Installation Instructions for IDH Max 1300 Mortise Locks

BEST ACCESS SYSTEMS

A Division of Stanley Security Solutions, Inc

2

Site survey

Use the following survey to record information about the

installation site. You need this information to determine

field wiring needs, select a power supply, and determine

how to prepare the door for the lock.

Lock information

Lock function:

❑EEL–Electrically locked with key

❑EEU–Electrically unlocked with key

❑NEL–Electrically locked without key

❑NEU–Electrically unlocked without key

Power source for lock:

❑Separate power supply

❑Power provided through the access control panel

Distance of lock site from lock power source: feet

Door information

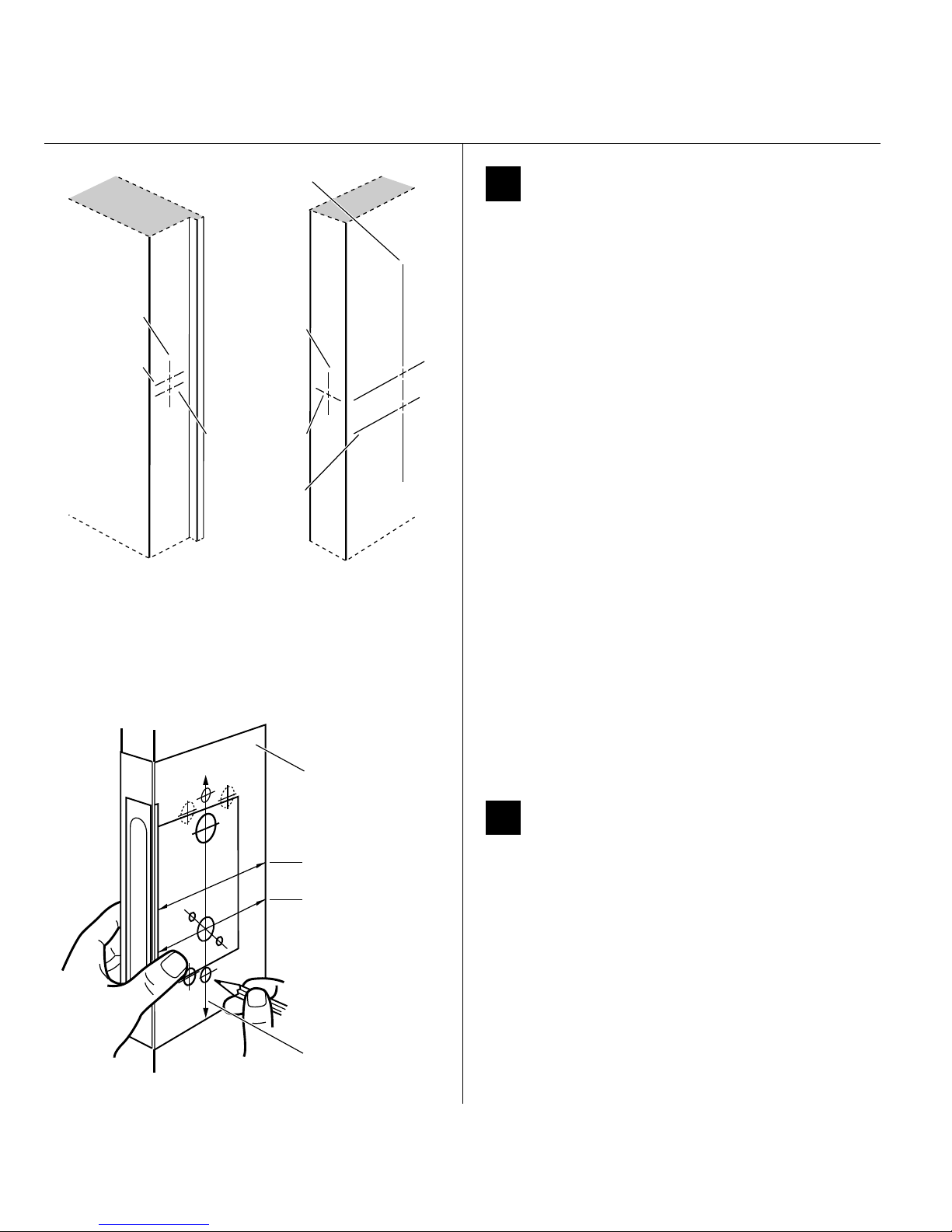

Door handing and bevel:

❑Left hand (LH)

❑Left hand, reverse bevel (LHRB)

❑Right hand (RH)

❑Right hand, reverse bevel (RHRB)

Door thickness: inches (1 3/4″– 3″)

Environment information

Ambient temperature:

❑Is within specifications. See the tables below.

This product meets the following Locked Door Outdoor

test requirements for ANSI/BHMA 156.25:

This product meets the following Full Indoor test require-

ments for ANSI/BHMA 156.25:

Side of door Range

Inside +66°F to +74°F (+19°C to

+23°C)

Outside –31°F to +151°F (–35°C to

+66°C)

Side of door Range

Inside and out-

side

+32°F to +120°F (0°C to

+49°C)

Use the following checklist to make sure that you have the

items necessary to install the components provided with

your 34HM–35HM IDH Max Mortise Lock.

Components provided in the box:

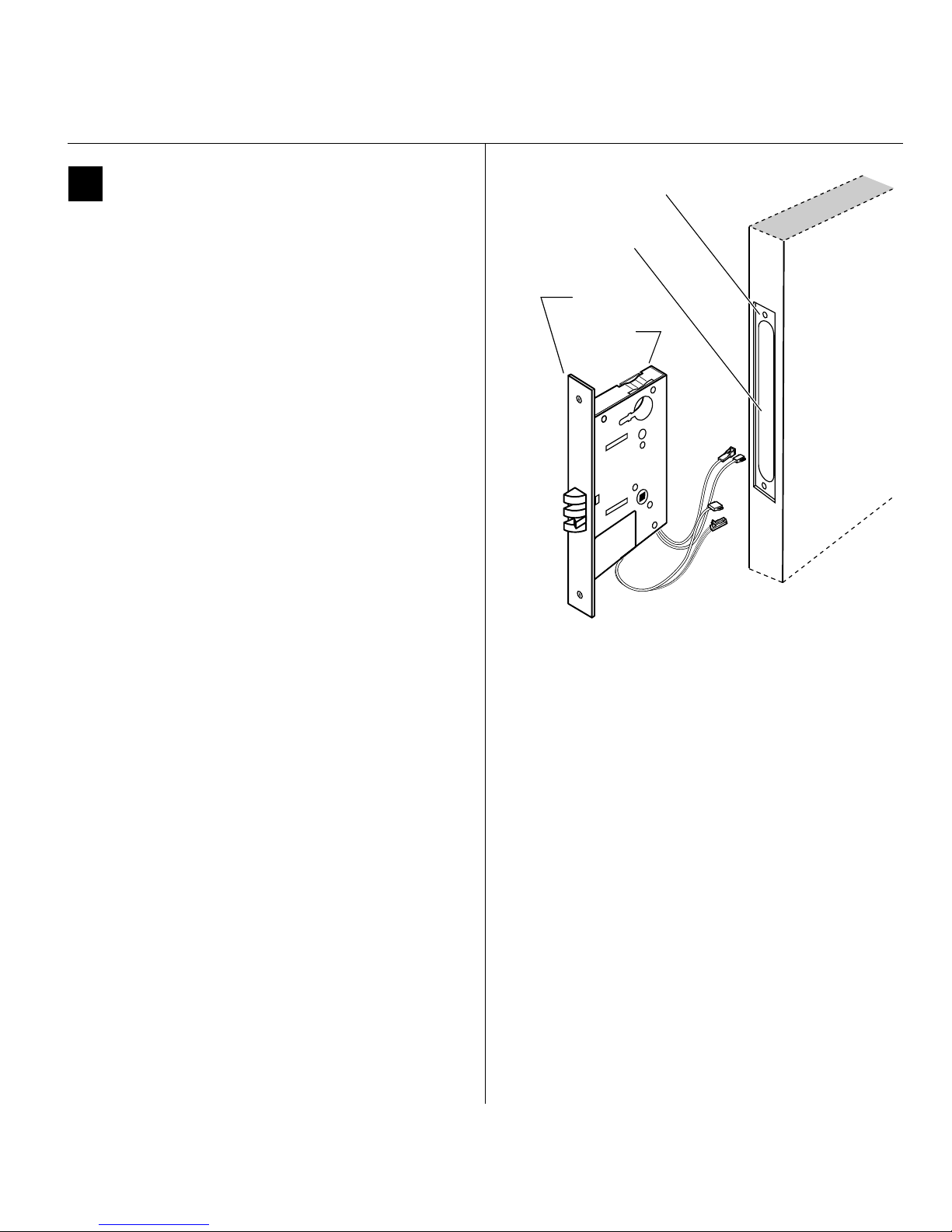

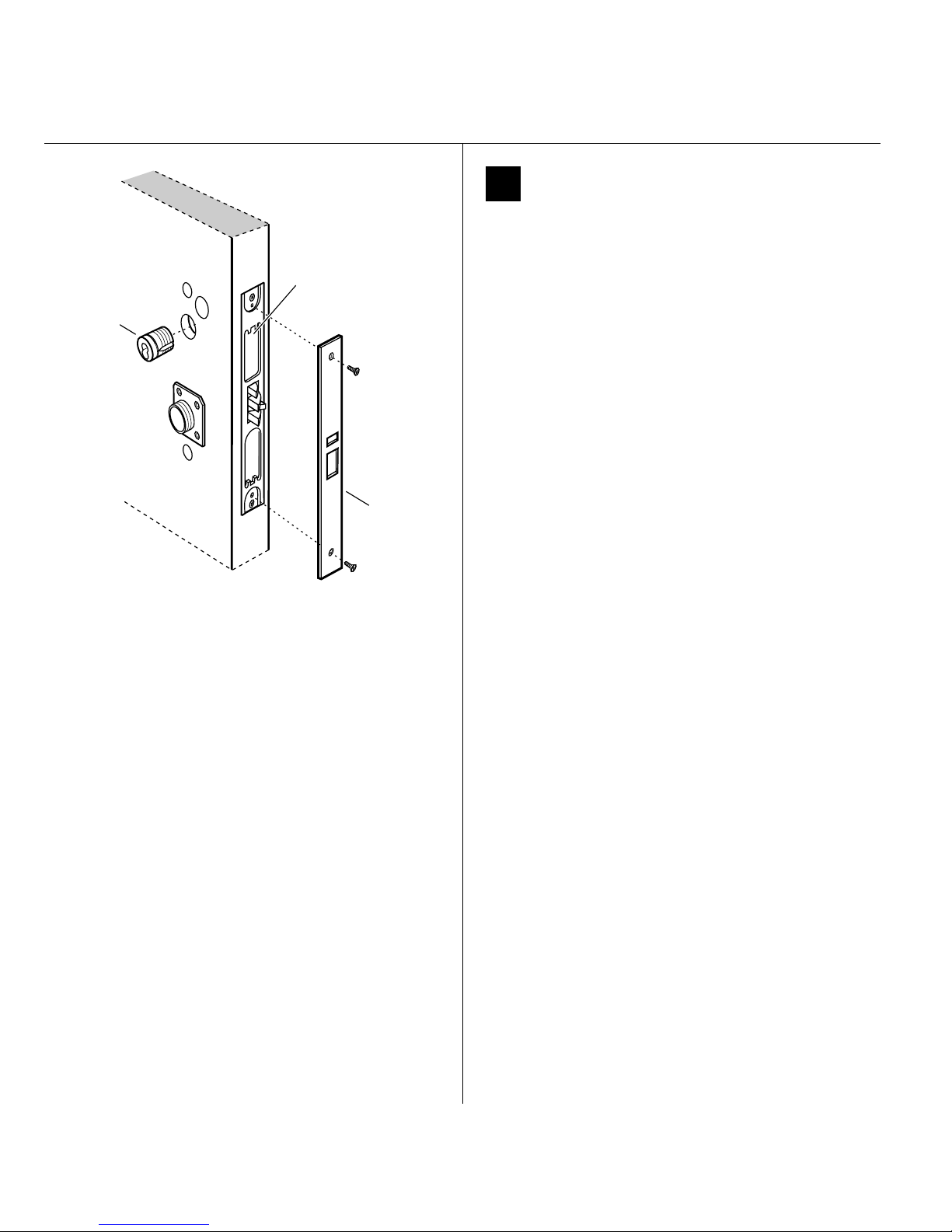

❑Mortise case assembly

❑Mortise case faceplate

❑Inside escutcheon assembly with field wire harness

❑Inside escutcheon access door

❑Outside escutcheon assembly

❑Inside and outside mounting plates

❑Inside knob/lever

❑Outside knob/lever & spindle assembly

❑Cylinder assembly (for use with EEL and EEU functions

only)

❑Mortise screw package

❑Trim hole insert package

❑Plastic bushing package

❑Escutcheon screw package

❑Strike

❑Strike box with magnet

❑Spacer (for 6-pin cores)

❑Bar code ID sticker (for your records)

Other items you’ll need:

❑Power supply for one IDH Max Mortise Lock (if you’re

providing a separate power supply): regulated;

12 volts DC at 1.1 amps

Note: If you intend to power more than one lock with the

same power supply, calculate the amperage for the

power supply by multiplying 1.1 by the number of

IDH Max Mortise Locks (.85 by the number of IDH Max

Cylindrical locks).

❑Wire transfer hinge: 8 conductors min.; 28 AWG min.

continued