Bertolini VIKING Quick guide

MOTORIZED CONTROL UNITS FOR

SPRAYERS

OPERATING, SET-UP, SERVICE

AND SAFETY INSTRUCTIONS

Reggio Emilia - Italy

Eng

VIKING

2

You have decided to choose “BERTOLINI” and you purchased a product manufactured using the

latest technology and the finest materials for the best in quality, duration and functionality.

We are grateful for your confidence in us.

Read this booklet and always keep it at hand; you will find it useful in resolving any doubts you may

have on the features and functionality of the product.

Thank you for choosing “Bertolini”

This instruction manual provides all the specific information necessary for familiarisation and use of

the remote control in your possession.

ATTENTION!

READ CAREFULLY THE INSTRUCTIONS CONTAINED IN THIS BOOKLET BEFORE

INSTALLING THE CONTROL AND REFER TO THEM WHENEVER DOUBTS ARISE ON USE OR

DURING MAINTENANCE OPERATIONS.

IDROMECCANICA BERTOLINI S.p.A. DECLINES EVERY CIVIL OR CRIMINAL

LIABILITY FOR DAMAGES AND ACCIDENTS, TO OBJECTS OR PERSONS,

THAT MAY ARISE ROM FAILURE TO OBSERVE THE SAFETY INSTRUCTIONS

PROVIDED IN THIS BOOKLET AND/OR SAFETY REGULATIONS IN FORCE IN

THE COUNTRY WHERE THE PRODUCT IS USED.

SAFETY INSTRUCTIONS

–Do not operate in the area of action of the system without being protected by suitable

protective goggles and clothing;

–Do not carry out operations without disconnecting the P.T.O. (stop the pump);

–Install adequate protection guards for all moving parts such as the shaft, pulleys, couplings,

etc;

–Do not remove the guards for the moving parts;

–Do not modify the control installation conditions and in particular do not modify the mounting

and hydraulic connections;

–Do not operate any taps not connected to a usage which may prevent accidental leakage of

the liquid being pumped;

–Make sure that there is safety valve of adequate capacity in the delivery circuit, in addition to

the pressure regulation valve;

–Make sure that the hoses are properly fixed before use by checking all the connections;

–Carry out, before use, the checks as specified in paragraph 6.

–Protect the control against icing in the winter period.

–Never leave the control at rest with the pumped liquid inside. Persistence of liquid in contact

with the internal parts of the control, when not necessary, can cause the control to deteriorate

more quickly.

–Stop the pump and release the pressure from the pressure circuit before carrying out all

maintenance or checks;

–Always DISCONNECT supply cables during maintenance on the machine or during long

periods of non-use;

–Children and animals must be kept far away from the pump;

–Do not use liquids with a temperature greater than 62°C or 145°F, or less than 5°C or 41°F;

–Do not introduce:

•Aqueous solutions with density and viscosity greater than those of water;

•Inflammable liquids or liquefied gases;

•Chemical solutions for which there is not guaranteed certainty of their compatibility with the

materials of which the control is made;

•Water for food purposes;

•Any kind or type of paints and varnishes;

3

•Solvents and thinners for any kind or type of paints and varnishes;

•Fuels or lubricants of any kind or type;

•Liquids containing granules or solid parts in suspension.

- Before any maintenance:

•Always make sure that the system pump is not operating and that the motorization of the

drive is completely disconnected.

•Make sure that the entire hydraulic circuit is not in pressure; therefore, close the pump

suction, relieve the pressure of the hydraulic circuit.

•Make sure that electrical supply connection is disconnected and that the metallic body of

any drive mechanisms is isolated.

•Always remove the battery connection cables while it is being recharged.

•Do not carry out electric welding with the power wires connected; make sure that they are

both (+ and –) disconnected, in order to avoid uncontrollable voltage peaks.

- Before using the system:

oMake sure that the connection hoses of the circuit are properly fastened by checking the

connections.

oCarry out adjustment of the distributor before work, only with clean water, making sure that

the various joints and connections are not leaking.

oEvery time the tractor is started and stopped the general valve must be brought to the OFF

position (“by-pass”), in order to avoid inconvenient problems;

oIn order to avoid danger to persons or the environment, it must be washed with clean water

at the end of every treatment.

Protect the environment from the liquids contained in the system.

Clean up residues and dispose of them regularly; no residue must enter the

canalization network or the ground.

ALL RIGHTS RESERVED. THIS MANUAL IS INTENDED

EXCLUSIVELY FOR USE BY THE CUSTOMER. ALL OTHER

USES ARE FORBIDDEN.

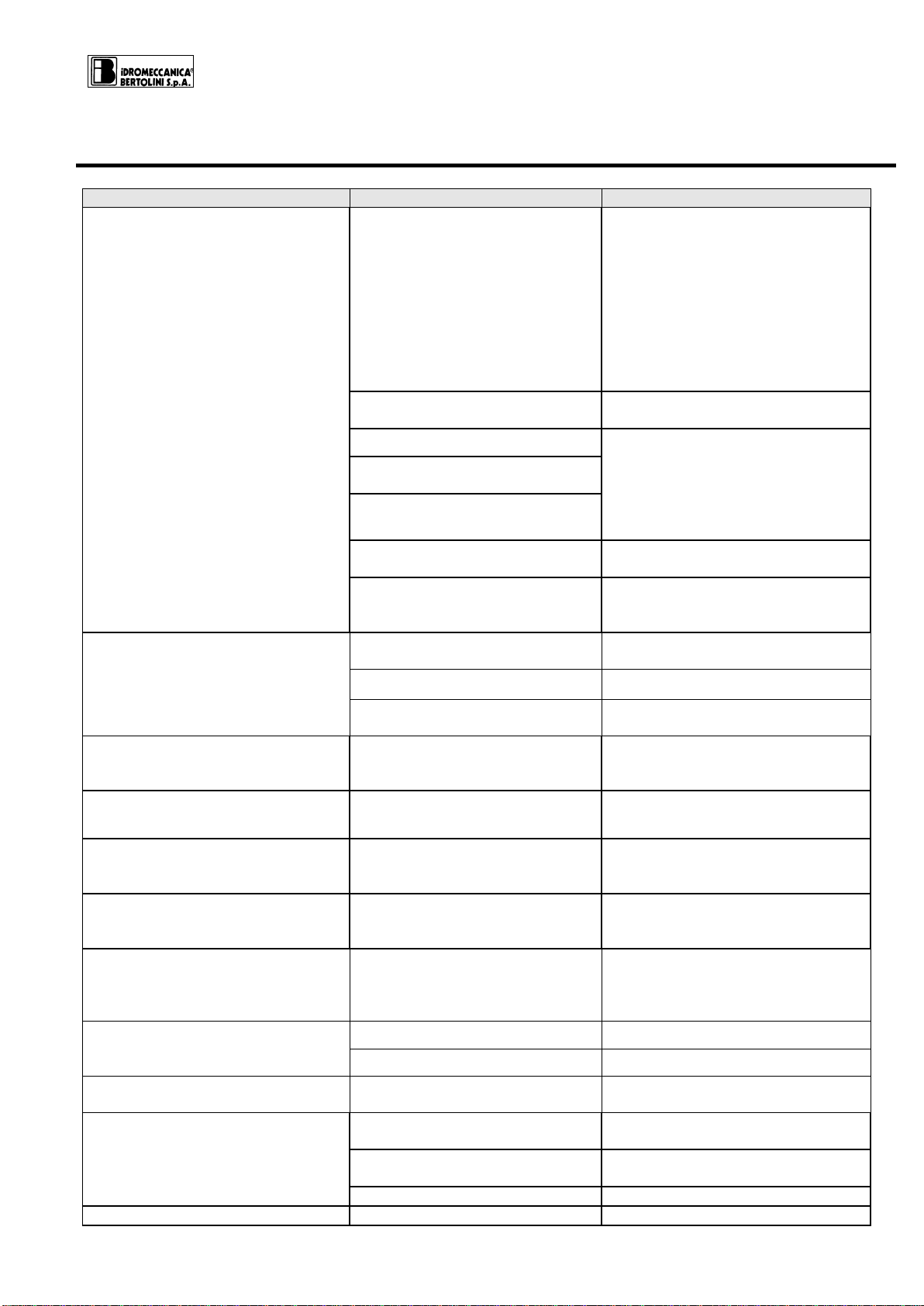

Index

1. General instructions and warnings.……………………………...………………………..….4

2. Product Description….……………………………………………………..………...………….6

3. Identification and description of components……...…………………………………...…..7

4. Installation………………………………………………………………………………………….9

5. Hydraulic connections…..……………….……………………………………………………....9

6. Control unit functioning and use…………..………….…..……….…………………………10

7. Control maintenance…………………………………………………………………………….12

8. Troubleshooting and cures………...….………………………………………......…………..13

9. Useful information…………..……….………………………………………………………......15

10. Components description-Wiring diagrams...………………………………………….…..16

4

1. General instructions and warnings

1.1 Assistance Service

It is possible to obtain assistance in all countries where the equipment is officially

distributed by Idromeccanica Bertolini (during and after the warranty period).

Any type of intervention required on the control unit must be carried out in accordance with

the information of this manual, or by following any agreements taken with Idromeccanica

Bertolini.

If this is not the case, the relevant warranty conditions may be annulled.

1.2 Warranty

Idromeccanica Bertolini S.p.A. undertakes, within a maximum of twelve (12) months

from the date of delivery of the product, to provide a replacement for any parts that have

manufacturing defects.

The warranty is valid only when the defect can be verified by the “Assistance Service”

and when it cannot be blamed on improper use or poor maintenance of the product.

Parts subject to normal wear and tear from use are excluded from the warranty

(parts made of rubber or plastic, gaskets), as well as labour costs and any other

request for damages or indemnity (for example, due to damages or interruption in

the use of the products).

“Idromeccanica Bertolini S.p.A.” IS NOT responsible in terms of warranty and

compensation, for damage caused in the case of:

•Transport damage (breakages, scratches, marks or similar)

•Use of the product different to those indicated in the manual

•Use that does not comply with the specific regulations in force

•Improper installation or defects originating from insufficiency or inadequacy of the

electrical system, or alterations deriving from environmental, climate or other types of

conditions.

•Use of unsuitable liquids

•Negligence, neglect, tampering, unskilled use or repairs carried out by unauthorised

personnel.

Poor maintenance

•Modifications or interventions not authorized expressly by “IDROMECCANICA

BERTOLINI S.p.A.”

•Use of spare parts and accessories that are not original and/or specific for the product

•Use of hoses and connections that are not prescribed by this manual or not suitable for

the product and its use.

Furthermore, the following are not covered by the warranty:

•Installation and adjustment

•System consultancy or makeshift inspections

•Various maintenance operations (such as cleaning of filters, nozzles etc.)

•Normal depreciation due to use

5

And in any case:

The restoration of the equipment will be carried out within time limits that are compatible

with the organizational requirements of the Assistance Centre.

•The products to be repaired must be washed in advance and cleaned of residues from

chemical products use

•Repairs carried out under warranty do not give rise to extensions or renewal of the

warranty

•NOBODY is authorized to modify the terms and conditions of warranty or to issue any

other verbal or written warranties

•The parts replaced under warranty remain the property of “IDROMECCANICA

BERTOLINI S.p.A”.

Where the product has been tampered with, “Idromeccanica Bertolini S.p.A.”, declines

all obligations under the warranty.

For all verifications, the products can be returned only on written authorisation from

Idromeccanica Bertolini S.p.A. and only freight prepaid.

6

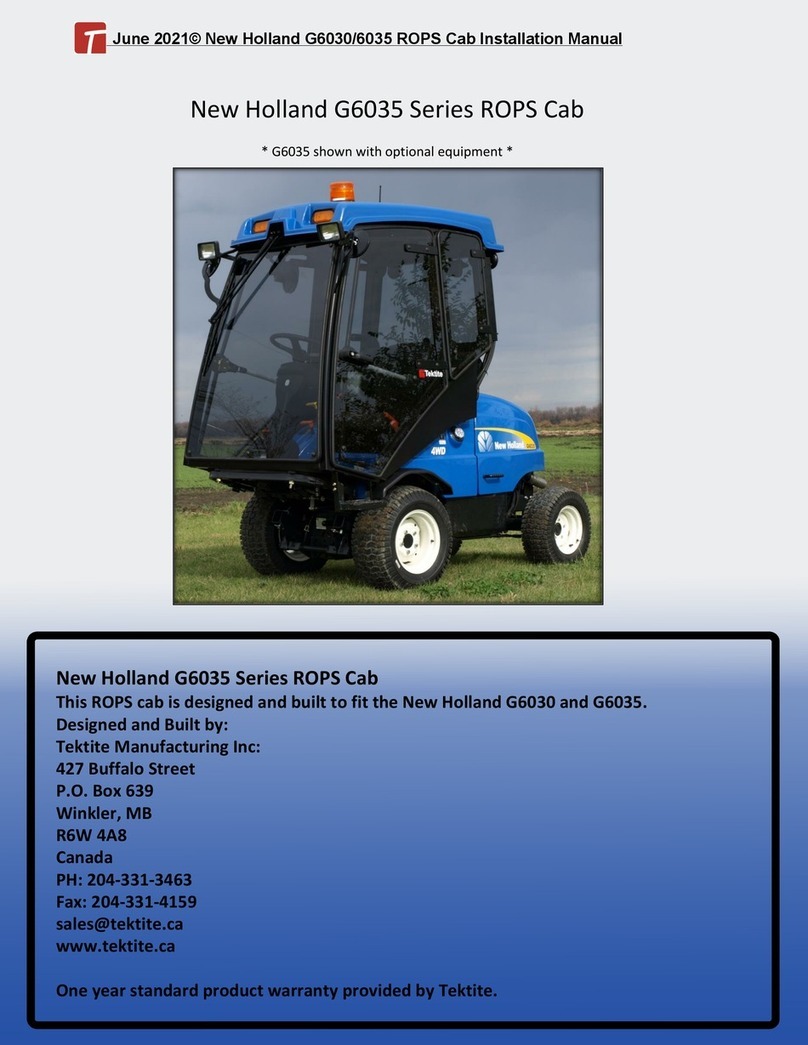

2. Product description

The spraying control units of Idromeccanica Bertolini are only applicable to the systems

driven by diaphragm or piston volumetric hydraulic pumps. They are suitable for sprayers

in agricultural field, atomizers, private and public hydraulic systems, fountains, etc.

The spraying control units are composed of motorized or/and manual electrical section

valves conceived and studied to overcome the traditional product problems ensuring

always high performances.

-The basic characteristics of those valves are:

-Non-deformable at high and low temperatures;

-Complete watertight seals;

-Free assembly position;

-Thermal protection against accidental circumstances;

-overtime duration;

-controllable with a simple bipolar switch;

-Single or parallel functioning;

-System versatility;

-No current absorption when adjusted.

The materials used are: high resistance plastic materials (polypropylene +Fiberglass),

stainless steel, and Viton gaskets and this makes them compatible with very aggressive

chemical solutions.

A motorized electric unit, modularly built in different configurations, each of them with

specific characteristics, according to the client’s need, is composed of section valves (until

7 max. sections), volumetric valve, adjustable pressure relief valve and main on-off valve.

The max working pressures, according to the technical characteristics of the components,

are: 20 bar or 40 bar.

The motorized valves are controlled by sprayer controls or by computer B.Matic 500 (all of

them supplied separately) and each of them is for DIN 43650-A/ISO4400 connections.

The voltage must be always:

12 VDC 2

0.5 A valve VV

12 VDC 2

1.5 A valves: VG, RS, RD

This is the normal voltage for a battery in the most common agricultural equipment.

Out of this field, you may incur functioning problems or damages to the internal electronic

circuit.

7

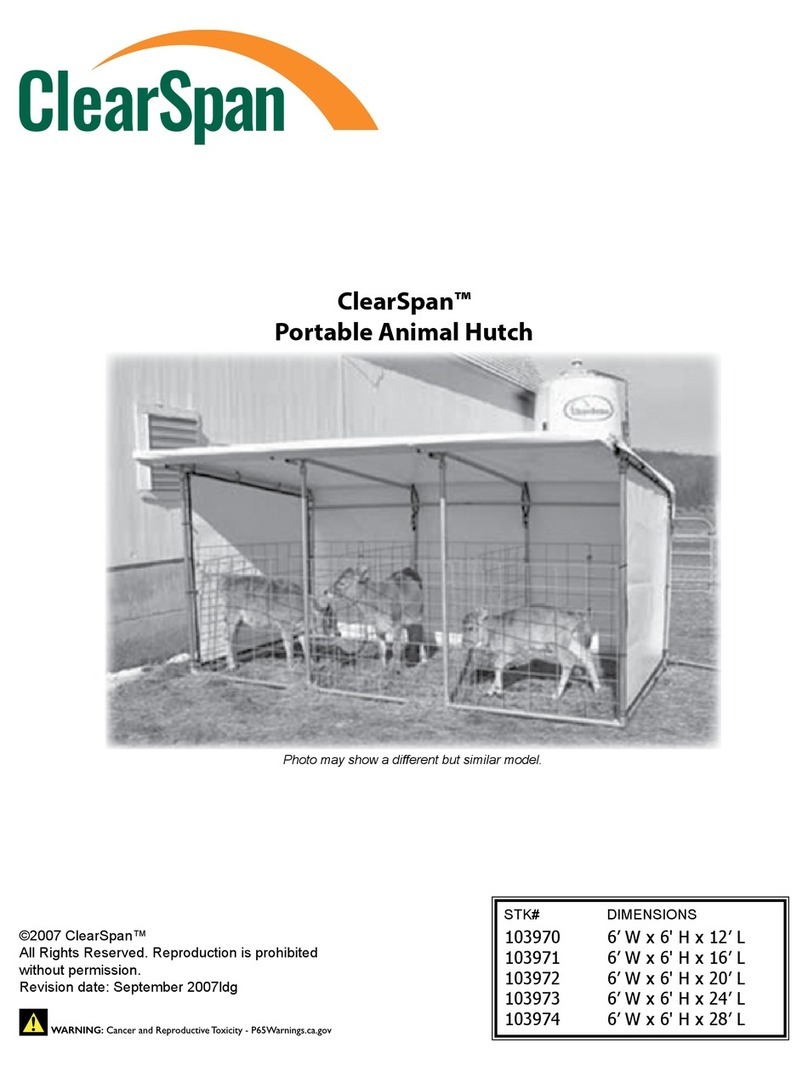

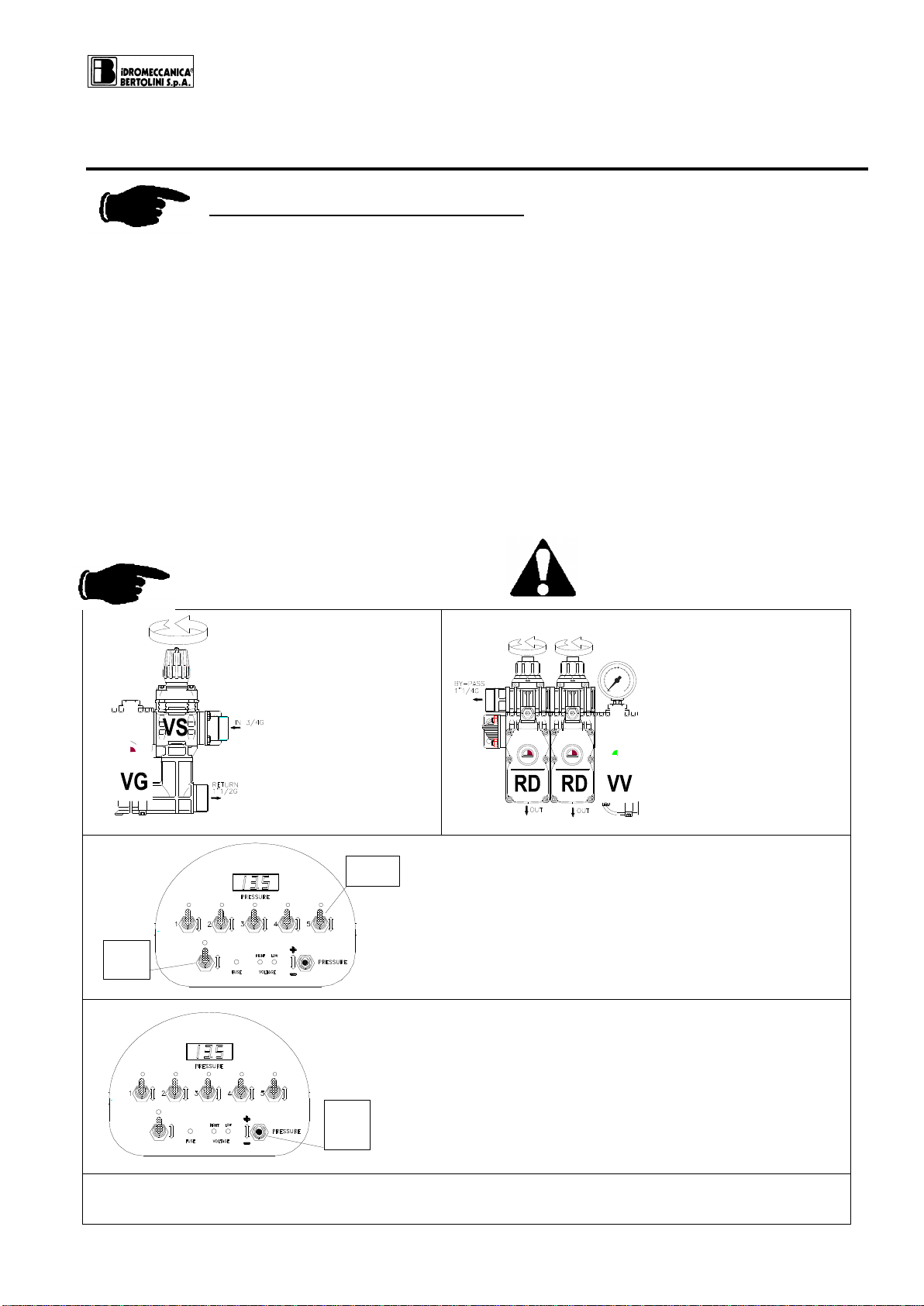

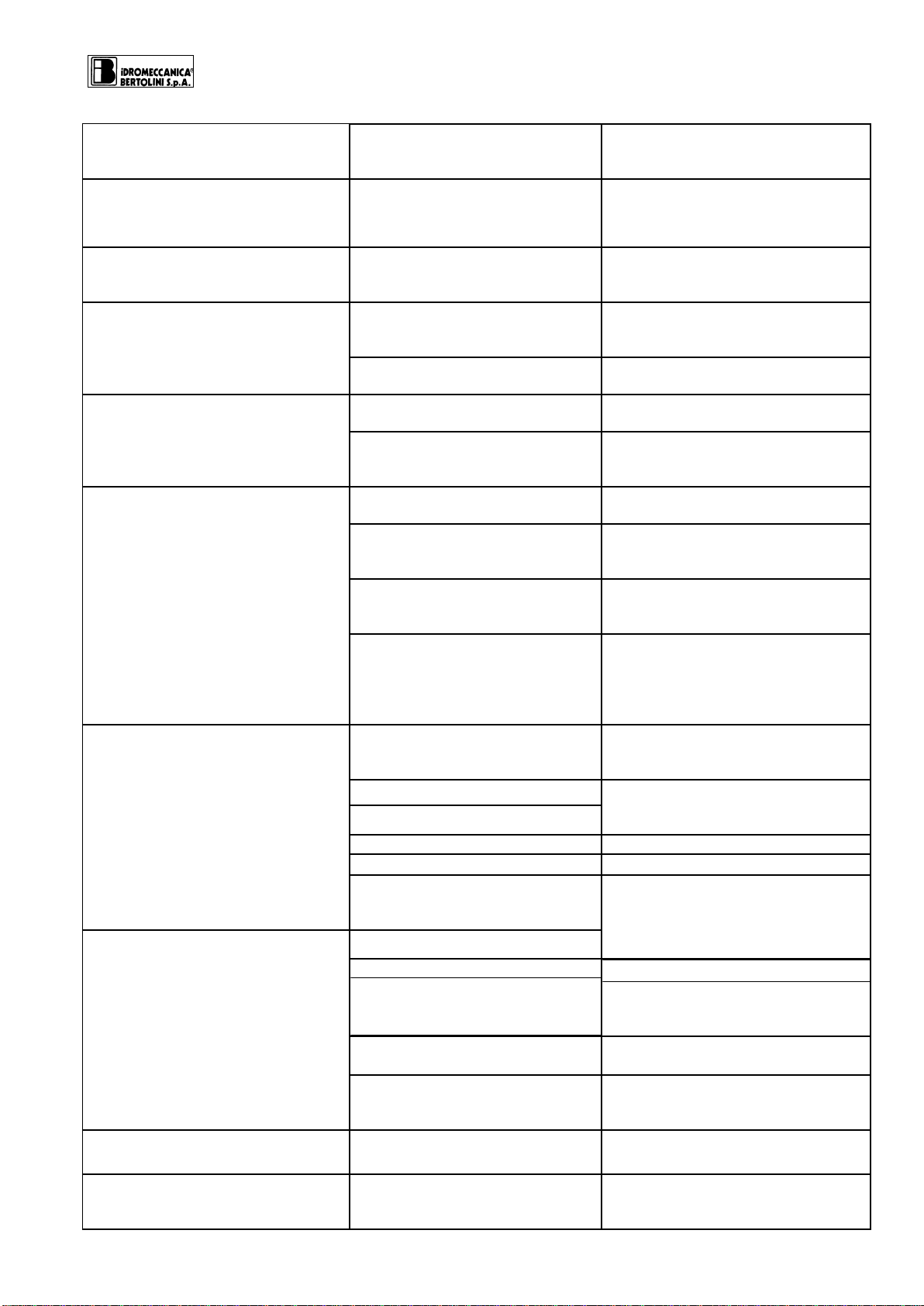

INSTALLATION DIAGRAM

vsvgvv

(RD)

RSRS

(RD)

Pompa

Cisterna

Uscite Barre

IN

OUT1

OUT2

VALVOLA DI

SICUREZZA

WARNING! For a correct

functioning, do not connect the

return hoses to the bottom of the

tank with the aim to use them as

hydraulic agitators, but connect

them exclusively to the top part

of the tank.

Use only components (hoses,

clamp, fittings, etc.), which

minimum characteristics are

equal to the max pressure of the

pump or the control; make sure

not to create throttling during the

course.

Components Index:

•VS: manual adjustable pressure relief valve;

•VG: main ON-OFF valve;

•VV: volumetric adjustable pressure valve

•RS: section valve RS

•RD: section valve RD

•A1: water inlet (connect the hose coming from the pump)

•A2: By-pass, section valve, general valve and volumetric valve discharges.

(connect the return hose to the tank)

•A3 (bypass): RD section valves discharge (connect the return hose to the tank)

•A4:Delivery system (connect to the boom)

•B: DIN plug 43650-A (2 poles + ground)

3. Identification and description of the components

8

•C: Position indicator, indicates, according to its colour, the ball position. The colours are

RED and GREEN.

•D: adjusting pressure relief valve knob. Unscrewing manually this part the maximum

pressure is increasing.

•E: compensating discharge adjustment knob. Unscrewing manually this component the

water coming back to the tank decreases, therefore pressure increases.

•M: Pressure gauge

All the control units made by IDROMECCANICA BERTOLINI S.p.A. are always fitted

with the VS adjustable pressure relief valve.

The adjustment of this valve is made by the operator, who must adjust the pressure

to a value that is higher than the maximum working pressure, but lower than the

maximum security pressure attainable by the hydraulic system.

ANYWAY THE MACHINE MUST BE PROVIDED WITH A SEPARATE SAFETY

VALVE, SET AT THE WORKING PRESSURE THAT IS NOT HIGHER THAT

10% OF THE MAX.PRESSURE OF THE HYDRAULIC SYSTEM.

Description of the functions

1. VS Pressure relief valve: It is adjusted manually by its knob (screwing it, pressure

increases, unscrewing it, pressure decreases).

It discharges into the tank the excess liquid when the adjustment pressure is obtained.

2. VG: Main ON-OFF ball valve: it opens or closes the discharge to the tank. The valve

position is showed by the indicator:

•“GREEN” position: discharge to the tank.

•“RED” position: working condition.

It is, for its function, always fitted after the VS valve, in order to use only one

discharge hose.

3. VV: volumetric adjustable pressure valve: It adjusts manually the spraying pressure,

if connected to a sprayer control or automatically if connected to a computer B Matic

500. In this case it provides to increase or to decrease pressure at variable driving

speed of the tractor, keeping the same amount of liquid per surface unit (ex.

Litre/hectare).

The liquid in excess is deviated to discharge.

The valve position is showed by the indicator:

•“GREEN” position: discharge to the tank

•“RED” position: working condition

The rotation of pin is not instantaneous but gradual; it can be 9 seconds (suggested for use

with computer) or 21 seconds (suggested for use with sprayer control).

4. RS section valve: it opens or closes the corresponding boom section; it discharges the

liquid in the tank by the VS valve or VG valve, if present.

The valve position is showed by the indicator:

•GREEN” position : closed boom (discharge in the tank)

•“RED” position: working condition (liquid to the boom)

5. RD section valve: The RD valve is a “deviating valve” that adjusts in by-pass the liquid

amount that you have established with reference to counter clockwise knob adjustment.

This implies a pressure variation if all of the section valves are not adjusted at the same

value (ATTENTION THE ADJUSTMENT IS VERY IMPORTANT).

If you want to increase the pressure to the boom the knob will be turned counter clock-

9

wise. If you want to decrease pressure you must turn it clockwise.

The section valve must be adjusted all the times that a different nozzle is used, so

the constant liquid distribution is ensured.

6. M Pressure gauge: it shows the working pressure when the VG main valve is closed

(red position showed by the indicator).

4. Installation

The control unit model must be chosen by the manufacturer, according to the

chemical product nature and the system features. Failure to follow this warning

can result in injury and/or property damage.

The sprayer manufacturer should take care of the proper selection and correct size of the

hoses and connections that must correspond to the dimensions of the recommended

fittings.

Be sure that the control unit is attached to a strong base plate and anchor it with bolts

sufficiently strong to hold it in place. We recommend to protect your control unit from the

bad weather and from the spraying effects during the treatment.

The hoses dimension should not be smaller than the control units’ pipe fittings diameter.

5. Hydraulic connections

•Connect the delivery hose from the pump to the INLET fitting (IN) ;

•Connect the return hoses to the tank for the unused liquid to the by-pass fittings (by-

pass);

•Connect the hoses to the boom to the delivery pipe fittings : they must be equivalent

(same number) to the boom sections or hydro-agitators , if any;

Failure to follow this warning can result in personal injury or environmental

damage and/or malfunctions of the control unit and consequently will void the

product warranty.

10

6. Control unit functioning and use

General checks before the use

•At every use, clean the filter on the control (if present) and every other filter present on

the system; this simple operation will help you to keep the system efficient and to carry

out the treatments in the best way possible.

•Close all pressure hoses connected to the nozzles or boom; an open nozzle can

cause serious damage to persons, animals or things in the vicinity.

•Check the state of the hoses each time the system is used; also make sure that all

connections are tight and secure.

•Check the state of connection cables and electrical connections each time the system

is used; also make sure that the batteries are charged optimally (for motorized versions

only).

•Inspect the control and its components periodically. Routine maintenance of the

system protects your investment.

•Make sure that when the pump is being started up, the general valve is kept in by-pass

position as indicated on the label.

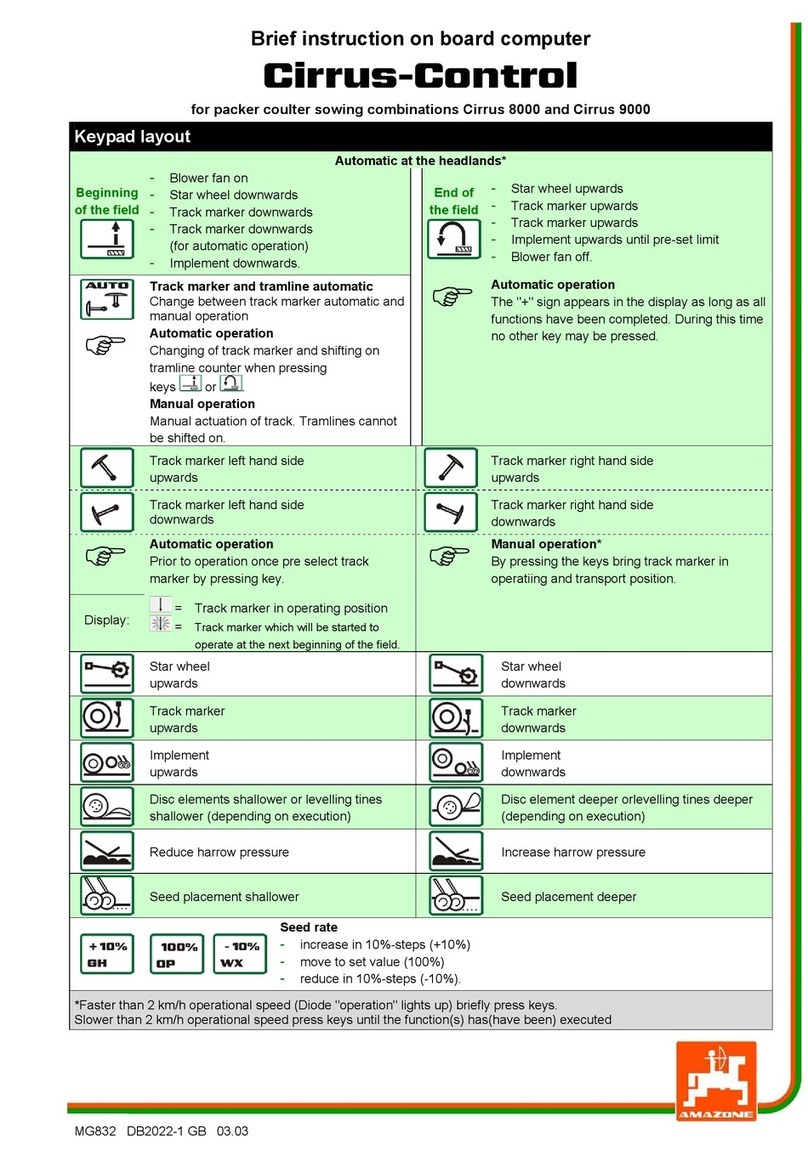

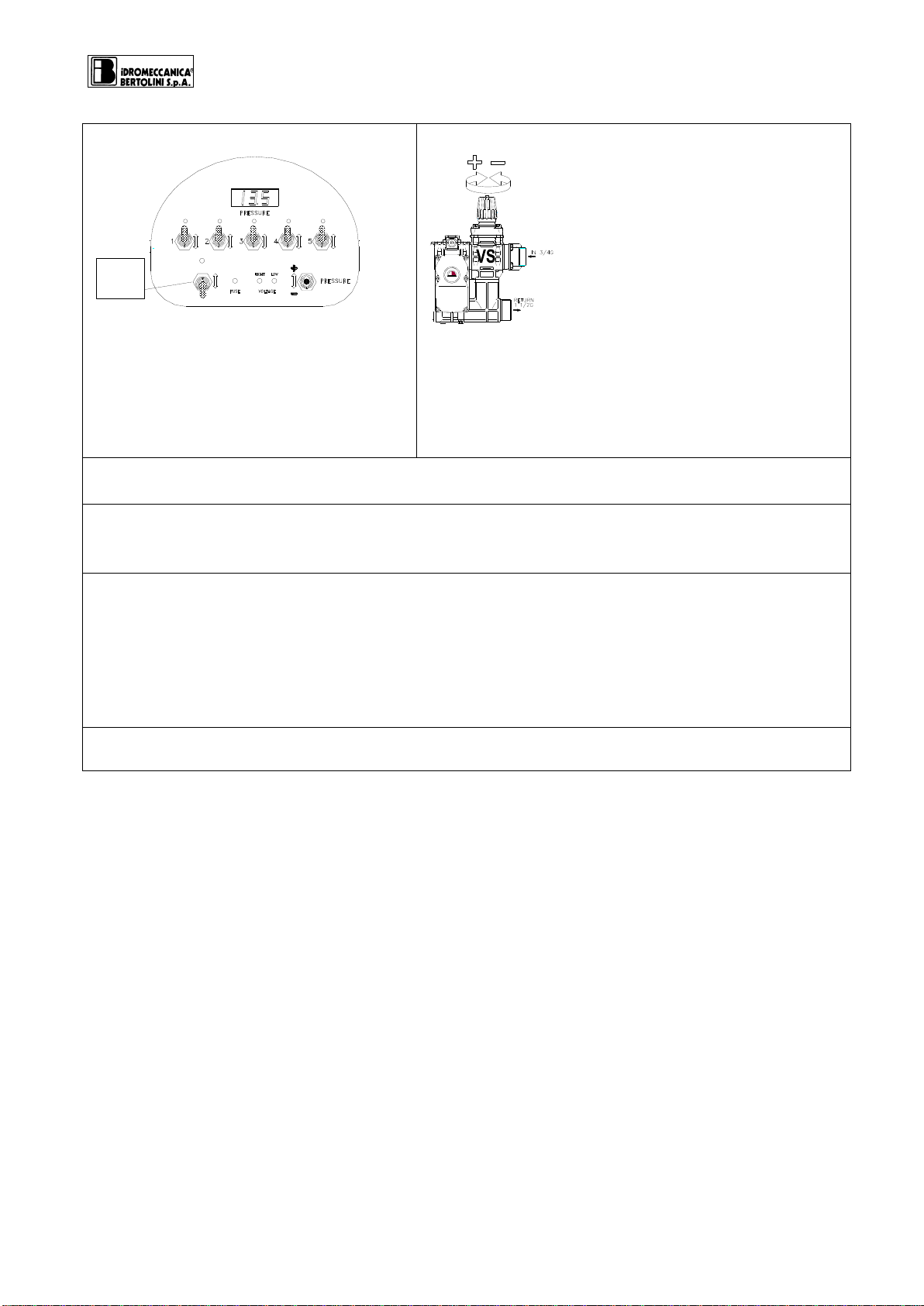

ADJUSTMENT (see Pict.1 page 9)

1

Unscrew

completely the

VS valve

adjustment knob

(minimum

pressure)

2

Unscrew

completely the RD

valve adjustment

knob (if it is

installed)

OFF

ON

COMANDO

VALVOLA

GENERALE

VG

INTERRUTTORI

COMANDO

BARRE

OFF

ON

OFF

ON ON

OFF

ON

OFF OFF

ON

3

Close all the RS or RD section valves operating

the control panel switches (“OFF” position: led

turned off)

Close the VG main on/off valve operating the

control panel switches

( “OFF” position: led turned off)

ON

OFF

ON

OFF

ON

OFF OFF

ON ON

OFF

ON

OFF

COMANDO

VALVOLA

REGOLAZ

PRESSIONE

VV

4

Operate the volumetric valve at the max.

pressure, by turning the switch upwards.

5

Start the pump and operate it to the correct R.P.M.

11

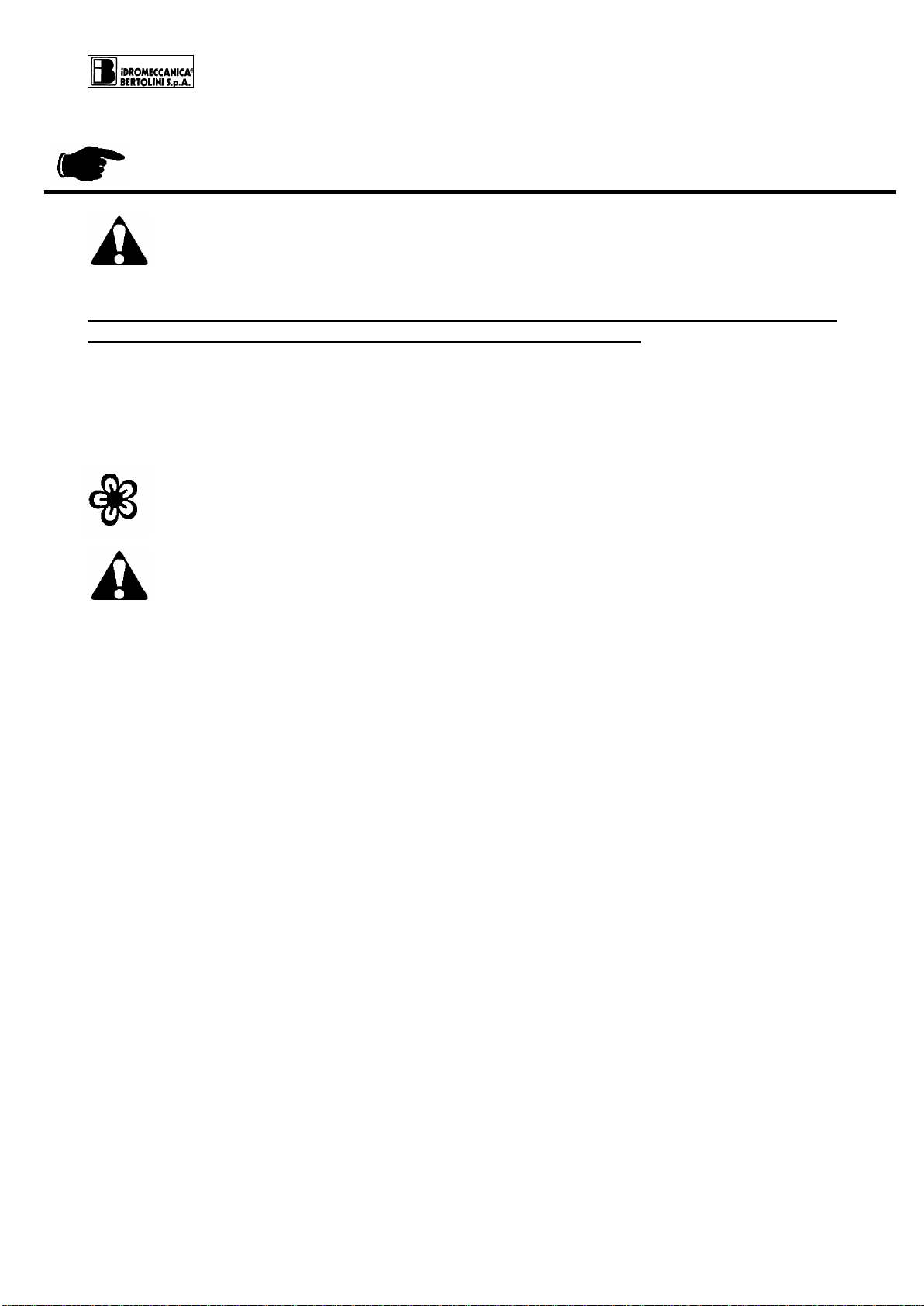

6

ON

COMANDO

VALVOLA

GENERALE

VG

OFF

ON ON

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

Open the VG main valve operating the

control panel switch ( “ON” position:

led on)

7

Adjust the pressure relief valve VS, turning the

knob in a clockwise direction, until pressure

reaches the established value, make sure not to

exceed the max pressure allowed. In any condition

this safety value will never be overcome, unless

the discharge hose is obstructed.

8

Open the booms operating the corresponding switches (“ON” position led on).

9

Operate the machine at the established working pressure, by turning the volumetric

valve switch.

(10) RD valves adjustment (IF THEY ARE FITTED)

The RD valve adjustment must be carried out operating one boom each time.

a) Close just one boom operating the corresponding switch. You will see in the

pressure gauge a pressure change compared to the previous value.

b) Adjust the pressure to the requested value moving the RD adjustable knob.

c) Open and close the boom checking that pressure is constant.

d) Repeat the operations of the previous steps for all the other booms.

The operations from step 6 to step 9 (10) must be repeated if the nozzles dimensions

are changed

12

7. Control valve maintenance

ATTENTION!

Before starting any maintenance operation or inspection of the control unit,

wash it first with pure water, then completely empty out all liquid contained.

Pay particular attention to the parking of the machine on which the control unit is

mounted, in order to avoid danger to you or those around you.

Never carry out maintenance with children nearby!

Protect hands, eyes and body with suitable clothing; the control unit could have

been used with chemicals that damage your health.

The control unit is made from inedible parts. Do not bite, suck, chew or ingest any

part of the control unit for any reason.

Protect the environment from the liquids contained in the control unit.

Clean up residues and dispose of them regularly; no residue must enter the

canalization network or the ground.

Attention! Bertolini electrical valves are designed in order not to be opened;

therefore, when necessary, always replace the complete valve. Opening or

tampering with valves by non-authorized personnel invalidates all terms of

warranty.

USING “ORIGINAL BERTOLINI SPARE PARTS”INCREASES THE LIFETIME OF

YOUR CONTROL UNIT, BY ALLOWING IT TO OPERATE IN THE BEST POSSIBLE

CONDITIONS.

In the case where the control unit has to be dismantled, it is advised to change the sealing

O-rings, since they could get damaged during this phase, causing leakage of liquid in the

various valves.

Routine maintenance of the distributor protects your investment.

During the functioning it is possible that with closed valves (red colour indicator) the liquid

is coming out from the boom, in this case it is possible that the ball and/or its gaskets are

worn.

•Ball and/or gaskets replacement:

Remove the flange of the ball, take out the ball and the gaskets and check wear.

Replace the necessary parts and reassemble.

The corresponding kit that must be ordered to IDROMECCANICA BERTOLINI, are the

following:

•Part N° 24.5334.97.3 →VG (40 bar), VV 39 (9-21 sec.) valves;

•Part.N° 24.5335.97.3 →VG (20 bar) valve;

•Part.N° 24.5336.97.3 →RS (40 bar), VV 27 (9-21 sec.) valves;

•Part.N° 24.5337.97.3 →RD (20 bar), RS (20 bar) valves;

•Part.N° 24.5338.97.3 →RD (40 bar) valve

•Wash carefully with water the internal parts of the distributor after each treatment.

•Disconnect voltage during any maintenance.

13

8. Troubleshooting and cures

Before contacting the “Bertolini Assistance Service”, check the following chart:

TROUBLES

CAUSES

CURES

The regulator does not reach the

desired pressure

Not enough liquid arrives at the

control unit

•Check that the pump rotation

speed is correct

•Check that the pump flow rate is

correct

•Check that there are no

deviations open before the

distributor

•Check that the nozzles are in

good condition and of the correct

dimension

The discharge of the self-cleaning

filter (if installed) is fully open

Close the discharge of the self-

cleaning filter

The safety valve is fully unscrewed

•Consult the use and

maintenance booklet

•Check the orientation of the

valves balls

•Consult the use and

maintenance booklet

The volumetric valve (if installed)

and/or the main on/off are fully open

The compensating discharges are

not properly calibrated

The safety valve seat and/or the

ceramic poppet are worn

Change the valve seat and/or the

ceramic poppet

The ball and/or valve seals of the

volumetric valve and /or of the main

on/off valve are worn

Change the worn ball and seals

Liquid comes out from the boom

and the led of the motor geared is

red

The ball and the section valve

seals are worn

Replace the ball and the seals

Wrong orientation of the ball

Check the ball position

The ball doesn’t rotate completely

to 90°

Replace the section valve

Liquid is escaping from the

control pin of the ball

of the valve

The O- Rings of the control pin

are worn

Replace O-Rings

Liquid is escaping from the knob of

the safety valve

Diaphragm and/or O-Rings of the

piston are worn

Replace the diaphragm and the O-

Ring of the piston

Liquid is leaking from the RD

discharge knobs or between valve

bodies and the discharge

O-Rings on the knobs are worn

Replace

Liquid is escaping between the

bodies of the section valves or

between the RD discharge hoses

O-Rings are worn

Replace

Liquid is escaping between the

valve body and the manifold or

between the valve and the ball

flange

O-rings are worn

Replace

The geared motors work but no

water comes out from the nozzles

Clogged nozzles

Clean the nozzles

Wrong position of the ball

Check the position of the ball

The control unit remains still in

pressure

The main VG valve doesn’t work

Check that the connections respect

the electrical diagram

The pump pressure hose is bursting

Hose with unsuitable dimensions or

characteristics

Use hoses with suitable dimensions or

characteristics

Pressure hose connected instead of

the discharge hose

Check the hose connections using the

correct diagram

Discharge hose obstructed

Check the condition of the hose

With the section valves open and

Nozzles clogged

Clean the nozzles

14

the main on/off valve in the ON

position, no water comes out of the

nozzles

The ball of the main on/off valve

is positioned incorrectly

Check the position of the ball

It is not possible to get an accurate

pressure adjustment

Not enough liquid arriving at the

control unit

Check that the pump RPM are correct

Check that there are no deviations

open before the control unit

When closing one or more sections

the pressure is subject to wide

variations

The RD outlets are badly calibrated

Consult the use and maintenance

booklet

The delivery hose, the pressure

gauge and/or the pressure value

read by the sensor pulsate

The inflation pressure of the

accumulator on the pump is not

correct

Adjust the pressure to a value suitable

to the working pressure (see the

instruction booklet of the pump)

Hydraulic agitator connected to the

main discharge

Connect the agitator to a free section

valve

Difference between the pressure

read on the gauge and that read by

the pressure sensor

Pressure gauge or sensor damaged

Check and change the damaged

device

The two instruments are situated in

areas with different working

pressures

Check the system and , if necessary,

move one of the two devices

None of the geared motors are

working.

Inversion of the power supply

polarity of the panel

Check the connections of the control

panel power supply

Control panel and/or wiring not

working

Check if all the connections of the

cables are correct

Change the control panel or the wiring

Inadequate supply voltage

Check the charge level of the battery

and/or that the alternator is functioning

properly.

No 12VDC power supply.

Check the state of the wiring and if

necessary restore any interrupted

connections.

Check the protection fuse that may be

present in the power supply circuit.

One or more valves do not work or

work intermittently.

Not enough power to drive all the

geared motors.

Check the charge level of the battery

and/or that the alternator is functioning

properly.

Connectors not connected.

Check the wiring.

Restore any disconnected

connections.

Connectors connected badly

Electric motor damaged

Change the geared motor

Damaged/defective electronic circuit

Change the circuit.

Wrong electrical connections

Check that the connections reflect the

electrical diagram

The geared motor performs a

movement and then stops working

(the polyfuse intervenes).

Wrong electrical connections

Damaged/defective electronic circuit

Excessive load on the ball

Change the circuit.

Reduce the load from the flange to the

ball, slightly loosening the screws of

the flange

Presence of deposits on the ball or

the rod.

Remove the deposits or change the

components

Moving mechanical parts worn /

damaged

Change the geared motor or the

components that are creating the

problem

The motor is working but the

control pin is not moving

Problem on the mechanical part of

the geared motor

Replace the geared motor

When operating the volumetric valve

pressure increases instead of

decreasing and vice versa

Wrong electrical connections

Check that the connections follow the

electrical diagram

15

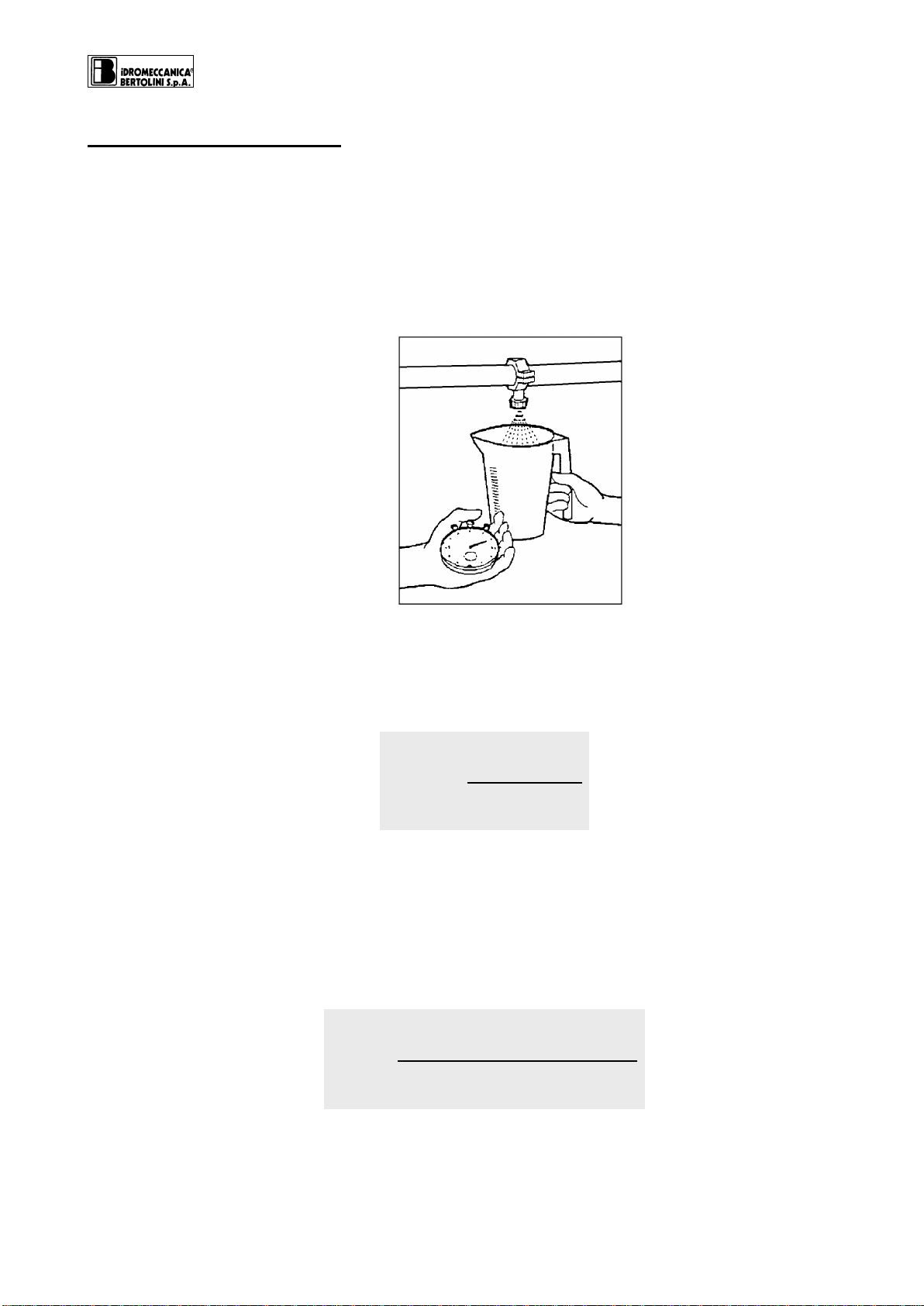

As a result of the normal wear of the nozzles it may become necessary to check their flow

rate and therefore their efficiency periodically. To do this, proceed as follows:

a. Take the system to working conditions.

b. Measure the flow rate (Q –litres supplied in one minute) of a nozzle using a graduated

container (Pict.17). Compare the values measured with the corresponding

measurements given in the charts provided by the manufacturer of the nozzles used.

If you wish to check the litres supplied per hectare (l/ha), insert the data in the following

formula:

Where:

Lh = applied volume (l/ha)

Q= nozzle capacity (l/min)

I= interspace between the nozzles (m)

V= advancing velocity (km/h)

If instead you need to know the required flow rate, insert the data in the following formula:

9. Useful information

Fig. 17

VI Q

Lh **600

=

600 ** VLbarraLh

Q=

16

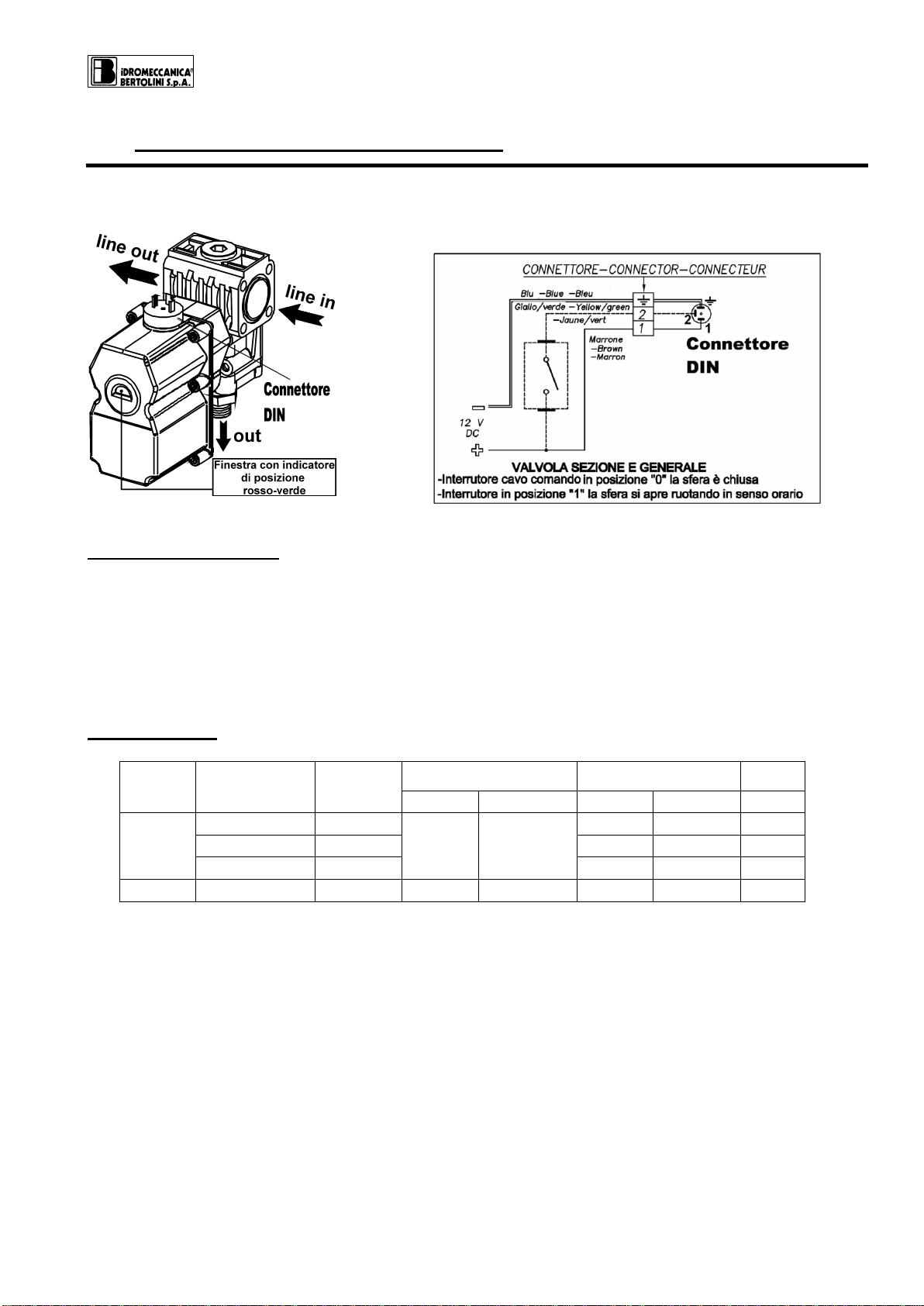

10. Components description Wiring diagrams

VS Adjustable pressure relief valve (20 –25 –40 Bar)

It is a manual pressure relief valve.

It is available in 2 versions:

•up to 20 bar;

•up to 40 bar

Technical data:

Model

Part. Number

Max. pressure

Flow

OUT

Bar

PSI

Lit/min.

USGPM

Gas

VS 20

24.5024.97.3

20

300

300

80

1”1/4

VS 25

24.5172.97.3

25

362

220

58

1”1/4

VS 40

24.5025.97.3

40

600

220

58

1”1/4

Constructive features:

1. Valve seat made up of AISI 303

stainless steel;

2. Ceramic poppet;

3. Body made of polyamide

strengthened with fibreglass;

4. NBR diaphragm.

Fig. 2

17

VG Main ON-OFF ball valve (20 –40 Bar)

The main on/off valve is a motor powered valve with 2 positions (ON-OFF) and by-pass

function.

Constructive features:

1. Polypropylene ball (20 bar) or stainless steel AISI 316 ball (40 bar);

2. PTFE seals;

3. Body made of polyamide strengthened with fibreglass;

4. DIN 43650-A / ISO 4400 connection;

5. IP 65 protection;

6. Viton gaskets.

Technical data:

Model

Part number

Ball

Max. pressure

Flow

OUT

Bar

PSI

Lit/min.

US GPM

Gas

VG 20

24.5125.97.3

39 P

20

300

450

120

1”1/4

VG 40

24.5137.97.3

39 I

40

600

120

32

1”1/4

P= Polypropylene I= Stainless steel

Electrical Diagram

Fig. 3

Fig. 4

18

RS Section boom valve (20-40 Bar)

The section boom valve is a motor powered valve with 2 positions (ON-OFF).

Constructive features:

1. Polypropylene ball (20 bar) or AISI 316 stainless steel ball (40 bar);

2. PTFE seals;

3. body made of polyamide strengthened with fibreglass;

4. DIN 43650-A / ISO 4400 connection;

5. IP 65 protection;

6. Viton gaskets.

Technical data:

Model

Part number

Ball

Max. pressure

Flow

OUT

Bar

PSI

Lit/min.

US GPM

Gas

RS 20

24.5133.97.3

39 P

20

300

450

120

1”1/4

24.5206.97.3

27.5 P

200

52

1”1/4

24.5207.97.3

27.5 P

120

32

B

RS 40

24.5144.97.3

27.5 i

40

600

120

32

1/2

P= Polypropylene I= Stainless steel B= Hose tail with bayonet

Electrical Diagram

Fig. 7

Fig. 8

19

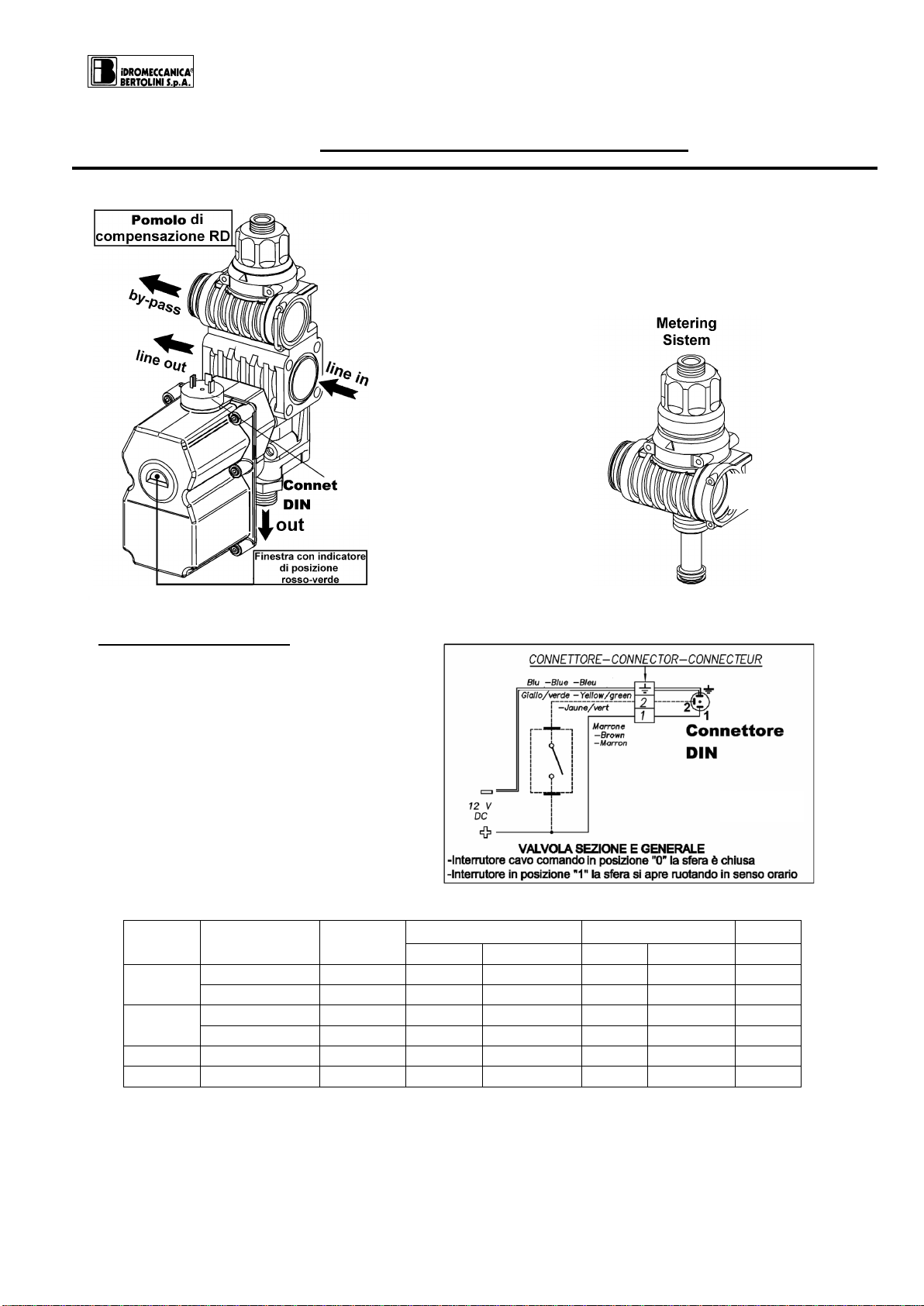

RD Section boom valve (20-40 Bar)

It is a motor powered valve with 2 positions (ON-OFF).

Technical data:

Model

Part Number

Ball

Max. pressure

Flow

OUT

Bar

PSI

Lit/min.

US GPM

Gas

RD 20 i

24.5128.97.3

27.5 P

20

300

120

32

B

24.5129.97.3

27.5 P

20

300

200

52

1” 1/4

RD 20 t

24.5130.97.3

27.5 P

20

300

120

32

B

24.5131.97.3

27.5 P

20

300

200

52

1” 1/4

RD 40 i

24.5140.97.3

27.5 I

40

600

120

32

1/2

RD 40 t

24.5142.97.3

27.5 I

40

600

120

32

1/2

i= intermediate t= terminal P= Polypropylene I= Stainless steel B= Hose tail with bayonet

Fig. 9

Fig. 10

Electrical Diagram

Constructive features:

1. Polypropylene ball (20 bar) or

AISI 316 stainless steel ball (40

bar);

2. Body made of polyamide

strengthened with fibreglass;

3. PTFE seals;

4. DIN43650-A / ISO4400

connections;

5. IP 65 protection;

6. Viton gaskets.

Component that originates the

RD configuration

RD knob

Fig. 11

20

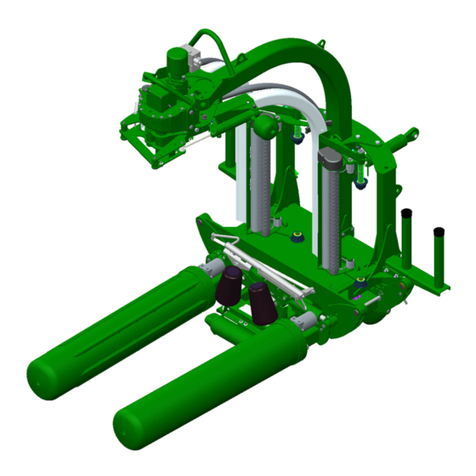

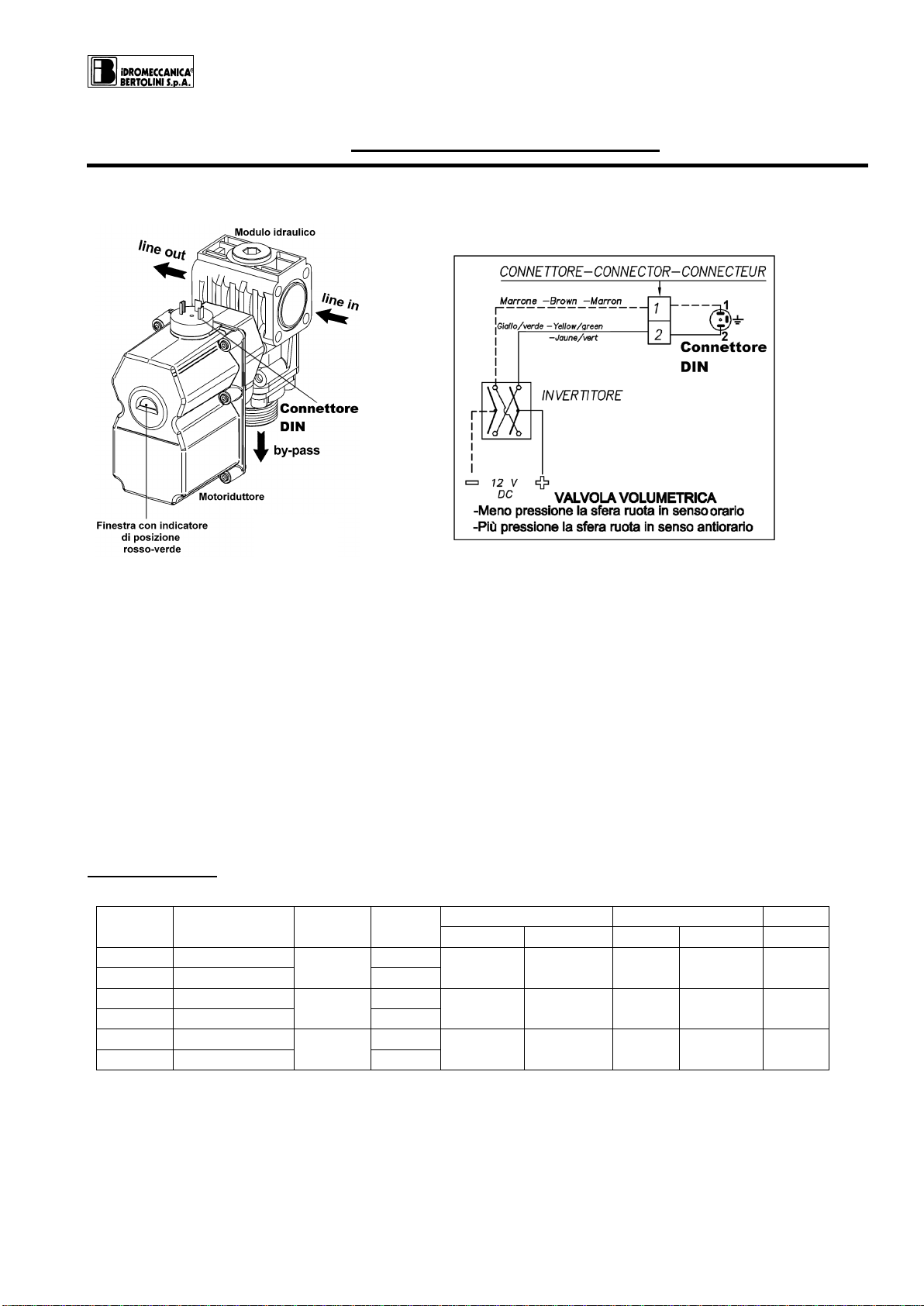

VV Volumetric pressure valve

The Volumetric valve is a proportional motor powered valve.

PICT. 5 a) Hydraulic unit; b) geared motor unit; c) Window with red- green position display

PICT. 6 a) VOLUMETRIC VALVE. Downward pressure the ball turns clockwise; Upward pressure

the ball turns counter clock-wise

Constructive features:

1. Ball or throttling system made up of AISI 316 stainless steel;

2. Body made of polyamide strengthened with fiberglass;

3. PTFE seals;

4. DIN 43650-A / ISO 4400 connections;

5. IP 65 protection;

6. Viton gaskets.

Technical data:

Valve

model

Part Number

Ball

mm.

Time

Sec.

Max. pressure

Flow

OUT

Bar

PSI

Lt./min.

US GPM

Gas

VV

24.5180.97.3

27.5 I

9

0 ÷ 20

0 ÷ 300

150

40

1” 1/4

VV

24.5181.97.3

21

VV

24.5126.97.3

39 I

9

0 ÷ 20

0 ÷ 300

200

52

1” 1/4

VV

24.5226.97.3

21

VV

24.5138.97.3

Farfalla

I

9

0 ÷ 40

0 ÷ 600

100

26

1” 1/4

VV

24.5238.97.3

21

I= Stainless steel

Fig. 5

Fig. 6

Electrical diagram

Table of contents

Other Bertolini Farm Equipment manuals