BEST ACCESS SYSTEMS AD432 User manual

SERVICE MANUAL

SERVICE MANUAL

CREDITS/COPYRIGHT

©2001 Best Lock Corporation dba Best Access Systems. All rights reserved. Printed in

the United States of America.

Information in this document is subject to change without notice and does not

represent a commitment on the part of Best Access Systems. The software described in

this document are furnished under a license agreement or nondisclosure agreement.

This publication is intended to be an accurate description and set of instructions

pertaining to its subject matter. However, as with any publication of this complexity,

errors or omissions are possible. Please call your BEST distributor or Best Access

Systems at (317) 849-2250 if you see any errors or have any questions. No part of this

manual and/or databases may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying, recording, or information

storage and retrieval systems, for any purpose, without the express written permission

of Best Access Systems.

This document is distributed as is, without warranty of any kind, either express or

implied, respecting the contents of this book, including but not limited to implied

warranties for the publication’s quality, performance, merchantability, or fitness for any

particular purpose. Neither Best Access Systems, nor its dealers or distributors shall be

liable to the user or any other person or entity with respect to any liability, loss, or

damage caused or alleged to be caused directly or indirectly by this publication.

The Life Safety Code is a registered trademark of the National Fire Protection

Association.

Written and designed by Best Access Systems and Avalon Group, Inc., Indianapolis,

Indiana.

T61804 Rev – 1837172 ER7991-6 October 2001

Key Combinator Service Manual iii

CONTENTS

FIGURES V

GETTING STARTED 1–1

Introduction 1–1

Product family diagram 1–2

Documentation package 1–3

Technical support 1–3

Support services 1–3

Telephone and web technical support 1–3

Training seminars 1–3

PARTS 2–1

Exploded diagram of a key combinator—left hand 2–2

Exploded diagram of a key combinator—right hand 2–3

Key options 2–4

Standard key 2–4

Premium key 2–4

Patented key 2–4

Keyway options 2–5

Contents

iv Key Combinator Service Manual

SERVICE AND MAINTENANCE 3–1

Combinator handing 3–2

Left-handed vs. right-handed combinators 3–2

Maintenance tools 3–2

BEST tools 3–2

Additional tools 3–3

Cutting keys 3–4

Loading the key 3–4

Cutting the key 3–5

Unloading the key 3–6

Converting the combinator between the A2, A3, and A4 systems 3–7

Replacing the depth selector 3–7

Replacing parts 3–9

Replacing the punch and die 3–9

Replacing the key carriage 3–11

Replacing the operating lever 3–13

Calibrating the key combinator 3–16

Cutting a calibration key 3–16

Placing the key in the gauge 3–18

Reading the gauge 3–18

Totaling the measurement 3–19

Checking the measurement 3–19

Adjusting the depth selector 3–20

Adjusting the key clamp spring 3–25

Preventative maintenance 3–27

Cleaning parts 3–27

Cleaning the punch and die 3–27

Cleaning the key carriage 3–27

Lubricating parts 3–28

Guidelines for lubrication 3–28

Lubricating the key combinator housing 3–28

Troubleshooting 3–31

GLOSSARY A–1

PREVENTATIVE MAINTENANCE B–1

INDEX C–1

Key Combinator Service Manual v

FIGURES

GETTING STARTED

Key combinator product family 1–2

PARTS

LH key combinator 2–2

RH key combinator 2–3

Standard key blank 2–4

Premium key blank 2–4

Patented key blank 2–4

SERVICE AND MAINTENANCE

BEST maintenance tools 3–2

Loading a key 3–4

Key in the key clamp spring 3–5

Cutting a key 3–6

Removing the depth selector 3–7

Reinstalling the depth selector 3–8

Punch and die assembly 3–9

Inserting the punch into the T-slot 3–10

Removing the key carriage 3–11

Reinstalling the key carriage 3–12

Depressing the key carriage plungers 3–13

Removing the operating lever 3–14

Reinstalling the operating lever 3–15

Cutting a calibration key 3–17

Figures

vi Key Combinator Service Manual

Inserting a key into the key gauge 3–18

Calibration measurement scale 3–19

Marking the depth selector assembly 3–20

Loosening the spanner nut 3–21

Turning the depth adjuster counterclockwise 3–22

Turning the depth adjuster clockwise 3–23

Loading a key 3–25

Adjusting the key clamp spring 3–26

Lubricating parts 3–29

Lubricating the punch and die 3–30

Key Combinator Service Manual 1–1

1GETTING STARTED

INTRODUCTION

The Key Combinator Service Manual contains

essential information to help you maintain your BEST

key combinator.

Getting Started

1–2 Key Combinator Service Manual

PRODUCT FAMILY DIAGRAM

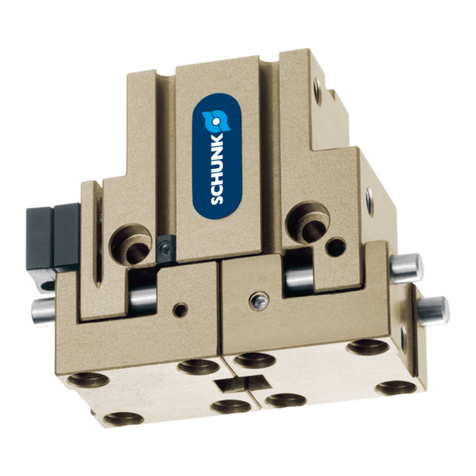

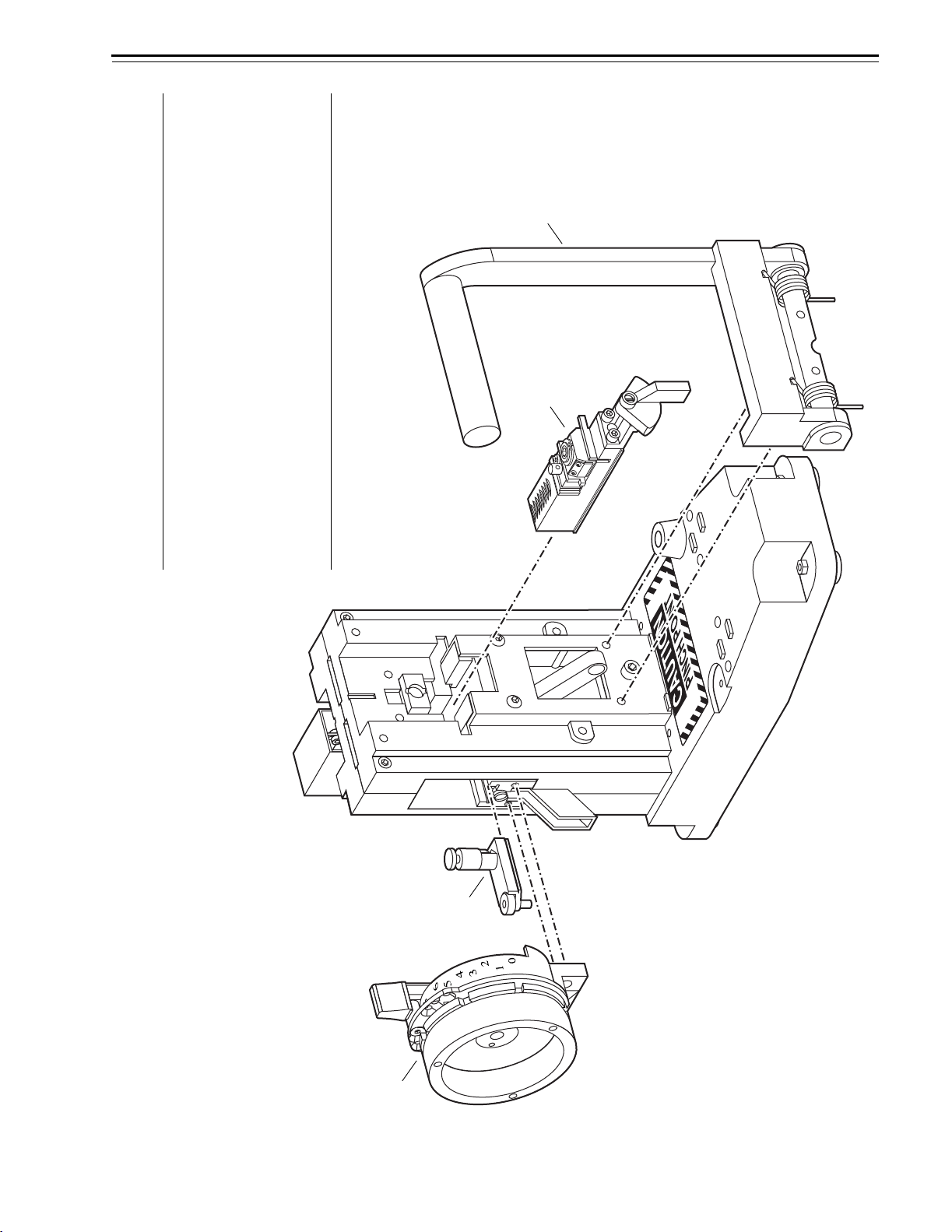

Figure 1.1 Key combinator product family

CAUTION

PINCH POINT

ALIBRATE

YSTEMA2

Patented key blank

Premium key blank

Standard key blank

Spanner wrench

Calibration gauge

Key combinator

Chip tray

Circlip pliers

Getting Started

Key Combinator Service Manual 1–3

DOCUMENTATION PACKAGE

The following documentation is available to help you with the

installation, operation, and maintenance of your BEST key combinator

along with associated service equipment. These documents also can be

ordered separately from the product.

TECHNICAL SUPPORT

Support

services

When you have a problem with a BEST key combinator, your first

resource for help is the Key Combinator Service Manual. If you cannot

find a satisfactory answer, contact your local BEST Representative.

Telephone and

web technical

support

A factory-trained Certified Product Specialist (CPS) is available in your

area whenever you need help. Before you call, however, please make

sure that the product is in your immediate vicinity, and that you are

prepared to give the following information:

■what happened and what you were doing when the problem arose

■what you have done so far to correct the problem.

Best Access Systems Representatives provide telephone technical

support for key combinators and related products. You may locate the

representative nearest you by calling (317) 849-2250 Monday through

Friday, between 7:00 a.m. and 4:00 p.m. eastern standard time; or visit

the web page, www.BestAccess.com.

Training

seminars

Best Access Systems regularly holds factory training seminars for

owners of BEST masterkey systems. Your BEST Representative may hold

regular seminars as well. Contact your representative for information on

these seminar opportunities.

Document Title Doc. No.

Core and Key Service Manual T35527

Operating Instructions for AD432 Key Combinator T35531

Operating Instructions for AD433 Key Combinator T35529

Operating Instructions for AD502 Micrometer Key Gauge T35530

Getting Started

1–4 Key Combinator Service Manual

Key Combinator Service Manual 2–1

2 PARTS

The following pages contain descriptions and figures

for the key combinator.

Par

t

s

2–2 Key Combinator Service Manual

EXPLODED DIAGRAM OF AKEY COMBINATOR—LEFT HAND

Figure 2.1 LH key combinator

CALIBRAT

SYSTEM A

Item†Part No. Qty. Description

1 A70595 1 Operating lever assembly

2

not shown

not shown

C70580

C70610

C70601

1

1

1

Premium key carriage

Key carriage for BEST/Peaks—7-pin

Key carriage for BEST/Peaks—6-pin

3

not shown

B70341

B70625

1

1

Punch and die assembly

Punch and die assembly for BEST/Peaks

4

not shown

not shown

A70325

A70326

A70327

1

1

1

Depth selector assembly—A2

Depth selector assembly—A3

Depth selector assembly—A4

†Seepage 3–7 for instructions on converting between the A2, A3, and

A4 Systems.

1

2

3

4

Par

t

s

Key Combinator Service Manual 2–3

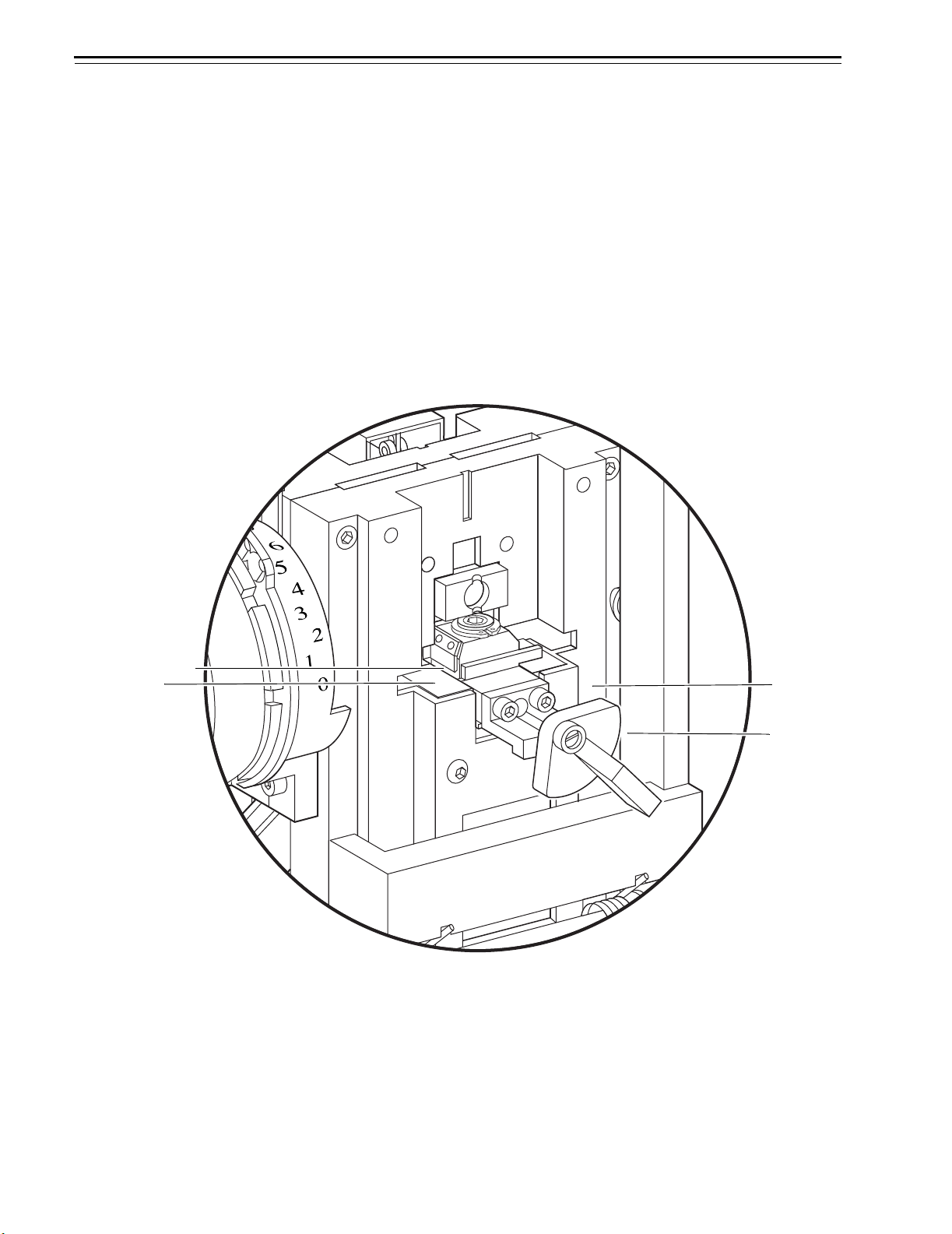

EXPLODED DIAGRAM OF AKEY COMBINATOR—RIGHT HAND

Figure 2.2 RH key combinator

ALIBRATE

YSTEMA2

Item†Part No. Qty. Description

1

not shown

not shown

C70322

C70323

C70324

1

1

1

Depth selector assembly—A2

Depth selector assembly—A3

Depth selector assembly—A4

2 B70341 1 Punch and die assembly

3

not shown

C70578

C70579

1

1

Standard key carriage

Premium key carriage

4 A70591 1 Operating lever assembly

†Seepage 3–7 for instructions on converting between the A2, A3, and

A4 Systems.

1

2

34

Parts

2–4 Key Combinator Service Manual

KEY OPTIONS

The following key options are offered by BEST. Refer to the Core and

Key Service Manual (T35527) for ordering information.

Standard key Standard keys are cut by the AD433 key combinator.

Premium key Premium keys are cut by the AD433P key combinator.

Patented key PEAKS patented keys are cut by the AD437 and AD436 key combinator.

Figure 2.3 Standard key blank

Figure 2.4 Premium key blank

Figure 2.5 Patented key blank

Parts

Key Combinator Service Manual 2–5

KEYWAY OPTIONS

The following section lists BEST keyways and the combinators that

must be used to cut the keys.

Note: BEST key combinators are available only to registered BEST

customers who currently have the A2, A3, or A4 masterkey system. For

more information, contact your local BEST Representative.

Standard keyways

All standard keyways require a RH configuration for the key

combinator.

Premium keyways

Some premium keyways require a LH configuration for the key

combinator and some require a RH configuration. See the table below.

Patented keyways

All patented keyways require a LH configuration. The B1 and B2

keyways are the only Peaks keyways available to use with the AD437

and AD436 key combinators.

Configuration Keyway

RH WA

WB

WC

WG

WH

WK

WY

LH WD

WE

Parts

2–6 Key Combinator Service Manual

Key Combinator Service Manual 3–1

3 SERVICE AND MAINTENANCE

This chapter contains instructions for servicing and

maintaining key combinator components, and a

section for troubleshooting common problems.

To

See

page

Understand combinator handing 3–2

Look at maintenance tools 3–2

Cut keys 3–4

Convert your combinator between A2,

A3, and A4 systems

3–7

Replace the punch and die 3–9

Replace the key carriage 3–11

Replace the operating lever 3–13

Calibrate the key combinator 3–16

Adjust the key clamp spring 3–25

Create a preventative maintenance plan 3–27

Clean the punch and die 3–27

Clean the key carriage 3–27

Lubricate parts 3–28

Troubleshoot common problems 3–31

Service and Maintenance

3–2 Key Combinator Service Manual

COMBINATOR HANDING

Left-handed vs.

right-handed

combinators

The terms “left-handed” and “right-handed” describe the handing of a

combinator, but this is not a convenience feature for left-handed or

right-handed individuals. The handing on a combinator is distinguished

by the position of its operating lever. The operating lever position

determines which types of keys the combinator can cut.

Left-handed key combinator

When facing the combinator, the operating handle is attached to the

left side of the left-handed or LH key combinator. A LH key combinator

cuts patented or left-handed premium keys. It does not cut standard

keys.

Right-handed key combinator

When facing the combinator, the operating handle is attached to the

right side of the right-handed or RH key combinator. A RH key

combinator cuts premium or right-handed standard keys. It does not cut

patented keys.

To determine which keys are appropriate for your security needs,

contact your BEST Representative. See page 2–5 for more information

on key combinators and their keyway types.

MAINTENANCE TOOLS

BEST tools The following tools are provided by BEST for servicing your key

combinator.

Maintenance tools parts list

Figure 3.1 BEST maintenance tools

12 3

Item

Nomen-

clature Part No. Qty. Description

1

not shown

AD502

AD502D

B70564

B70574

1

1

Key calibration gauge—standard

Key calibration gauge—digital

2 A70558 1 Spanner wrench

3 HT03009 1 Circlip pliers

Service and Maintenance

Key Combinator Service Manual 3–3

Additional tools The following Allen wrenches are used for servicing your key

combinator:

■3/32″

■7/64″

■1/8″

■9/64″

■5/32″

■3/16″.

Service and Maintenance

3–4 Key Combinator Service Manual

CUTTING KEYS

BEST recommends that you secure your key combinator to a flat surface

before you begin cutting keys. You can install bolts either through each

of the rubber feet or through two holes on the base of the combinator.

Contact BEST for further instructions.

Loading the key To load a BEST standard key blank:

1. Gripping the key clamp knob, pull the key carriage completely

forward.

2. Turn the key clamp knob counterclockwise to open the key clamp

spring (for left-handed combinators, turn the key clamp knob

clockwise). See Figure 3.2.

3. With the curved edge of the key blank against the locating surface,

slide the key blank into the key opening. Make sure that the knife

edge of the key clamp spring fits into the groove of the key. See

Figure 3.3.

Figure 3.2 Loading a key

ALIBRATE

YSTEM A2

Key

carriage

Key clamp

knob

Front view of combinator

Key opening

Locating surface

This manual suits for next models

5

Table of contents

Popular Industrial Equipment manuals by other brands

INOXPA

INOXPA INNOVA Mini N Installation, service and maintenance instructions

Siemens

Siemens Flender FLUDEX 4600 Series operating instructions

Schmalz

Schmalz SBP Series operating instructions

Continental Refrigerator

Continental Refrigerator PC125-RCD Operator's manual

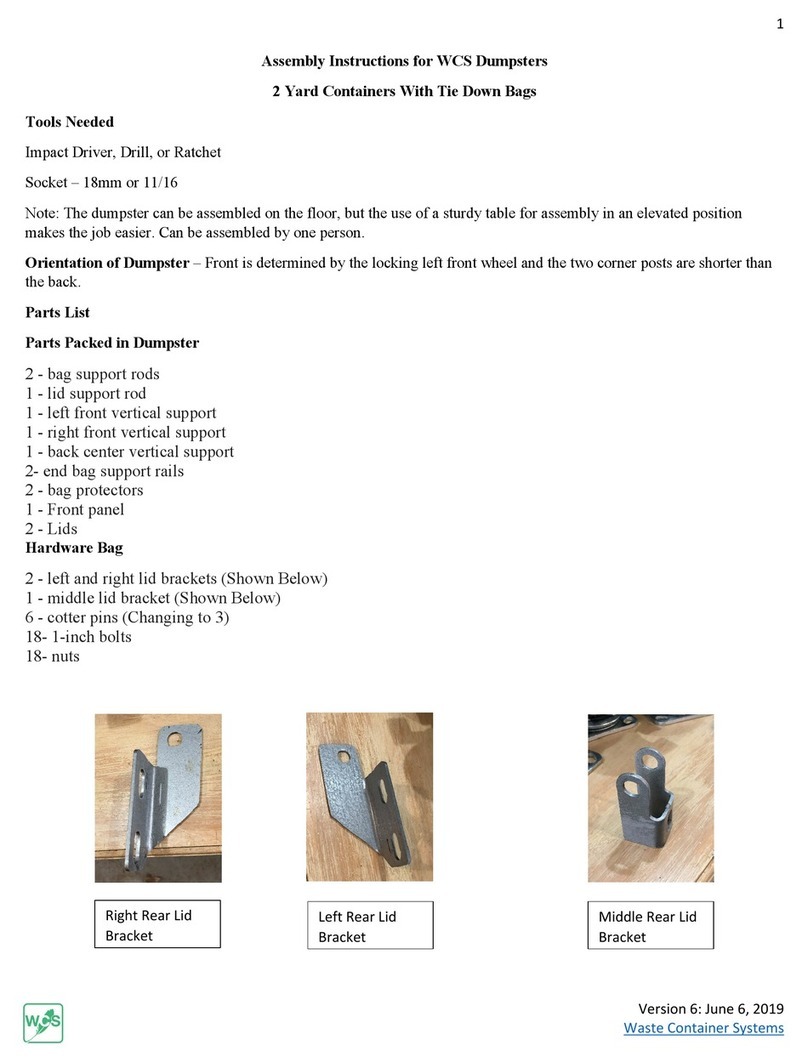

WCS

WCS Dumpster Assembly instructions

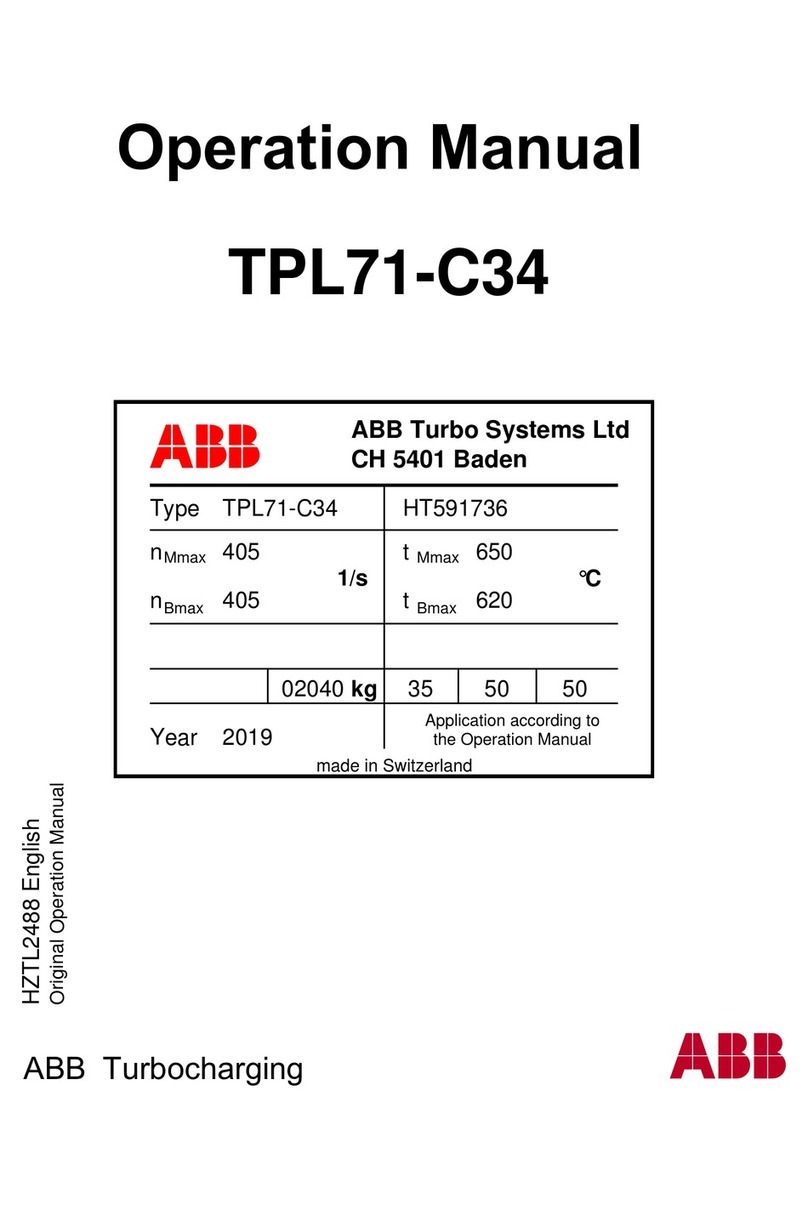

ABB

ABB HT591736 Operation manual