Table of Contents 3

© Lutz-Jesco GmbH 2021

Subject to technical changes.

210527

BA-22404-02-V03

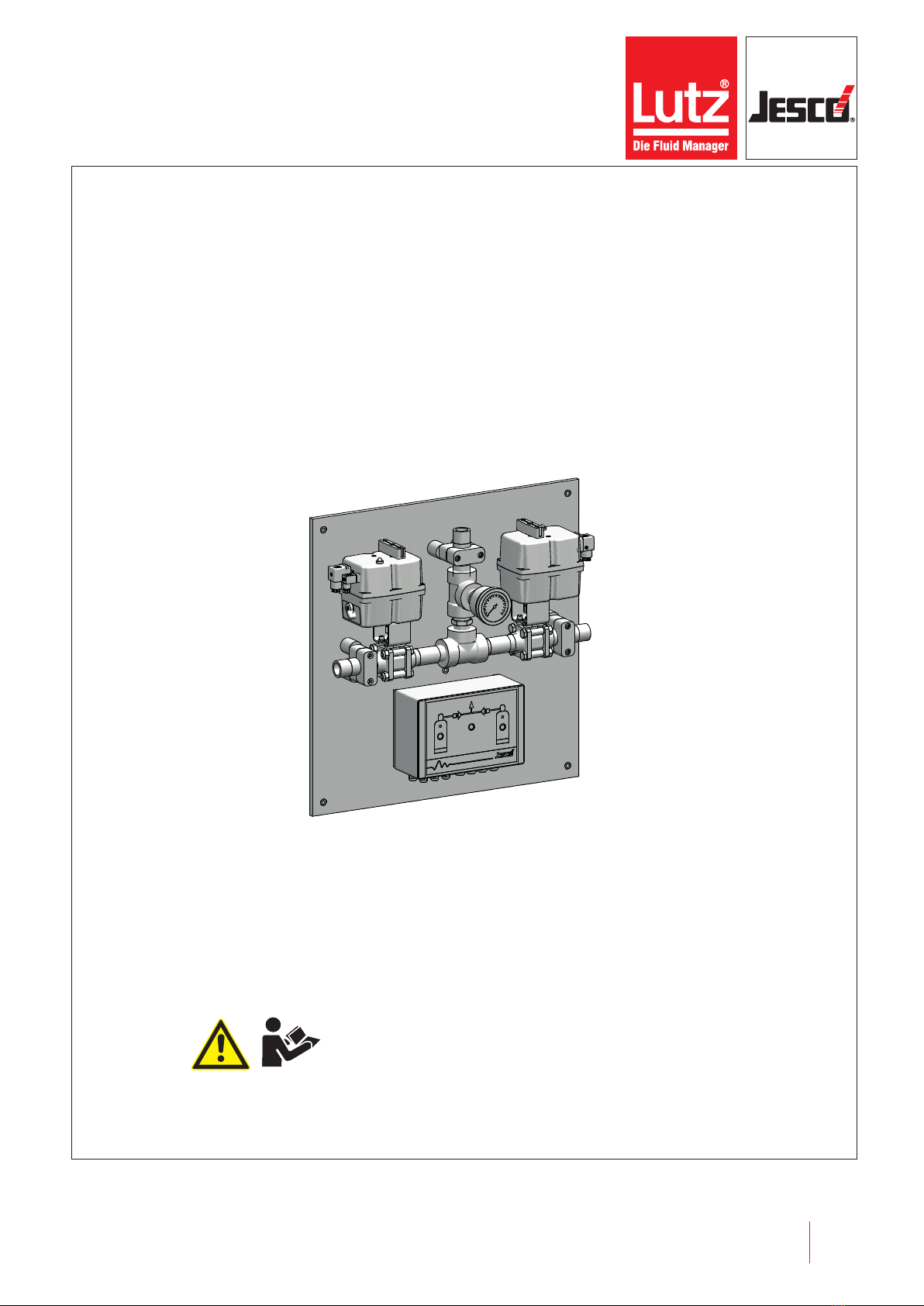

Chlorine changeover unit C 7520 Operating instructions

Table of Contents

1 Notes for the Reader ..........................................................4

1.1 General non-discrimination......................................................4

1.2 Explanation of the signal words ................................................4

1.3 Explanation of the warning signs ..............................................4

1.4 Identification of warnings.........................................................4

1.5 Identification of action instructions ...........................................4

2 Safety .................................................................................5

2.1 General warnings.....................................................................5

2.2 Information about chlorine .......................................................5

2.3 Hazards due to non-compliance with the safety instructions .....5

2.4 Working in a safety-conscious manner .....................................6

2.5 Personal protective equipment.................................................6

2.6 Personnel qualification.............................................................6

2.7 Personnel tasks .......................................................................6

3 Intended use ......................................................................7

3.1 Notes on product warranty .......................................................7

3.2 Intended purpose.....................................................................7

3.3 Prohibited dosing media...........................................................7

4 Product description ...........................................................8

4.1 Scope of delivery .....................................................................8

4.2 Design and function .................................................................8

4.3 Rating plate .............................................................................9

5 Technical data..................................................................10

6 Dimensions ......................................................................11

7 Installation .......................................................................12

7.1 Installation location................................................................12

7.2 Installing the device ...............................................................12

7.3 Hydraulic installation..............................................................12

7.4 Electric installation.................................................................13

7.5 Completing the installation.....................................................16

7.6 Installation example...............................................................17

8 Control..............................................................................18

8.1 Controls.................................................................................18

8.2 Operating modes ...................................................................18

9 Commissioning ................................................................20

9.1 Inspecting the pressure system..............................................20

9.2 Turning on the device .............................................................21

9.3 Adjusting the switching contact..............................................21

10 Operation..........................................................................22

10.1 Tank change ........................................................................22

10.2 Shutting down in an emergency ...........................................22

10.3 Optical check.......................................................................22

11 Shutdown.........................................................................23

11.1 Short-term shutdown...........................................................23

11.2 Long-term shutdown ...........................................................23

11.3 Disposal of old equipment....................................................23

12 Maintenance ....................................................................24

12.1 Maintenance intervals..........................................................24

12.2 Maintenance accessories.....................................................24

12.3 Preparing the system for maintenance .................................24

12.4 Maintenance on the ball valve ..............................................24

12.5 Cleaning the pressure gauge................................................26

12.6 Functional control ................................................................27

12.7 Finishing maintenance.........................................................27

13 Troubleshooting ...............................................................28

14 Spare parts.......................................................................29

15 EU Declaration of Conformity...........................................30

16 Declaration of no objection..............................................31

17 Warranty claim.................................................................32

18 Index.................................................................................33