Brave MBRP750DP3 User manual

800-350-8739

1

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

MBRP750DP3

Owner’s Manual

Brave 3” Diaphragm Water Pump

WARNING

Read and understand all instructions. Failure to follow all instructions may

result in serious injury or property damage.

• WARNING: Wear appropriate protective gear. This list includes, but is not limited to:

- safety glasses, protective boots with slip resistant soles, gloves, hearing protection.

• WARNING: Keep guards in place and in working order. Never operate the product without the guards in place.

• WARNING: LETHAL EXHAUST GAS! An internal combustion engine discharges carbon monoxide, which is a poisonous

and odorless invisible gas. Death or serious illness may result if inhaled. Operate only in an area with good ventilation.

• DANGER: Do not smoke when refueling.

• WARNING: Do not use pump in explosive atmosphere.

• WARNING: Do not pump volatile or flammable liquids such as gasoline, fuel oil, kerosene, etc.

• CAUTION: Do not attempt to operate pump, if any parts are missing or damaged.

• CAUTION: For proper handling techniques and cautions when pumping certain chemicals, contact your chemical supplier

or local agencies (fire dept etc)

• CAUTION: The engine is hot enough to cause injury, do not touch the exterior of the engine, especially the muffler and

surrounding area.

• WARNING: Even though this unit will operate with minimal supervision, it should not be left operating by itself. Depending

on the application and area unit is operating (high traffic, people in area, etc.) will dictate the necessity of having someone

watching over the unit.

• CAUTION: Do not allow pump to be located in freezing or colder weather. Damage to pump will result.

• CAUTION: Maximum discharge head is 25 feet or 10.9 PSI. Operation over this head or pressure will cause pump to stall

and/or gearbox damage.

• CAUTION: Do not control discharge capacity with a valve or similar device.

• CAUTION: If pump has stopped or stalled for any unknown reason, clean out pump cavity thoroughly. Failure to comply

with the “caution” could result in damage to crank, plunger arm or other parts of assembly.

STOP!

ADD OIL TO ENGINE BEFORE USING: Engine is shipped without oil. DO NOT start engine without first adding oil.

INSPECT COMPONENTS: Closely inspect to make sure no components are missing or damaged.

Any Questions, Comments, Problems or Parts Orders

Call Brave Support 1-800-350-8739

ITEM NUMBERS: BRP750DP3

MANUAL SERIAL TAG HERE

800-350-8739

2

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

Please read and save this Owner’s Manual. Read this manual carefully before attempting to operate or maintain this pump. Protect yourself and others

by observing all safety information. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or

property damage! Retain instructions for future reference. Brave reserves the right to discontinue any model or change specifications at any time

without incurring any obligation.

Periodic maintenance and inspection is required on all pumps to ensure proper operation. Unit must be clear of debris and sediment. Inspect for leaks

and loose bolts. Failure to do so voids warranty.

Diaphragm Pumps

DESCRIPTION

This diaphragm pump is a high capacity, self-priming (to 25 ft. lift), portable unit shipped completely assembled (except for handle). The pumps are used

for operation with fluids mixed with abrasive solids such as sand, silt, mud, sludge and waste. Not for use with pumping cement or mortar. Handles

liquids from 40º to 180º F (4º to 82 º C). Pump is capable of handling solids up to 1-5/8" diameter. For use with water and other non-flammable fluids

compatible with pump component materials.

Model

Engine Type

Material

Diaphragm

Check Valve

Gear Box

Bearings

NPT

BRP750DP3

Honda GX120

Aluminum

Thermoplastic/TPE

Neoprene

Oil Bath

Needle

3"

UNPACKING

After unpacking the unit, inspect carefully for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts.

Specific Safety Information for Ga

soline Engine

Driven Pumps

1. Carefully read the instruction manuals supplied by the

engine manufacturer befor

e attempting to assemble,

disassemble or operate the engine or any other part. The

"Warning" and "Caution" statements in this manual signal

potentially hazardous conditions to the

operator or

equipment. Know when these conditions can exist. Take

necessary steps to protect personnel, as well as equipment.

Gasoline is a highly combustible fuel. Use it with care! The

improper use, handling and/or storage of gasoline can be

dangerous. Help prevent accidents by following these safety

rules:

a. Use gasoline only as a fuel, never as a cleaning fluid.

b. Always use an approved container to hold or store gasoline.

Never store gasoline in familiar containers such as milk

gallons or soda pop bottles.

c. Never store gasoline near a heater or an open flame.

d. When storing or using gasoline, make sure container is out

of the reach of children.

e. Never add gasoline to a running or hot engine. Spilled

gasoline on a hot engine may cause a fire or an explosion.

Fill gasoline tank outdoors and wipe up any spills.

f. Have a fire extinguisher nearby. Be sure extinguisher is in

operating condition – check the pressure gauge or indicator.

Be familiar with its proper use. Consult the local fire

department for the correct type of extinguisher for your

application. Extinguishers rated ABC by the National Fire

Protection Association are appropriate for all applications.

g. On permanent installations, be sure all fuel supplies have a

positive shutoff valve. Fuel lines must be of steel piping,

adequately secured and free from leaks. Do not use copper

piping on flexible lines as copper becomes hardened and

brittle and will break. Use black pipe on natural gas or

gaseous fuels, but not on gasoline or diesel fuels. Piping at

the engine should be a suitable flexible line that is

compatible with the fluid.

Positively no smoking!

2. Check engine oil, fuel levels and gear box oil levels before

initial startup each day. Stay away from moving parts due to

the danger of becoming caught in moving parts. Avoid loose

jackets, shirts, sleeves and ties. Make sure all nuts and bolts

are secure. Keep power shields and guards in place. If

adjustment MUST be made while the unit is running, use

extreme caution around hot manifolds, moving parts, etc.

3. Do not work with this equipment when mentally or physically

fatigued.

4. Be careful not to touch the exterior of the engine, especially

the muffler and the area around it. It is hot enough to be

painful or cause injury.

5. To prevent accidental starting, always remove the spark

plug or disconnect and ground the spark plug wire before

working on the engine or the equipment driven by the

engine.

6. DO NOT RUN THE ENGINE IN AN ENCLOSED AREA!!

Exhaust gases contain carbon monoxide, which is an

odorless and deadly gas that will cause death if breathed too

long.

800-350-8739

3

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

Diaphragm Pumps

General Safety Information (All Units)

1. Know the pump application, limitations and potential hazards.

Do not use to pump flammable or explosive fluids such as

gasoline, fuel oil, or kerosene, etc. Do not use in flammable and/or

explosive atmospheres. Pump should only be used with liquids

compatible with pump component materials. Failure to follow this

warning can result in personal injury and/or property damage.

2. Provide adequate protection and guarding around moving

parts.

3. Release all pressure within the system before servicing any

component.

4. Drain all liquids from the system before servicing.

5. Secure the discharge line before starting the pump. An

unsecured discharge line will whip, possibly causing personal

injury and/or property damage.

6. Check hoses for weak or worn condition before each use,

making certain that all connections are secure.

7. Periodically inspect pump and system components. Perform

routine maintenance as required (see Maintenance Section).

8. Provide a means of pressure relief fo

r pumps whose

discharge line can be shut off or obstructed.

9. Personal Safety:

a. Wear safety glasses at all times when working with

pumps.

b. Wear a face shield and proper apparel when

pumping hazardous chemicals.

c. Keep work area clean, uncluttered and properly

lighted.

d. Keep visitors at a safe distance from the work area.

.

ASSEMBLY

HANDLE ON 3" PUMP (Refer to Figure A)

a. Remove two bolts from front holes in gear box,

mounting feet base (Ref. No. A6).

b. Place handle 3354-116-90 on top and reinstall bolts

and washers.

c. Reinstall two hex bolts and washer assemblies,

then tighten.

2. ROTATING SUCTION/DISCHARGE PORTS (OPTIONAL)

(Refer to Figure A,W,P)

In some applications, it may be preferable to have suction/discharge

ports rotated 90 degrees to be in line with driver. If so, proceed as

follows:

a. Remove four hex cap screws (Ref. No. A9), hex nut (Ref. No.

A13) and washers (Ref. Nos. A11 & A12) from pump

assembly to separate pump well (Ref. No. A3) from pump

base (Ref. No. A8).

b. Rotate pump well 90 degrees clockwise so that driver is

positioned over top of discharge plate (Ref. No. W7).

c. Be sure that pump well base and diaphragm (Ref. No. P17)

are aligned properly with one another. Then, reinstall four hex

cap screws, hex nuts and washer assemblies and tighten.

GEAR BOX OIL (Refer to Figure A,G)

3. Place pump on a level surface. Fill pump gear box (Ref. No.

A1) with gear box oil before the pump is operated. Gear oil

must meet requirements of API GL-5 and military

specification MIL-L-2105B. Remove gear box housing fill plug

(Ref. No. G6). Remove level plug (Ref. No. G5). Pour gear oil

into gear box slowly until oil comes out of level plug.

Warranty on this unit is void unless the gear box is lubricated with

appropriate gear oil listed above. DO NOT OVER FILL!

INSTALLATION

NOTE: In any installation where property damage can occur by pumps

not operating due to power outages, discharge line freezing or any

other reason, a backup system(s) and/or warning system(s) should be

used.

1. Place the pump on a level, solid foundation, locating it as

close to the liquid as possible, making the suction line as

short and direct as possible.

2. Install pipe nipples (Ref. No. A36) so the smoother side of

pipe end faces the suction and discharge hose.

Maximum discharge head is 25 feet or 10.9 psi. Operation over

this head or pressure will cause pump to stall and/or gearbox

damage. Use only rigid hoses.

3. Attach suction piping to the suction inlet (Ref. No. W2) and

discharge piping to the discharge outlet (Ref. No. W7). The

suction line should be positioned such that there is a

continual upward slope from the fluid source to the pump.

Avoid using loops or sections of pipe or fittings, which might

permit air to become trapped.

NOTE: If hose is used, be sure to use reinforced hose on both the

suction and discharge. DO NOT USE canvas or similar collapsible

materials. NEVER USE PIPE REDUCER; PIPE SIZE MUST BE

EQUAL TO OR LARGER THAN PUMP PORT SIZE. Suction line

must be airtight so that air cannot leak in and destroy priming vacuum.

On a permanent installation where piping is used, always connect a

piece of flexible hose between pump and piping so pump is free to

move slightly.

4. It is advisable to use a strainer (Ref. No. W16) on the inlet

end of the suction hose or pipe. A properly sized strainer is

supplied with this unit and should be used at all times to

prevent damage. Keep the strainer clean. If possible,

suspend it to keep it from becoming clogged with muck,

roots, debris or leaves. It is best to keep hose free of kinks

as they will restrict flow and add excess loading to pump

and gearing.

5. GASOLINE ENGINE UNITS: Follow all instructions in the

engine manual before starting the engine. Fill engine with

oil, gasoline, etc.

6. Input RPM (to pump) – Input RPM must be between 1750

and 2750 RPM. Final pump speed will be 40 strokes/min.

with a 1750 RPM input and 60 strokes/min. with a 2750

RPM input.

Do not exceed 60 strokes per minute with the diaphragm pump.

OPERATION

Operate the diaphragm pump in an upright position only.

1. This diaphragm pump is capable of priming "dry" up to

fifteen feet; it will prime much faster when it is filled with

clean water through priming cap (Ref. No. W6). Primed, it

can lift to 25 feet.

Do not control discharge capacity with a valve or similar device.

CLEARING JAM-UP

If large solids or an accumulation of sand or other sediment becomes

lodged in the pump well (Ref. No. A3) preventing the plunger arm

(Ref. No. A2) from making a full stroke, the pump should be

thoroughly cleaned as described in "If Pump Stalls" shown below.

Refer to parts list and illustration for parts identification.

800-350-8739

4

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

Diaphragm Pumps

If pump has stopped or stalled for any unknown reason, clean

out pump cavity thoroughly. Failure to comply with the "caution"

could result in damage to crank (Ref. No. P5/P9), plunger arm

(Ref. No. P1) or other parts of assembly.

1. IF PUMP STALLS:

a. Remove handle (Ref. No. A35).

b. Remove four bolts (Ref. No. A9 & A10).

c. Clean obstruction and all debris from pump well

(Ref. No. A3).

d. Reassemble pump in reverse orde

r of

disassembly and return to service.

2. IF PLUNGER ARM (Ref. No. P1) SEIZES AND GEAR BOX

OUTPUT SHAFT (Ref. No. G8) TURNS IN CRANK (Ref.

No. P5):

a. Remove sheet metal guard (Ref. No. A4) by

loosening hand knob screws (Ref. No. A5).

b. Disassemble pump and clean as described in

steps (a) through (d) listed for stalled engine jam

up.

c. Torque the crank lock screw (Ref. No. P6) to 70

foot pounds with an appropriate torque wrench

(see Figure 3).

Figure 3

d. Reassemble the

pump in reverse order of

disassembly and return to service.

Pump jamming with an over-torqued lock screw may cause

internal damage. Under torqueing may allow the output shaft to

spin and wear parts necessitating replacement.

MAINTENANCE

1. Check gear box oil level every 20 hours of operation or at

least once a week; more often if any leakage is detected

around the gear box. Change gearbox oil after the first 40

hours of operation. Fill to the oil level plug. Change gearbox

oil every 350 hours of operation.

2. The plunger bearing (Ref. No. P3) must be greased (any

automotive grease) after every 8 hours of use. This is done

by rotating plunger bearing to the 12 o’clock position. At this

point, grease fitting will be visible through hole in guard (Ref.

No. A4). Bearing may be cleaned and kept well lubricated

by pumping grease slowly into fitting until new grease oozes

out between bearing and journal.

3. During freezing weather, be sure to drain the pump when it

is not running. Remove discharge hose and tip unit towards

discharge side.

4. Keep pump clean. After use with liquids containing foreign

materials, flush with clean water.

REPLACEMENT OF FLAPPER VALVE

(Ref. No. W15)

1. Remove two bolts (Ref. No. W3) and remove suction

priming chamber (Ref. No. W2). Replace flapper (Ref. No.

W15) on flapper pin to locate on priming chamber.

2. Remove two bolts (Ref. No. W8) and remove discharge

plate (Ref. No. W7). Replace flapper valve on flapper pin to

locate valve on pump well (Ref. No. W1).

REPLACEMENT OF DIAPHRAGM

(Ref. No. P13)

1. Remove sheet metal guard (Ref. No. A4) by loosening hand

knob screws (Ref. No. A5).

2. Rotate pump until plunger arm (Ref. No. A2) is in the down

position.

3. Remove handle (Ref. No. A35).

4. Remove pump well (Ref. No. A3) by removing screws, (Ref.

No. A9/A10).

5. Remove diaphragm by removing three nuts (Ref. No. P12)

from bolts (Ref. No. P11).

6. Replace diaphragm and reverse steps 1 through 5 for

reassembly.

GEAR BOX OVERHAULING

A completely assembled gear box is available as a replacement part

(Ref. No. G28).

DISASSEMBLY

1. Remove diaphragm (Ref. No. P13) as described in

"Replacement of Diaphragm".

2. Remove crank (Ref. No. P5) by removing machine screw

(Ref. No. P6). Use screwdriver in slot of crank to release

clamp on output shaft (Ref. No. G8).

3. Drain oil from gear box by removing drain plug (Ref. No.

G4).

4. Remove driver (Ref. Nos. A28/A32) from adapter (Ref. No.

G26) by removing four bolts (Ref. No. A27) plus 4 additional

bolts (Ref. No. A29) from engine mount bracket (Ref. No.

A16) for gas driver models. Slide driver back from adapter

until driver shaft disengages pinion (Ref. No. G20).

5. Remove adapter by removing four bolts (Ref. No. G27).

6. Remove gear box from pump base (Ref. No. A8) by

removing four bolts (Ref. No. A9 & A10).

7. Remove pinion/bearing assembly (Ref. Nos. G15, G24,

G20, G16) by pulling straight out. Use a slide hammer puller

gripping in pinion groove

8. Remove twelve bolts (Ref. No. G3) holding gear box halves

(Ref. Nos. G1 & G2) together.

9. Carefully separate gearbox halves.

10. Remove gasket (Ref. No. G22).

11. Remove output shaft/bearing assembly (Ref. Nos. G8, G9,

G12, G11, G12, G13) and idler pinion/bearing assembly

(Ref. Nos. G13, G14, G17, G18, G19).

12. Remove output shaft oil seal (Ref. No. G23)

13. Remove bearings (Ref. Nos. G15 & G16) from ends of input

pinion shaft (Ref. No. G20).

14. Remove bearings (Ref. Nos. G13 & G14) from ends of idler

pinion shaft (Ref. No. G17).

15. Remove internal spur gear (Ref. No. G19) and key (Ref. No.

G18) from idler pinion shaft.

16. Remove retaining ring (Ref. No. G10) and bearings (Ref.

Nos. G12 & G13) from ends of output shaft (Ref. No. G8).

17. Remove output gear (Ref. No. G11) and key (Ref. No. G9)

from output shaft.

REASSEMBLY

1. Assemble input pinion/bearing assembly

, idler

pinion/bearing assembly and output shaft/bearing assembly.

2. Install output shaft oil seal into gearbox output half.

Lubricate lip seal.

3. Slide output shaft through lip seal. Start output bearing in

bore in gear box output half. Position idler pinion bearing

assembly in its bore in output half. Simultaneously press

both assemblies into output half.

800-350-8739

5

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

Diaphragm Pumps

4. Install gasket on output half.

5. Position gear box input half; align shaft bearings with bearing

bores. Press gear box halves together, align pins in output

half with pin bore in input half.

6. Secure halves together with twelve bolts.

7. Slide input pinion/bearing assembly into bore in gear box

input half. Rotate pinion during installation to make sure gear

teeth align with internal spur gear teeth.

8. Install O-ring (Ref. No. G25) on outside of pinion bearing.

9. Reassemble gear box to pump base with four bolts.

10. Reassemble adapter to gear box with four bolts.

11. Align driver shaft key (Ref. No. A26) with keyway in pinion.

Slide driver into pinion, secure to adapter with four bolts (Ref.

No. A27).

a. (Gas engine only) Attach engine to engine mount

with four additional screw assemblies (Ref. No.

A29).

12. Reassemble crank to output shaft as described under

"Operation" section.

13. Replace diaphragm as described under "Replacement of

Diaphragm" section.

14. Fill gear box with oil as described under "Assembly" section.

15. Pump should be checked daily, weekly, monthly for proper

operation.

NOTE: Only qualified service personnel should attempt to repair this

unit. Improper repair and/or assembly can cause pump damage, driver

damage and/or an electrical shock hazard depending on model.

800-350-8739

6

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

Diaphragm Pumps

Symptom Possible Cause(s) Corrective Action

Pump will not prime or retain

1. Air leak in suction line

1. Repair or replace

prime after operating

2. Defective flapper valves

2. Replace

3. Clogged foot valve or strainer

3. Clean or replace

4. No liquid in suction line

4. Fill suction line & pump with liquid

5. Material jammed in pump well

5. Clean (See Maintenance)

Flow rate is slow

1. Incorrect driver speed

1. Increase speed (see Specifications)

2. Piping is fouled or damaged

2. Clean or replace

3. Clogged pump

3. Clean

4. Discharge line restricted or

undersized

4. Flush out piping or replace

5. Collapsible discharge hose

5. Replace with rigid or non-collapsible

hose

6. Too many bends

6. Straighten hose

7. Lines are too long

7. Shorten lines

Pump runs but no fluid

1. Faulty suction piping

1. Replace

2. Pump located too far from fluid

source

2. Place pump closer to source

3. Gate valve closed

3. Open gate valve

4. Clogged strainer

4. Clean or replace

5. Discharge height too great

5. Lower discharge height

Pump starts and stops pumping

1. Leak in suction line

1. Repair

2. Leak in foot valve

2. Repair or replace

3. Diaphragm has a crack or hole

3. Replace

4. Defective or clogged flapper valves

4. Clean or replace

Excessive noise while pump in

operation

1. Pump not secured to firm foundation

1. Secure properly

2. Restricted suction line

2. Clean or correct

Pump stalls repeatedly or

1. Discharge height over 25 feet of

head

1. Lower height (see Specifications)

stops for no apparent reason

2. Material jammed in pump well

2. Clean out pump well (See Operation &

Maintenance section)

800-350-8739

7

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

For Repair Parts contact dealer where pump was purchased.

Please provide following information:

-Model Number

-Serial Number (if any)

Part description and number as shown in parts list

Assembled Pump – Figure A

800-350-8739

8

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

Repair Parts List - Assembled Pump (Reference Figure A)

3" Engine

Ref.

Driven Pump

No.

Description

Part Number

Qty.

A1

Gearbox Assembly

Ref. Page 8

1

A2

Plunger/Diaphragm Assembly

Ref. Page 10

1

A3

Well Assembly

Ref. Page 11

1

A4

Plunger Guard

3354-103-00

1

A5

¼-20X1/2 Plastic Knob

1716-010-00

2

A6

½-13x1-1/2 Hex Head Cap Screw

1766-013-00

2 (3" Version)

4 (2" Version)

A6

½-13x2-1/4 Hex Head Cap Screw

1766-016-00

2

A7

½ Lock Washer

1798-001-00

4

A8

Base

3354-001-01

1

A9

½-13x2-1/4 Hex Head Bolt Grade-5

1766-016-00

2

A10

½-13x2-1/4 Hex Head Bolt Grade-5

1766-016-00

2

A11

½ Flat Washer

1798-002-00

4

A12

½ Lock Washer

1798-001-00

4

A13

½-13 Hex Nut

1782-002-00

4

A15

Mount Brace

3354-107-00

2

A16

Engine Mount

3354-108-00

1

A16

Engine Mount Kit for Hatz

335Z-101-90

1

A17

Wheel Bracket

3354-109-00

2

A18

Wheel

1663-000-00

2

A19

5/8-11x4 Hex Head Bolt

1769-000-00

2

A20

5/8 Flat Washer

1799-000-00

2

A21

5/8-11 Hex Nut

1782-020-00

2

A22

5/16-18x3/4 Hex Flange Screw

1745-002-00

4

A23

¼-20x3 Hex Head Bolt

1734-013-00

2

A24

¼ Flat Washer

1789-000-00

2

A25

¼-20 Hex Nut

1776-000-00

2

A26

3/16 Square Key

1517-001-00

1

A27

5/16-24x1 Hex Flange Screw

1753-000-00

4

A27

3/8-16X1-1/4 Hex Head Cap Screw

N/A

4

A28

Engine ¾ Keyed PTO

See Chart

1

A29

5/16-18x1-1/2 Hex Head Bolt

1748-000-00

4

A29

5/16-18 x ¾ Hex Bolt (Hatz)

1745-002-00

4

A30

5/16 Flat Washer

1790-000-00

4

A31

5/16-18 Hex Nut

1785-000-00

4

A32

Motor

N/A

1

A33

Cord Assembly

N/A

1

A34

Switch Assembly (not shown)

N/A

1

A35

Handle Kit (not shown)

3354-116-90

1

A36

Nipple Pack (2 NPT nipples)

3270-170-00

1

*Transport Handle (not shown) 3354-116-90 1

800-350-8739

9

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

For Repair Parts contact dealer where pump was purchased.

Please provide following information:

-Model Number

-Serial Number (if any)

Part description and number as shown in parts list

Gearbox – Figure G

800-350-8739

10

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

Repair Parts List -Gearbox (Reference Figure G)

Ref.

3" Pumps

No.

Description

Part Number

Qty.

G1

Gearbox Output Half

3354-090-01

1

G2

Gearbox Input Half

3354-091-01

1

G3

¼-20x7/8” Screws and Washer Kit (12 each)

3354-420-90

1

G4

¼ NPT Plug (drain) (kit includes 1)

1767-002-00

1

G5

¼ NPT Plug (oil level) (kit includes 1)

1767-002-00

1

G6

½ NPT Vented Plug (fill) (kit includes 1)

1767-001-00

1

G7

Lift Bracket

3354-106-00

1

G8

Output Shaft

3354-140-00

1

G9

Woodruff Key #1008

2141-000-00

1

G10

External Retaining Ring SH-112

1806-064-00

1

G11

Output Gear

3354-120-00

1

G12

Bearing –Open- 35x80x21 #6307 JEM

3354-190-00

1

G13

Bearing –Open- 20x52x15 #6304 JEM

3354-191-00

2

G14

Bearing –Open- 15x42x13 #6302 JEM

3354-192-00

1

G15

Bearing –Open- 35x62x14 #6007 JEM

3354-194-00

1

G16

Bearing –Sealed- 35x62x14 #6007 2RSJEM

3354-193-00

1

G17

Idler Pinion Shaft

3354-121-00

1

G18

Woodruff Key #406

2157-000-00

1

G19

Internal Spur Gear

2149-000-00

1

G20

Input Pinion (3/4 keyed engine)

3354-122-00

1

G20

Input Pinion (5/8 keyed 56C motor)

3354-123-00

1

G21

1/4x1 Dowel Pin

1717-002-00

1

G22

Gasket

3354-300-00

1

G23

Oil Lip Seal 1.25x1.75x0.25

2148-000-00

1

G24

Oil Lip Seal 40x62x8

2148-001-00

1

G25

O-Ring- Buna #143

2181-005-00

1

G26

Adapter (engine)

3354-093-01

1

G26

Adapter (56C motor)

3354-092-01

1

G27

5/16-18x3/4 Hex Flange Screw

1745-002-00

4

G28

Assembled Gearbox for Gas Engine Models

3354-402-90

1

(includes Ref. Nos. G1 thru G24)

G28

Assembled Gearbox for Electric Models

3354-403-90

1

(includes Ref. Nos. G1 thru G24)

800-350-8739

11

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

For Repair Parts contact dealer where pump was purchased.

Repair Parts List - Plunger Assembly (Reference Figure P)

Ref.

3" Pumps

No.

Description

Part Number

Qty.

P1

Plunger

2134-000-01

1

P2

Retaining Ring

3350-190-00

1

P3

Plunger Bearing

2138-000-90

1

(includes Ref. No. P4)

P4

Bearing Lock Nut

Incl. w/P3

1

P5

Crank Assembly Kit

2140-000-90

1

(includes Ref. Nos. P6, P7, P8, P9)

P6

5/16-18x1/2 Socket Set Screw

Incl. w/P5

1

P7

½-13 Hex Head Cap Screw Grade-5

Incl. w/P5

1

P8

½ Lock Washer

Incl. w/P5

1

P9

Bearing Shim

Incl. w/P5

2

P10

Diaphragm Retaining Plate

2133-000-00

1

P11

Carriage Bolt Kit

3350-011-90

1

P12

½-13 Hex Nut

1782-001-00

3

P12

3/8-16 Hex Nut

N/A

-

P13

Diaphragm (Santoprene)

2132-000-00

1

Please provide following information:

-Model Number

-Serial Number (if any)

Part description and number as shown in parts list

Plunger Assembly – Figure P

800-350-8739

12

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

For Repair Parts contact dealer where pump was purchased.

Repair Parts List - Well Assembly (Reference Figure W)

Ref.

3" Pumps

No.

Description

Part Number

Qty.

W1

Well

2120-001-00

1

W2

Suction Plate

2123-000-01

1

W3

½-13x1-1/2 Hex Head Cap Screw Grade-5

1766-013-00

2

W3

3/8-16x1-1/2 Hex Head Cap Screw Grade-5

N/A

-

W4

½ Lock Washer

1798-001-00

2

W4

3/8 Lock Washer

N/A

-

W5

Gasket

Incl. w/W6

1

W6

Cap

2124-000-00

1

(includes Ref. Nos. W5, W6)

W7

Discharge Plate

2131-000-01

1

W8

½-13x1-1/2 Hex Head Cap Screw Grade-5

1766-013-00

2

W8

3/8-16x1-1/2 Hex Head Cap Screw Grade-5

N/A

-

W9

½ Lock Washer

1798-001-00

2

W9

3/8 Lock Washer

N/A

-

W10

Check Valve (neoprene)

Incl. w/W15

2

W11

Check Valve Weight Top

Incl. w/W15

2

W12

Check Valve Weight Bottom

Incl. w/W15

2

W13

¼-20x1/2 Hex Head Cap Screw

Incl. w/W15

4

W14

1/8 diameter x 3/8 Pin

2121-000-00

2

W15

Flapper Valve Assembly Kit

3354-071-90

2

(includes Ref. Nos. W10, W11, W12, W13)

W16

Suction Strainer (not shown)

1680-000-00

1

Suction Strainer w/ Hose Shank Kit for British Threads

C311-999-90

1

W17

NPT x BSPT Pipe Nipple Kit

C370-999-90

1

Please provide following information:

-Model Number

-Serial Number (if any)

Part description and number as shown in parts list

Well Assembly – Figure W

800-350-8739

13

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

800-350-8739

14

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

PAGE INTENTIONALLY LEFT BLANK

800-350-8739

15

BRP750DP3 Rev A | 3/2020

Specifications Information and Repair Parts Manual BRP750DP3

This manual suits for next models

1

Table of contents

Other Brave Water Pump manuals

Popular Water Pump manuals by other brands

dooch

dooch XQ-Drive Series Installation instructions manual

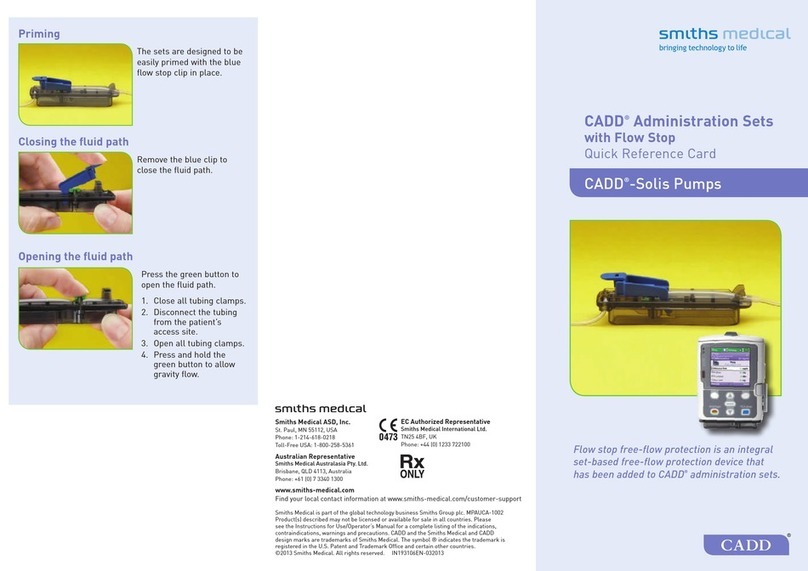

Smiths Medical

Smiths Medical CADD Administration Sets with Flow Stop Quick reference card

Garden

Garden GP00 Installation and user manual

Graco

Graco 06529 instructions

SKF

SKF LINCOLN 1886 Series Original instructions

Hilti

Hilti DD VP-U Safety sheet

EINHELL Bavaria

EINHELL Bavaria BPW 48 operating instructions

Xylem

Xylem LOWARA LR Series Installation, operation and maintenance instructions

Homa

Homa CH150WA Original instruction manual

Huge Pump

Huge Pump HP 05 user manual

BRINKMANN PUMPS

BRINKMANN PUMPS TH11 Series operating instructions

Jesco

Jesco MAGDOS 20-100 Operation & maintenance instructions