2

1

General information............................................................................................ 4

1.1

About this operating manual.................................................................... 4

1.2

Identification of the implement................................................................. 5

1.3

Service..................................................................................................... 6

1.4

EC Declaration of Conformity.................................................................. 6

2

Description .......................................................................................................... 7

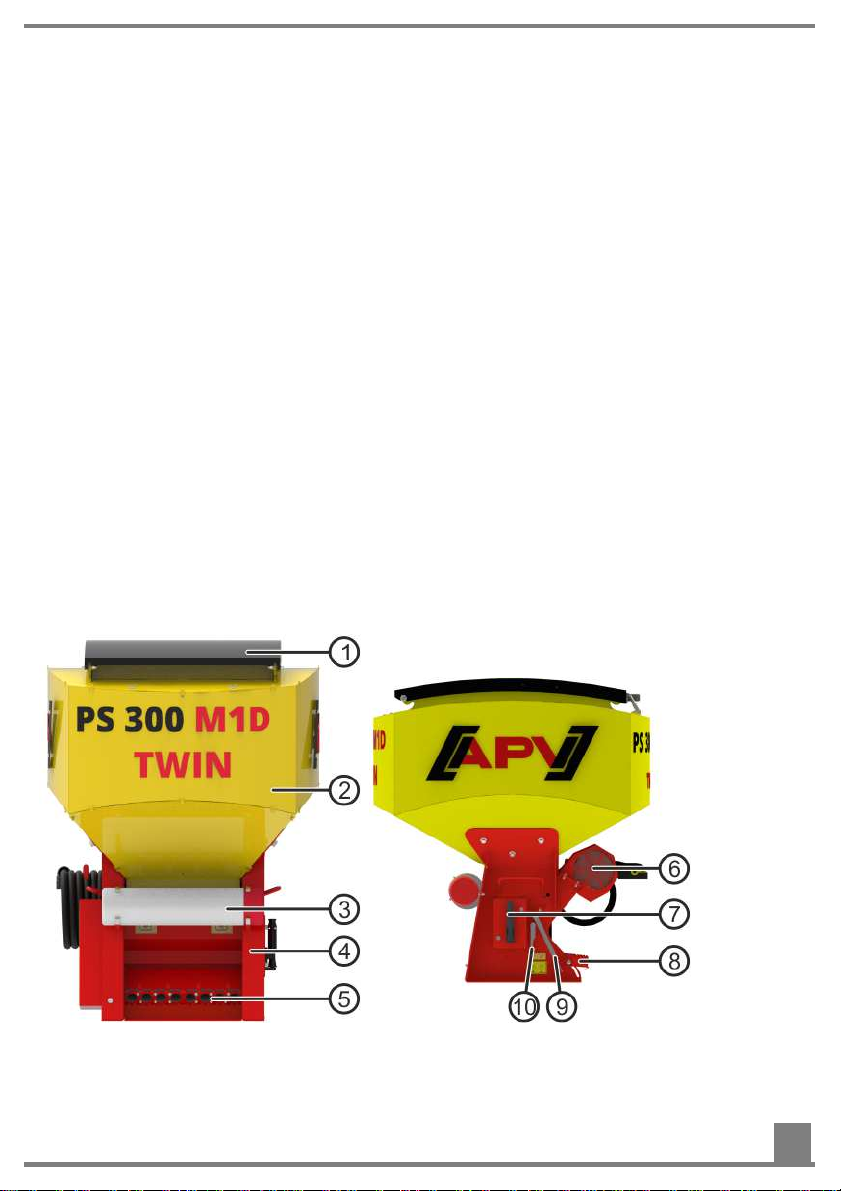

2.1

Layout and functioning of the seed drill................................................... 7

2.2

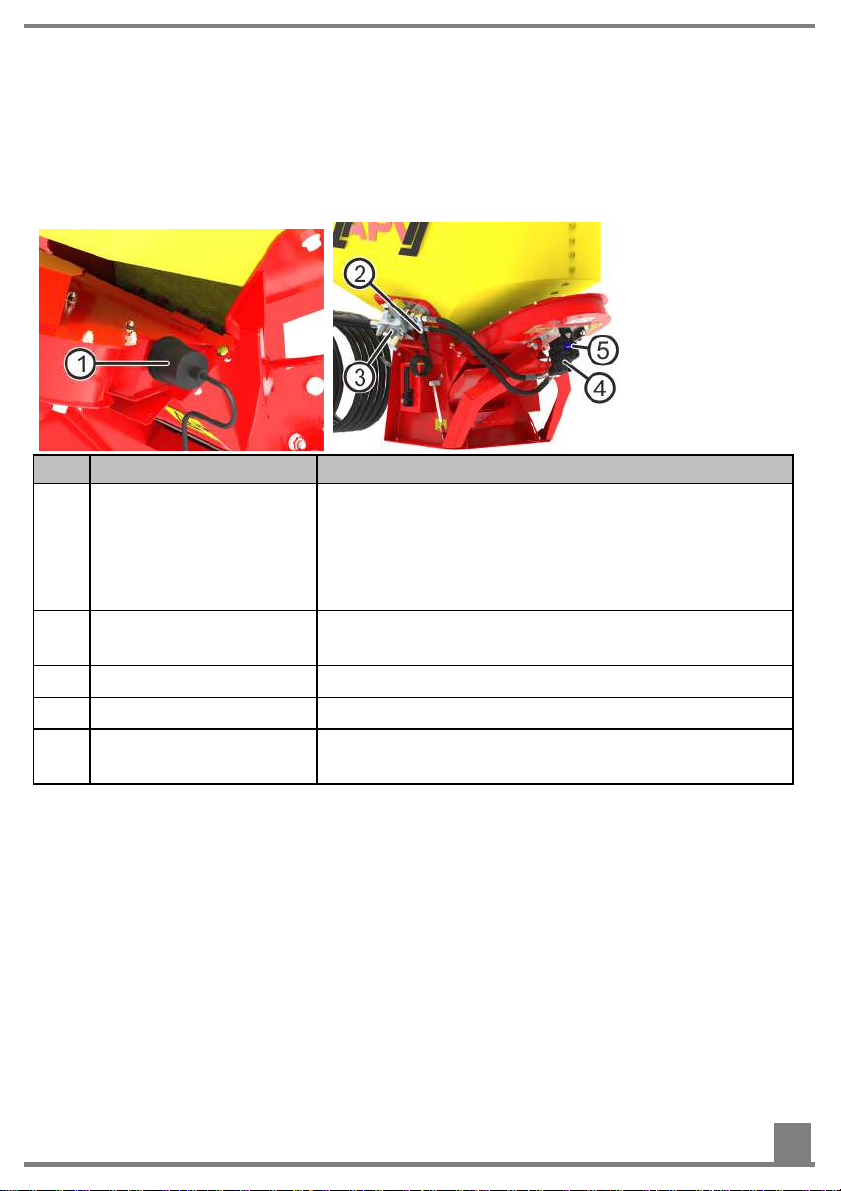

Layout and function of the hydraulic fan (HG 300 M1)............................ 9

2.3

Layout and function of the fill level sensor ............................................ 10

2.4

Scope of delivery................................................................................... 10

2.5

Technical data ....................................................................................... 11

3

Safety ................................................................................................................. 12

3.1

Safety instructions in this document...................................................... 12

3.2

Basic safety regulations ........................................................................ 12

3.3

Intended use.......................................................................................... 13

3.4

Personnel requirements ........................................................................ 13

3.5

Personal protective equipment.............................................................. 14

3.6

Safety devices ....................................................................................... 15

3.7

Dangers and safety measures .............................................................. 17

4

Transport, installation and commissioning ................................................... 20

4.1

Attaching the seed drill to a soil tillage implement ................................ 20

4.2

Attaching the seed drill to a tractor........................................................ 21

4.3

Installing the dispersion plates on the soil tillage implement................. 22

4.4

Connecting the hoses............................................................................ 24

4.5

Connecting the hydraulic fan (HF)......................................................... 25

5

Operation ........................................................................................................... 27

5.1

Setting the hydraulic fan (HF)................................................................ 27

5.2

Setting and adjusting the spread rate.................................................... 29

5.3

Regulating the seed flow rate (calibration test) ..................................... 30

5.4

Preparing the seeding shaft .................................................................. 31

5.5

Selecting the right seeding shaft ........................................................... 32

5.6

Changing the seeding shaft................................................................... 32

5.7

Checking the ease of motion of the seeding shaft ................................ 35

5.8

Setting the brush pressure .................................................................... 35

5.9

Setting the air control flaps.................................................................... 36

5.10

Setting the fill level sensor..................................................................... 37

5.11

Filling the spreading material tank......................................................... 38

Table of Contents