Benzlers M Series Maintenance and service guide

INSTALLATION &

MAINTENANCE

Series M. C. F. K.

IGM1.00GBA0707

Series MCFK Cover:English Cover (Series F) 06.07 17/7/07 16:54 Page 2

3URGXFW6DIHW\

,03257$17

3URGXFW6DIHW\,QIRUPDWLRQ

*HQHUDO7KHIROORZLQJLQIRUPDWLRQLVLPSRUWDQWLQHQVXULQJVDIHW\,WPXVWEHEURXJKWWRWKHDWWHQWLRQRISHUVRQQHOLQYROYHGLQWKHVHOHFWLRQRI0&)DQG.

WUDQVPLVVLRQHTXLSPHQWWKRVHUHVSRQVLEOHIRUWKHGHVLJQRIWKHPDFKLQHU\LQZKLFKLWLVWREHLQFRUSRUDWHGDQGWKRVHLQYROYHGLQLWVLQVWDOODWLRQXVHDQG

PDLQWHQDQFH

7KLVHTXLSPHQWZLOORSHUDWHVDIHO\SURYLGHGLWLVVHOHFWHGLQVWDOOHGXVHGDQGPDLQWDLQHGSURSHUO\$VZLWKDQ\SRZHUWUDQVPLVVLRQHTXLSPHQWSURSHU

SUHFDXWLRQVPXVWEHWDNHQDVLQGLFDWHGLQWKHIROORZLQJSDUDJUDSKVWRHQVXUHVDIHW\

3RWHQWLDO+D]DUGVWKHVHDUHQRWQHFHVVDULO\OLVWHGLQDQ\RUGHURIVHYHULW\DVWKHGHJUHHRIGDQJHUYDULHVLQLQGLYLGXDOFLUFXPVWDQFHV,WLVLPSRUWDQWWKHUHIRUH

WKDWWKHOLVWLVVWXGLHGLQLWVHQWLUHW\

)LUH([SORVLRQ

D 2LOPLVWVDQGYDSRXUDUHJHQHUDWHGZLWKLQJHDUXQLWV,WLVWKHUHIRUHGDQJHURXVWRXVHQDNHGOLJKWVLQWKHSUR[LPLW\

RIJHDUER[RSHQLQJV

E ,QWKHHYHQWRIILUHRUVHULRXVRYHUKHDWLQJRYHU&FHUWDLQPDWHULDOVUXEEHUSODVWLFVHWFPD\GHFRPSRVHDULGSURGXFHIXPHV&DUHVKRXOG

EHWDNHQWRDYRLGH[SRVXUHWRWKHIXPHVDQGWKHUHPDLQVRIEXUQHGRURYHUKHDWHGSODVWLFUXEEHUPDWHULDOVVKRXOGEHKDQGOHGZLWKUXEEHUJORYHV

F ,IFRUUHFWO\LQVWDOOHGDQGRSHUDWHGWKHHTXLSPHQWFRPSOLHVWR(&$7(;DDVPDUNHGRQWKHQDPHSODWH)DLOXUHWRFRPSO\FRXOGOHDGWR

VHYHUHRUIDWDOLQMXU\

*XDUGV5RWDWLQJVKDIWVDQGFRXSOLQJVPXVWJXDUGHGWRHOLPLQDWHWKHSRVVLELOLW\RISK\VLFDOFRQWDFWRUHQWDQJOHPHQWRIFORWKLQJ,WVKRXOGEHRIULJLG

FRQVWUXFWLRQDQGILUPO\VHFXUHG

1RLVH+LJKVSHHGJHDUER[HVDQGJHDUER[GULYHQPDFKLQHU\PD\SURGXFHQRLVHOHYHOVZKLFKDUHGDPDJLQJWRWKHKHDULQJZLWKSURORQJHGH[SRVXUH(DU

GHIHQGHUVVKRXOGEHSURYLGHGIRUSHUVRQQHOLQWKHVHFLUFXPVWDQFHV5HIHUHQFHVKRXOGEHPDGHWRWKH'HSDUWPHQWRI(PSOR\PHQW&RGHRI3UDFWLFHIRU

UHGXFLQJH[SRVXUHRIHPSOR\HGSHUVRQVWRQRLVH

/LIWLQJ :KHUHSURYLGHGRQODUJHUXQLWVRQO\WKHOLIWLQJSRLQWVRUH\HEROWVPXVWEHXVHGIRUOLIWLQJRSHUDWLRQVVHHPDLQWHQDQFHPDQXDORUJHQHUDO

DUUDQJHPHQWGUDZLQJIRUOLIWLQJSRLQWSRVLWLRQV)DLOXUHWRXVHWKHOLIWLQJSRLQWVSURYLGHGPD\UHVXOWLQSHUVRQDOLQMXU\DQGRUGDPDJHWRWKHSURGXFWRU

VXUURXQGLQJHTXLSPHQW.HHSFOHDURIUDLVHGHTXLSPHQW

/XEULFDQWVDQG/XEULFDWLRQ

D 3URORQJHGFRQWDFWZLWKOXEULFDQWVFDQEHGHWULPHQWDOWRWKHVNLQ7KHPDQXIDFWXUHUVLQVWUXFWLRQVPXVWEHIROORZHGZKHQKDQGOLQJOXEULFDQWV

E 7KHOXEULFDWLRQVWDWXVRIWKHHTXLSPHQWPXVWEHFKHFNHGEHIRUHFRPPLVVLRQLQJ5HDGDQGFDUU\RXWDOOLQVWUXFWLRQVRQWKHOXEULFDQWSODWHDQGLQWKH

LQVWDOODWLRQDQGPDLQWHQDQFHOLWHUDWXUH+HHGDOOZDUQLQJWDJV)DLOXUHWRGRVRFRXOGUHVXOWLQPHFKDQLFDOGDPDJHDQGLQH[WUHPHFDVHVULVNRI

LQMXU\WRSHUVRQQHO

(OHFWULFDO(TXLSPHQW2EVHUYHKD]DUGZDUQLQJVRQHOHFWULFDOHTXLSPHQWDQGLVRODWHSRZHUEHIRUHZRUNLQJRQWKHJHDUER[RUDVVRFLDWHGHTXLSPHQWLQ

RUGHUWRSUHYHQWWKHPDFKLQHU\EHLQJVWDUWHG

,QVWDOODWLRQ0DLQWHQDQFHDQG6WRUDJH

D ,QWKHHYHQWWKDWHTXLSPHQWLVWREHKHOGLQVWRUDJHIRUDSHULRGH[FHHGLQJPRQWKVSULRUWRLQVWDOODWLRQRUFRPPLVVLRQLQJORFDODSSOLFDWLRQ

HQJLQHHULQJVWDIIPXVWEHFRQVXOWHGUHJDUGLQJVSHFLDOSUHVHUYDWLRQUHTXLUHPHQWV8QOHVVRWKHUZLVHDJUHHGHTXLSPHQWPXVWEHVWRUHGLQDEXLOGLQJ

SURWHFWHGIURPH[WUHPHVRIWHPSHUDWXUHDQGKXPLGLW\WRSUHYHQWGHWHULRUDWLRQ

7KHURWDWLQJFRPSRQHQWVJHDUVDQGVKDIWVPXVWEHIXPHGDIHZUHYROXWLRQVRQFHDPRQWKWRSUHYHQWEHDULQJVEULQHOOLQJ

E ([WHUQDOJHDUER[FRPSRQHQWVPD\ EHVXSSOLHGZLWKSUHVHUYDWLYHPDWHULDOVDSSOLHGLQWKHIRUPRIDZD[HGWDSHRYHUZUDSRUZD[ILOPSUHVHUYDWLYH

*ORYHVVKRXOGEHZRUQZKHQUHPRYLQJWKHVHPDWHULDOV7KHIRUPHUFDQEHUHPRYHGPDQXDOO\WKHODWWHUXVLQJZKLWHVSLULWDVDVROYHQW

3UHVHUYDWLYHVDSSOLHGWRWKHLQWHUQDOSDUWVRIWKHJHDUXQLWVGRQRWUHTXLUHUHPRYDOSULRUWRRSHUDWLRQ

F ,QVWDOODWLRQPXVWEHSHUIRUPHGLQDFFRUGDQFHZLWKWKHPDQXIDFWXUHUVLQVWUXFWLRQVDQGEHXQGHUWDNHQE\VXLWDEO\TXDOLILHGSHUVRQQHO

G %HIRUHZRUNLQJRQDJHDUER[ RUDVVRFLDWHGHTXLSPHQWHQVXUHWKDWWKHORDGKDVEHHQUHPRYHGIURPWKHV\VWHPWRHOLPLQDWHWKHSRVVLELOLW\RIDQ\

PRYHPHQWRIWKHPDFKLQHU\DQGLVRODWHSRZHUVXSSO\:KHUHQHFHVVDU\SURYLGHPHFKDQLFDOPHDQVWRHQVXUHWKHPDFKLQHU\FDQQRWPRYHRU

URWDWH(QVXUHUHPRYDORIVXFKGHYLFHVDIWHUZRUNLVFRPSOHWH

H (QVXUHWKHSURSHUPDLQWHQDQFHRIJHDUER[HVLQRSHUDWLRQ8VHRQO\WKHFRUUHFWWRROVDQGDSSURYHGVSDUHSDUWVIRUUHSDLUDQGPDLQWHQDQFH

&RQVXOWWKH0DLQWHQDQFH0DQXDOEHIRUHGLVPDQWOLQJRUSHUIRUPLQJPDLQWHQDQFHZRUN

+RW6XUIDFHVDQG/XEULFDQWV

D 'XULQJRSHUDWLRQJHDUXQLWVPD\EHFRPHVXIILFLHQWO\KRWWRFDXVHVNLQEXUQV&DUHPXVWEHWDNHQWRDYRLGDFFLGHQWDOFRQWDFW

E $IWHUH[WHQGHGUXQQLQJWKHOXEULFDQWLQJHDUXQLWVDQGOXEULFDWLRQV\VWHPVPD\UHDFKWHPSHUDWXUHVVXIILFLHQWWRFDXVHEXPV$OORZHTXLSPHQWWR

FRROEHIRUHVHUYLFLQJRUSHUIRUPLQJDGMXVWPHQWV

6HOHFWLRQDQG'HVLJQ

D :KHUHJHDUXQLWVSURYLGHDEDFNVWRSIDFLOLW\HQVXUHWKDWEDFNXSV\VWHPVDUHSURYLGHGLIIDLOXUHRIWKHEDFNVWRSGHYLFHZRXOGHQGDQJHUSHUVRQQHO

RUUHVXOWLQGDPDJH

E 7KHGULYLQJDQGGULYHQHTXLSPHQWPXVWEHFRUUHFWO\VHOHFWHGWRHQVXUHWKDWWKHFRPSOHWHPDFKLQHU\LQVWDOODWLRQZLOOSHUIRUPVDWLVIDFWRULO\DYRLGLQJ

V\VWHPFULWLFDOVSHHGVV\VWHPWRUVLRQDOYLEUDWLRQHWF

F 7KHHTXLSPHQWPXVWQRWEHRSHUDWHGLQDQHQYLURQPHQWRUDWVSHHGVSRZHUVWRUTXHVRUZLWKH[WHUQDOORDGVEH\RQGWKRVHIRUZKLFKLWZDV

GHVLJQHG

G $VLPSURYHPHQWVLQGHVLJQDUHEHLQJPDGHFRQWLQXDOO\WKHFRQWHQWVRIWKLVFDWDORJXHDUHQRWWREHUHJDUGHGDVELQGLQJLQGHWDLODQGGUDZLQJVDQG

FDSDFLWLHVDUHVXEMHFWWRDOWHUDWLRQVZLWKRXWQRWLFH

7KHDERYHJXLGDQFHLVEDVHGRQWKHFXUUHQWVWDWHRINQRZOHGJHDQGRXUEHVWDVVHVVPHQWRIWKHSRWHQWLDOKD]DUGVLQWKHRSHUDWLRQRIWKHJHDUXQLWV

$Q\IXUWKHULQIRUPDWLRQRUFODULILFDWLRQUHTXLUHGPD\EHREWDLQHGE\FRQWDFWLQJ\RXUORFDODSSOLFDWLRQHQJLQHHULQJRIILFH

Series MCFK Cover:English Cover (Series F) 06.07 2/7/07 11:06 Page 3

Information

Page 1 Issue 2

Section Description Page No

1GeneralInformation 2

2 Weather Protection 2

3 Reading The Nameplate 2

4 Marking 3

5 Installation

5.1SafetyWarning 4

5.2 Prior to Installation 4

5.3 Fitting Components to Input or Output Shafts 4

5.4Lifting 5

5.5 Installing Foot or Flange mount units 6

5.6 Installing Shaft Mount Units 7

5.7 Units for use in a potentially explosive atmosphere 7

6 Lubrication

6.1General 8

6.2Ventilator 8

6.3OilLevel 8

7 Motor Connections 9

8 StartingUp 9

9 Operation

9.1Noise 9

9.2GeneralSafety 9

9.3 Units for use in a potentially explosive atmosphere 9

10 Maintenance

10.1 Prior to any Maintenance Operations 10

10.2 Oil Plugs & Ventilator 10

10.3 Lubrication 11

10.4 Bearings 11

10.5 Grease Lubrication 11

10.6 Cleaning 11

11 Fault Diagnosis 12

Appendix

1 Shaft Alignment 13-14

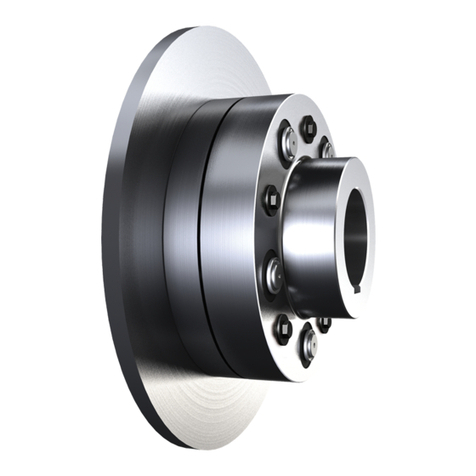

2A Series C, F & K Hollow Output Bore Details 15-18

2B Series F Kibo Bush Details 19-20

2C Series K Shrink Disc Details 21-22

2D Series C, F & K Torque Arm Details 23 - 25

3 Three Phase Induction Motor Installation 26

4 Lubrication Information 27-37

Safety warning Symbols

Electrical Hazard

Could result in death or

serious injury

Danger

Could result in serious, slight

or minor injuries

Danger (Touch Hazard)

Could result in death or

serious injury

Damaging Situation

Could result in damage to

gear unit or driven machinery

Important notes on Explosion

Protection

Cleaning

Periodic cleaning necessary

Information

Page 2 Issue 2

1. General Information

The following instructions will help you achieve a satisfactory installation of your gear unit, ensuring the

best possible conditions for a long and trouble free operation.

All units are tested and checked prior to despatch, a great deal of care is taken in packing and shipping

arrangements to ensure that the unit arrives at the customer in the approved condition.

2. Weather Protection of Unit

All Series M C F & K units are provided with protection against normal weather conditions. Where units are

to operate in extreme conditions, or where they are to stand for long periods without running, eg during

plant construction, consult our application engineers so that arrangements for adequate protection can be

made.

3. Reading the Nameplate

Unit Identification

When requesting further information, or service support quote the

following information from the nameplate:

• Unit type (Model No)

• Order Number / Year of Manufacture

Lubrication Grade

The grade is marked on the nameplate. See Appendix 4 for type and quantity of lubricant.

Information

Page 3 Issue 2

4. Marking

These gear units are intended for use in industrial systems.

Provided they are correctly selected marked and installed in accordance with these instructions (gear

units only) they comply with the EU directive 94/9/EC ATEX 100a Group II Cat 2 zones 1 & 21 & Cat 3

zones 2 & 22.

Motors, couplings, or any other equipment fitted to the gear unit must also comply with this directive.

If the gear unit is supplied as a geared motor package it is important to check the nameplates of the gear

unit and the motor (or any other equipment fitted) corresponds with the classification of the potentially

explosive atmosphere in which the unit is to be installed.

Understanding EU Directive 94/9/EC (ATEX 100a) Markings.

II 2 G EEx c,k, T4

Temp classTemp class

Ex-Atmosphere

Category

Group

T3 Max. surface temperature 200°C

T4 Max. surface temperature 135°C

T5 Max. surface temperature 100°C

Protection type of gear unit

G = Gas

D = Dust

Examples:

II 2 G - (Zone 1) occasional hazardous explosive atmosphere

II 3 G - (Zone 2) rare short-term hazardous explosive atmosphere

II 2 D - (Zone 21) occasional hazardous explosive atmosphere during normal

operation due to presence of combustible dust

II 3 D - (Zone 22) short-term hazardous explosive atmosphere due to presence

of combustible dust; no hazard during normal operation

Installation

Page 4 Issue 2

5. Installation

5.1. Safety Warning

WARNING! The customer shall be responsible for the proper use of articles supplied by

the company, particularly the rotating shafts between their driving and driven members,

and their guarding for safety, and the company shall not be responsible for any injury or

damage sustained as a result of the improper use of the articles supplied.

Attention is hereby drawn to the danger of using naked lights in proximity to openings in

gearboxes and gear units supplied by the company, and the company shall not be liable

for any claim for injury or damage arising from any action in contravention of this warning.

5.2. Prior to Installation

5.2.1. Check gear unit has not been damaged.

5.2.2. Check the gear unit / motor nameplate matches the requirements of the machine the unit is to be

installed into.

5.2.3. Thoroughly clean the shaft and mounting surfaces that are to be used of anti-corrosion agents using

a commercially available solvent. Ensure solvent does not make contact with the oil seals.

5.3. Fitting of components to either the unit input or output shaft

The input or output shaft extension diameter tolerance is to ISO tolerance k6 (for shaft diameter ≤

50mm) and m6 (for shaft diameter > 50mm) and the fitted components should be to ISO tolerance

M7 (for bore diameter ≤50mm) and K7 (for bore diameter > 50mm).

5.3.1. Ensure shaft extensions, bores & keys etc are cleaned.

5.3.2. Items (such as gears, sprockets, couplings etc) should not be hammered onto these shafts since

this would damage the shaft support bearings.

5.3.3. The item should be pushed onto the shaft using a screw jack device fitted into the threaded hole

provided in the end of the shaft. See table 1 below.

5.3.4. Items being fitted may be heated to 80/100°C to aid assembly further.

Over To

13 16

16 21

21 24

24 30

30 38

38 50

50 85

85 130

Shaft Diameter Threaded Hole Details

M5 x 0.8 12 deep

M6 x 1.0 16 deep

M24 x 3.0 55 deep

M8 x 1.25 19 deep

M10 x 1.5 22 deep

M12 x 1.75 28 deep

M20 x 2.5 42 deep

M16 x 2.0 36 deep

Table 1

Installation

Page 5 Issue 2

5.4. Lifting

Use only lifting points provided.

Larger Series M & C units are supplied with a lifting eye.

Series F & K units, have a lifting hole in the gear housing as shown.

Lifting Hole

Series K

Lifting Hole

Series F

On units supplied with a lifting eye on the motor, both the lifting point on the gear unit and motor

should be used.

Use both lifting points

Installation

Page 6 Issue 2

5.5. Foot mounted or flange mounted units

5.5.1. Ensure the base foundation / flange mounting surface is flat¹, vibration absorbing and torsionally

rigid.

5.5.2. The gear unit must be installed in the specified mounting position. The maximum deviation from the

designated mounting position is ± 5° (unless gear unit is suitably modified and approved for non

standard mounting positions).

5.5.3. Align unit (see Appendix 1).

Note: It is important to ensure when aligning unit on baseplate that all machined mounting

points are supported over their full area.

If steel packings are used, these should be placed either side of the foundation bolt as close

as possible.

During final bolting ensure the unit or baseplate is not distorted as this would cause strains in

the gear case resulting in errors of alignment of shafts and gearing.

Check all mounting points are fully supported and adjust if necessary by using steel

packings.

Torque tighten bolts to torque specified in table 2 below.

5.5.4. Secure unit, or baseplate if fitted to a rigid foundation using heavy duty bolts to ISO grade 8.8

minimum

-

-

M30

M36

1220 Nm

2150 Nm

350 Nm

610 Nm

10 Nm

18 Nm

37 Nm

64 Nm

150 Nm

260 Nm

-

25 Nm

50 Nm

85 Nm

200 Nm

Tightening Torque

Holding Down Bolts /

Output Flange Bolts Motors to Gearhead

10 Nm

M12

M16

M20

M24

Set Screw

Size

M6

M8

M10

Table 2

5.5.5. Recommended fasteners (Basemount units):

Unit Size Unit Size Unit Size

M01 K03 C03

M02 K04 C04

M03 K05 C05

M04 K06 C06

M05 K07 C07

M06 K08 C08

M07 K09 C09

M08 K10 C10

M09 K12

M10

M13

M14

M36 x 100L

Recommended Fastener Size

M8 x 20L

M10 x 30L

M10 x 30L

M12 x 40L

M16 x 50L

M20 x 65L

M24 x 75L

M24 x 80L

M36 x 100L

Recommended Fastener Size

M10 x 25L

M10 x 30L

M12 x 35L

M12 x 40L

M16 x 50L

M20 x 60L

M24 x 70L

M30 x 80LM16 x 60L

M20 x 70L

M24 x 80L

M30 x 90L

M12 x 40L

M12 x 40L

M12 x 40L

M16 x 45L

Recommended Fastener Size

M8 x 25L

M8 x 30L

M8 x 30L

Table 3

¹ Maximum permissible flatness error for mounting surface is 0.12mm.

Installation

Page 7 Issue 2

5.6. Shaft mounted units

5.6.1. The gear unit must be installed in the specified mounting position.

5.6.2. Assembly of gear unit on to the machine shaft:

There are four assembly methods dependant on the gear unit type:

• Standard straight bore with keyway. See Appendix 2A.

• Unit fitted with KIBO® bushes. See Appendix 2B.

• Unit fitted with shrink disc. See Appendix 2C.

5.6.3. Anchor gear unit to a secure point on the structure by means of a torque arm. (See Appendix 2E)

5.7. Units for use in a potentially explosive atmosphere

5.7.1. If the unit has been damaged in transit do not use. (Remove all transport fixtures and packings prior

to start up)

5.7.2. Check nameplate of unit corresponds with the sites potentially explosive atmosphere classification.

5.7.3. Check ambient temperature falls within lubricant grade recommendations. (See Approved

Lubricants p27)

5.7.4. Make sure no potentially explosive atmosphere exists during installation.

5.7.5. Make sure that gear unit is sufficiently ventilated with no external heat input – cooling air

temperature should not exceed 40°C

5.7.6. Ensure mounting position corresponds to that marked on the nameplate. (Note! ATEX approval is

only valid for mounting position specified on the nameplate.)

5.7.7. Check motors, couplings or any other equipment fitted to the gear unit has ATEX approval.

Check information listed on nameplates correspond to the environmental conditions of the site.

5.7.8. Ensure gearbox is not subjected to any loading greater than those marked on the nameplate.

5.7.9. For units operated with inverter drives, check motor suitability for use with the inverter.

Ensure that the inverter parameters do not exceed those of the motor.

5.7.10. For belt driven units, check all belts fitted are of sufficient electrical leakage resistance. (< 109Ω).

5.7.11. Ensure gear unit and other equipment is electrically grounded (Earthed).

5.7.12. Check and adjust guards and covers so that there is no ignition source from sparks that may be

thrown by moving parts making contact with guards etc. Ensure coupling guards, covers etc are

dust tight or are designed in such a way that a build up of dust deposits cannot form when the unit

is used in Zone 21 & Zone 22 classification areas.

Lubrication

Page 8 Issue 2

6. Lubrication

6.1. General

6.1.1. Series M F & K size 7 and below will be supplied factory filled with a quantity of EP mineral oil

(Grade 6E) appropriate to the intended mounting position. However if, as requested, the gear unit is

supplied without lubricant then the oil quantity required is obtained from Appendix 4. Gear units size

8 and larger are supplied without lubricant (unless factory filled by request). Recommended

lubricants are listed in our Approved Lubricants pages in Appendix 4.

6.1.2. Series C size 6 and below are supplied factory filled with synthetic lubricant (Grade 6G). Size 7 and

larger are supplied without lubricant.

Temperature Limitations

The standard lubricant is suitable for operation in ambient temperatures of 0° to 35°C. Outside of this

consult Table L1 or Application Engineers.

6G (VG 320) 7G (VG 460)

Polyglycol

based S

y

nthetic

(type G)

Polyalphaolefin

based S

y

nthetic

with EP additive

(type H)

CLP (PG) 5G (VG 220)

Ambient Temperature Range

Lubricant(ISO)

EP Mineral Oil

(type E)

CLP (CC) 5E (VG 220) 6E (VG 320) 7E (VG 460)

-5°C to 20°C (type E)

-30°C to 20°C (type G & H) 0°C to 35°C 20°C to 50°C

CLP (HC) 5H (VG 220) 5H (VG 220) 6H (VG 320)

Table L1

Note! CLP (CC) & CLP (HC) are the recommended lubricants for Series F K & M.

6.2. Ventilator

6.2.1. Clean & secure the ventilator (if supplied) in the correct location for the required mounting position.

(See Appendix 4)

6.3. Oil Level:

Units supplied without oil:

6.3.1. Fill gear unit with correct type of lubricant until oil escapes from level plug. See Appendix 4

Factory filled units:

6.3.2. If the unit is fitted with a level plug, (See Appendix 4) check oil level and top up with correct oil type

as necessary.

WARNING Do not overfill as excess may cause overheating and leakage.

6.3.3. Re-fit plugs & tighten to correct torque figure – see notes in maintenance section. Clean away any

oil spillage from the surface of the gear unit and driven machinery.

Start Up

Page 9 Issue 2

7. Motor Connections

To mains:

7.1. Connection of the electric motor to the mains supply should be made by a qualified person. The current

rating of the motor will be identified on the motor plate, and correct sizing of the cables to electrical

regulations is essential.

Motor terminal connection:

7.2. Circuit diagrams for the correct wiring of the motor terminal box are included as Appendix 3 of this

document if the motor is fitted with our ‘own brand’ motor.

Alternatively if the motor is supplied separately or if fitted with a motor from a different manufacturer,

then this should have appropriate documentation provided with it.

8. Starting Up

8.1. Prior to starting up

8.1.1. Ensure ventilator is fitted (if supplied) see lubrication section 6.2

8.1.2. Check oil level, top up if necessary.

8.1.3. Ensure all safety devices are in place (ie guards fitted). Check and adjust guards and covers so that

there is no ignition source from sparks that may be thrown by moving parts making contact with

guards etc. Ensure coupling guards, covers etc are dust tight or are designed in such a way that a

build up of dust deposits cannot form when the unit is used in Zone 21 & Zone 22 classification

areas.

8.1.4. Remove any safety devices fitted to prevent machine rotation.

8.1.5. Starting up should only be performed or supervised by suitably qualified personnel.

Caution: Any deviation from normal operating conditions, (increased temperature, noise,

vibrations, power consumption etc) suggest a malfunction, inform maintenance personnel

immediately.

8.1.6. Units fitted with backstop, ensure motor is correctly wired for free direction of rotation.

9. Operation

9.1. Noise

The range of product satisfies a noise (sound pressure level) of 85dB(A) or less when measured at 1

metre from the unit surface.

Measurements taken in accordance with B.S.7676 Pt1 : 1993 (ISO 8579-1 : 1993).

9.2. General Safety

Potential hazards which can be encountered during installation, maintenance and operation of drives

is covered in greater detail in the product safety page at the front of this booklet.

Advice is also given on sensible precautions which need to be taken to avoid injury or damage.

PLEASE READ!

9.3. Gear units for use in a potentially explosive atmosphere

After 3 hours of operation check the gear unit surface temperature. This temperature should not

exceed 110°C. If temperature exceeds this limit, shut down immediately and contact your local sales

office.

Maintenance

Page 10 Issue 2

10. Maintenance

10.1. Prior to any maintenance operations

10.1.1. De-energise the drive and secure against un-intentional switch on.

10.1.2.Wait until the unit has cooled down – Danger of skin burns & pressure build up.

10.2. Oil plugs/ventilator

10.2.1. Prior to removing plugs, ensure that the unit has cooled sufficiently so that oil will not burn.

10.2.2. Remove ventilator plug prior to removing level and/or drain plug. Warning do not stand over

ventilator plug whilst removing as pressure build up behind valved ventilator may cause it to eject

when removed.

10.2.3. Place a container under the oil drain plug to be removed. Note: it is recommended that the oil

should be slightly warm, (40-50°C) when drained. (Cooler oil will be more difficult to drain correctly).

10.2.4. Top ups or refills should be done through the ventilator position.

10.2.5.Remember to refit all plugs and torque tighten to table M1 below.

M10 12Nm

M12 20Nm

M14 26Nm

M16 34Nm

M22 65Nm

Plug Size Tightening

Tor

q

ue

Table M1

10.2.6. Clean away any oil spillage.

Maintenance

Page 11 Issue 2

10.3. Lubrication

10.3.1. Periodic inspection.

For Units fitted with level plug or other level indicating device, check the oil level every 3000 hours

or 6 months whichever is sooner and if necessary top up with the recommended type of lubricant.

10.3.2. Oil changes.

• Smaller units (supplied without ventilator) are supplied lubricated for life* except for the

following conditions:

Units that are required to work in explosive atmosphere (94/9/EC Atex 100a Group II category

2 zones 1 & 21 & category 3 zones 2 & 22) should be drained and refilled with correct quantity

of lubricant in accordance with the schedule as listed on the tables below. See Appendix 4 for

correct oil quantity.

• Larger units (supplied with ventilator) should be drained and refilled with correct quantity of

lubricant in accordance with the tables below. See Appendix 4 for correct oil quantity.

Oil Change Period: Series F K & M

MINERAL OIL SYNTHETIC OIL

75 OR LESS 17000 HOURS OR 3 YEARS 26000 HOURS OR 3 YEARS

80 12000 HOURS OR 3 YEARS 26000 HOURS OR 3 YEARS

85 8500 HOURS OR 3 YEARS 21000 HOURS OR 3 YEARS

90 6000 HOURS OR 2 YEARS 15000 HOURS OR 3 YEARS

95 4200 HOURS OR 17 MONTHS 10500 HOURS OR 3 YEARS

100 3000 HOURS OR 12 MONTHS 7500 HOURS OR 2 1/2 YEARS

105 2100 HOURS OR 8 MONTHS 6200 HOURS OR 2 YEARS

110 1500 HOURS OR 6 MONTHS 2100 HOURS OR 18 MONTHS

Oil Change Period: Series C

MINERAL OIL SYNTHETIC OIL

65 OR LESS 17000 HOURS OR 3 YEARS 26000 HOURS OR 3 YEARS

70 12000 HOURS OR 3 YEARS 26000 HOURS OR 3 YEARS

75 8500 HOURS OR 3 YEARS 22000 HOURS OR 3 YEARS

80 6000 HOURS OR 2 YEARS 15000 HOURS OR 3 YEARS

85 4200 HOURS OR 17 MONTHS 10500 HOURS OR 3 YEARS

90 3000 HOURS OR 12 MONTHS 7500 HOURS OR 2 1/2 YEARS

95 2100 HOURS OR 8 MONTHS 6000 HOURS OR 2 YEARS

100 1500 HOURS OR 6 MONTHS 4500 HOURS OR 18 MONTHS

UNIT OPERATING

TEMPERATURE °C

RENEWAL PERIOD

NB: INITIAL FILL OF OIL SHOULD BE CHANGED IN A NEW GEAR UNIT AFTER 1000 HOURS

OPERATION OR ONE YEAR OR HALF THE ABOVE LIFE WHICHEVER IS THE SOONEST

UNIT OPERATING

TEMPERATURE °C

RENEWAL PERIOD

NB: INITIAL FILL OF OIL SHOULD BE CHANGED IN A NEW GEAR UNIT AFTER 1000 HOURS

OPERATION OR ONE YEAR OR HALF THE ABOVE LIFE WHICHEVER IS THE SOONEST

*Mineral oil filled units operating over 70°C should be removed, drained and refilled with the correct

quantity of oil after 3 years operation.

Warning.

Do not mix Synthetic and Mineral lubricants.

Do not overfill the unit as this can cause leakage and overheating.

10.4. Bearings

10.4.1 Bearings should be replaced every 5 years for . marked units.

10.5. Grease Lubrication

10.5.1. Where re-greasing points are provided add 2 shots monthly of NLGI 2 grade grease.

10.6. Cleaning

10.6.1. With the drive stationary periodically clean any dirt or dust from the gear unit and the electric motor

cooling fins and fan guard to aid cooling.

10.6.2. Ensure dust build up does not exceed 5mm (maximum)

Problem Solving

Page 12 Issue 2

11. Fault diagnosis

11.1. Gear unit problems:

Symptom Possible Causes Remedy

Output shaft does not rotate, Drive between shafts interupted in the gear unit Return the gear unit / geared motor for repair

even though the motor is running

or the input shaft is rotating.

Unusual, regular running noise a) A meshing or grinding sound : damage to bearings a) Check oil (See Inspection and Maintenance)

b) A knocking sound : irregularity in the gearing b) Contact our Application Engineers

Unusual, irregular running noise Foreign matter present in the oil a) Check oil (See Inspection and Maintenance)

b) Stop the unit, Contact our Application Engineers

Oil leaking¹ a) Defective gasket on gear unit cover a) Retighten screws on gear unit cover and observe gear

• from the gear unit cover b) Defective gasket unit. If oil still leaks contact our Application Engineers

• from the motor flange c) Gear unit not ventilated b) Contact our Application Engineers

• from the gear unit flange c) Vent the gear unit (see Appendix 4 - Mounting positions)

• from the output end oilseal

Oil leaking a) Gear unit over filled with oil a) Correct the oil level (see lubrication section)

from the ventilator b) Gear unit installed in an incorrect mounting positon b) Fit the ventilator in the correct position (see Appendix 4 -

c) Frequent cold starts (oil foaming) and/or high Mounting positions) and check oil level (see lubrication)

oil level. c) Check the oil level (see lubrication)

1) it is normal for small amounts of oil/grease to leak out of the oil seal during the running in period (24 hours running time)

When contacting our sales office

Please have the following information available:

• Nameplate data (complete)

• Type and extent of the problem encountered

• The time and the circumstances the problem occurred

• A possible cause

Any further information or clarification required may be obtained by contacting our sales office,

please see contact details at the back of this booklet.

Appendix 1

Page 13 Issue 2

Appendix 1

Page 14 Issue 2

Errors of Eccentricity

The procedure for measuring eccentricity is precisely analogous to that used for angularity.

In this case, however, the measurements are taken in a radical direction and the most

convenient and accurate means of doing this utilises a dial indicator suitably clamped to one

half coupling, and bearing on the hub or flange of the other, as shown in figures 4 and 5 on

page 13.

Care must, however, be taken to ensure the support for the dial indicator is sufficiently rigid

to prevent the weight of the indicator from causing deflection and, in consequence,

inaccurate readings. Extra care should be taken where taper roller bearings are fitted to

ensure that alignment is checked with shafts in mid-point position and a final check made

with the unit at operating temperature.

Rigid

All Other types Please see appropiate installation and maintenance

manual for coupling type fitted

Type of Coupling Unit Size Allowable Eccentricity

(mm)

SIZE 08 & UNDER 0.025

SIZE 09 & OVER 0.035

SPECIAL NOTE CONCERNING RIGID COUPLINGS

In lining up elements involving rigid couplings it is important that no attempt is made to

correct errors of alignment or eccentricity greater than those above by tightening of the

coupling bolts (This applies when the system is cold or at operating temperature). The result

is miss-alignment and the setting up of undue stresses in the shaft, coupling and bearings.

This will be revealed by the springing apart of the coupling faces if the bolts are slackened

off. A check on the angularity of a pre-assembled job, after bolting down, can be obtained in

the case of rigid couplings by slackening off the coupling bolts, when any mis-alignment will

cause the coupling faces to spring apart. This check may not, however, reveal any strains

due to eccentricity owing to the constant restraint imposed by the spigot.

SERIES X COUPLINGS

We produce standard flexible couplings to cover the complete range of gear units, please

contact Application Engineering for details.

Appendix 2A

Page 15 Issue 2

Series C, K & F Standard Bore Assembly.

UNIT Bore d da l l1 l2 l3 l4 l5 m R T u u1

22.000/

21.946

28.000/

27.948

0.6

0.4R

0.6

0.4R

1.2R

0.8R

71.0

70.8

90.0

89.8

53

46

M20 x 2.5

42 deep

M24 x 3.0

50 deep

225.5

225.0

238.5

238.0

3

10

120

150

40

45

79.6

99.6

260

327

C10

Reduced

Std

79.990/

79.971

99.988/

99.966

20.000/

19.948

25.000/

24.948

0.6

0.4R

0.6

0.4R

1.2R

1.2R

62.5

62.3

81.0

80.8

58

58

M20 x 2.5

42 deep

M24 x 3.0

50 deep

177.5

177.0

221.5

221.0

3

3

105

135

35

45

69.6

76.6

227

227

C09

Reduced

Std

69.990/

69.971

89.988/

89.966

18.000/

17.957

20.000/

19.948

0.4

0.25R

0.6

0.4R

1.2R

1.2R

53.0

52.8

62.5

62.3

37

37

M20 x 2.5

42 deep

M20 x 2.5

42 deep

148.5

148.0

177.5

177.0

3

3

91

105

31

35

59.6 183

69.990/

69.971 69.6 183

C08

Reduced

Std

59.990/

59.971

44.5

44.3

14.000/

13.957

0.4

0.25R

M20 x 2.5

42 deep 1.2R 53.0

52.8

18.000/

17.957

0.4

0.25R

35

38

M16 x 2

38 deep 1.2R

130.5

130.0

148.5

148.0

3

3

75

90

25

30

49.6

59.6

153

153

C07

Reduced

Std

49.991/

49.975

59.990/

59.971

0.8R 39.5

39.3

14.000/

13.957

0.4

0.25R

101.5

101.0 331

M16 x 2

36 deep

44.6 125 68 23

0.8R 35.0

34.8

12.000/

11.957

0.4

0.25R

100.5

100.0 331

M16 x 2

36 deep

39.6 125 60 20

C06

Reduced

Std

39.991/

39.975

44.991/

44.975

0.8R 30.0

29.8

10.000/

9.964

0.16

0.25R

77.3

77.0 323

M12 x 1.75

28 deep

34.6 104 53 18

0.8R 26.0

25.8

8.000/

7.964

0.16

0.25R

79.3

79.0 323

M10 x 1.5

22 deep

29.6 104 45 15

C05

Reduced

Std

29.993/

29.980

34.991/

34.975

0.8R 26.0

25.8

8.000/

7.964

0.16

0.25R

0.16

0.25R

29.993/

29.980 29.6 99 45 15 79.3

79.0 326

M10 x 1.5

22 deep

M10 x 1.5

22 deep 0.8R 21.0

20.8

8.000/

7.964

Std

C04

24.993/

24.980 24.6

16.5

16.4

6.000/

5.970

0.16

0.25R

Reduced 99 38 13 79.3

79.0 323

322

M6 x 1.0 16

deep 0.8R82 30 10 61.3

61.0

C03 Std 19.993/

19.980 19.6

F03 & K03 - 29.993/

29.980 29.6 82 45 15 70.3

70.0

26.0

25.8

8.000/

7.964

0.16

0.25R

323

M10 x 1.5

22 deep 0.8R

F04 & K04 - 34.991/

34.975 34.6 109 60 20 90.5

90.0 323

M12 x 1.75

28 deep 0.8R 30.0

29.8

10.000/

9.964

0.16

0.25R

F05 & K05 - 39.991/

39.975 39.6 112 60 20 35.0

34.8

12.000/

11.957

0.4

0.25R

92.5

92.0 330

M16 x 2

36 deep

126 75 25

0.8R

F06 & K06 - 39.991/

39.975 39.6 100.5

100.0 330

M16 x 2

36 deep 0.8R 35.0

34.8

12.000/

11.957

0.4

0.25R

F07 & K07 - 44.991/

44.975 49.6 153 75 25 101.5

101.0

44.5

44.3

14.000/

13.957

0.4

0.25R

330

M16 x 2

36 deep 0.8R

F08 & K08 - 59.990/

59.971 59.6 173 90 30 148.5

148.0 337

M20 x 2.5

42 deep 0.8R 53.0

52.8

18.000/

17.957

0.4

0.25R

F09 & K09 - 69.990/

69.971 69.6 232 105 35 161.5

161.0 338

M20 x 2.5

42 deep 0.8R 62.5

62.3

20.000/

19.948

0.6

0.4R

F10 &K10 - 79.990/

79.971 79.6 275 120 40 188.5

188.0 537

M20 x 2.5

42 deep 0.8R 71.0

70.8

22.000/

21.946

0.6

0.4R

K12 - 99.988/

99.966 99.6 327 150 45 238.5

238.0 10 46 M24 x 3.0

50 deep 0.8R 90.0

89.8

28.000/

27.948

0.6

0.4R

F02 - 24.9931/

24.980 24.6 82 40 13 70.3

70.0

21.0

20.8

8.000 /

7.964

0.16

0.25R

323

M10 x 1.5

22 deep 0.8R

See next page for shaft assembly instructions

Appendix 2A

Page 16 Issue 2

Shaft Assembly Instructions.

1. Spray the hollow shaft bore and mating diameter of output shaft with an anti fret compound.

2. Fit the shaft to hollow bore location key in position in the output shaft.

3. Fit the circlip into the output sleeve.

4. Fit the output shaft into the output sleeve. Remember to fit the spacer tube if the output shaft has

no shoulder.

5. Secure in place with the washer and bolt, tighten to the values stated in the table below.

6. Fit the protective cover over the open end of the output sleeve.

M10 15

M12 20

M16 45

M20 85

M24 200

Bolt Size Tightening Torques

Nm

Appendix 2A

Page 17 Issue 2

Series C, K & F Standard Bore Disassembly.

UNIT Bore c4 c6 c7 D (H7) d2 d3 d4 l2 m m1 t u

C03 Std 5 10 12 20 7 19.9 11.2 120 3 M10 x 1.5 22 6

Reduced 5 15 17 25 13 24.9 16.2 23 3 M16 x 2 28 8

Std 5 15 17 30 13 29.9 20.8 160 3 M16 x 2 33 8

Reduced 5 15 17 30 13 29.9 20.8 260 3 M16 x 2 33 8

Std 5 15 17 35 13 34.9 25.2 160 3 M16 x 2 38 10

Reduced 5 20 23 40 20 39.9 30.9 220 3 M24 x 3 43 12

Std 5 20 23 45 20 44.9 34.1 220 3 M24 x 3 49 14

Reduced 5 20 23 50 20 49.9 39 220 3 M24 x 3 54 14

Std 8 24 27 60 26 59.9 47.4 250 5 M30 x 3.5 64 18

Reduced 8 24 27 60 26 59.9 47.4 250 5 M30 x 3.5 64 18

Std 8 24 27 70 26 69.9 58.4 310 5 M30 x 3.5 74.5 20

Reduced 8 24 27 70 26 69.9 58.4 310 5 M30 x 3.5 74.5 20

Std 8 24 27 90 26 89.9 75.3 360 5 M30 x 3.5 95 25

Reduced 8 24 27 80 26 79.9 65.5 360 5 M30 x 3.5 85 22

Std 8 30 34 100 32 99.9 84.1 420 5 M36 x 4 106 28

F02 - 5 15 17 25 10 24.9 16 120 3 M12 x 17.5 28 8

F03 & K03 - 5 15 17 30 13 29.9 20.8 130 3 M16 x 2 33 8

F04 & K04 - 5 15 17 35 13 34.9 25.2 160 3 M16 x 2 38 10

F05 & K05 - 5 20 23 40 20 39.9 29.9 190 3 M24 x 3 43 12

F06 & K06 - 5 20 23 40 20 39.9 29.9 190 3 M24 x 3 43 12

F07 & K07 - 5 20 23 50 20 49.9 39 220 3 M24 x 3 53.5 14

F08 & K08 - 8 24 27 60 26 59.9 47.4 250 5 M30 x 3.5 64 18

F09 & K09 - 8 24 27 70 26 69.9 56.4 310 5 M30 x 3.5 74.5 20

F10 & K10 - 8 24 27 80 26 79.9 65.5 360 5 M30 x 3.5 95 25

K12 - 8 30 34 100 32 99.9 84.1 420 5 M36 x 4 116 28

C06

C05

C04

C10

C09

C08

C07

Appendix 2A

Page 18 Issue 2

Series C, K & F Shaft Mount Units.

Alternative Shaft Fixing Methods.

This manual suits for next models

3

Table of contents

Other Benzlers Industrial Equipment manuals