BERI UDYOG FIELDKING User manual

1

FIELDKING

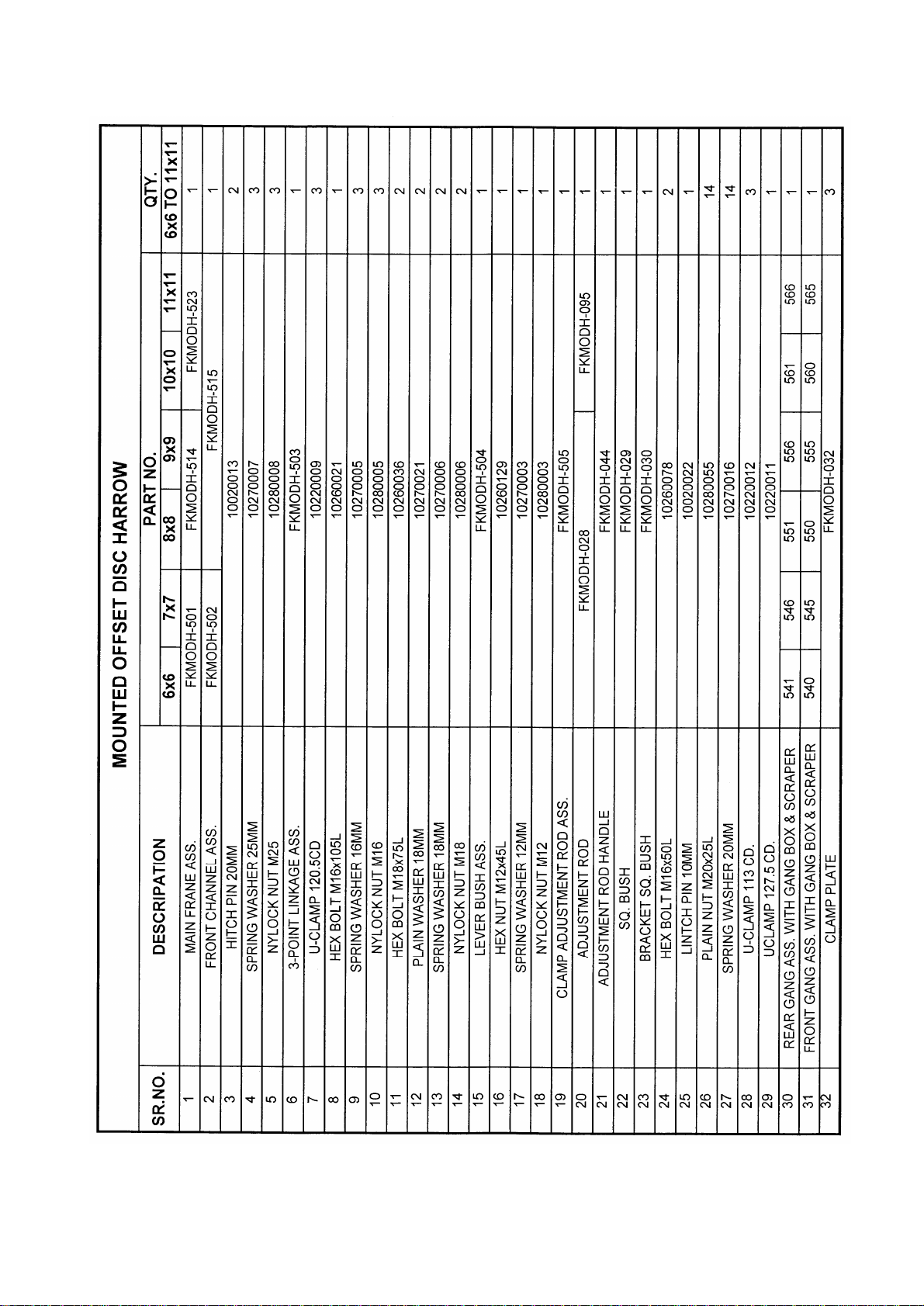

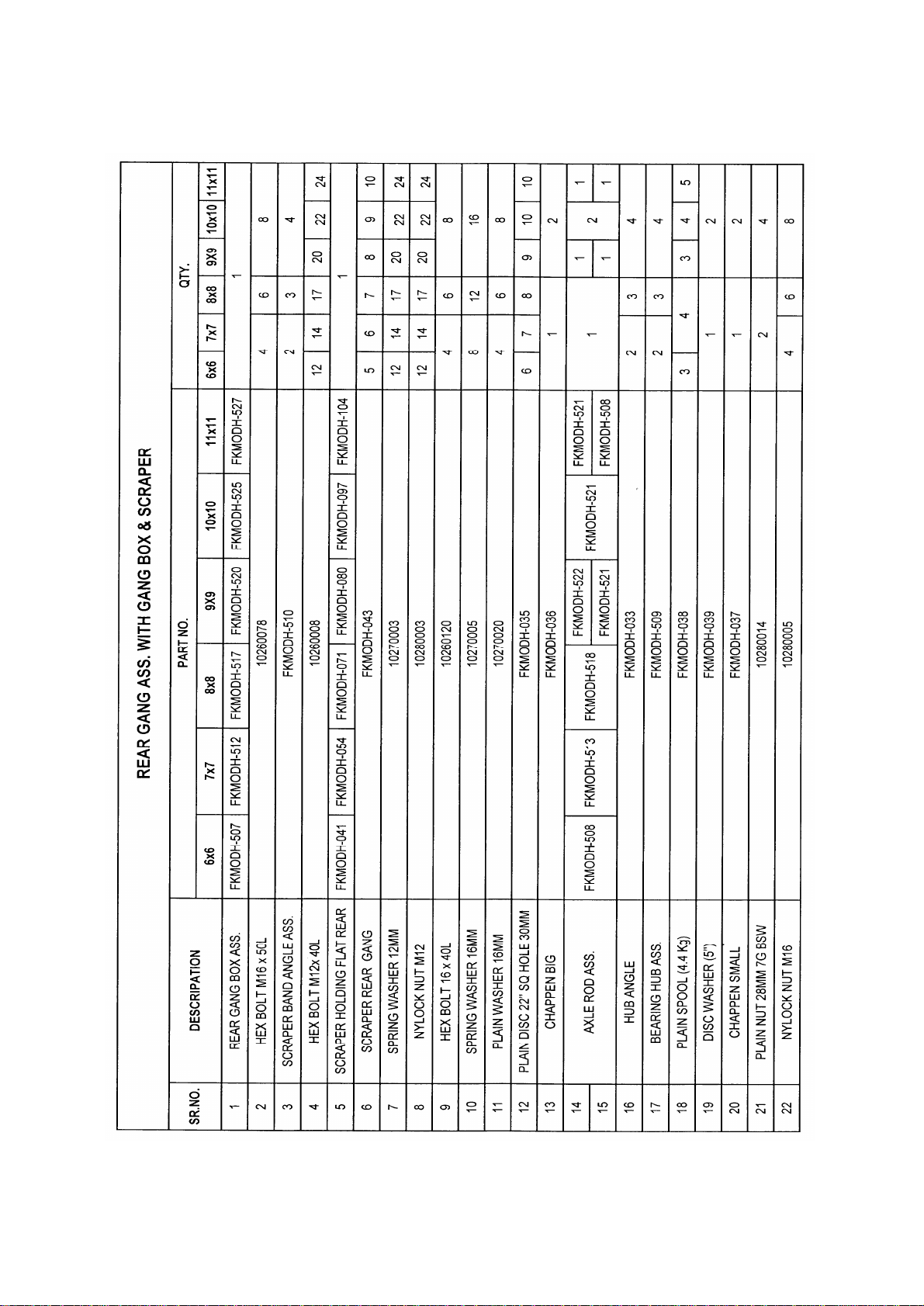

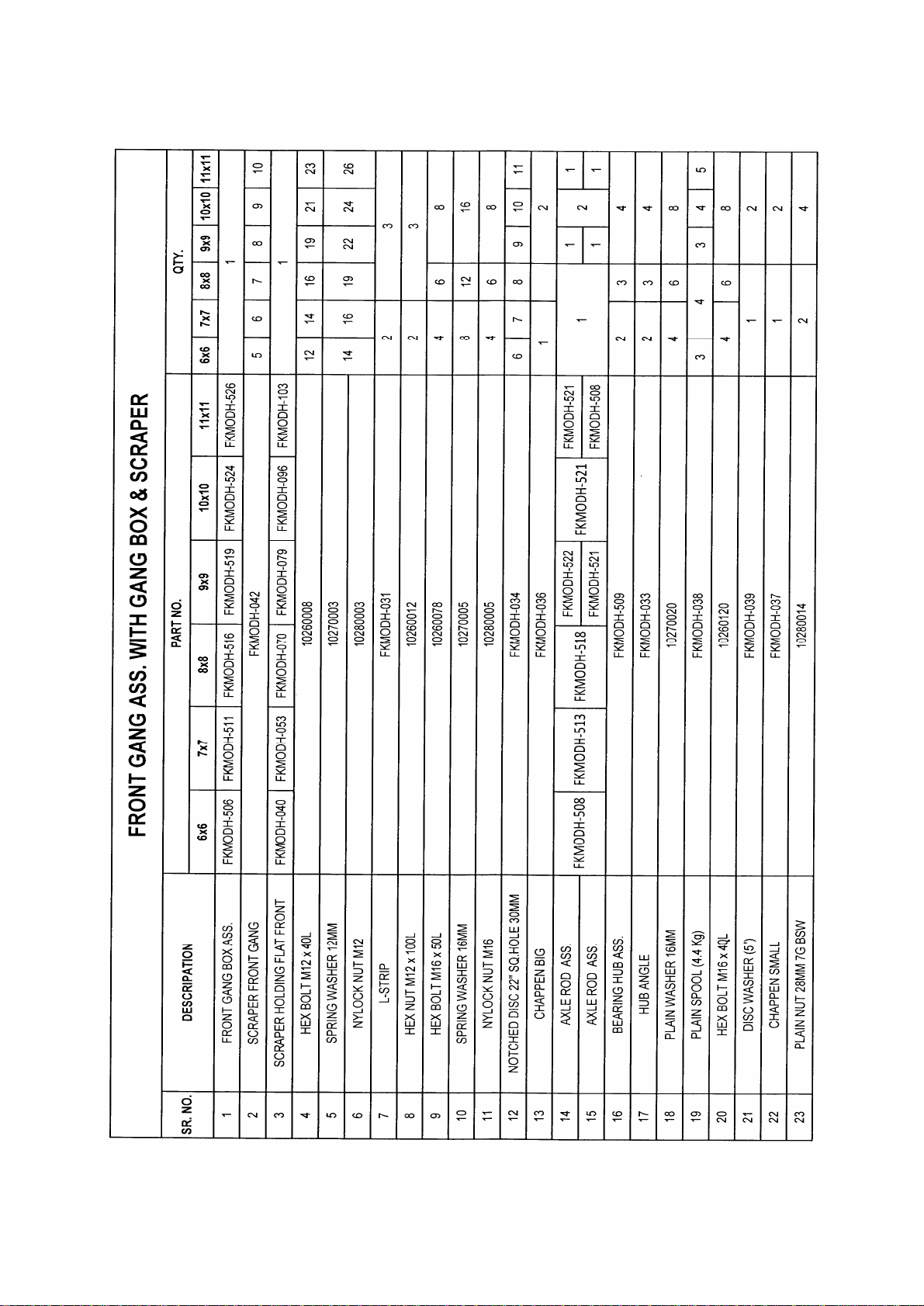

MOUNTED OFFSET DISC HARROW

BERI UDYOG PVT. LTD.

INDIA

(An ISO 9001-2008 Company)

OPERATOR MANUAL/ SERVICE MANUAL / PART CATALOGUE

3

TO THE PURCHASER

This manual contains valuable information about your new “FIELDKING”

Mounted offset disc harrow. It has been carefully prepared to give you

helpful suggestions for operating, adjusting, servicing and ordering spare

parts.

Keep this manual in a convenient place for quick and easy

reference. Study it carefully. You have purchased a dependable and sturdy

Mounted offset disc harrow, but only by proper care and operation can you

expect to receive the service and long life designed and built into it.

Sometime in the future your Mounted offset disc harrow may

need new parts to replace those that are worn or broken. If so, go to your

dealer and provide him with the model and part number.

Customer Information

Name _______________________________________

Purchased From ______________________________

Date Purchased ______________________________

Model No. ___________________________________

Serial No. ___________________________________

4

It is the purchaser and/or operator’s responsibility to….

1. Read and understand the information contained in this manual.

2. Operate, lubricate, assemble and maintain the equipment in accordance with all

instructions and safety procedures in this manual.

3. Inspect the equipment and replace or repair any parts that are damaged or worn

which under continued operation would cause damage, wear to other parts, or

cause a safety hazard.

4. Return the equipment or parts to the authorized FIELDKING dealer, from where it

was purchased, for service or replacement of defective parts that are covered by

warranty. (The FIELDKING Factory may inspect equipment or parts before

warranty claims are honored.)

5. Payment of all costs incurred by the dealer for traveling to or transporting the

equipment for warranty inspection and claims.

5

INDEX

1.

TECHNICAL DATA

1.1 Introduction

1.2 Warranty

1.3 When the warranty becomes void

1.4 Warning

2.

USAGE INSTRUCTIONS

2.1 Before Use & Adjustments

2.2 Attaching Harrow to the tractor

2.3 Warning for driver

2.4 Safety

3.

MAINTENANCE

3.1 Maintenance Instructions

3.2 Storage of machine after work

3.3 Lubrication

3.4 Instruction for driver

4.

OPERATIONAL GUIDELINES FOR HARROW

5.

TROUBLE SHOOTING CHART

6

1.

TECHNICAL DATA

1.1 INTRODUCTION

This handbook contains the use and maintenance instructions with a list of the spare parts

of the Disc Harrow.

This Disc harrow is equipped with heavy-duty channel frame specially designed for

harrowing / land preparation of rough soil (Secondary finer operation).

Regular and satisfactory operation together with economic and long lasting use of the

implement depends on the compliance with instructions given in this handbook.

Compliance with the instructions in this handbook is also important since Manufacturer

declines all and every responsibility for damage to persons or property caused by

negligence and failure to comply with these instructions.

1.2 WARRANTY

When the machine is delivered, check that it has not been subjected to damage during

transport and that the accessories are in a perfect condition and complete.

Any claims following the receipt of damaged goods shall be presented in writing within 8

days from the receipt of the goods.

The purchaser may only make the claims under guarantee when he has complied with the

warranty conditions in the supply contract.

1.3 WHEN THE WARRANTY BECOMES VOID

Besides the cases specified in the supply agreement, the guarantee shall in any case

become void:

When the implement has been used beyond the specified power limit like (Tractor Horse

Power)

When repairs made by the customer without authorization from the manufacturer or

owing to installation of spurious spare parts, the machine is subjected to variations and

the damage can be ascribed to these variations.

When the user has failed to comply with the instructions in this handbook.

If the implement is used in very hard/stony soil no warranty of discs will be given.

No warranty will be given if the service and greasing is not done on time.

1.4 WARNING

Thoroughly read the instruction manual before proceeding with the various operations.

Maintain the harrow as per the instructions of this handbook to be entitled for

warranty.

7

2. USAGE INSTRUCTIONS

2.1 BEFORE USE & ADJUSTMENTS

1. Before mounting of disc harrow make sure that all nuts & bolts are properly

secured.

2. Also determine soil and trash conditions of the field and make the preliminary

adjustments. e.g.

a) Disc gang angle adjustment :-

Gang angle (Angle between two gangs) ranges between 40

0

to50

0

. The

angle can be increased for better penetration in dry soil while it should be

reduced to avoid plugging in wet soil.

b) Disc harrow leveling: - To eliminate uneven penetration and side draft, leveling

is done by means of top link. While tractor pulls to right the rear gang should be

lowered a little. When the tractor pulls to the left the rear gang should be raised.

c) Scrapper adjustment:-

The scrapper can be adjusted by loosening the bolts at the scrappers clamp.

d) Depth control:-

The depth at which the implement is required to work is controlled

hydraulically by raising or lowering the control lever on the tractor.

e) Disc harrow penetration :-

Factors affecting disc harrow penetration are:-

Angle of the gang

Weight of the harrow

Disc diameter

Disc sharpness

(Blunt disc increases the draft considerably, check the disc sharpness)

Angle of hitch

2.2 ATTACHING THE HARROW TO THE TRACTOR

1. Place the harrow duly leveled on the flat piece of land.

2. Reverse the tractor to the harrow ( Do not drag the harrow up the tractor)

3. Attach the left arm of the tractor to the harrow first.

4. Attach the central arm to the harrow. To attach, turn the screws on both sides to

an equal length. If the arm is too short or too long, turn the screw to adjust both

at the same time until aligned with the hole on the central arm.

8

5. Attach the lower right arm, turn the screw until the mounting pin is at the same

level as the hole on the tractor arm. If the gap between the hole and mounting

pin is too close or too distant, turn the control arm in or pull it away to an

appropriate distance. You may have to adjust both height and distance at the

same time. When the hole at tractor arm and mounting pin are even, insert the

pin in the hole and lock it with the lynch pin.

6. After attaching the harrow, lift it and adjust the control arm parallel to the

ground. When you look from both rear or sideways, the discs should all be

touching the ground uniformly.

2.3 WARNING FOR THE DRIVER

Before harrowing check all nuts & bolts of the disc harrow.

Be vigilant about the tree roots and stones. Don’t harrow on stony soil.

Tractor should be in first high or fourth low gear.

Don’t allow anyone to come across the harrow.

Lift the disc harrow on every turn.

Lift the harrow before approaching the road.

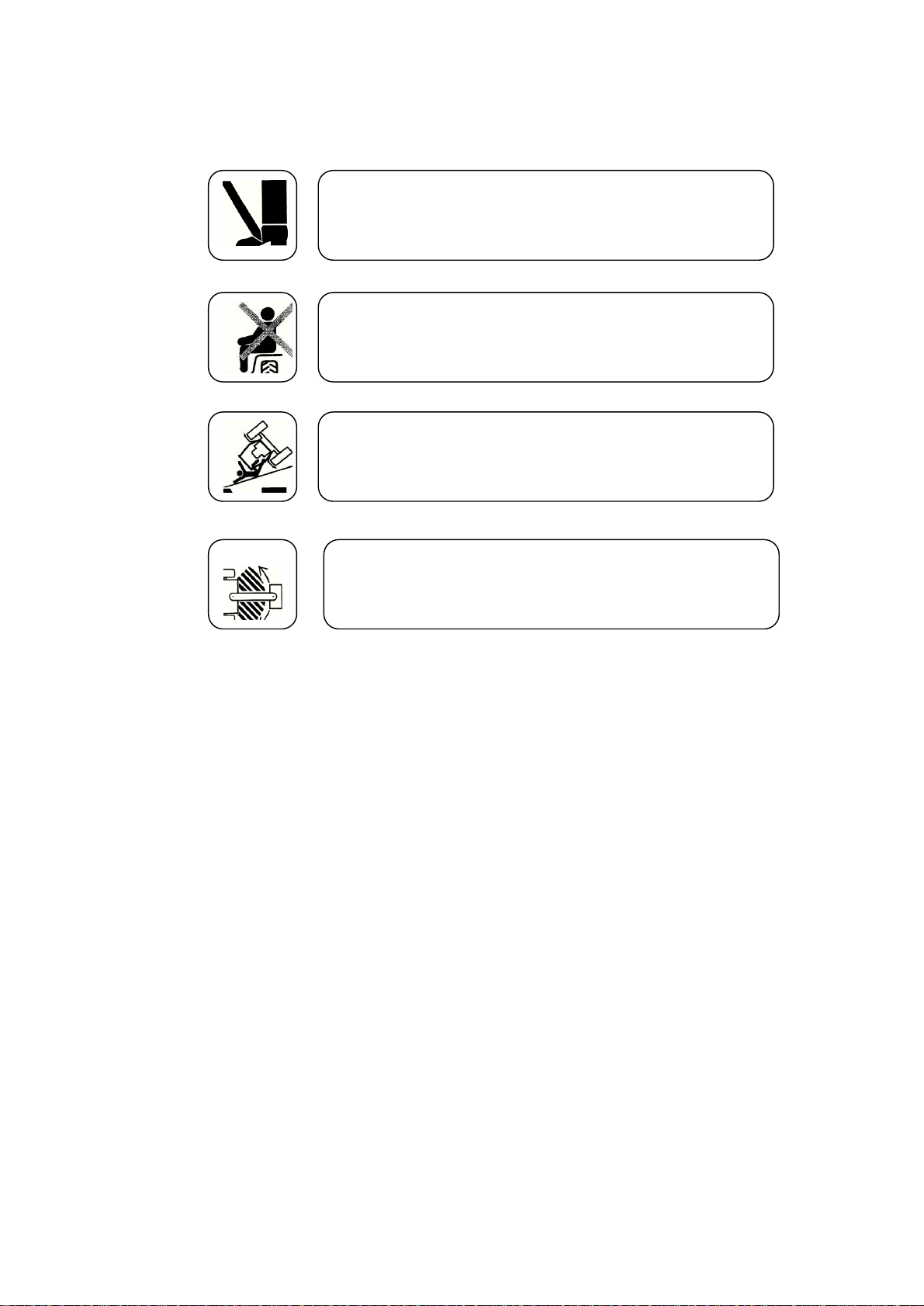

1.4 SAFETY

Understanding the Machine Safety Labels

The machine safety labels shown in this section are

placed in important areas on your machine to draw

attention to potential safety hazards

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-

alert symbol. DANGER identifies the most serious

hazards.

The operator’s manual also explains any potential safety

hazards whenever necessary in special safety messages

that are identified with the word, CAUTION, and the

safety alert symbol.

Before harrowing with Disc harrow take care that nobody stands near it.

9

3. MAINTENANCE

3.1 MAINTENANCE INSTRUCTIONS

If you work the Disc harrow on stony land then maintenance also increases.

1. If the soil has entered the grease nipple, then change the nipple.

2. If disc harrow is new after initial working of first two hours, tighten all nuts &

bolts.

3. After every fifty hours grease all greasing points with grease gun and tighten all

nuts & bolts.

4. After fifty hours, open the bracket spool of Disc harrow & cleanse with diesel oil

& pump in new grease.

3.2 STORAGE OF MACHINE AFTER WORK

1. Wash the Disc harrow after work.

2. Replace the worn out nuts & bolts.

3. If disc harrow has to remain unused for long time then clean it & apply a layer of

used oil for rust prevention.

These steps will enhance the life of your Disc harrow.

In order to protect yourself always wear adequate

clothes and shoes during the operations.

Never allow riders on the tractor or implement unless

on additional seat is available.

Be careful whe

n moving around steep graders to avoid

over turn.

Never transport the implement on rough roads during

the night. When operating, avoid to make sharp turns

that may contact with the implement

10

3.3 LUBRICATION

Please take care that high quality grease is used in spools.

3.4 INSTRUCTIONS FOR DRIVER

1. When Disc harrow is ready for use don’t stand between disc harrow & the

Tractor.

2. Properly fit the three point linkage as mentioned above & lock with lynch pin.

3. In case of scrapper touching the discs, loosen the scrapper bolt and readjusts the

scrapper.

4. Never turn the tractor to the right or left when the harrow is engaged in the soil.

5. Never reverse the tractor when the harrow is engaged in the soil.

6. To get good results from the harrow, disc should be replaced when its diameter

is reduced by 5”from its original size.

4. OPERATIONAL GUIDELINES FOR HARROW

1. Lift the harrow on turning for effective independent breaking of soil.

2. Adjust internal /external check chains to obtain implement swing range with in 50

mm (2”) when raised.

3. Always maintain the correct tyre pressure to avoid wheel slippage.

4. Adding of wheel weights/water ballasting or combination of both is recommended

when excessive rear wheel slippage is experienced.

5. Always set hydraulic levers correctly for draft and position control operation.

The following settings are necessary to ensure that uniform working depth is

maintained:-

a.) Side draft:-

The offset disc harrow will trail correctly behind the tractor provided the side thrust of

the front gang is equal to that of rear. In case it is different there will be side draft. To set

it correctly, the gang angle should be changed.

b.) Severe Side Draft:-

In case of severe side draft the cutting depth of rear disc gang should be increased or

decreased with the help of tractor top link. For instance when tractor pulls to right, lower

the rear gang and when tractor pulls to left, raise the rear gang.

Precautions during transportation:-

1. When transporting the harrow, shorten up top link to minimum length.

2. Set hydraulic levers in top raised position and lock levers.

3. Maintain the speed to avoid jumps.

4. Watch while overtaking on road.

5. Always use SMV (Slow Moving Vehicles) symbols.

11

5. TROUBLE SHOOTING CHART

SR.

NO.

POSSIBLE CAUSES

POSSIBLE REMIDIES

A. Side Draft

1.

Disc not running level

Adjust using leveling lever

2.

Gangs improperly angled

Set the gangs

3.

Too much left hand offset.

Swing

the hitch to the left.

B. Excessive field slippage

1.

Tractor overloaded

Reduce angle, reduce depth.

2.

Not enough tractor ballast

Add wheel weight or liquid

C. Not filling the furrow

1.

Too much left hand offset

Swing hitch to the left

2.

Tracto

r wheel running in furrow enlarging

it

Drive the tractor in unworked ground

3.

Disc too far from furrow

Keep the left front discs in furrow

4.

Rear gang set wrong, laterally.

Move the rear gang right or left. The left

rear should be centered in the space

between left front discs.

D. Poor penetration

1.

Hard ground

Swing hitch to the right. Increase angle in

front and rear gang.

E. Disc unsteady

1.

Too much angle in gang

Reduce the gang angle

F. Gang plugging

1.

Field too wet.

Disc at shallo

w depth for first pass to

speed

up drying process.

2.

Gang set in maximum angle.

Reduce the angle

3.

Not using scrappers

Install scrappers.

4.

Scrappers worn out or not set properly.

Replace worn ones. Adjust scrappers

close to the disc

5.

Discing too

deep in damp soil

Reduce penetration

12

13

14

15

16

17

18

19

Other manuals for FIELDKING

1

Table of contents

Popular Farm Equipment manuals by other brands

Z.I.P.P.ER MASCHINEN

Z.I.P.P.ER MASCHINEN ZI-MD500HST user manual

Frontier

Frontier RT 1142 Operator's manual

APV

APV PS 300 M1 D operating instructions

Fast

Fast 8200 Operation manual

Goldacres

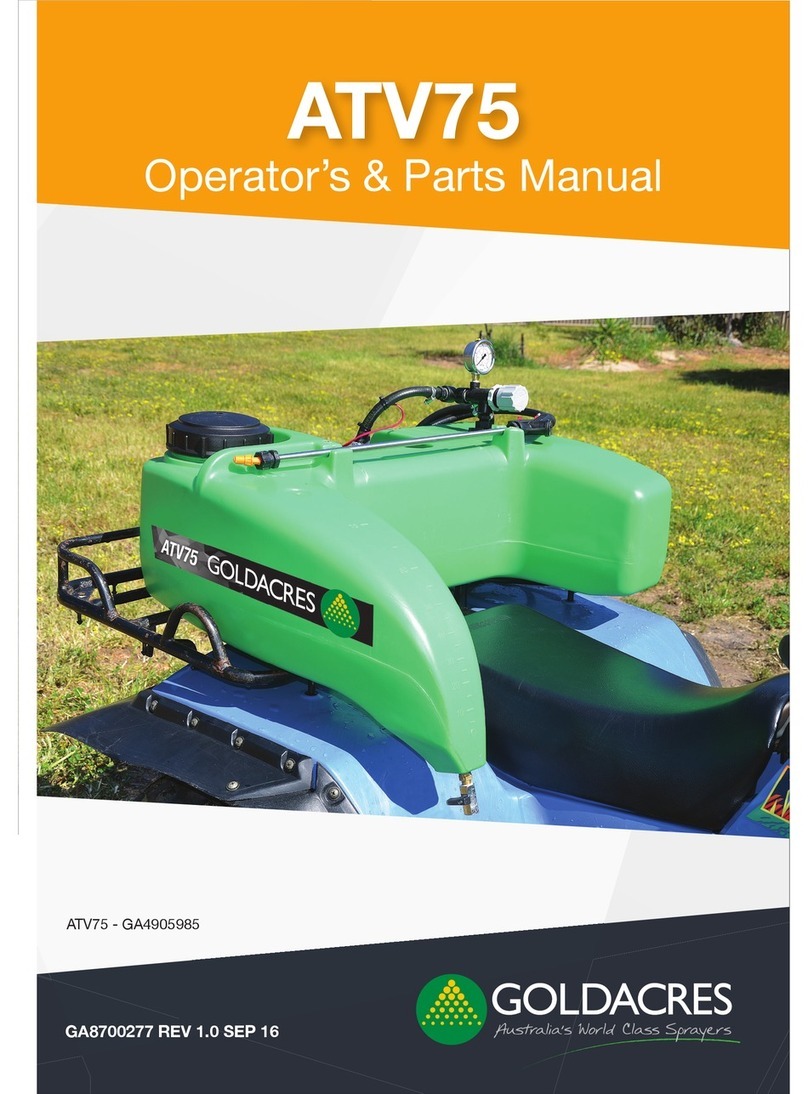

Goldacres ATV75 Operator's & parts manual

Farmi Forest Corporation

Farmi Forest Corporation VARIO 101 Operating, Maintenance and Spare Parts Manual