PeroxiDraw™Dispenser

INSTALLATION INSTRUCTIONS

I-883 Pg. 3 of 6

05/05

C. CHEMICAL SUPPLY:

Open the bottom cabinet on the PeroxiDraw™dispenser. Slip a ceramic weight over a chemical supply tube. Place tube into

Gallon bottle of Green Earth®Peroxide Cleaner.

DRIP TRAY:

The Drip Tray is installed by simply inserting the tabs in the back of the tray into the slots in the door of the case. Push tray

down to secure in place. Two-sided tape or Velcro (not included) may be used to secure drip tray to door.

D. OUTLET TUBING:

Attach one end of the 1/2” ID tubing to the proportioner outlet barb and run the other end through the hole located at the

bottom of the case. Attach tubing hanger to end of tubing, to hang up when not in use. NOTE: Do not force outlet tubing

onto the larger barbs on the proportioner.

3. OPERATION:

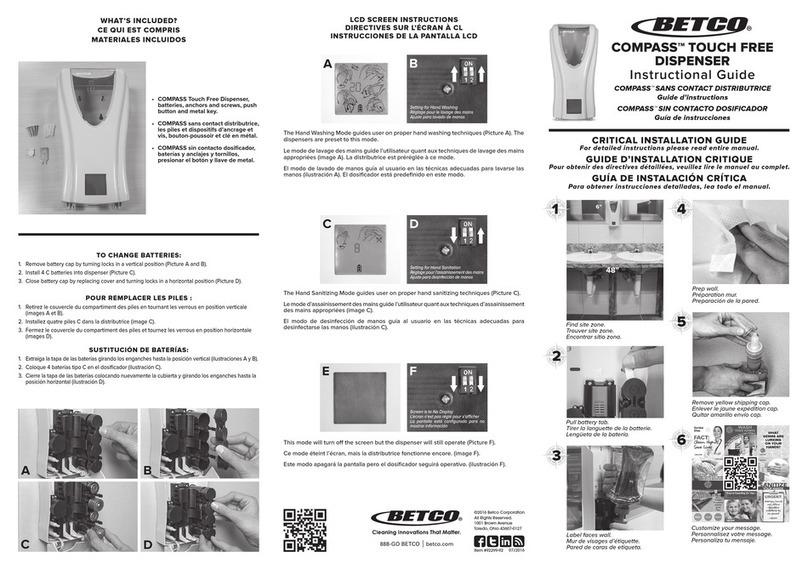

The PeroxiDraw™dispenser is now ready for use. Depressing a push button will allow water to flow through the proportioner and

mix a chemical water solution at the desired ratio. The buttons are spring loaded to prevent accidental overflow if unattended, but

may be converted to locking buttons by cutting off the tab at the notch (See Figure 2). Pushing the button and turning it a 1/4 turn

clockwise at the end of its travel allows the valve to lock on. This makes it unnecessary for the attendant to hold the button while

filling large containers. Turning the button in a counterclockwise direction will release it, allowing the valve to shut off.

4. SERVICING:

Caution: Turn off water supply before servicing.

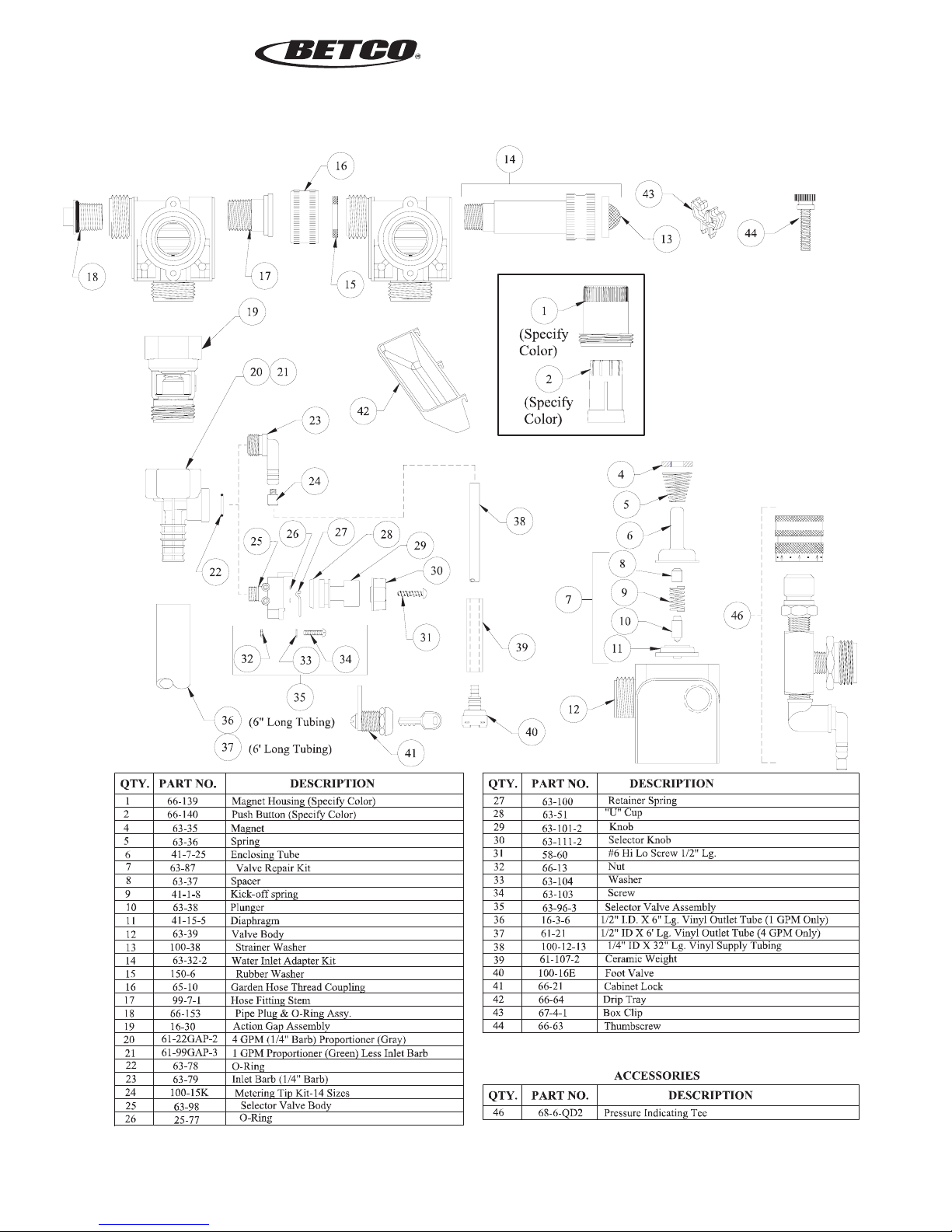

A. Proportioner fails to draw chemical:

1) Pinch outlet tube to create back pressure, which will cause unit to prime. The foot valve will keep the inlet tube primed

thereafter.

2) Insufficient water supply pressure. 20 PSI is the minimum allowable.

B. Proportioner stops drawing chemical:

1) Inspect foot valve for dried chemical or dirt. Soak in hot water to clean.

2) Proportioner metering tip clogged with dried chemical. Remove tip and try injecting in hot water. If there is no suction,

remove proportioner and soak in hot water to clear interior passages.

3) Inspect proportioner to ensure that there are no mineral deposit build-ups on the nozzle. If so, soak proportioner body in

deliming solution. (Remove all parts attached to proportioner before soaking in deliming solution.) Note: Use care

when handling hazardous chemicals.

C. Valve Malfunction:

Check that the button moves freely in & out, bottle lever moves up and down freely (select models only) and that a "click"

can be heard when the button is pushed and released, indicating that the magnet is activating the plunger properly. Remove

cover. To inspect internal parts, unscrew magnet housing and carefully pull off the enclosing tube so as not to drop the

plunger, kick-off spring, and spacer. Check for dirt or damage impeding plunger and kick-off spring movement. Inspect the

diaphragm, making sure the two small pinholes (bleed holes) in the diaphragm convolution are clear to allow the valve to

close.

Caution: When servicing unit, be sure that replacement parts have been installed according to the drawing.

NOTE: THE MAXIMUM TEMPERATURE ALLOWABLE IS 150

F (65

C). THE MAXIMUM PRESSURE

ALLOWABLE IS 150 PSI (10 BAR).