Benzlers BS Series Maintenance and service guide

Series BS

Installation & Maintenance

2

CONTENTS

3

PRODUCT SAFETY INFORMATION 2

1 INFORMATION ............................................................................................ 4

1.1 General information ........................................................................... 4

1.2 Safety warning Symbols .................................................................... 4

1.3 Weather Protection of Unit ................................................................. 5

1.4 Reading the Nameplate ..................................................................... 5

1.5 Marking ....................................................................................... 6

2 INSTALLATION ........................................................................................... 7

2.1 Safety Warning ................................................................................... 7

2.2 Prior to Installation ............................................................................. 7

2.3 Fitting of components to either the unit input or output shaft ............. 7

2.4 Lifting ................................................................................................. 8

2.5 Footmountedorangemountedunits .............................................. 8

2.6 Shaft mounted units ......................................................................... 10

2.7 Units for use in a potentially explosive atmosphere ......................... 10

3 LUBRICATION .......................................................................................... 11

3.1 General ............................................................................................ 11

3.2 Ventilator .......................................................................................... 11

3.3 Approved lubricants ......................................................................... 11

4 MOTOR CONNECTIONS ......................................................................... 12

5 STARTING UP .......................................................................................... 12

5.1 Prior to starting up ............................................................................ 12

5.2 Running-in .........................................................................................12

6 OPERATION ............................................................................................. 13

6.1 Noise ................................................................................................... 13

6.2 General Safety .................................................................................... 13

6.3 Initial start up for gear units operating in a potentially

explosive atmosphere ............................................................................... 13

7 MAINTENANCE 1...................................................................................... 14

7.1 Prior to any maintenance operations ............................................... 14

7.2 Oil plugs / Ventilator ......................................................................... 14

7.3 Maintaining lubrication ..................................................................... 14

7.4 Bearings ........................................................................................... 16

7.5 Oil Seals ........................................................................................... 16

7.6 Cleaning ........................................................................................... 16

8 FAULT DIAGNOSIS .................................................................................. 17

8.1 Gear unit problems ............................................................................. 17

APPENDIX 1 SHAFT ALIGNMENT .......................................................... 18

APPENDIX 2 ALTERNATIVE SHAFT FIXING METHODS ....................... 20

APPENDIX 2A TORQUE ARM DETAILS BS ............................................ 21

APPENDIX 3 THREE PHASE INDUCTION MOTOR INSTALLATION ..... 22

APPENDIX 4 APPROVED LUBRICATION ............................................... 23

APPENDIX 5 DECLARATION OF CONFORMITY ................................... 25

4

INFORMATION

1.1 General information

The following instructions will help you achieve a satisfactory installation of your Benzlers or Radicon gear unit, ensuring

the best possible conditions for a long and trouble free operation.

All units are tested and checked prior to despatch, a great deal of care is taken in packing and shipping arrangements to

ensure that the unit arrives at the customer in the approved condition.

Series BS gear units will perform satisfactorily if subjected to full load immediately after installation. However optimum

performanceisbestachievedbyaprocessofgradualloadincrements,uptothefullvalue,overtherst50hoursorsoof

their working life. During these early stages of running, sensible temperature may occur over many hours until the unit has

reacheditshighestefciency.

The gear unit must not be used until the machine it is incorporated in, has been shown to comply with EEC Machinery

Directive 2006/42/EC.

1.2 Safety warning Symbols

There are four different warning symbols used at the manual to mark out the hazardous moments that may cause risk of

human injury or equipment injuries.

5

INFORMATION

1.3 Weather Protection of Unit

All series BS units are provided with protection against normal weather conditions.

Where units are to operate in extreme conditions, or where they are to stand for long periods without running, e.g. during

plantconstruction,pleaseconsultyourlocalsalesofcesothatarrangementsforadequateprotectioncanbemade.

Gear units that are installed outdoors or have to work under adverse conditions, for example in hot, dusty or damp

premises,mustbettedwithappropriateprotection.Thecirculationofairaroundthegearunitmustnotbeobstructed,

however.

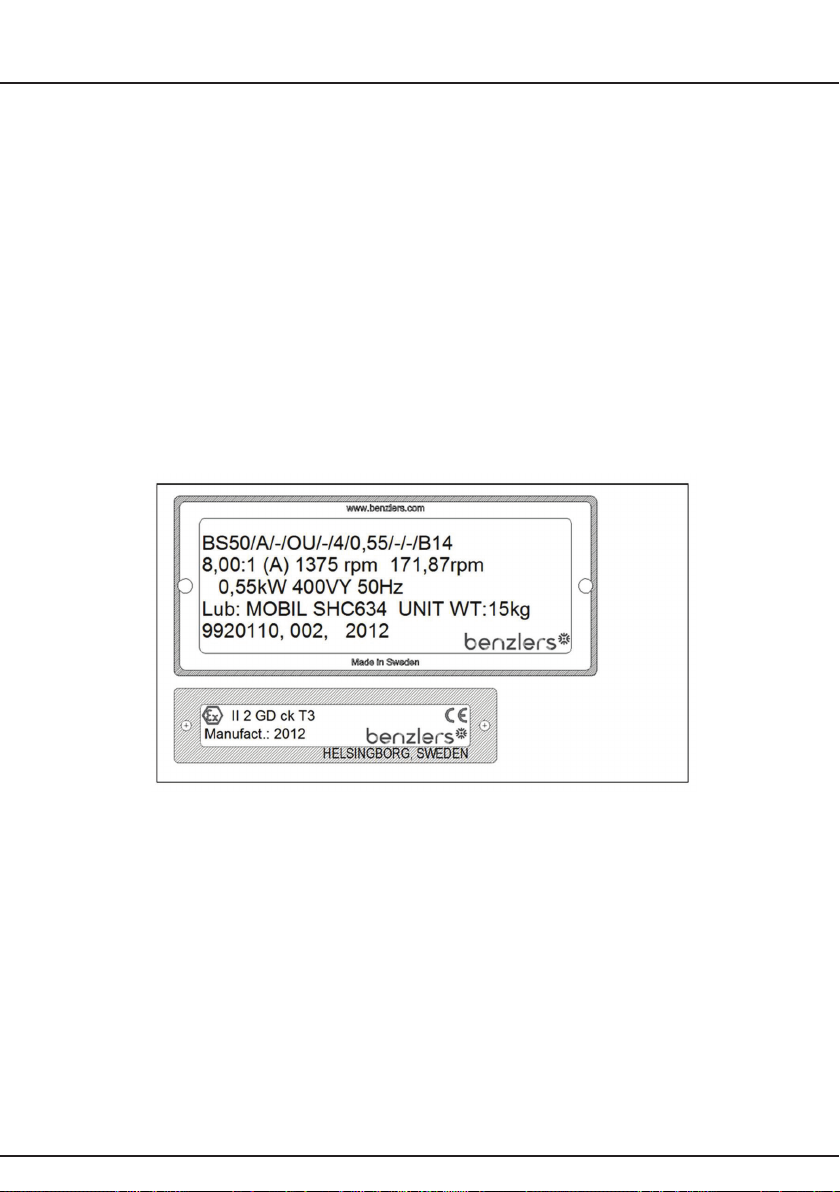

1.4 Reading the Nameplate

1.4.1 Unit Identication

When requesting further information or service support, quote the following information

from the nameplate:

Unit type (Model No.)

Order Number / Year of Manufacture

1.5 Lubrication Grade

SeriesBSwormgearunitsaresuppliedlubricatedforlife.(Factorylledwithsyntheticlubricant.)

The lubrication grade is marked on the nameplate. See Appendix 4 for type and quantity of lubricant.

6

INFORMATION

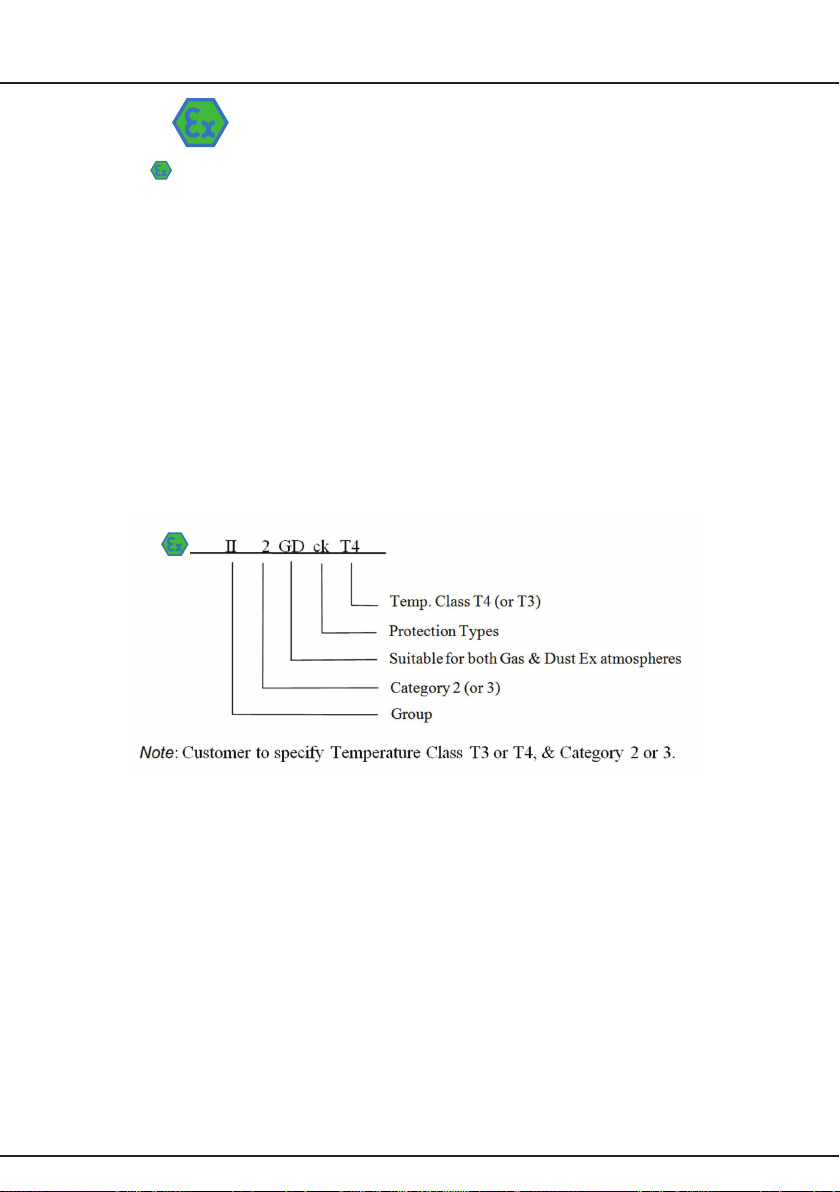

1.6 Marking

Gear units with -marking are especially selected for use as a component of an industrial system operating in a

potentially explosive atmosphere.

Provided they are correctly installed in accordance with these instructions (gear units only) they comply with the EU

directive 94/9/EC (ATEX 100a).

The units must be selected for use in potentially explosive atmospheres classied as Group II Cat 2 (zones 1 & 21)

orGroupIICat3(zones2&22).

Motors,couplings,oranyotherequipmentttedtothegearunitmustalsocomplywiththisdirective.

If the gear unit is supplied as a geared motor package it is important to check that the nameplates of the gear unit and the

motor(oranyotherequipmenttted)correspondswiththeclassicationofthepotentiallyexplosiveatmosphereinwhich

the unit is to be installed.

1.6.1 Understanding EU Directive 94/9/EC (ATEX 100a) Markings.

The product will be typically marked as shown:

7

INSTALLATION

2 Installation

2.1 Safety Warning

NOTE!

The customer shall be responsible for the proper use of articles supplied by Benzlers or Radicon,

particularly rotating shafts between the driving and driven members, and the provision of safety

guarding. They shall not be responsible for any injury or damage sustained as a result of the improper

use of the articles supplied.

Attention is hereby drawn to the danger of using naked lights in proximity to openings in gearboxes

and gear units supplied by Benzlers or Radicon, and they shall not be liable for any claim for injury or

damage arising from any action in contravention of this warning.

2.2 Prior to Installation

1. Check that there are no damages at the gear unit.

2. Check that the gear unit and the motor name plate, matches the requirements of the machine the unit is to

be installed into.

3. Thoroughly clean the gearbox mounting surfaces that are to be used and the shafts of paint and anti-corrosion

agents, using a commercially available solvent. Ensure solvent does not make contact with the oil seals.

2.3 Fitting of components to either the unit input or output shaft

The input or output shaft extension diameter tolerance is to ISO tolerance j6 (for shaft diameter ≤40 mm) and k6

(for shaft diameter >40 mm). Fitted components should be to ISO tolerance K7.

1.Ensureshaftextensions,bores&keysetcarecleaned.

2. Items (such as gears, sprockets, couplings etc.) should not be hammered onto these shafts since this would damage

the shaft support bearings.

3.Itemsbeingttedmaybeheatedto80/100°Ctoaidassembly.

NOTE!

You must absolutely not use any violent forces!

8

INSTALLATION

2.4 Lifting

The gear motor must never be lifted by the lifting eye on the motor alone.

NOTE!

The gear motor must never be lifted by the lifting eye on the motor alone.

2.5 Foot mounted or ange mounted units

1.Ensurethebasefoundationmountingsurfaceisat

1

, vibration absorbing and torsionally rigid.

Note! Units on baseplates should, if possible, be mounted on the same bedplate as the prime mover.

2.Ifachainsprocketisttedtotheoutputshaft,thedirectionofpullshouldbechosensothatthegearhousingispressed

against the foundation.

3. Align unit (See Appendix 1).

Note! It is important to ensure when aligning unit on baseplate that all machined mounting points are supported over

their full area.

If steel packings are used, these should be placed either side of the foundation bolt as close as possible.

Duringnalboltingensuretheunitorbaseplateisnotdistortedasthiswouldcausestrainsinthegearcaseresultingin

errors of alignment of shafts and gearing.

Check all mounting points are fully supported and adjust if necessary by using steel packings.

TorquetightenboltstotorquespeciedinTable1below.

4.Secureunit,orbaseplateiftted,toarigidfoundationusingheavydutyboltstoISOgrade8.8minimumorClass8.

1)Maximumpermissibleatnesserrorformountingsurfaceis0.12mm.

9

INSTALLATION

Set

Screw

Size

Tightening Torque according

to quality class 8.8

Holding Down Bolts/

Output Flange Bolts

M4 2.8 Nm = 25 Lbf.in

M5 5.5 Nm = 49 Lbf.in

M6 10 Nm = 89 Lbf.in

M8 25 Nm = 221 Lbf.in

M10 50 Nm = 442 Lbf.in

M12 85 Nm = 752 Lbf.in

M16 200 Nm = 1770 Lbf.in

Table 1

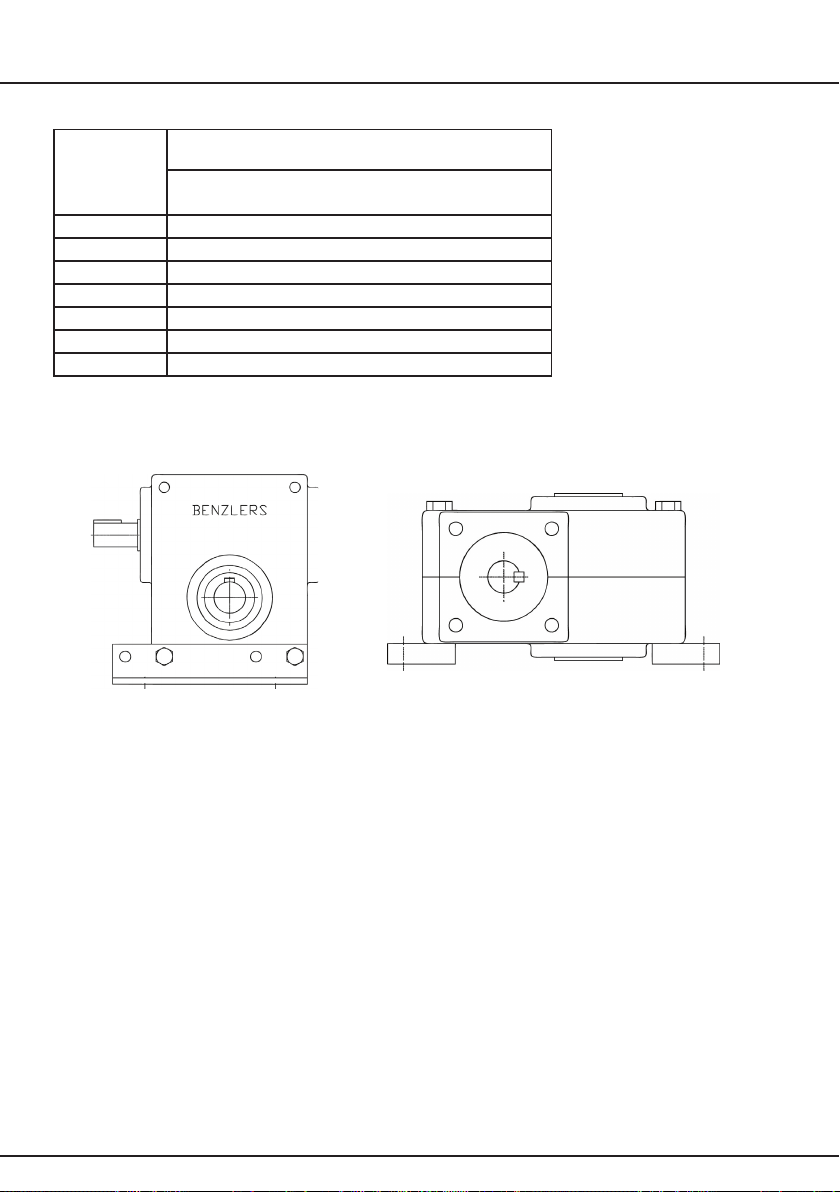

2.5.1 Foot Mounting

The gear housing for BS40-BS71 with a vertical secondary shaft will have separate feet.

WhenttingtheanglefeetforBS40-BS71,lockingwashers(DIN6797)mustbettedtotheboltsbetween

the gear housing and the angle feet. When tightened, the gear housing should be pressed against the mating

surface of the feet.

2.5.2 Flange Mounting

Wheninstallingwithasecondaryange,youmustensurethatnostressisexertedonthegearunitwhenthe

angemountingboltsaretightened.

10

INSTALLATION

Follow the mounting procedure below:

1.Fittheangeorangeadaptorwithouttighteningthebolts.

2. Fit the locking ring for the extra bearing on the shaft.

3. Fix the bearing on the shaft with Loctite 641 or an equivalent before sliding it up against the locking ring.

4. Fit the keys and all locking rings except the outermost locking ring on the shaft.

5. Lubricate the shaft with Molykote BR2 corrosion inhibitor or equivalent before mounting.

6. Fit in the rear locking ring and tighten the bolts to the correct torque, see Table 1, in Section 2.5. If necessary,

tshimsbetweentheangeandgearhousing.AlignmenttolerancesmustcomplywithDIN42955.

7. Fit the connecting ring, if used.

2.6 Shaft mounted units

The gear unit is normally mounted on a shaft with tolerance of h6-js6. The hollow shaft has a tolerance of H7.

1.GreasetheshaftwithMolykoteBR2oranequivalentbeforettingthegearunit.

NOTE!

The gear unit must not be driven onto the shaft with force.

2. Assembly of gear unit on to the machine shaft (See Appendix 2).

3. Anchor gear unit to a secure point on the structure by means of torque arm (See Appendix 2A).

2.7 Units for use in a potentially explosive atmosphere

2.Removealltransportxturesandpackings.Checkthatithastheappropriate-markingpriortostartup.

NOTE!

If the unit has been damaged in transit, do not use.

2.Checknameplateofunitcorrespondswiththesitespotentiallyexplosiveatmosphereclassication.

4. Check ambient temperature falls within lubricant grade recommendations.

5. Make sure no potentially explosive atmosphere exists during installation.

6. Make sure that gear unit is sufciently ventilated with no external heat input - cooling air temperature should

notexceed40°C.

7.Checkmotors,couplingsoranyotherequipmentttedtothegearunithasATEXapproval.Checkinformationlistedon

nameplates correspond to the environmental conditions of the site.

8. Ensure gearbox is not subjected to any loading greater than those marked on the nameplate.

9. For units operated with inverter drives, check motor suitability for use with the inverter. Ensure that the inverter parameters

do not exceed those of the motor.

10.Forbeltdrivenunits,checkallbeltsttedareofsufcientelectricalleakageresistance(<10°Ω).

11. Ensure gear unit and other equipment is electrically grounded (Earthed).

12. Check and adjust guards and covers so that there is no ignition source from sparks that may be thrown by moving parts

making contact with guards etc. Ensure coupling guards, covers etc. are dust tight or are designed in such a way that a

buildupofdustdepositscannotformwhentheunitisusedinZone21&Zone22classicationareas.

13.UnitsttedwithplasticprotectioncoversareonlysuitableforCategory3(Zone2&22).

11

LUBRICATION

3 Lubrication

3.1 General

BS40-BS71 gear units are supplied with synthetic oil MOBIL SHC 634. These lubricants are specially suited to worm gears.

Duringnormaloperation,thelubricantwillneverrequirereplacement.Ambienttemperaturerange±30°C.

3.2 Ventilator

Clean and secure the ventilator in the correct location for the required mounting position

(See Appendix 4).

3.3 Approved lubricants

3.3.1 Oils

Mobil SHC 634

12

START UP

4 Motor connections

To mains

Connectionoftheelectricmotortothemainssupplyshouldbemadebyaqualiedperson.Thecurrentratingofthemotor

willbeidentiedonthemotorplate,andcorrectsizingofthecablestoelectricalregulationsisessential.

High voltage!

Caution when working with the mains.

Motor terminal connection

Circuit diagrams for the correct wiring of the motor terminal box are included as Appendix 3 of this document if the motor is

suppliedseparatelyorifttedwithamotorfromadifferentmanufacturer,thenthisshouldhaveappropriatedocumentation

provided with it.

Motor Fitting

ForBS40-BS71amotorangeandelasticcouplingareused.

5 Starting Up

5.1 Prior to starting up

Startingupshouldonlybeperformedorsupervisedbysuitablyqualiedpersonnel.

1.Ensureventilatoristted(ifsupplied)seelubricationsection3.2

2. Check that oil is topped up.

3.Ensureallsafetydevicesareinplace(i.e.guardstted).Checkandadjustguardsandcoverssothatthereisnoignition

source from sparks that may be thrown by moving parts making contact with guards etc. Ensure coupling guards, covers

etc. are dust tight or are designed in such way that a build up of dust deposits cannot form when the unit is used in Zone 21

andZone22classicationareas.

4.Removeanysafetydevicesttedtopreventmachinerotation.

5.Unitsttedwithbackstop,ensuremotoriscorrectlywiredforfreedirectionofrotation.

Caution!

Any deviation from normal operating conditions (increased temperature, noise, vibrations, power

consumption etc.) suggests a malfunction, inform maintenance personnel immediately.

5.2 Running-in

Thegearunitshouldberun-inunderpartialloadfortherst10-30hours.Theloadcanthenbegraduallyincreasedtofull

load. If it is not possible to run under partial load, the gear unit should be run for several hours under no load. The gear unit

should then be run under load but stopped at regular intervals to cool down. The gear unit can then be considered as fully

run-in and ready for normal operation.

Under an increasing load the temperature of the gear unit may exceed ambient temperature by 60-70 ºC.

The grease temperature and temperature of the gear unit may reach 90 ºC without effecting its operation.

At higher temperatures special measures must be taken.

Gear units that are not used for a long period should if possible be run for a brief period about once every three months.

13

START UP

6 Operation

6.1 Noise

Therangeofproductsatisesanoise(soundpressurelevel)of85dB(A)orlesswhenmeasuredat1meterfromthe

unit surface. Measurements taken in accordance with ISO 8579-1:2002.

6.2 General Safety

Potential hazards which can be encountered during installation, maintenance and operation of drives is covered in

greater detail in the product safety page at the front of this booklet. (See chapter 1 Information).

Advice is also given on sensible precautions which need to be taken to avoid injury or damage. Please read!

6.3 Initial start up for gear units operating in a potentially explosive atmosphere

After 3 hours of operation check the gear unit surface temperature. This temperature should not exceed 110 degrees.

Iftemperatureexceedsthislimit,shutdownimmediatelyandcontactyourlocalsalesofce.

Hot surfaces!

The gear unit becomes very hot during operation. Use protective gloves.

14

MAINTENANCE

7. Maintenance

7.1 Prior to any maintenance operations

1. De-energize the drive and secure against unintentional switch-on.

2. Wait until the unit has cooled down.

Hot Surfaces!

Dangerofskinburns&pressurebuild-up.

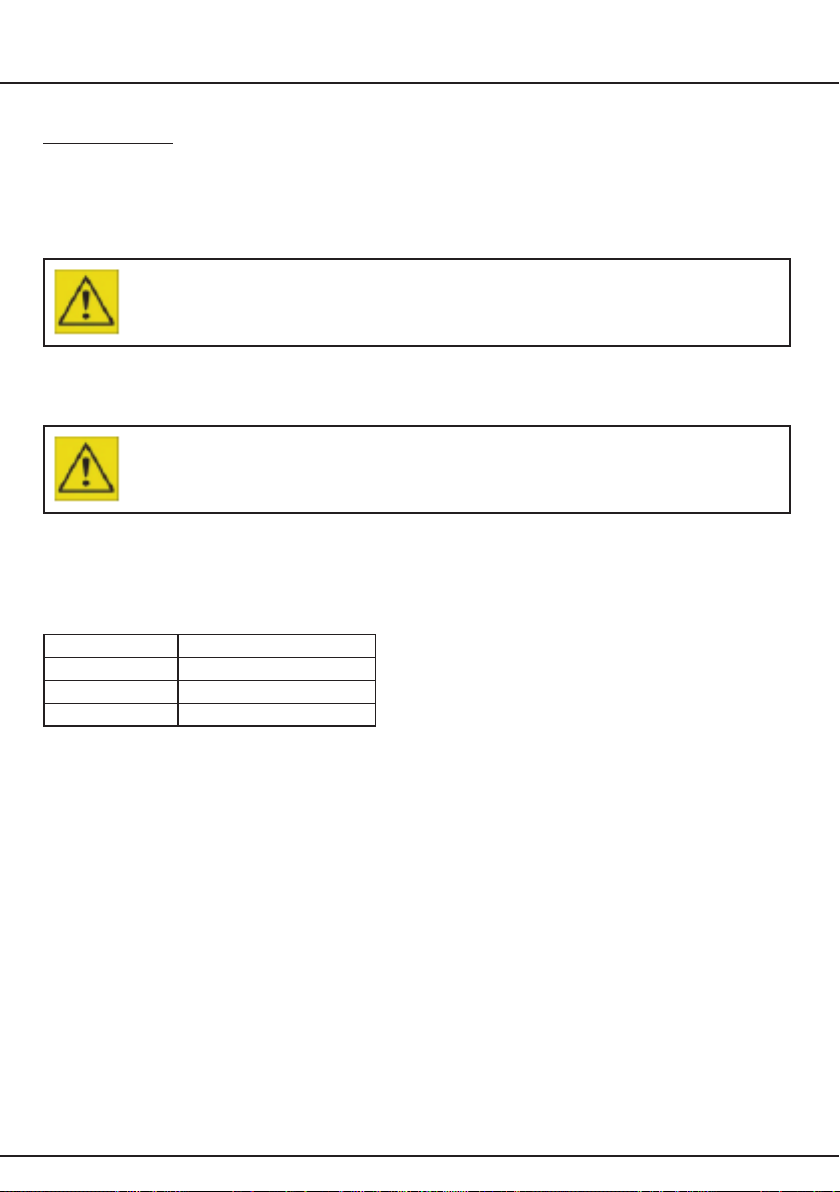

7.2 Oil plugs / Ventilator

1.Priortoremovingplugs,ensurethattheunithascooledsufcientlysothatoilwillnotburnonunitswithoutventilator.

Danger!

Do not stand over plug whilst removing, as pressure build-up may cause it to eject when removed.

2. Place a container below the oil drain plug to be removed.

Note!Itisrecommendedthattheoilshouldbeslightlywarm(40–50°C)whendrained.

(Cooleroilwillbemoredifculttodraincorrectly).

3.Top-upsorrellsshouldbedone(wherepossible)throughtheventilatorposition.

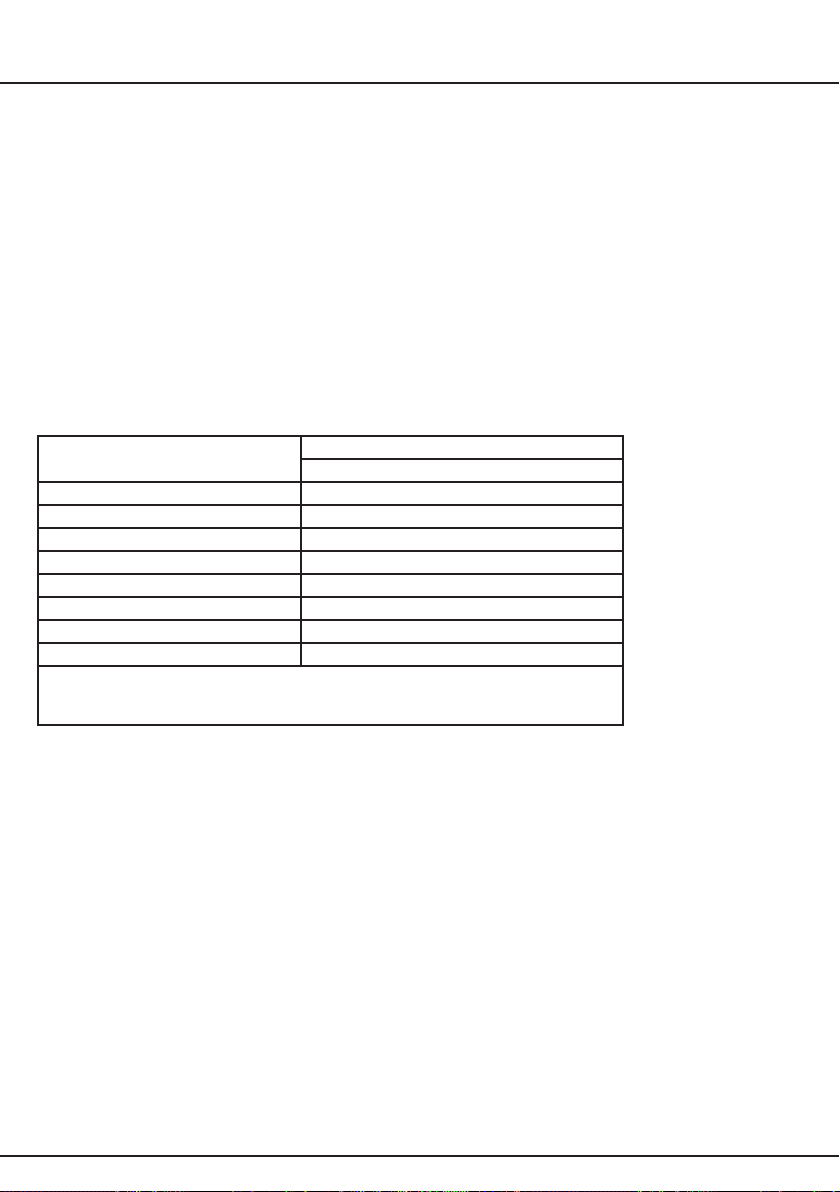

4.Remembertoretallplugsandtorque,tightentoTableM1below.

Table M1

5. Clean away any oil spillage.

7.3 Maintaining lubrication

7.3.1 Periodic inspection

Forunitsttedwithlevelindicatingdevice,checktheoillevelevery1000hoursor6months,whicheverissoonerandif

necessary, top up with the recommended type of lubricant.

Plug Size Tightening Torque

1/8” 10 Nm

1/4” 25 Nm

3/8” 50 Nm

15

MAINTENANCE

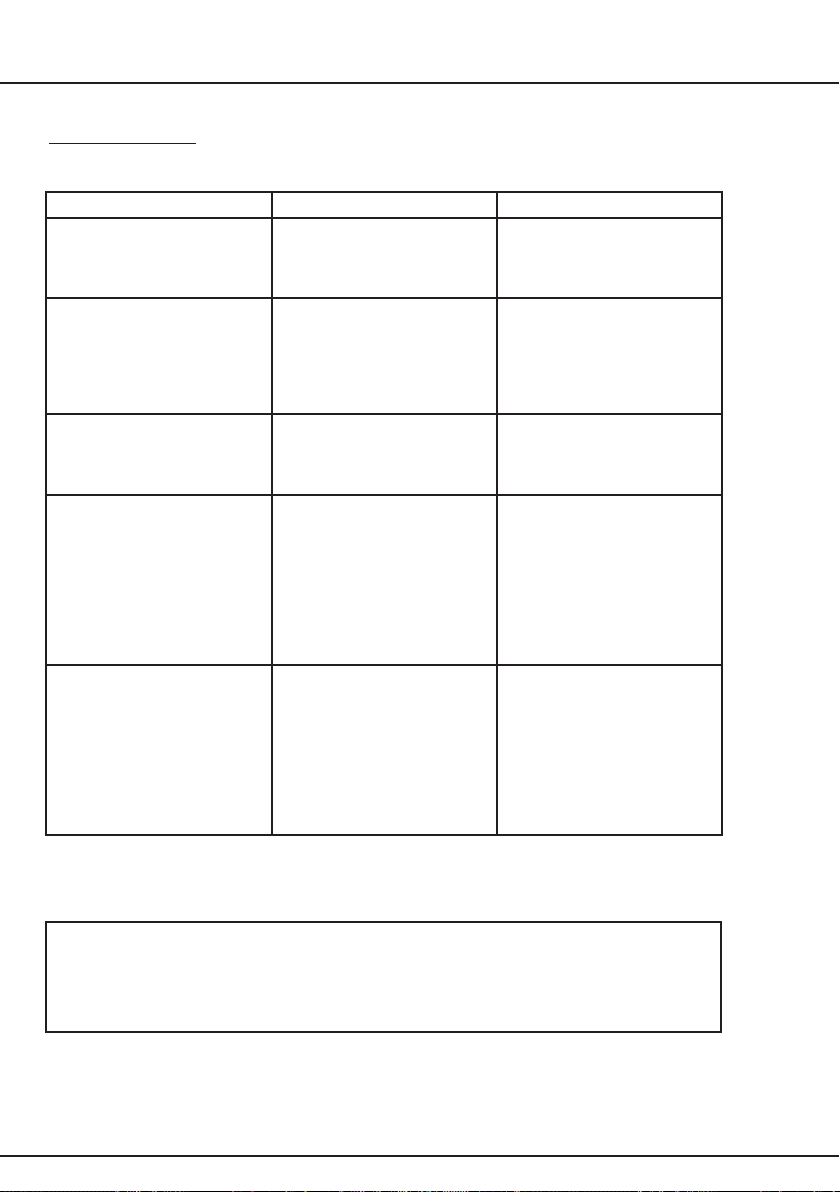

Unit Operating

Temperature °

Renewal Period

Synthetic Oil

65 or less 26000 Hours or 3 years

70 26000 Hours or 3 years

75 22000 Hours or 3 years

80 15000 Hours or 3 years

85 10500 Hours or 3 years

90 7500 Hours or 2.5 years

95 6000 Hours or 2 years

100 4500 Hours or 18 months

Note! INITIAL FILL OF OIL SHOULD BE CHANGED IN A NEW GEAR UNIT

AFTER 1000 HOURS OPERATION OR ONE YEAR OR HALF THE ABOVE

LIFE, WHICHEVER IS THE SOONEST

7.3.2 Oil changes

Smaller BS worm gear units are supplied lubricated for life except for the following conditions: Units that are required

toworkinexplosiveatmosphere(94/9/ECATEX100aGroupIICategory2Zones1&21&Category3Zones2&22)

shouldbedrainedandrelledwithcorrectquantityoflubricantinaccordancewiththerenewalperiodofTableM2.

See Appendix 4 for correct oil quantity.

Following factors should be used to determine the frequency at which oil changes are carried out:

a. Oil temperature – unit operating under load

b. Type of oil

c. Environment – humidity, dust, etc.

d. Operating conditions – shock, loading, etc.

At elevated temperatures the effective life of the oil is very much reduced. To prevent damage to the unit through lubricant

breakdown the oil should be renewed as detailed in Table M2.

Table M1

Note! Figures quoted are for oil temperatures when the unit has attained normal running temperature when operating

underload.Theseguresarebasedonnormalrunningbutwhereconditionsareparticularlysevereitmaybenecessary

tochangetheoilmorefrequently.Whenchanginglubricant,ifsamelubricantisnotusedtheunitmustbeushedoutand

lledwithonetypeoflubricant.

16

MAINTENANCE

Warning!

Do not mix Synthetic with Mineral lubricants.

Donotoverlltheunitasthiscancauseleakageandoverheating.

7.4 Bearings

Bearings should be replaced every 5 years for marked units.

7.5 Oil Seals

Oil seals have dimensions:

Table 3

*) Sealing Cover

and must be mounted with grommet and mandrel

input shaft, sealing ring 4 mm (BS40 3 mm)

input shaft, cover 0 mm

output shaft, sealing ring 3.5 mm

inside the gear house.

Before mounting, the seal lip must be greased by a grease of Lithium type NLGI, class 1-2.

7.6 Cleaning

Withthedrivestationary,periodicallycleananydirtordustfromthegearunitandtheelectricmotorcoolingnsandfan

guard, to aid cooling.

Ensure that the build-up of dirt or dust does not exceed 5 mm (maximum).

Unit Input Shaft Resp. Output Shaft

BS 40 20 x 47 x 7 47 x 6.5*) 30 x 47 x 7

BS 50 20 x 47 x 7 47 x 6.5*) 40 x 52 x 7

BS 63 30 x 62 x 10 62 x 7*) 45 x 60 x 8

BS 71 35 x 72 x 10 72 x 9*) 50 x 72 x 8

17

PROBLEM SOLVING

8 Fault diagnosis

8.1 Gear unit problems

Table 4

1) It is normal for small amounts of oil / grease to leak out of the oil seal during the running in period

(24 hours running time).

Symptom Possible Causes Remedy

Output shaft does not

rotate, even though the

motor is running or the

input shaft is rotating.

Drive between shafts

interrupted in the gear unit.

Return the gear unit / geared

motor

for repair.

Unusual, regular

running noise

a) A meshing or grinding

sound: damage to

bearings.

b) A knocking sound:

irregularity in the

gearing.

a) Check oil (See Inspection

and Maintenance).

b) Contact your local sales

ofce for more details.

Unusual, irregular

running noise

Foreign matter present in

the oil

a) Check oil (See Inspection

and Maintenance).

b) Stop the unit, contact your

local sales ofce.

Oil leaking 1)

• from gear unit cover

• from motor ange

• from gear unit ange

• from output end oil seal

a) Defective gasket on

gear unit cover

b) Defective gasket

c) Gear unit not ventilated

a) Retighten screws on gear

unit cover and observe gear

unit. If oil still leaks, contact

your local sales ofce.

b) Contact your local sales

ofce for more details

c) Vent the gear unit. (See

Appendix 4 – Mounting

position).

Oil leaking

from the ventilator

a) Gear unit over-lled with oil

b) Gear unit installed in an

incorrect mounting position

c) Frequent cold starts (oil

foaming) and/or high oil

level

a) Correct the oil level (See

Lubrication).

b) Fit the ventilator in the

correct position (See Appendix

4 –Mounting positions)

and check oil level (See

Lubrication).

c) Check the oil level (See

Lubrication).

Whencontactingyourlocalsalesofce,pleasehavethefollowinginformationavailable:

•Nameplatedata(complete)

•Typeandextentoftheproblemencountered

•Thetimeandthecircumstancestheproblemoccurred

•Apossiblecause

Anyfurtherinformationorclaricationrequiredmaybeobtainedbycontactingyoursalesofce,orthesee

contact details at the back of this booklet.

18

APPENDIX 1

Shaft Alignment

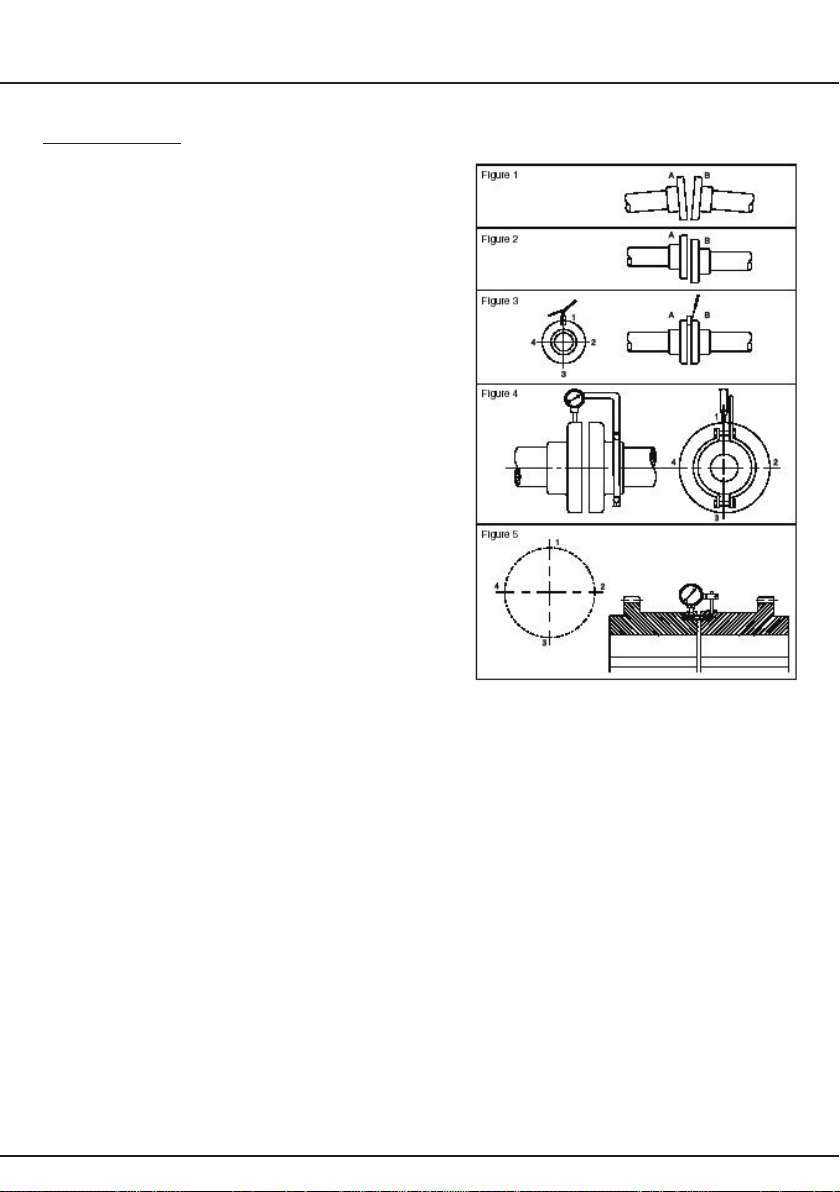

Errors of alignment fall into categories of angularity (See Figure 1)

and eccentricity (see Figure 2), or a combination of both.

Errors of angularity should be checked for, and corrected, before

errors of eccentricity.

Alignment in accordance with the following procedure will ensure

vibration levels meeting those set out in ISO 10816 Part 1

Errors of Angularity

If the faces are perfectly true, the angularity can be checked by

keeping both shafts stationary and taking measurements with a

block gauge and feelers at the four points 1, 2, 3 and 4 as shown

in Figure 3. The difference between the readings 1 and 3 will give

the error of alignment in the vertical plane, over the length of the

shaftequaltothediameterofthecouplinganges,andfromthis

the difference in the relative heights of the feet of the motor or

other connected machine can be found by proportion. Similarly,

the difference between the reading 2 and 4 gives the amount of

sideways adjustment necessary to correct any errors of alignment

in the horizontal plane.

Generally, however, the coupling faces will not be absolutely true

and whilst any errors so found, could be allowed for in checking

angularity by the stationary method an easier method presents

itself. This consists in making the points 1 on both “A” and “B” and

rotating both half couplings, keeping the marked points together.

By taking measurements each quarter-revolution the errors in the

vertical and horizontal planes are again found.

NOTE! Check the alignment after running the unit until it has

attained its normal working temperature. Any discrepancies can

thenberectied.

19

APPENDIX 1

Type of Coupling Allowable Gap (G)

(mm)

Rigid Coupling G = 0.0005 D

All other types Please see appropriate Installation and

MaintenanceManualforcouplingtypetted.

The permitted angularity error is as follows:

Table 5

Note! D is the diameter (mm) at which the gap is measured.

Errors of Eccentricity

The procedure for measuring eccentricity is precisely analogous to that used for angularity. In this case, however, the

measurements are taken in a radial direction and the most convenient and accurate means of doing this utilises a dial

indicatorsuitablyclampedtoonehalfcoupling,andbearingonthehuborangeoftheother,asshowninFigure4

and Figure 5 on Page 22.

Carehowevermustbetakentoensurethesupportforthedialindicatorissufcientlyrigidtopreventtheweightofthe

indicatorfromcausingdeectionand,inconsequence,inaccuratereadings.Extracareshouldbetakenwheretaper

rollerbearingsarettedtoensurethatalignmentischeckedwithshaftsinmid-pointpositionandanalcheckmade

with the unit at operating temperature.

The permitted eccentricity error which can be accommodated in addition to that of the angularity error is as follows:

Table 6

SPECIAL NOTE CONCERNING RIGID COUPLINGS

In lining up elements involving rigid couplings it is important that no attempt is made to correct errors of alignment or

eccentricity greater than those above by tightening of the coupling bolts. (This applies when the system is cold or at

operating temperature). The result is misalignment and the setting up of undue stresses in the shaft, coupling and

bearings. This will be revealed by the springing apart of the coupling faces if the bolts are slackened off. A check on the

angularity of a pre-assembled job, after bolting down, can be obtained in the case of rigid couplings by slackening off

the coupling bolts, when any misalignment will cause the coupling faces to spring apart. This check may not, however,

reveal any strains due to eccentricity owing to the constraint restrain imposed by the spigot.

Type of Coupling Allowable Eccentricity

(mm)

Rigid Coupling 0.025

All other types Please see appropriate Installation and

MaintenanceManualforcouplingtypetted.

20

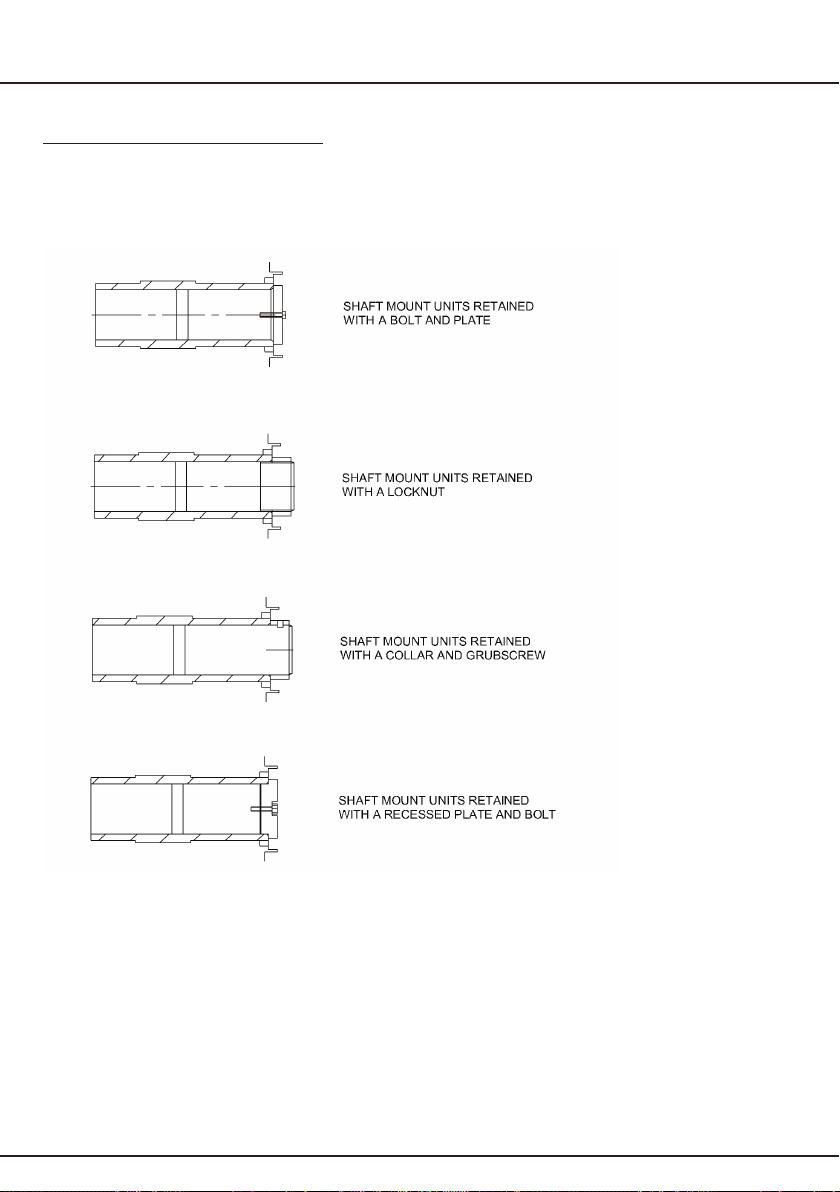

APPENDIX 2

Alternative Shaft Fixing Methods

This manual suits for next models

4

Table of contents

Other Benzlers Industrial Equipment manuals