1

BWC Tilt-up Tower & BWC EXCEL1

INSTALLATION MANUAL

TableofContents

Safety..............................................................................................................................2

1) Components...............................................................................................................4

2) Anchors & Base Plate................................................................................................6

3) Tower Assembly.......................................................................................................12

4) Initial Tower Raising.................................................................................................19

5) Lowering the Tower..................................................................................................21

6) Installing the EXCEL1 Wind Turbine........................................................................22

7) Final Tower Raising .................................................................................................29

8) Misc. Reference Material .........................................................................................31

9) Tilt Tower Packing Lists...........................................................................................37

TableofFigures

Figure 1: Major Tower Components...............................................................................5

Figure 2: Anchor Layout.................................................................................................7

Figure 3: Base Plate Assembly....................................................................................10

Figure 4: Anchor Installation.........................................................................................11

Figure 5: Guy Wire Attachment....................................................................................15

Figure 6: Gin-pole Safety Wire Assembly.....................................................................16

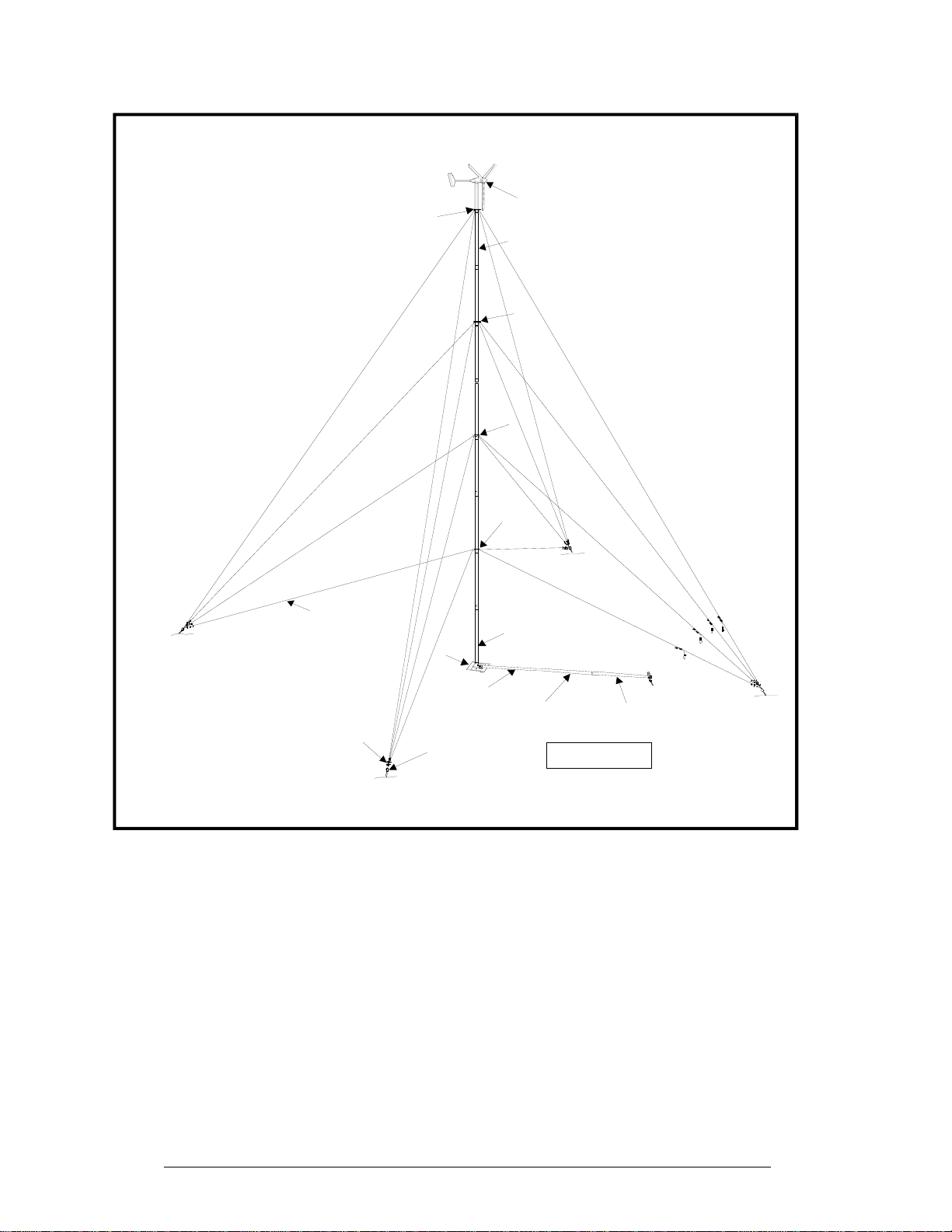

Figure 7: Tower Tilt-up Sequence................................................................................19

Figure 8: Major Components of the EXCEL 1..............................................................22

Figure 9: EXCEL 1 Wiring Schematics.........................................................................23

Figure 10: Turbine Mounting........................................................................................25

Figure 11: Blade and Spinner Fasteners......................................................................26

Figure 12: Nut Tightening Order...................................................................................27

Figure 13: Tail Fin Attachment.....................................................................................27

Figure 14: Tail Boom Attachment.................................................................................28

Figure 15: Guy Wire Transfer Sequence......................................................................29

Figure 16: Concrete Anchors .......................................................................................33

TableofTables

Table 1: Pull-up Force and Cable Travel......................................................................17

Table 2: Recommended Wire Sizes for the EXCEL1 24V............................................24

Table 3: Soil Classifications .........................................................................................32