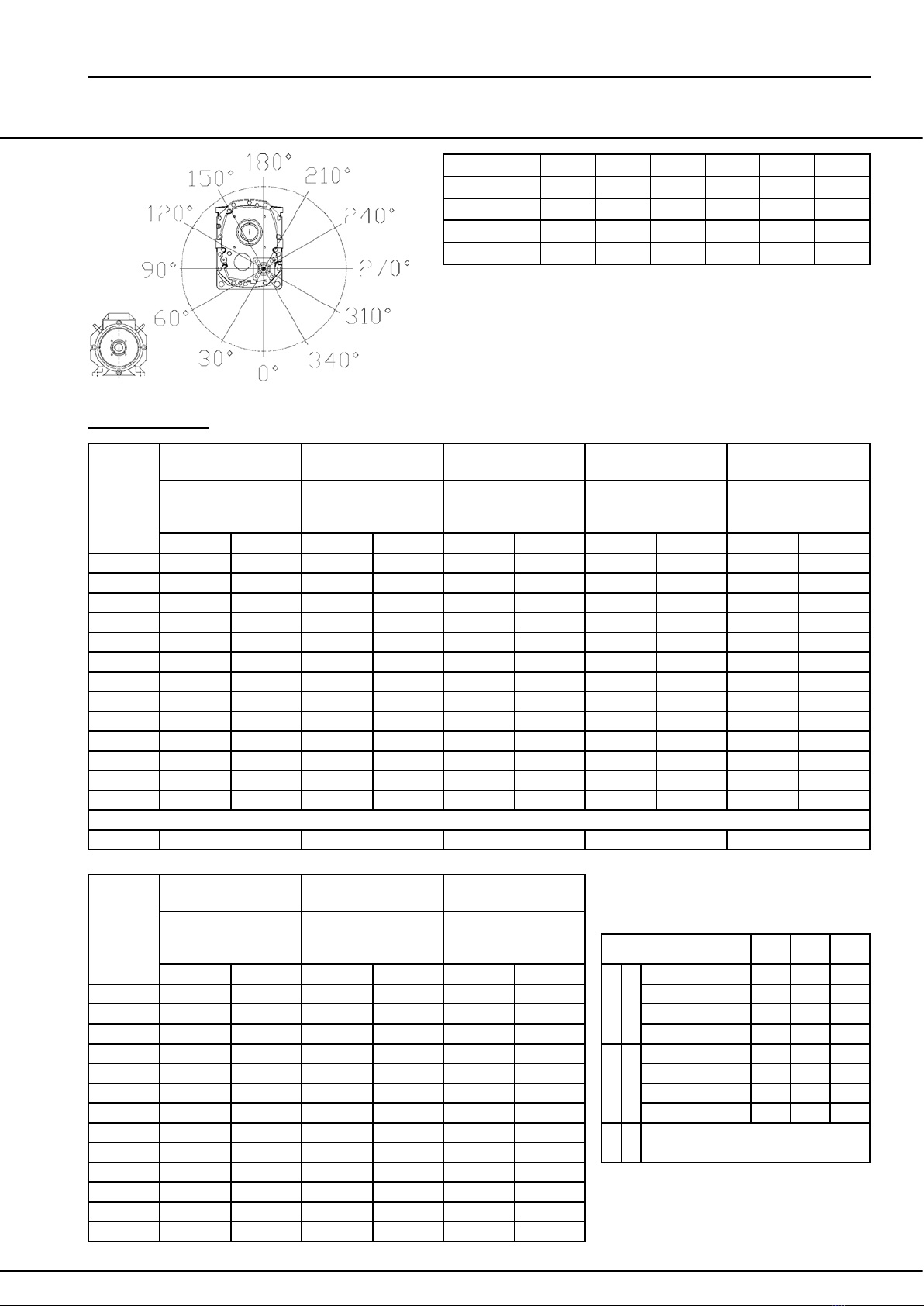

Fig.1

Specication of factor for V-belt forces in different angles. Power

ratings have to be multiplied with this factor for sizes J100 - 190 when

motor is located in angle 90 - 210 °.

SERIES J

8

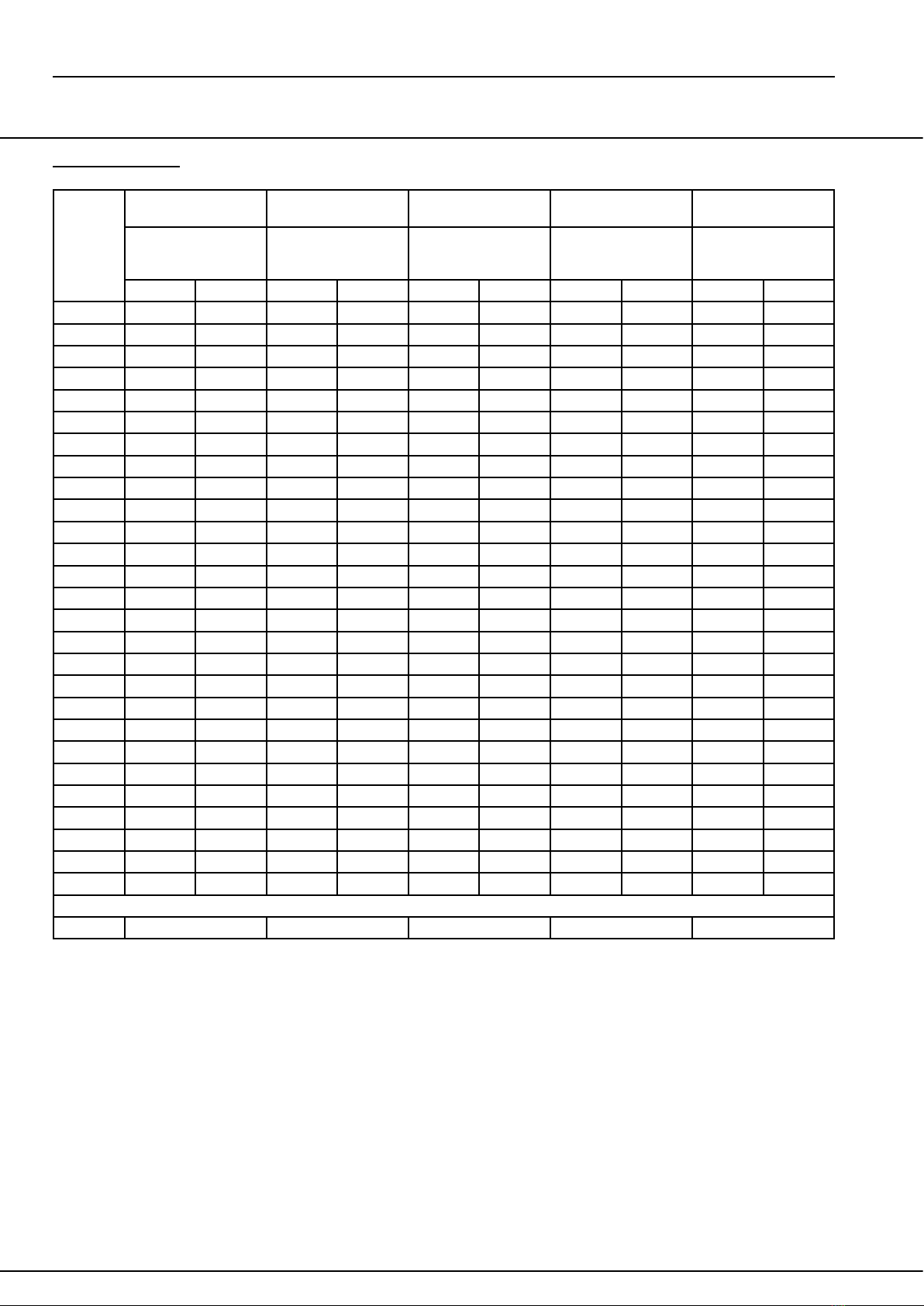

POWER RATINGS -

DOUBLE REDUCTION 15:1

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 lbf.ft)

Output

rpm

J12

15.09:1

J22

15.22:1

J32

15.45:1

J52

15.39:1

J72

14.61:1

for driven

pulley

Pitch ø140

for driven

pulley

Pitch ø160

for driven

pulley

Pitch ø180

for driven

pulley

Pitch ø200

for driven

pulley

Pitch ø280

kW Nm kW Nm kW Nm kW Nm kW Nm

6 0.5 800 .94 1500 1.38 2200 1.82 2900 3.14 5000

8 0.67 800 1.26 1500 1.84 2200 2.43 2900 4.19 5000

10 0.84 800 1.57 1500 2.3 2200 3.03 2898 5.24 5000

12 1.01 800 1.88 1500 2.76 2196 3.64 2893 6.28 4995

14 1.17 800 2.2 1500 3.21 2193 4.23 2888 7.31 4987

16 1.34 800 2.51 1500 3.67 2190 4.83 2884 8.34 4979

18 1.51 800 2.82 1498 4.12 2187 5.43 2880 9.37 4971

20 1.68 800 3.13 1496 4.57 2184 6.02 2876 10.4 4964

22 1.84 800 3.44 1495 5.03 2182 6.62 2872 11.42 4958

24 2.01 800 3.75 1493 5.48 2180 7.21 2869 12.44 4951

26 2.18 800 4.06 1492 5.93 2177 7.8 2865 13.46 4945

28 2.35 800 4.37 1490 6.26 2135 8.39 2862 14.48 4939

30 2.51 800 4.68 1489 6.57 2091 8.98 2859 15.5 4934

35 2.93 800 5.45 1486 7.32 1996 10.45 2852 18.04 4921

40 3.35 800 6.21 1483 8.03 1918 11.92 2845 20.56 4909

45 3.77 800 6.97 1480 8.72 1851 13.38 2839 22.61 4798

50 4.18 799 7.74 1478 9.39 1794 14.83 2833 24.34 4649

55 4.6 798 8.43 1463 10.04 1743 16.29 2828 26.02 4518

60 5.0 796 8.95 1425 10.67 1698 17.74 2823 27.66 4402

65 5.41 795 9.47 1391 11.28 1658 19.18 2818 29.25 4297

70 5.82 794 9.98 1361 11.89 1622 20.62 2813 30.81 4203

80 6.63 792 10.95 1307 13.05 1558 23.49 2804 33.83 4038

90 7.41 786 11.89 1262 14.17 1504 26.34 2795 36.73 3897

100 7.86 751 12.81 1223 15.26 1457 29.18 2787 39.54 3776

110 8.37 727 13.68 1188 16.31 1416 32.02 2780 42.27 3670

120 8.78 699 14.55 1158 17.33 1379 34.83 2772 44.92 3575

140 9.73 664 16.2 1105 19.31 1317 39.86 2719 50.03 3413

Thermal rating Pt in kW at 25º C ambient temperature, outdoor and 24 hours daily working.

Pt kW 10 15 21 27 33

SERIES J

9

Thermal rating Pt in kW at 25º C ambient temperature, outdoor and 24 hours daily working.

POWER RATINGS -

DOUBLE REDUCTION 15:1

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 lbf.ft)

Output

rpm

J100

15.94:1

J110

15.95:1

J125

14.79:1

J140

14.75:1

J160

15.04:1

J190

15.71:1

for driven

pulley

Pitch ø250

for driven

pulley

Pitch ø280

for driven

pulley

Pitch ø315

for driven

pulley

Pitch ø355

for driven

pulley

Pitch ø400

for driven

pulley

Pitch ø450

kW Nm kW Nm kW Nm kW Nm kW Nm kW Nm

6 6.28 10000 8.89 14157 12.74 20270 19.29 30700 28.59 45504 36.31 57800

8 8.38 10000 11.84 14133 16.98 20270 25.72 30700 38.12 45504 48.42 57800

10 10.47 10000 14.76 14100 21.23 20270 32.15 30700 47.65 45504 60.52 57800

12 12.57 10000 17.68 14069 25.47 20270 38.58 30700 57.18 45504 72.63 57800

14 14.66 10000 20.59 14042 29.71 20267 45.01 30700 66.71 45504 84.73 57800

16 16.75 10000 23.48 14016 33.89 20229 51.43 30700 76.24 45504 96.84 57800

18 18.85 10000 26.37 13992 38.06 20193 57.86 30700 85.77 45504 108.94 57800

20 20.94 10000 29.26 13970 42.22 20160 64.29 30700 95.3 45504 121.05 57800

22 23 9986 32.13 13948 46.37 20128 70.72 30700 104.83 45504 133.15 57800

24 25.06 9973 35 13928 50.51 20098 77.15 30700 114.36 45504 145.26 57800

26 27.11 9959 37.86 13908 54.64 20069 83.58 30700 123.89 45504 157.36 57800

28 29.16 9947 40.72 13890 58.76 20041 90.01 30700 133.41 45504 169.47 57800

30 31.21 9935 43.58 13872 62.87 20015 96.44 30700 142.85 45474 181.57 57800

35 36.3 9906 50.68 13829 73.12 19952 112.51 30700 163.46 44601 211.83 57800

40 41.38 9880 57.76 13790 83.33 19894 124.59 29745 179.48 42850 242.09 57800

45 46.44 9855 64.8 13753 93.49 19840 135.3 28713 194.9 41362 272.36 57800

50 51.48 9832 71.83 13719 103.61 19789 145.65 27819 209.82 40075 301.23 57535

55 56.5 9810 78.82 13686 113.69 19740 155.7 27035 224.29 38945 322.01 55913

60 61.5 9789 85.79 13655 123.73 19694 165.48 26339 238.38 37942 342.24 54473

65 66.49 9769 92.74 13626 133.75 19651 175.02 25714 252.12 37042 361.96 53180

70 71.47 9750 99.66 13597 143.73 19609 184.33 25148 265.54 36227 381.23 52011

80 79.86 9533 113.46 13544 163.59 19529 202.4 24161 291.56 34805 418.58 49968

90 86.72 9202 125.64 13332 180.37 19139 219.79 23322 316.61 33596 454.56 48234

100 93.36 8916 135.1 12902 193.49 18478 236.61 22596 340.85 32551 489.35 46733

110 99.81 8665 143.97 12499 206.18 17900 252.93 21959 364.36 31633 523.1 45415

120 106.06 8441 151.55 12061 218.5 17389 268.81 21393 387.24 30818 555.96 44245

140 118.16 8060 166.84 11381 242.15 16518 299.45 20427 431.38 29426 619.31 42246

Output

speed

rpm

J100

15.94:1 2-stage

J110

15.95:1 2-stage

J125

14.79:1 2-stage

no fan electric fan no fan electric fan no fan electric fan

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

2 - 50 42 64 69 126 53 75 89 132 90 136 150 211

51 - 80 52 72 71 147 55 93 106 159 74 129 165 251

81 - 100 49 67 77 163 54 96 120 183 45 109 164 291

> 101 Contact our Application Engineers

Output

speed

rpm

J140

14.75:1 2-stage

J160

15.04:1 2-stage

J190

15.71:1 2-stage

no fan electric fan no fan electric fan no fan electric fan

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

2 - 50 115 173 170 258 161 208 311 426 270 415 825 1136

51 - 80 105 190 216 347 130 229 357 529 235 418 630 860

81 - 100 59 181 179 313 - 226 361 596 130 310 520 730

> 101 Contact our Application Engineers

SERIES J

10

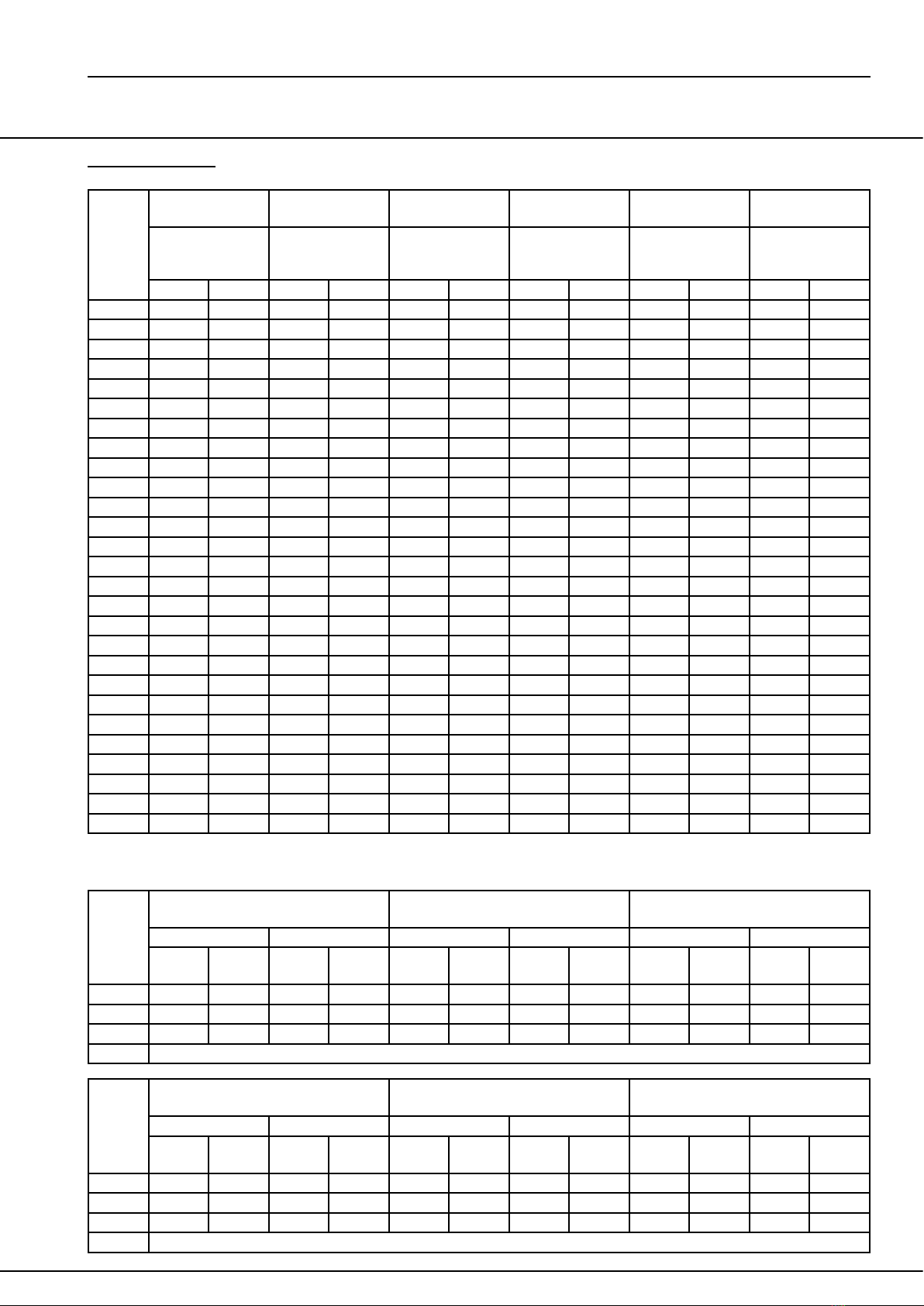

POWER RATINGS -

DOUBLE REDUCTION 20:1

Thermal rating Pt in kW at 25º C ambient temperature, outdoor and 24 hours daily working.

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 lbf.ft)

Output

rpm

J100

19.99:1

J110

19.95:1

J125

19.91:1

J140

19.97:1

J160

20.62:1

J190

20.92:1

for driven

pulley

Pitch ø250

for driven

pulley

Pitch ø280

for driven

pulley

Pitch ø315

for driven

pulley

Pitch ø355

for driven

pulley

Pitch ø400

for driven

pulley

Pitch ø450

kW Nm kW Nm kW Nm kW Nm kW Nm kW Nm

6 6.28 10000 8.89 14157 12.74 20270 19.29 30700 28.59 45504 36.31 57800

8 8.38 10000 11.84 14133 16.98 20270 25.72 30700 38.12 45504 48.42 57800

10 10.47 10000 14.76 14100 21.23 20270 32.15 30700 47.65 45504 60.52 57800

12 12.57 10000 17.68 14069 25.47 20270 38.58 30700 57.18 45504 72.63 57800

14 14.66 10000 20.59 14042 29.71 20267 45.01 30700 66.71 45504 84.73 57800

16 16.75 10000 23.48 14016 33.89 20229 51.43 30700 76.24 45504 96.84 57800

18 18.85 10000 26.37 13992 38.06 20193 57.86 30700 85.77 45504 108.94 57800

20 20.94 10000 29.26 13970 42.22 20160 64.29 30700 95.3 45504 121.05 57800

22 23.04 10000 32.13 13948 46.37 20128 70.72 30700 104.83 45504 133.15 57800

24 25.13 9999 35 13928 50.51 20098 77.15 30700 114.36 45504 145.26 57800

26 27.19 9986 37.86 13908 54.64 20069 83.58 30700 123.89 45504 157.36 57800

28 29.24 9974 40.72 13890 58.76 20041 90.01 30700 133.41 45504 169.47 57800

30 31.29 9962 43.58 13872 62.87 20015 96.44 30700 142.85 45474 181.57 57800

35 36.41 9934 50.68 13829 73.12 19952 112.51 30700 166.04 45306 211.83 57800

40 41.5 9909 57.76 13790 83.33 19894 125.77 30027 183.09 43712 242.09 57800

45 46.58 9885 64.8 13753 93.49 19840 136.58 28985 198.82 42194 272.36 57800

50 51.63 9862 71.83 13719 103.61 19789 147.03 28083 214.04 40881 300.82 57457

55 56.68 9841 78.82 13686 113.69 19740 157.17 27291 228.81 39729 321.57 55837

60 61.7 9820 85.79 13655 123.73 19694 167.05 26588 243.17 38705 341.77 54399

65 66.71 9801 92.74 13626 133.75 19651 176.67 25957 257.19 37787 361.47 53108

70 70.83 9663 99.66 13597 143.73 19609 186.08 25386 270.88 36956 380.71 51940

80 77.76 9283 113.46 13544 163.24 19487 204.31 24390 297.42 35505 418.02 49901

90 84.45 8961 126.77 13452 177.28 18811 221.87 23543 322.98 34272 453.94 48168

100 90.91 8682 135.1 12902 190.84 18225 238.85 22810 347.71 33206 488.68 46669

110 97.18 8437 143.97 12499 204.01 17712 255.33 22167 371.7 32270 522.4 45354

120 103.29 8220 151.55 12061 216.82 17255 271.36 21596 395.03 31438 555.2 44185

140 115.05 7848 166.84 11381 241.52 16475 302.28 20620 440.04 30017 618.46 42188

Output

speed

rpm

J100

19.99:1 2-stage

J110

19.95:1 2-stage

J125

19.91:1 2-stage

no fan electric fan no fan electric fan no fan electric fan

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

2 - 50 42 64 69 126 53 75 89 132 90 136 150 211

51 - 80 52 72 71 147 55 93 106 159 74 129 165 251

81 - 100 49 67 77 163 54 96 120 183 45 109 164 291

> 101 Contact our Application Engineers

Output

speed

rpm

J140

19.97:1 2-stage

J160

20.62:1 2-stage

J190

20.92:1 2-stage

no fan electric fan no fan electric fan no fan electric fan

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

2 - 50 115 173 170 258 161 208 311 426 270 415 825 1136

51 - 80 105 190 216 347 130 229 357 529 235 418 630 860

81 - 100 59 181 179 313 - 226 361 596 130 310 520 730

> 101 Contact our Application Engineers

SERIES J

11

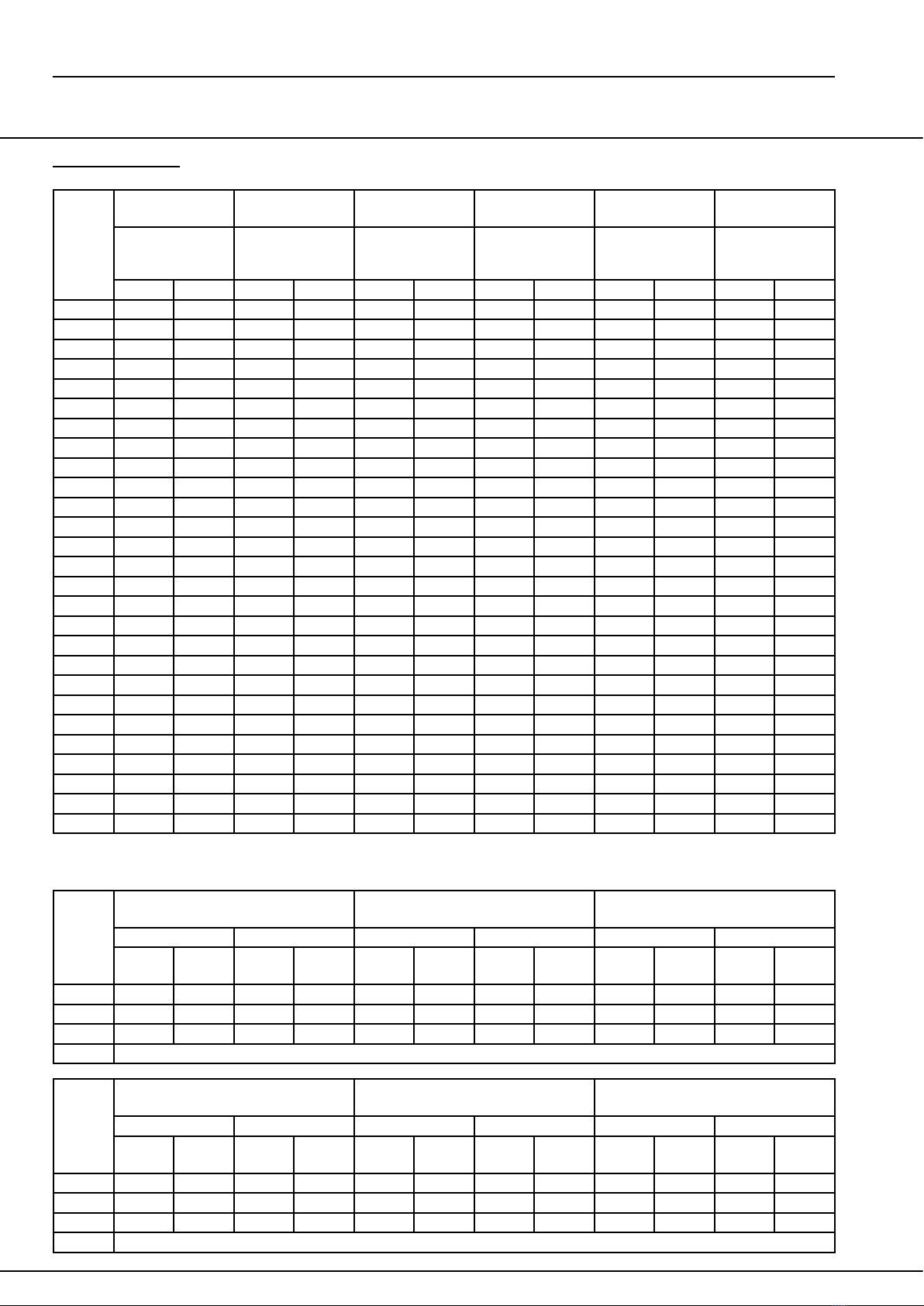

POWER RATINGS -

DOUBLE REDUCTION 25:1

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 lbf.ft)

Output

rpm

J12

24.94:1

J22

24.38:1

J32

24.17:1

J52

24.72:1

J72

24.44:1

for driven

pulley

Pitch ø140

for driven

pulley

Pitch ø160

for driven

pulley

Pitch ø180

for driven

pulley

Pitch ø355

for driven

pulley

Pitch ø355

kW Nm kW Nm kW Nm kW Nm kW Nm

6 .5 800 .94 1500 1.38 2200 1.82 2900 3.14 5000

8 .67 800 1.26 1500 1.84 2200 2.43 2900 4.19 5000

10 .84 800 1.57 1500 2.3 2200 3.03 2898 5.24 5000

12 1.01 800 1.88 1500 2.76 2196 3.64 2893 6.28 4995

14 1.17 800 2.2 1500 3.21 2193 4.23 2888 7.31 4987

16 1.34 800 2.51 1500 3.67 2190 4.83 2884 8.34 4979

18 1.51 800 2.82 1498 4.12 2187 5.43 2880 9.37 4971

20 1.68 800 3.13 1496 4.51 2155 6.02 2876 10.4 4964

22 1.84 800 3.36 1460 4.82 2094 6.62 2872 11.42 4958

24 2.01 800 3.58 1423 5.13 2040 7.21 2869 12.44 4951

26 2.18 800 3.78 1389 5.42 1992 7.8 2865 13.46 4945

28 2.35 800 3.98 1358 5.71 1948 8.39 2862 14.48 4939

30 2.51 800 4.18 1331 5.99 1908 8.98 2859 15.5 4934

35 2.93 800 4.65 1270 6.68 1822 10.45 2852 18.04 4921

40 3.35 800 5.11 1221 7.33 1750 11.92 2845 20.56 4909

45 3.77 800 5.55 1178 7.96 1689 13.38 2839 23.07 4897

50 4.18 799 5.97 1141 8.57 1637 14.47 2763 24.85 4746

55 4.6 798 6.39 1109 9.16 1591 15.41 2676 26.57 4613

60 5 796 6.79 1081 9.74 1550 16.34 2600 28.23 4494

65 5.28 776 7.18 1055 10.3 1513 17.23 2531 29.86 4387

70 5.56 758 7.56 1032 10.85 1480 18.1 2470 31.45 4291

80 6.01 717 8.3 991 11.91 1422 19.79 2362 34.53 4122

90 6.49 689 9.02 957 12.93 1372 21.4 2271 37.5 3979

100 6.88 657 9.71 927 13.92 1329 22.96 2193 40.37 3855

110 7.34 637 10.38 901 14.88 1292 24.46 2124 43.16 3747

120 7.77 618 11.03 878 15.82 1259 25.92 2063 45.86 3650

140 8.5 580 12.28 838 17.59 1200 28.73 1960 51.09 3485

Thermal rating Pt in kW at 25º C ambient temperature, outdoor and 24 hours daily working.

Pt kW 10 15 21 27 33

SERIES J

12

POWER RATINGS -

DOUBLE REDUCTION 25:1

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 lbf.ft)

Thermal rating Pt in kW at 25º C ambient temperature, outdoor and 24 hours daily working.

Output

speed

rpm

J100

25.00:1 2-stage

J110

24.95:1 2-stage

J125

24.86:1 2-stage

no fan electric fan no fan electric fan no fan electric fan

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

2 - 50 42 64 69 126 53 75 89 132 90 136 150 211

51 - 80 52 72 71 147 55 93 106 159 74 129 165 251

81 - 100 49 67 77 163 54 96 120 183 45 109 164 291

> 101 Contact our Application Engineers

Output

speed

rpm

J140

25.51 2-stage

J160

24.36:1 2-stage

J190

25.53:1 2-stage

no fan electric fan no fan electric fan no fan electric fan

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

mineral

kw

synthetic

kw

2 - 50 115 173 170 258 161 208 311 426 270 415 825 1136

51 - 80 105 190 216 347 130 229 357 529 235 418 630 860

81 - 100 59 181 179 313 - 226 361 596 130 310 520 730

> 101 Contact our Application Engineers

Output

rpm

J100

25.00:1

J110

24.95:1

J125

24.86:1

J140

25.61:1

J160

24.36:1

J190

25.53:1

for driven

pulley

Pitch ø250

for driven

pulley

Pitch ø280

for driven

pulley

Pitch ø315

for driven

pulley

Pitch ø355

for driven

pulley

Pitch ø400

for driven

pulley

Pitch ø450

kW Nm kW Nm kW Nm kW Nm kW Nm kW Nm

6 6.28 10000 8.89 14157 12.74 20270 19.29 30700 28.59 45504 36.31 57800

8 8.38 10000 11.84 14133 16.98 20270 25.72 30700 38.12 45504 48.42 57800

10 10.47 10000 14.76 14100 21.23 20270 32.15 30700 47.65 45504 60.52 57800

12 12.57 10000 17.68 14069 25.47 20270 38.58 30700 57.18 45504 72.63 57800

14 14.66 10000 20.59 14042 29.71 20267 45.01 30700 66.71 45504 84.73 57800

16 16.75 10000 23.48 14016 33.89 20229 51.43 30700 76.24 45504 96.84 57800

18 18.85 10000 26.37 13992 38.06 20193 57.86 30700 85.77 45504 108.94 57800

20 20.94 10000 29.26 13970 42.22 20160 64.29 30700 95.3 45504 121.05 57800

22 23.04 10000 32.13 13948 46.37 20128 70.72 30700 104.83 45504 133.15 57800

24 25.13 9999 35 13928 50.51 20098 77.15 30700 114.36 45504 145.26 57800

26 27.19 9986 37.86 13908 54.64 20069 83.58 30700 123.89 45504 157.36 57800

28 29.24 9974 40.72 13890 58.76 20041 90.01 30700 133.41 45504 169.47 57800

30 31.29 9962 43.58 13872 62.87 20015 96.44 30700 142.85 45474 181.57 57800

35 36.41 9934 50.68 13829 73.12 19952 112.51 30700 166.04 45306 211.83 57800

40 41.5 9909 57.76 13790 83.33 19894 125.77 30027 183.09 43712 242.09 57800

45 46.58 9885 64.8 13753 93.49 19840 136.58 28985 198.82 42194 272.36 57800

50 51.63 9862 71.83 13719 103.61 19789 147.03 28083 214.04 40881 300.82 57457

55 56.68 9841 78.82 13686 113.69 19740 157.17 27291 228.81 39729 321.57 55837

60 61.7 9820 85.79 13655 123.73 19694 167.05 26588 243.17 38705 341.77 54399

65 66.71 9801 92.74 13626 133.75 19651 176.67 25957 257.19 37787 361.47 53108

70 70.83 9663 99.66 13597 143.73 19609 186.08 25386 270.88 36956 380.71 51940

80 77.76 9283 113.46 13544 163.24 19487 204.31 24390 297.42 35505 418.02 49901

90 84.45 8961 126.77 13452 177.28 18811 221.87 23543 322.98 34272 453.94 48168

100 90.91 8682 135.1 12902 190.84 18225 238.85 22810 347.71 33206 488.68 46669

110 97.18 8437 143.97 12499 204.01 17712 255.33 22167 371.7 32270 522.4 45354

120 103.29 8220 151.55 12061 216.82 17255 271.36 21596 395.03 31438 555.2 44185

140 115.05 7848 166.84 11381 241.52 16475 302.28 20620 440.04 30017 618.46 42188

SERIES J

13

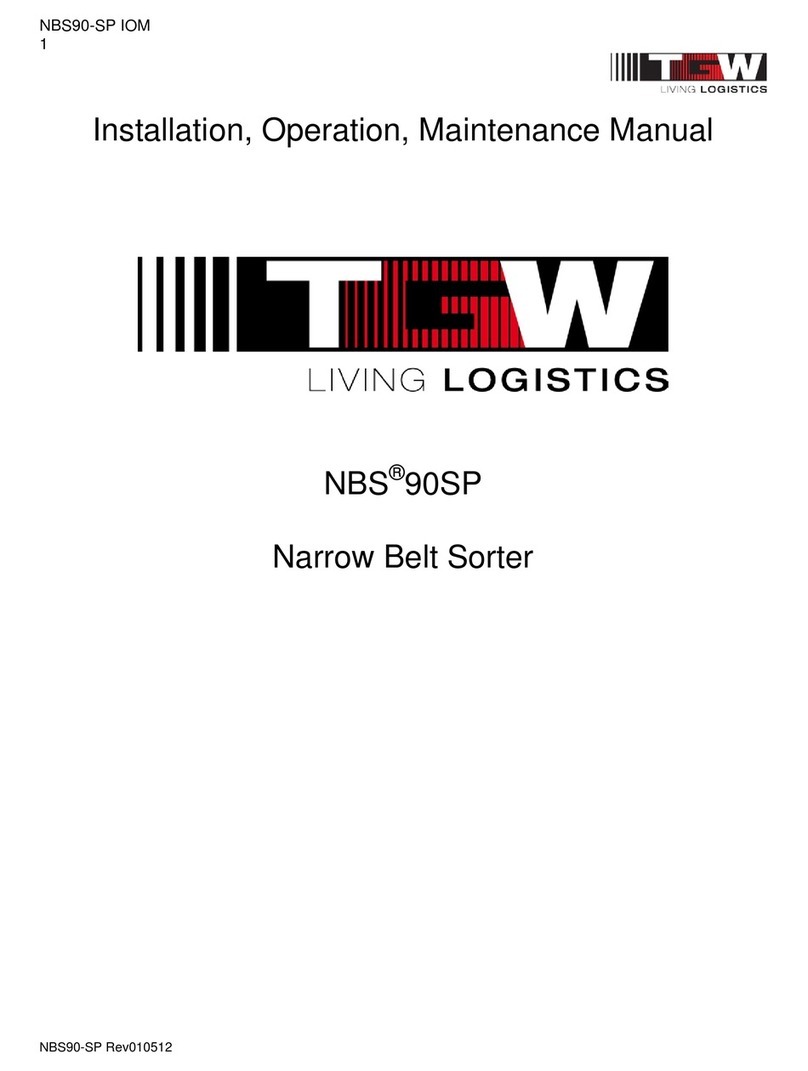

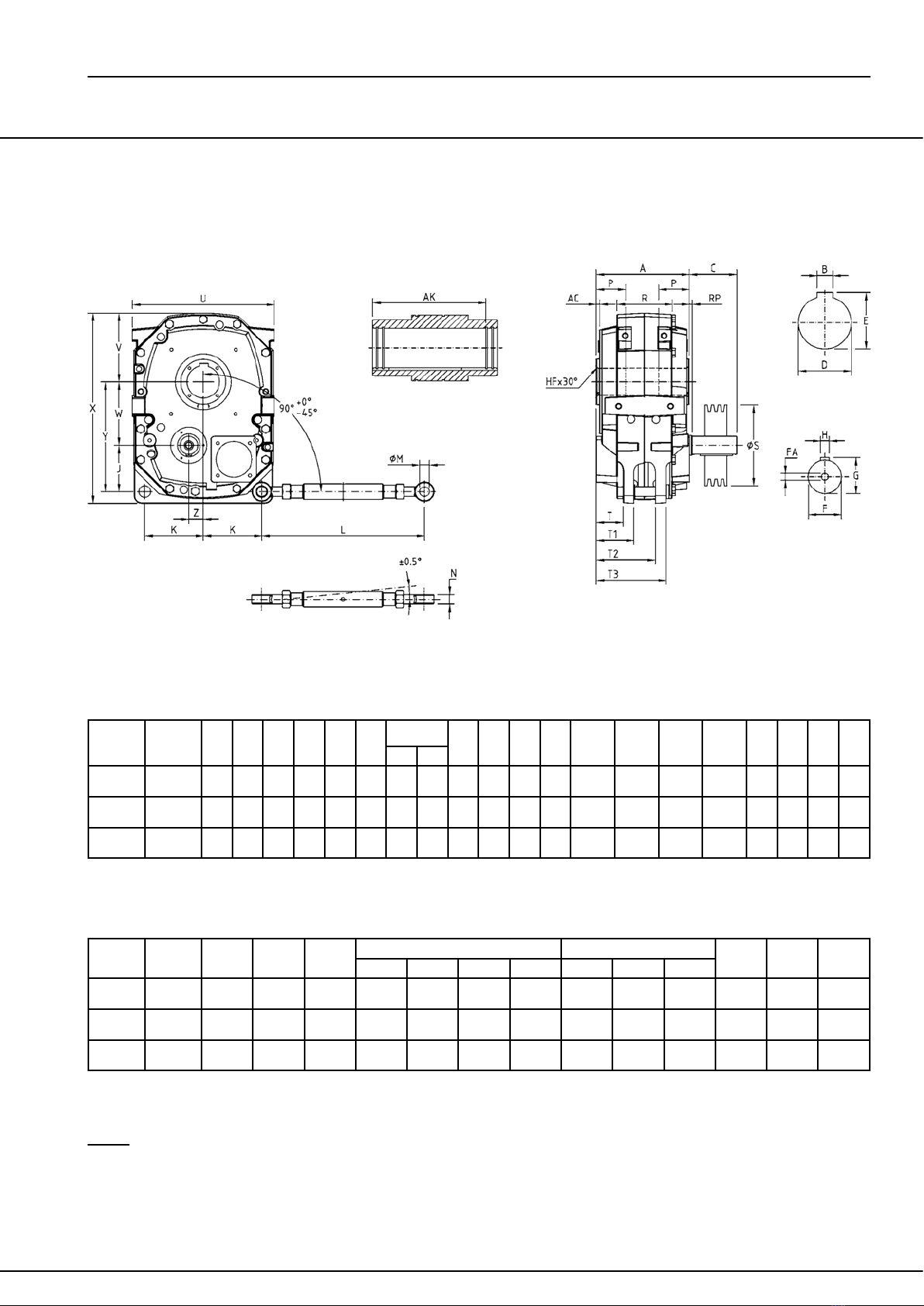

V

W

J

Y

X

U

Z

KK

L

90° +0

-45

øM

N

AK 2

R

P P

A C

øS

H

G

F

B

E

D

T

T1

T2

T3

HFx45°

FA

±0.5°

AC

°

°

DIMENSIONS - SINGLE REDUCTION

J11 - 71 Single Reduction

Size Ratio A AC C1J K LM N P R T T1 T2 T3 S2U V W

max min

J11A 4.94:1 137 16 42 65 83 350 240 12 14 35 76 50 65 90 105 140 200 108 83

J11B 4.94:1 137 16 42 65 83 350 240 12 14 35 76 50 65 90 105 140 200 108 83

J21A 5.00:1 157 18 52 81 100 400 280 16 18 45 86 52 70 96 114 160 236 118 99

J21B 5.00:1 157 18 52 81 100 400 280 16 18 45 86 52 70 96 114 160 236 118 99

J31A 5.00:1 172 16 62 84 114 400 280 16 18 50 104 57 79 110 132 180 272 134 120

J31B 5.00:1 172 16 62 84 114 400 280 16 18 50 104 57 79 110 132 180 272 134 120

J51A 5.08:1 189 10 82 105 138 460 330 20 22 55 104 62 87 118 143 355 320 160 146

J51B 5.08:1 189 10 82 105 138 460 330 20 22 55 104 62 87 118 143 355 320 160 146

J71A 4.94:1 203 16 87 114 166 460 330 20 22 75 134 60 85 123 148 355 388 200 167

J71B 4.94:1 203 16 87 114 166 460 330 20 22 75 134 60 85 123 148 355 388 200 167

1. The V-belt pulley should be placed as close to the

housing as possible.

2. These dimensions are minimum diameters of driven

pulley to prevent overloading of the bearings.

3. Tolerances according to ISO H7.

4. Tolerances according to ISO E9.

Size Ratio X Y Z Input shaft Shaft sleeve 5 HF AK Weight

kg

F6H7G FA D3,8 B4E

J11A 4.94:1 272 15 28 19 6 21.5 - 35 10 38.3 1 130 16

J11B 4.94:1 272 15 28 19 6 21.5 - 45 14 48.8 1 130 16

J21A 5.00:1 318 15 35 24 8 27 - 45 14 48.8 2 149 24

J21B 5.00:1 318 15 35 24 8 27 - 55 16 59.3 2 149 24

J31A 5.00:1 360 20 31 28 8 31 - 55 16 59.3 2 161 35

J31B 5.00:1 360 20 31 28 8 31 - 65 16 69.4 2 161 35

J51A 5.08:1 443 20 40 38 10 41 M8 60 18 64.4 2 178 53

J51B 5.08:1 443 20 40 38 10 41 M8 75 20 79.9 2 178 53

J71A 4.94:1 508 24 48 42 12 45 M8 70 20 74.9 2 192 82

J71B 4.94:1 508 24 48 42 12 45 M8 85 22 90.4 2 192 82

5. The reducer should normally be mounted on a shaftwith

tolerance ISO js6. On heavy duty applications closer

tolerances are recommended.

6. Tolerances according to ISO js6.

7. Tolerances according to ISO h9.

8. Space for spacer if locking ring is used.

notes

Please note: Dimensions R, T, T1, T2, T3

are not machined, deviations can occur.

SERIES J

14

DIMENSIONS - SINGLE REDUCTION

KIBO

J11 - 71 Single Reduction

Please note: Dimensions R, T, T1, T2, T3

are not machined, deviations can occur.

Size Ratio A AC C1J K LM N P R T T1 T2 T3 S2U V W

max min

J11A 4.94:1 116 11.6 36.4 65 83 350 240 12 14 40 76 47 62 87 102 140 200 108 83

J11B 4.94:1 116 11.6 36.4 65 83 350 240 12 14 40 76 47 62 87 102 140 200 108 83

J21A 5.00:1 136 12.2 46 81 100 400 280 16 18 48.8 86 51 69 93 112 160 236 118 99

J21B 5.00:1 136 12.2 46 81 100 400 280 16 18 48.8 86 51 69 93 112 160 236 118 99

J31A 5.00:1 148 15.5 54 84 114 400 280 16 18 58 104 56 78 109 131 180 272 134 120

J31B 5.00:1 148 15.5 54 84 114 400 280 16 18 58 104 56 78 109 131 180 272 134 120

J51A 5.08:1 168 16.4 72.6 105 138 460 330 20 22 61 104 68 93 124 149 355 320 160 146

J51B 5.08:1 168 16.4 72.6 105 138 460 330 20 22 61 104 68 93 124 149 355 320 160 146

J71A 4.94:1 182 19.5 72.5 114 166 460 330 20 22 67.5 134 64 89 127 152 355 388 200 167

J71B 4.94:1 182 19.5 72.5 114 166 460 330 20 22 67.5 134 64 89 127 152 355 388 200 167

Size Ratio X Y Z Input shaft Shaft sleeve 5 RP Weight

kg

F6H7G FA D3,8 B4E

J11A 4.94:1 272 15 28 19 6 21.5 - 35 10 38.3 3.6 16

J11B 4.94:1 272 15 28 19 6 21.5 - 45 14 48.8 3.6 16

J21A 5.00:1 318 15 35 24 8 27 - 45 14 48.8 3.9 24

J21B 5.00:1 318 15 35 24 8 27 - 55 16 59.3 3.9 24

J31A 5.00:1 360 20 31 28 8 31 - 55 16 59.3 6 35

J31B 5.00:1 360 20 31 28 8 31 - 65 16 69.4 6 35

J51A 5.08:1 443 20 40 38 10 41 M8 60 18 64.4 7.4 53

J51B 5.08:1 443 20 40 38 10 41 M8 75 20 79.9 7.4 53

J71A 4.94:1 508 24 48 42 12 45 M8 70 20 74.9 12.5 82

J71B 4.94:1 508 24 48 42 12 45 M8 85 22 90.4 12.5 82

1. The V-belt pulley should be placed as close to the

housing as possible.

2. These dimensions are minimum diameters of driven

pulley to prevent overloading of the bearings.

3. Tolerances according to ISO H7.

4. Tolerances according to ISO E9.

5. The reducer should normally be mounted on a shaft

with tolerance ISO js6. On heavy duty applications

closer tolerances are recommended.

6. Tolerances according to ISO js6.

7. Tolerances according to ISO h9.

8. Space for spacer if locking ring is used.

notes

SERIES J

15

DIMENSIONS - SINGLE REDUCTION

J100 - 125 Single Reduction

Size Ratio A AC C1RP J K LM N P R T T1 T2 T3 S2U V W

max min

J100 5:1 286 10 146 6 142 180 755 500 30 30 100 170 83 116 182 215 224 436 211 195

J110 5:1 330 13 161 21 178 197 730 490 35 36 120 228 97 132 198 233 250 496 253 226

J125 5:1 375 14 175 5 220 214 730 490 35 36 125 246 117.5 152.5 226.5 261.5 280 534 261 240

Please note: Dimensions R, T, T1, T2, T3

are not machined, deviations can occur.

Size Ratio X Y Z Input shaft Shaft sleeve5

HF AK5Weight

kg

F6H7G FA D3,8 B4E

J100 5:1 584 337 44.4 55 16 59 M20 100 28 106.4 3 249 206

J110 5:1 704 405 42.5 55 16 59 M20 110 28 116.4 4 288 295

J125 5:1 768 461 47 60 18 64 M20 125 32 132.4 4 335 384

1. The V-belt pulley should be placed as close to the

housing as possible.

2. These dimensions are minimum diameters of driven

pulley to prevent overloading of the bearings.

3. Tolerances according to ISO H7.

4. Tolerances according to ISO E9.

5. The reducer should normally be mounted on a shaft

with tolerance ISO js6. On heavy duty applications

closer tolerances are recommended.

6. Tolerances according to ISO m6.

7. Tolerances according to ISO h9.

8. Space for spacer if locking ring is used.

notes

Dimensions for threaded

holes at gearhouse sides,

see page 53.

SERIES J

16

DIMENSIONS - SINGLE REDUCTION

KIBO

J100 - 125 Single Reduction

Please note: Dimensions R, T, T1, T2, T3

are not machined, deviations can occur.

Size Ratio U V W X Y Z Input shaft Shaft sleeve5Weight

kg

F6H7G FA D3,8 B4E

J100 5:1 436 211 195 584 337 44.4 55 16 59 M20 100 28 106.4 208

J110 5:1 496 253 226 704 405 42.5 55 16 59 M20 110 28 116.4 298

J125 5:1 534 261 240 768 461 47 60 18 64 M20 125 32 132.4 387

1. The V-belt pulley should be placed as close to the

housing as possible.

2. These dimensions are minimum diameters of driven

pulley to prevent overloading of the bearings.

3. Tolerances according to ISO H7.

4. Tolerances according to ISO E9.

5. The reducer should normally be mounted on a shaft

with tolerance ISO h8. On heavy duty applications

closer tolerances are recommended.

6. Tolerances according to ISO m6.

7. Tolerances according to ISO h9.

8. Space for spacer if locking ring is used.

notes

Dimensions for threaded

holes at gearhouse sides,

see page 53.

Size Ratio A AC C1RP J K LM N P R T T1 T2 T3 S2

max min

J100 5:1 274 22 129 11 142 180 755 500 30 30 83 170 98 131 197 230 224

J110 5:1 312 24 145 6 178 197 730 490 35 36 75 228 112 147 213 248 250

J125 5:1 355 26 149 21 220 214 730 490 35 36 78 246 133.5 168.5 242.5 277.5 280

SERIES J

17

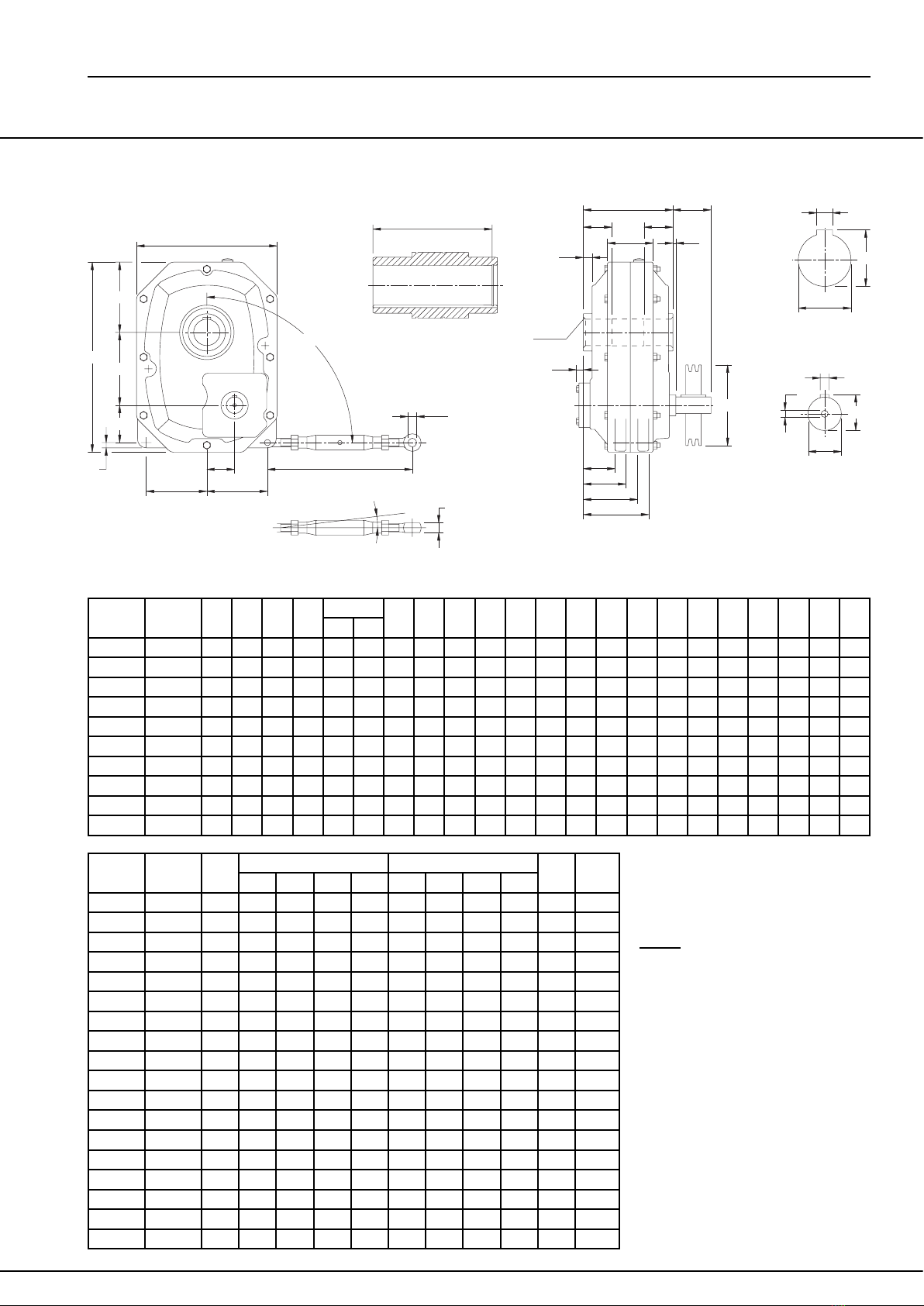

DIMENSIONS - DOUBLE REDUCTION

J12 - 72 Double Reduction

Please note: Dimensions R, T, T1, T2, T3

are not machined, deviations can occur.

V

W

J

Y

X

U

Z

KK

L

90° +0

-45

øM

N

2

R

P P

A C

øS

H

G

F

FA

B

E

D

Q

T

T1

T2

T3

HFx45°

±0.5°

AK

AC

°

°

1. The V-belt pulley should be

placed as close to the housing as

possible.

2. These dimensions are minimum

diameters of driven pulley to

prevent overloading of the

bearings.

3. Tolerances according to ISO H7.

4. Tolerances according to ISO E9.

5. The reducer should normally

be mounted on a shaft with

tolerance ISO js6. On heavy duty

applications closer tolerances are

recommended.

6. Tolerances according to ISO m6.

7. Tolerances according to ISO h6.

8. Space for spacer if locking ring is

used.

Size Ratio A AC J K LM N P Q R T T1 T2 T3 S2U V W X Y Z

max min

J12A 15/25:1 137 14 47 83 350 240 12 14 35 0 76 50 65 94 109 140 200 108 100 272 15 29

J12B 15/25:1 137 14 47 83 350 240 12 14 35 0 76 50 65 94 109 140 200 108 100 272 15 29

J22A 15/25:1 157 14 63 100 400 280 16 18 45 5 86 52 70 96 114 160 236 118 119 318 15 38

J22B 15/25:1 157 14 63 100 400 280 16 18 45 5 86 52 70 96 114 160 236 118 119 318 15 38

J32A 15/25:1 172 15 67 114 400 280 16 18 50 3 104 57 79 114 136 180 272 134 137 360 20 51

J32B 15/25:1 172 15 67 114 400 280 16 18 50 3 104 57 79 114 136 180 272 134 137 360 20 51

J52A 15/25:1 189 15 85 138 460 330 20 22 55 4 104 64 89 125 150 200 320 160 166 443 20 63

J52B 15/25:1 189 15 85 138 460 330 20 22 55 4 104 64 89 125 150 200 320 160 166 443 20 63

J72A 15/25:1 203 16 87 166 460 330 20 22 75 4 134 60 85 123 148 280 388 200 193 508 24 75.5

J72B 15/25:1 203 16 87 166 460 330 20 22 75 4 134 60 85 123 148 280 388 200 193 508 24 75.5

Size Ratio C1Input shaft Shaft sleeve5AK Weight

kg

F6H7G FA D3,8 B4E HF

J12A 15/25:1 42 19 6 21.5 - 35 10 38.3 1 130 20

J12B 15/25:1 42 19 6 21.5 - 45 14 48.8 1 130 20

J22A 15:1 52 24 8 27 - 45 14 48.8 2 149 28

J22B 15:1 52 24 8 27 - 55 16 59.3 2 149 28

J22A 25:1 52 19 6 21.5 - 45 14 48.8 2 149 28

J22B 25:1 52 19 6 21.5 - 55 16 59.3 2 149 28

J32A 15:1 62 28 8 31 - 55 16 59.3 2 161 39

J32B 15:1 62 28 8 31 - 65 18 69.4 2 161 39

J32A 25:1 52 24 8 27 - 55 16 59.3 2 161 39

J32B 25:1 52 24 8 27 - 65 18 69.4 2 161 39

J52A 15:1 82 38 10 41 M8 60 18 64.4 2 178 60

J52B 15:1 82 38 10 41 M8 75 20 79.9 2 178 60

J52A 25:1 62 28 8 31 M8 60 18 64.4 2 178 60

J52B 25:1 62 28 8 31 M8 75 20 79.9 2 178 60

J72A 15:1 87 42 12 45 M8 70 20 74.9 2 192 90

J72B 15:1 87 42 12 45 M8 85 22 90.4 2 192 90

J72A 25:1 87 38 10 41 M8 70 20 74.9 2 192 90

J72B 25:1 87 38 10 41 M8 85 22 90.4 2 192 90

notes

This manual suits for next models

6

Table of contents

Other Benzlers Industrial Equipment manuals