Page 2 of 28

REV 0.1

TABLE OF CONTENTS

RECOMMEND TOOL LIST………………………………………………………………………………………4

TORQUE VALUES……………………………………………………………………………………………….…5

TURBINE HARDWARE……………………………………………………………………………………………6

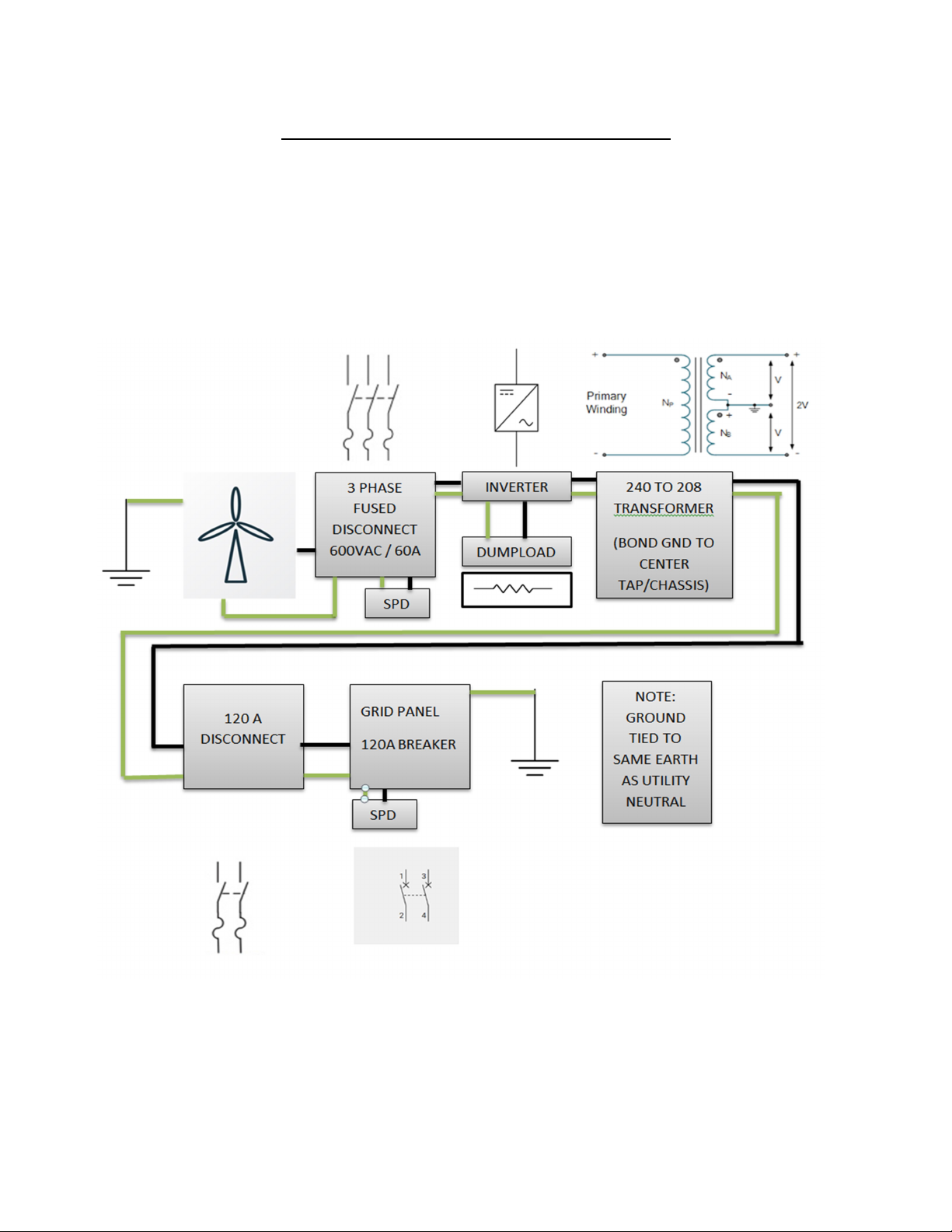

ELECTRICAL STANDARD 240VAC…………………………………………………………………………..7

ELECRICAL TRANSFORMER REQUIRED………………………………………………………………….8

WIRE SIZE CHART…………………………………………………………………………………………………9

GETTING STARTED………………………………………………………………………………………………10

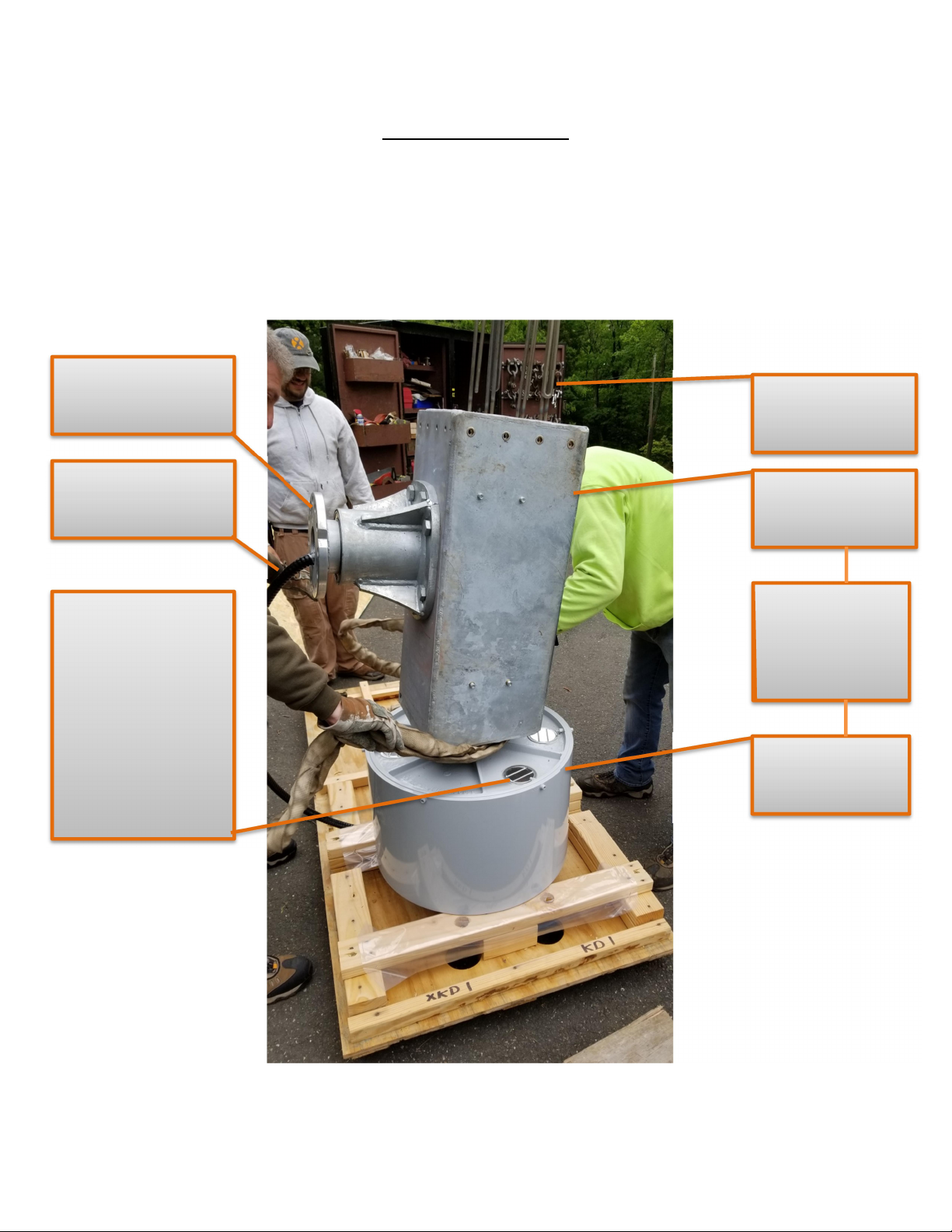

POSITIONING THE UNIT FOR TAIL ASSEMBLY…………………………………………………….11

TAIL INSTALLATION………………………………………………………………………………………12-13

TAIL FIN INSTALLATION………………………………………………………………………………………14

RIGGING THE TURBINE FOR THE LIFT…………………………………………………………………15

BLADE INSTALLATION…………………………………………………………………………………………16

CLAMP PLATE SPACERS…………………………………………………………………………….17

BLADE ORIENTATION………………………………………………………………………………..18

FITTING BLADES………………………………………………………………………………………..19

BLADE TORQUE…………………………………………………………………………………………20

NOSE CONE INSTALLATION…………………………………………………………………………………21

APPLYING A PHASE TO PHASE SHORT…………………………………………………………………22

RAISING THE TURBINE………………………………………………………………………………………..23